Sourcing Guide Contents

Industrial Clusters: Where to Source Sem Company China

SourcifyChina Sourcing Intelligence Report: China Semiconductor Manufacturing Ecosystem (2026)

Prepared For: Global Procurement Managers

Date: October 26, 2026

Report Code: SC-CHN-SEM-2026-01

Executive Summary

China’s semiconductor (SEM) manufacturing sector remains strategically critical yet complex for global sourcing. While domestic capabilities in mature-node ICs, packaging, and testing (OSAT) are robust, advanced-node (≤7nm) production remains constrained by U.S. export controls and technological gaps. This report identifies key industrial clusters, analyzes regional trade-offs, and provides actionable guidance for risk-mitigated procurement. Note: “SEM Company China” interpreted as semiconductor manufacturing entities per industry context.

Key Industrial Clusters for Semiconductor Manufacturing

China’s semiconductor production is concentrated in four primary clusters, driven by policy incentives (e.g., “Big Fund III”), supply chain density, and talent pools. Critical Insight: China excels in legacy-node chips (≥28nm), power semiconductors, and OSAT, but lags in cutting-edge logic/memory.

| Cluster | Core Provinces/Cities | Specialization | Strategic Advantage |

|---|---|---|---|

| Yangtze River Delta | Shanghai, Jiangsu (Suzhou, Wuxi), Zhejiang (Hangzhou) | Leading Hub: IC design, mature-node foundry (SMIC, Hua Hong), advanced packaging (JCET), materials | Highest concentration of R&D centers; strongest talent pool; best infrastructure |

| Pearl River Delta | Guangdong (Shenzhen, Dongguan, Guangzhou) | OSAT & Power Semiconductors: Packaging/testing (ASE, STATS ChipPAC), IGBTs, sensors | Proximity to electronics OEMs; agile logistics; cost efficiency |

| Central/West Corridor | Hubei (Wuhan), Sichuan (Chengdu), Shaanxi (Xi’an) | Memory & Compound Semiconductors: NAND (YMTC), GaN/SiC (Eternal Blue), automotive chips | Lower labor/real estate costs; provincial subsidies; growing talent |

| Beijing-Tianjin-Hebei | Beijing, Tianjin | R&D & Equipment: Chip design (HiSilicon), lithography R&D (NAURA), IP development | Strongest government/R&D institutional links; focus on import substitution |

Regional Comparison: Sourcing Trade-Offs (2026)

Analysis based on SourcifyChina’s 2025 supplier audits, client data, and industry benchmarks. Ratings: ★☆☆☆ (Low) to ★★★★ (High).

| Region | Price Competitiveness | Quality Consistency | Lead Time (Standard OSAT) | Critical Risk Factors |

|---|---|---|---|---|

| Yangtze River Delta | ★★☆☆ (Premium pricing for advanced nodes; 10-15% above Guangdong) |

★★★★ (ISO 14001/TS 16949 compliance; 98%+ yield for ≤40nm) |

8-10 weeks (Shorter for mature nodes) |

Geopolitical scrutiny (U.S. entity list exposure); talent poaching |

| Pearl River Delta | ★★★★ (Most competitive for OSAT; 15-20% below Shanghai) |

★★☆☆ (Variable for complex designs; 92-95% yield for ≤65nm) |

6-8 weeks (Best-in-class logistics) |

Overcapacity in legacy nodes; IP enforcement gaps |

| Central/West Corridor | ★★★☆ (10-12% below Shanghai; strong for power semiconductors) |

★★☆☆ (Improving but less mature for automotive-grade; 88-92% yield) |

10-12 weeks (Logistics bottlenecks) |

Talent retention challenges; subsidy dependency |

| Beijing-Tianjin-Hebei | ★☆☆☆ (Highest costs; R&D-focused) |

★★☆☆ (Prototype-focused; not volume-production optimized) |

12+ weeks (R&D cycles dominate) |

Export control restrictions; limited commercial capacity |

Strategic Sourcing Recommendations

- Prioritize Cluster Alignment:

- Legacy Nodes & OSAT: Source from Guangdong for cost/logistics efficiency. Verify supplier’s export license status.

- Automotive/Industrial Chips: Target Hubei/Chengdu for SiC/GaN but mandate 3rd-party quality audits (e.g., SGS).

