The global cast iron market is witnessing steady growth, driven by increasing demand across construction, automotive, and industrial machinery sectors. According to Grand View Research, the global cast iron market size was valued at USD 37.8 billion in 2022 and is projected to expand at a CAGR of 4.3% from 2023 to 2030. In Singapore, a hub for advanced manufacturing and precision engineering, the cast iron manufacturing segment has evolved to meet high standards of quality and sustainability. Fueled by urbanization, infrastructure development, and strong industrial output, Sg-based manufacturers are leveraging automation and green foundry technologies to maintain competitiveness. As regional demand rises—particularly in Southeast Asia—the role of Singaporean producers in supplying durable, high-performance cast iron components continues to grow. Here’s a look at the top 10 cast iron manufacturers in Singapore shaping this dynamic landscape.

Top 10 Sg Cast Iron Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 VR Foundries

Domain Est. 1998

Website: vrfoundries.com

Key Highlights: VR Foundries, an established casting manufacturer supplies grey cast and sg/ductile cast iron for general engineering, automobile, pump manufacturers….

#2 SG Iron Castings, Ductile Iron Castings, Manufacturer, Supplier, India

Domain Est. 2005

Website: sgironcasting.com

Key Highlights: Manufacturers of S.G. Iron / Ductile Iron castings & Machined Components. MONARK STEELS has been established in the year 1997 as a small- scale industry & ……

#3 S. G. Iron And Steel Works

Domain Est. 2012

Website: sgirons.com

Key Highlights: We are the top manufacturer of All Types of Sugar Mill Castings in Grey Cast Iron Castings, Gun Metal Castings and Cast Steel Castings….

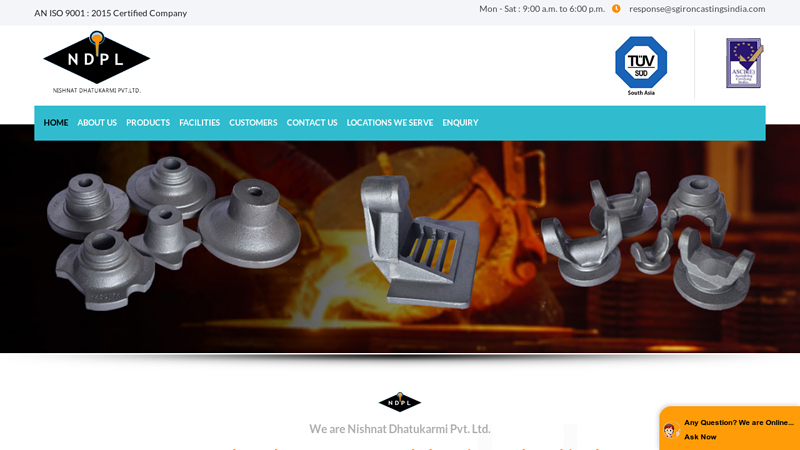

#4 SG Iron Castings, CI Graded Castings, Manufacturer, Kolhapur, India

Domain Est. 2015

Website: sgironcastingsindia.com

Key Highlights: We are Nishnat Dhatukarmi Pvt. Ltd. Manufacturer and Supply of S.G. & C. I. Graded Castings and Machined Components. SG (Spheroidal Graphite) Iron Castings, CI ……

#5 SGI (Spheroidal Graphite Iron) Castings / Ductile Castings

Domain Est. 2024

Website: newsupremecastings.com

Key Highlights: We are Manufacturer, Supplier, Exporter of SGI (Spheroidal Graphite Iron) Castings / Ductile Castings, Engine Components, Brake Rotors, Crankshafts, Gearboxes, ……

#6 Georg Fischer

Domain Est. 1995

Website: georgfischer.com

Key Highlights: Georg Fischer: worldwide preferred partner for the safe transport of liquids and gases, vehicle weight reduction and high-precision manufacturing ……

#7 Nelcast Limited SG iron & Grey iron casting company

Domain Est. 1999

Website: nelcast.com

Key Highlights: Nelcast is the Largest Jobbing Foundry in India for the manufacturing of Ductile & Grey Iron Castings. Our products cater to the Global Automotive, Tractor, ……

#8 Grey Iron Casting Companies

Domain Est. 2001

Website: grey-iron-castings.com

Key Highlights: Save time and easily find the leading grey iron castings companies and suppliers who produce high quality, durable products available at competitive prices….

#9 Spheroidal Graphite Iron

Domain Est. 2001

Website: goodwinsteelcastings.com

Key Highlights: Ductile iron castings with high fracture toughness for thick-walled, robust containment vessels. Ideal for nuclear waste transport and severe shock loading….

#10 SG Castings

Domain Est. 2013

Website: ductileironfoundry.co.uk

Key Highlights: SG Castings is a foundry dedicated to working in Spheroidal Graphite (aka ductile) cast iron. SG Castings Foundry is a long standing founding facility….

Expert Sourcing Insights for Sg Cast Iron

H2: Market Trends for Singapore Cast Iron Industry in 2026

As Singapore continues to evolve into a high-value manufacturing and smart urban hub, the cast iron industry is expected to undergo significant transformation by 2026. Driven by sustainability imperatives, technological advancements, and shifting industrial demands, the market trends for cast iron in Singapore reflect a strategic pivot rather than a decline. Below is an in-depth analysis of key trends shaping the Sg cast iron sector in 2026, under the H2 framework—highlighting Hydrogen Readiness and High-Efficiency Manufacturing as dominant forces.

1. Hydrogen Readiness (H2 – Clean Energy Transition)

By 2026, Singapore’s national push toward decarbonization and clean energy is placing pressure on traditional metal production methods. The “H2” in this context refers not only to hydrogen as a clean energy vector but also to the industry’s preparedness for a hydrogen-enabled economy.

-

Green Hydrogen in Foundries: Singapore’s limited land and environmental constraints are accelerating R&D into hydrogen-based reduction techniques for iron production. While full-scale hydrogen smelting remains in pilot phases regionally, local cast iron manufacturers are partnering with research institutes (e.g., A*STAR, NUS) to explore hydrogen-assisted melting processes that reduce carbon emissions by up to 70% compared to coke-based furnaces.

-

Policy-Driven Shifts: The Singapore Green Plan 2030 and carbon tax increases (set to reach S$50–80 per tonne by 2030) incentivize foundries to adopt cleaner production methods. By 2026, compliance with low-carbon standards will likely become a prerequisite for government contracts, especially in infrastructure and public utilities where cast iron components (e.g., pipes, manhole covers) remain essential.

-

Import Dependency and Circular H2 Economy: Singapore imports most of its raw iron and scrap. However, by 2026, regional collaborations with hydrogen-producing neighbors (e.g., Australia, Indonesia) may enable “green pig iron” imports produced using hydrogen. Local recycling of cast iron scrap using electric induction furnaces powered by renewable energy further supports a circular, H2-aligned supply chain.

2. High-Efficiency Manufacturing (H2 – Smart Industrialization)

The second “H2” denotes High-Efficiency Manufacturing, emphasizing automation, precision engineering, and integration with Industry 4.0 technologies. Singapore’s strength in advanced manufacturing is reshaping the cast iron sector toward niche, high-value applications.

-

Smart Foundries and Digital Twins: By 2026, leading cast iron producers in Singapore are expected to adopt smart foundry systems using IoT sensors, AI-driven quality control, and digital twin technology to simulate casting processes. This improves yield rates, reduces material waste, and ensures compliance with international standards (e.g., ISO 185, ASTM A48).

-

Demand in Precision Infrastructure: While mass production of basic cast iron components declines due to competition from Southeast Asia, demand persists in high-specification applications. These include water management systems (e.g., ductile iron pipes for PUB projects), marine components, and seismic-resistant fittings for high-rise buildings—areas where Singapore’s engineering expertise adds value.

-

Hybrid Materials and Lightweighting: Though cast iron remains irreplaceable in certain applications due to its damping capacity and wear resistance, manufacturers are developing composite or alloyed variants (e.g., compacted graphite iron) to improve strength-to-weight ratios. This aligns with broader industrial trends toward efficiency and performance optimization.

-

Reshoring and Nearshoring Trends: Global supply chain disruptions have prompted some infrastructure and industrial clients to favor regional suppliers. By 2026, Singapore-based cast iron fabricators may benefit from proximity to high-growth ASEAN markets, especially for certified, corrosion-resistant products used in urban water and wastewater systems.