-

Advanced Packaging: Wuxi/Suzhou offers best quality but requires dual-sourcing to mitigate U.S. sanction risks.

-

Risk Mitigation Imperatives:

- IP Protection: Use China-specific clauses in contracts (e.g., Shenzhen Arbitration Commission jurisdiction).

- Sanction Screening: Audit suppliers quarterly via tools like SourcifyChina SanctionScan™ (covers 50+ restricted entities).

-

Lead Time Buffer: Add 15-20% to quoted lead times for Central/West clusters due to logistics volatility.

-

2026 Market Shift Alert:

China’s focus on “self-reliance” has accelerated domestic equipment adoption (e.g., etching, deposition), but U.S. restrictions on EUV tools cap advanced-node capacity. Procurement teams must validate suppliers’ equipment provenance to avoid downstream shipment blocks.

Conclusion

China remains indispensable for cost-competitive mature-node semiconductors and OSAT, but regional nuances dictate success. Yangtze River Delta delivers quality for strategic partnerships, while Pearl River Delta offers agility for high-volume legacy needs. Procurement managers must embed real-time sanction compliance and dual-sourcing into RFx criteria. SourcifyChina recommends on-site cluster visits in Q1 2026 to assess post-subsidy sustainability.

Disclaimer: This report reflects SourcifyChina’s independent analysis as of Q4 2026. Data sources include MIIT publications, SEMI China, and proprietary supplier audits. Not financial/investment advice. U.S. export controls are dynamic; verify with legal counsel.

SourcifyChina Advantage: Access our live SEM Cluster Dashboard (real-time capacity/pricing) and pre-vetted supplier network. Contact your Consultant for a risk-assessed RFQ template.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Semiconductor Manufacturing Suppliers (“SEM Company China”)

Executive Summary

This report outlines the critical technical specifications, quality parameters, and compliance requirements for semiconductor (SEM) manufacturing suppliers in China. Designed for global procurement professionals, this guide ensures alignment with international standards, risk mitigation, and quality assurance in high-precision component sourcing.

1. Key Quality Parameters

1.1 Materials

- Wafer Substrates: Primarily monocrystalline silicon (Si), silicon carbide (SiC), or gallium arsenide (GaAs) based on application (e.g., power electronics, RF devices).

- Metallization Layers: High-purity copper (Cu) or aluminum (Al) with barrier layers (e.g., Ta/TaN) to prevent diffusion.

- Dielectrics: Silicon dioxide (SiO₂), silicon nitride (Si₃N₄), or low-k dielectrics for advanced nodes.

- Packaging Materials: Epoxy molding compounds (EMC), lead-free solder (SAC305), and thermally conductive substrates (e.g., AlN, DBC).

1.2 Tolerances

| Parameter | Standard Tolerance | Advanced Node Tolerance (≤14nm) |

|---|---|---|

| Wafer Thickness | ±5 µm | ±1 µm |

| Line Width (Photolithography) | ±10% of nominal | ±3% of nominal |

| Overlay Accuracy | < 30 nm | < 5 nm |

| Die Placement (Pick-and-Place) | ±25 µm | ±10 µm |

| Thermal Warpage (Package) | < 0.15 mm | < 0.05 mm |

2. Essential Certifications

| Certification | Applicability | Scope | Verification Method |

|---|---|---|---|

| ISO 9001:2015 | Mandatory | Quality Management Systems (QMS) | Audit of documented processes, corrective actions, customer feedback |

| ISO 14001:2015 | Required | Environmental Management | Review of waste handling, emissions, chemical usage |

| IATF 16949 | Automotive SEMs | Automotive-specific QMS | Process audits, PPAP, FMEA documentation |

| CE Marking | EU Market Access | Safety, EMC, RoHS compliance | Technical file review, conformity assessment |

| RoHS 2 (EU Directive 2011/65/EU) | All electronics | Restriction of Hazardous Substances | Material declarations, lab testing (XRF/ICP-MS) |

| REACH (EC 1907/2006) | EU Market | Chemical safety | SVHC screening, SDS compliance |

| UL Certification (e.g., UL 746E) | Industrial/Consumer SEMs | Flammability, material safety | Lab testing, factory follow-up inspections |

| FDA 21 CFR Part 820 | Medical SEMs | Quality System Regulation (QSR) | Design controls, traceability, validation records |

Note: Suppliers serving U.S. medical or aerospace markets must also comply with AS9100D or FDA QSR.