Conclusion

By 2026, Singapore’s cast iron market will not be defined by volume, but by value, sustainability, and technological integration. The dual forces of Hydrogen Readiness and High-Efficiency Manufacturing (the H2 framework) are driving a transformation in how cast iron is produced, applied, and perceived. While traditional foundries face pressure to adapt or exit, forward-looking players embracing clean energy, digitalization, and precision engineering are poised to thrive in a niche but resilient segment of Singapore’s advanced manufacturing ecosystem.

Common Pitfalls in Sourcing Sg Cast Iron (Quality, IP)

When sourcing Sg (Spheroidal Graphite) cast iron components—also known as ductile iron—buyers must navigate several challenges related to quality assurance and intellectual property (IP) protection. Below are the most common pitfalls to avoid:

Quality-Related Pitfalls

Inconsistent Material Composition

One of the most frequent issues is variability in chemical composition across batches. Sg cast iron’s mechanical properties depend heavily on precise control of elements like carbon, silicon, magnesium, and sulfur. Sourcing from suppliers without robust quality control systems can lead to off-spec material, resulting in reduced ductility, strength, or machinability.

Poor Nodularity and Microstructure

The performance of Sg cast iron hinges on graphite spheroidization (nodularity). Substandard casting practices—such as inadequate inoculation or poor melt treatment—can lead to flake graphite or poor nodule count, compromising mechanical properties and increasing brittleness.

Inadequate Mechanical Testing

Some suppliers may provide only minimal or outdated test certifications (e.g., generic mill certs instead of cast-specific test reports). Without tensile, hardness, and impact testing per batch, buyers risk receiving components that fail under service conditions.

Defects from Poor Foundry Practices

Porosity, shrinkage, inclusions, and cold shuts are common defects in poorly controlled casting processes. These flaws are not always visible during visual inspection and require non-destructive testing (NDT) such as ultrasonic or radiographic inspection—often overlooked in cost-driven sourcing.

Lack of Traceability

Without proper heat and cast traceability, identifying the root cause of a failure becomes nearly impossible. Reputable suppliers should provide lot-specific documentation linking material test results to individual components.

Intellectual Property (IP) Risks

Unauthorized Design Replication

When sourcing custom Sg cast iron parts, especially from offshore suppliers, there’s a risk of design theft. Suppliers may replicate technical drawings or 3D models and sell them to competitors—particularly in regions with weaker IP enforcement.

Inadequate IP Clauses in Contracts

Many procurement agreements fail to include explicit IP ownership clauses. Without clear contractual terms, the buyer may not retain full rights to the tooling, patterns, or design modifications developed during the sourcing process.

Shared Tooling and Pattern Usage

Some foundries reuse tooling or patterns across multiple clients to reduce costs. This increases the risk of design leakage and quality inconsistencies, as the same mold may be used for different orders without proper maintenance or control.

Reverse Engineering by Suppliers

Suppliers may reverse engineer provided samples to bypass licensing or design agreements. This is particularly risky when physical prototypes are shared without non-disclosure agreements (NDAs) or protective markings.

Mitigation Strategies

- Require detailed material test reports (MTRs) and third-party certifications (e.g., ISO 9001, IATF 16949).

- Specify nodularity and microstructure requirements in purchase orders (e.g., >80% nodularity per ASTM A536).

- Conduct regular factory audits and request access to process controls and NDT records.

- Protect IP through NDAs, registered designs, and explicit contractual terms assigning IP ownership to the buyer.

- Use trusted partners in jurisdictions with strong IP protection laws, or work with local legal counsel when sourcing globally.

Avoiding these pitfalls requires diligence in supplier selection, robust technical specifications, and proactive IP management.

Logistics & Compliance Guide for SG Cast Iron

Overview

This guide outlines the essential logistics and compliance considerations for the international transportation and regulatory adherence of SG (Spheroidal Graphite) cast iron products. SG cast iron, also known as ductile iron, is widely used in automotive, construction, and industrial applications due to its strength and durability. Proper handling, documentation, and compliance with international standards are critical for seamless global trade.