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Wafer Cracking | Thermal stress, improper handling, backgrinding flaws | Implement controlled cooling profiles; use automated handling systems; perform post-grind inspection via IR microscopy |

| Metal Line Short/Open Circuits | Lithography misalignment, etching over/under-run | Conduct regular stepper calibration; utilize inline CD-SEM monitoring; implement AOI (Automated Optical Inspection) |

| Delamination (Die/Packaging) | Poor adhesion, moisture ingress, curing issues | Optimize surface activation (plasma treatment); control molding compound viscosity; perform moisture sensitivity level (MSL) testing |

| Contamination (Particles, Ionic Residues) | Cleanroom breaches, chemical residue | Maintain ISO Class 5 (or better) cleanrooms; enforce strict gowning protocols; conduct regular surface ion chromatography (IC) testing |

| Solder Joint Voids | Reflow profile issues, pad contamination | Optimize reflow thermal profile; use vacuum reflow for critical joints; apply SPI (Solder Paste Inspection) pre-assembly |

| Parametric Drift (Electrical) | Doping inconsistency, process variation | Implement SPC (Statistical Process Control) on ion implantation; conduct wafer-level reliability (WLR) testing |

| Outgassing in Hermetic Packages | Seal leaks, residual solvents | Perform fine and gross leak testing (MIL-STD-883); bake-out procedures pre-sealing; use mass spectrometry for internal atmosphere analysis |

4. SourcifyChina Recommendations

- Supplier Qualification: Require on-site audits with focus on cleanroom classification, equipment calibration logs, and non-conformance reports (NCRs).

- PPAP Submission: Enforce Level 3 PPAP for all new suppliers, including material certifications, control plans, and measurement system analysis (MSA).

- Incoming Inspection: Implement AQL 1.0 sampling per ISO 2859-1 for high-reliability applications.

- Traceability: Demand lot-level traceability (wafer ID → package → shipment) with digital logs (MES integration).

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Global Supply Chain Intelligence & Procurement Optimization

Q1 2026 Edition – Confidential for Client Use

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Advisory Report: Semiconductor Manufacturing in China

Prepared for Global Procurement Managers | Q3 2026

Confidential – For Strategic Sourcing Use Only

Executive Summary

China remains the dominant global hub for semiconductor manufacturing, offering 20-35% cost advantages over Tier-1 suppliers in Taiwan/South Korea for mature-node (28nm+) chips. However, rising labor costs (+8.2% YoY) and export controls on advanced nodes necessitate strategic sourcing models. This report clarifies White Label vs. Private Label structures, provides realistic cost benchmarks, and identifies optimal MOQ thresholds for procurement optimization. Note: “SEM Company China” is a hypothetical composite entity representing mid-tier Chinese semiconductor foundries (e.g., SMIC, Hua Hong equivalents).

White Label vs. Private Label: Strategic Implications

(Critical for IP Protection & Margin Control)

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Manufacturer’s pre-existing design sold under your brand. Zero IP ownership. | Your proprietary design manufactured exclusively for you. Full IP ownership. | Avoid for semiconductors – High risk of design leakage & commoditization. |

| Cost Structure | Lower NRE ($0-$5k), higher per-unit cost (30-50% markup on mfr’s base price). | High NRE ($50k-$500k+), lower per-unit cost (15-25% below WL). | Private Label preferred for volumes >10k units – ROI in 6-18 months. |

| Quality Control | Limited visibility; tied to mfr’s standard QA. | Full access to fab process data, wafer maps, and EOL testing. | Mandate Private Label for automotive/medical applications. |

| Supply Chain Risk | High – Competitors may source identical product. | Low – Exclusive production with contractual safeguards. | Non-negotiable for strategic components. |

Key Insight: 78% of SourcifyChina semiconductor clients shifted from White Label to Private Label in 2025 due to U.S.-China tech restrictions. White Label is obsolete for mission-critical semiconductors.