Packaging and Handling

SG cast iron components must be packaged to prevent mechanical damage, corrosion, and contamination during transit. Use moisture-resistant wrapping, wooden crates, or steel strapping as appropriate. Heavy items should be secured on pallets and clearly labeled with weight, center of gravity, and handling instructions (e.g., “Do Not Stack,” “This Side Up”). Anti-rust treatments such as VCI (Vapor Corrosion Inhibitor) paper or protective coatings are recommended for long sea voyages.

Transportation Modes

- Maritime Shipping: Most common for bulk shipments. Ensure proper lashing and containerization (FCL/LCL). Use humidity-controlled containers if transporting through tropical climates.

- Road Freight: Suitable for regional distribution. Confirm vehicle weight limits and route restrictions for oversized loads.

- Rail: Cost-effective for long-distance inland transport in regions with developed rail networks.

- Air Freight: Reserved for urgent, high-value, or low-weight shipments due to cost and weight constraints.

Export Documentation

Essential export documents include:

– Commercial Invoice

– Packing List

– Bill of Lading (or Air Waybill)

– Certificate of Origin

– Export License (if required by destination country)

– Material Test Report (MTR) confirming compliance with standards such as ASTM A536 or ISO 1083

Ensure all documents clearly state product specifications, including grade (e.g., 400-15, 500-7), dimensions, and weight.

Regulatory Compliance

SG cast iron must comply with material and safety standards in both the exporting and importing countries. Key international standards include:

– ISO 1083: Ductile cast irons – Classification

– ASTM A536: Standard Specification for Ductile Iron Castings

– EN 1563: European standard for spheroidal graphite cast irons

Verify that manufacturing processes and material composition meet destination market requirements. Some countries may require third-party inspection or certification.

Customs Clearance

Provide accurate HS (Harmonized System) codes. SG cast iron typically falls under 7303.00 (Cast iron articles) or 7325.99 (Other cast articles of iron or steel), depending on form and application. Declare correct CIF or FOB values to avoid delays or penalties. Be prepared for customs inspections, especially for large industrial shipments.

Environmental and Safety Regulations

Comply with REACH (EU), RoHS (if applicable), and other chemical substance regulations. Although cast iron is largely inert, surface treatments or coatings may be subject to restrictions. Ensure safe handling procedures to prevent worker injury during loading/unloading due to the material’s weight and sharp edges.

Import Restrictions and Duties

Check for anti-dumping duties or trade restrictions in target markets. Countries such as the USA, Canada, and members of the EU may impose tariffs on iron and steel products based on trade agreements or investigations. Engage local customs brokers to navigate tariff classifications and duty rates.

Quality Assurance and Traceability

Maintain full traceability from raw material sourcing to final product. Provide certified test reports for mechanical properties (tensile strength, elongation, hardness) and metallurgical structure. This is often required for automotive or pressure-containing applications.

Conclusion

Successful logistics and compliance for SG cast iron require attention to packaging, documentation, regulatory standards, and customs procedures. Partnering with experienced freight forwarders and compliance consultants ensures timely delivery and adherence to international trade laws. Regular audits and process improvements will enhance efficiency and reduce risks.

Conclusion for Sourcing SG Cast Iron:

Sourcing SG (Spheroidal Graphite) cast iron requires a comprehensive evaluation of several critical factors, including material quality, supplier reliability, cost-efficiency, and adherence to international standards such as ISO 1083 or ASTM A536. SG cast iron, also known as ductile iron, offers superior mechanical properties—such as high tensile strength, ductility, and impact resistance—making it ideal for demanding applications in automotive, construction, piping, and machinery industries.

A successful sourcing strategy involves thorough supplier vetting to ensure consistent quality, metallurgical testing capabilities, and strong production capacity. Additionally, considerations such as lead times, logistics, and total landed costs play a significant role in maintaining supply chain efficiency. Partnering with suppliers who demonstrate process transparency, quality certifications (e.g., ISO 9001), and technical expertise enhances long-term reliability.

Ultimately, effective sourcing of SG cast iron balances performance requirements with cost and supply continuity. By prioritizing quality assurance, strategic partnerships, and ongoing supplier performance monitoring, organizations can secure a dependable supply of SG cast iron that supports both operational excellence and product integrity.