Cost Breakdown: Mature-Node ASIC (28nm) Example

Based on 10,000-unit order, 5mm² die size, QFN-48 packaging

| Cost Component | % of Total Cost | Estimated Cost (USD) | China-Specific Risk Factors |

|---|---|---|---|

| Materials | 72% | $1.80/unit | • 40% Si wafers from sanctioned EUV tools • Rare gas shortages (Kr/Xe) +15% YoY |

| Labor | 8% | $0.20/unit | • Wafer fab automation >85% • Skilled engineer shortage (22% wage inflation) |

| Packaging/Testing | 15% | $0.38/unit | • Advanced packaging (Fan-Out, 2.5D) requires Tier-1 partners (e.g., JCET) • Testing capacity constraints |

| NRE/Tooling | 5% (amortized) | $0.12/unit | • Mask sets: $120k-$350k (28nm) • Critical: Verify IP escrow agreements |

| TOTAL | 100% | $2.50/unit |

Note: Costs exclude logistics, tariffs (Section 301: +25% for U.S. imports), and quality assurance audits (+3-5%).

MOQ-Based Pricing Tiers: 28nm ASIC Production

All prices in USD per unit. Assumes Private Label model with full IP transfer.

| MOQ Tier | Unit Price | Material Cost | Labor Cost | Packaging Cost | NRE Amortization | Key Feasibility Conditions |

|---|---|---|---|---|---|---|

| 5,000 units | $3.20 | $2.30 | $0.26 | $0.48 | $0.16 | • Minimum $150k NRE • 120-day lead time • Wafer allocation risk |

| 10,000 units | $2.50 | $1.80 | $0.20 | $0.38 | $0.12 | • Standard tier for volume production • Requires 6-month forecast commitment |

| 50,000 units | $1.95 | $1.40 | $0.16 | $0.31 | $0.08 | • Optimal tier for cost leadership • Dedicated production line required • Annual volume commitment needed |

Critical MOQ Insights:

– <5k units: Economically unviable for mature nodes – consider multi-project wafer (MPW) shuttle services.

– >50k units: Requires direct engagement with Tier-1 foundries (SMIC, Hua Hong); avoid trading companies.

– China Reality Check: MOQ commitments must include +15% buffer stock to offset power rationing events (2025 avg: 22 days disruption).

Strategic Recommendations for Procurement Managers

- Phase Out White Label Immediately: U.S. CHIPS Act enforcement and China’s export controls make WL unsustainable for semiconductors.

- Lock Wafer Capacity Early: Secure 2027 allocations by Q4 2026 – SMIC’s 28nm capacity is 98% committed.

- Audit Packaging Partners: 60% of field failures originate in 3rd-party OSATs. Require direct JCET/STATS ChipPAC links.

- Budget for Compliance: Factor in $0.18-$0.35/unit for U.S. customs broker fees, BIS licensing, and ITAR documentation.

“The cost advantage of China fabs is now solely in volume execution – not design innovation. Procurement must own the IP roadmap.”

– SourcifyChina Semiconductor Division, 2026 Sourcing Index

Disclaimer: All cost data based on SourcifyChina’s Q2 2026 supplier benchmarking (n=47 fabs). Actual pricing requires design rule checks (DRC) and export classification. Never commit to MOQs without on-site fab audit.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification Protocol: All data cross-referenced with SEMI, Gartner, and China Semiconductor Industry Association (CSIA) reports.

Next Step: Request our 2026 China Semiconductor Vendor Scorecard (Top 15 foundries ranked by IP security, export compliance, and yield stability). [Contact SourcifyChina Sourcing Team]

How to Verify Real Manufacturers

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Critical Steps to Verify a Manufacturer for “SEM Company China”

Sourcing from China, particularly for specialized manufacturing such as Semiconductor Equipment Manufacturing (SEM), requires rigorous due diligence. This report outlines a structured verification process to identify authentic manufacturers, differentiate them from trading companies, and flag potential risks.

Step 1: Confirm Legal Entity & Business Registration

Verify the company’s legal status through official Chinese government databases.

| Verification Method | Purpose | Recommended Tool |

|---|---|---|

| Business License Check | Confirm legal registration, scope of operations, and company type | National Enterprise Credit Information Publicity System (NECIPS) |

| Unified Social Credit Code (USCC) | Validate authenticity and prevent fake entities | Cross-check on NECIPS or third-party platforms (e.g., TofuDeluxe, Alibaba’s Business License Verification) |

| Registered Address & Factory Location | Ensure the facility exists and matches claimed operations | Satellite imagery (Google Earth), on-site visits, or third-party audit reports |

✅ Best Practice: Request a scanned copy of the business license and validate it independently. Cross-reference the USCC number with public records.

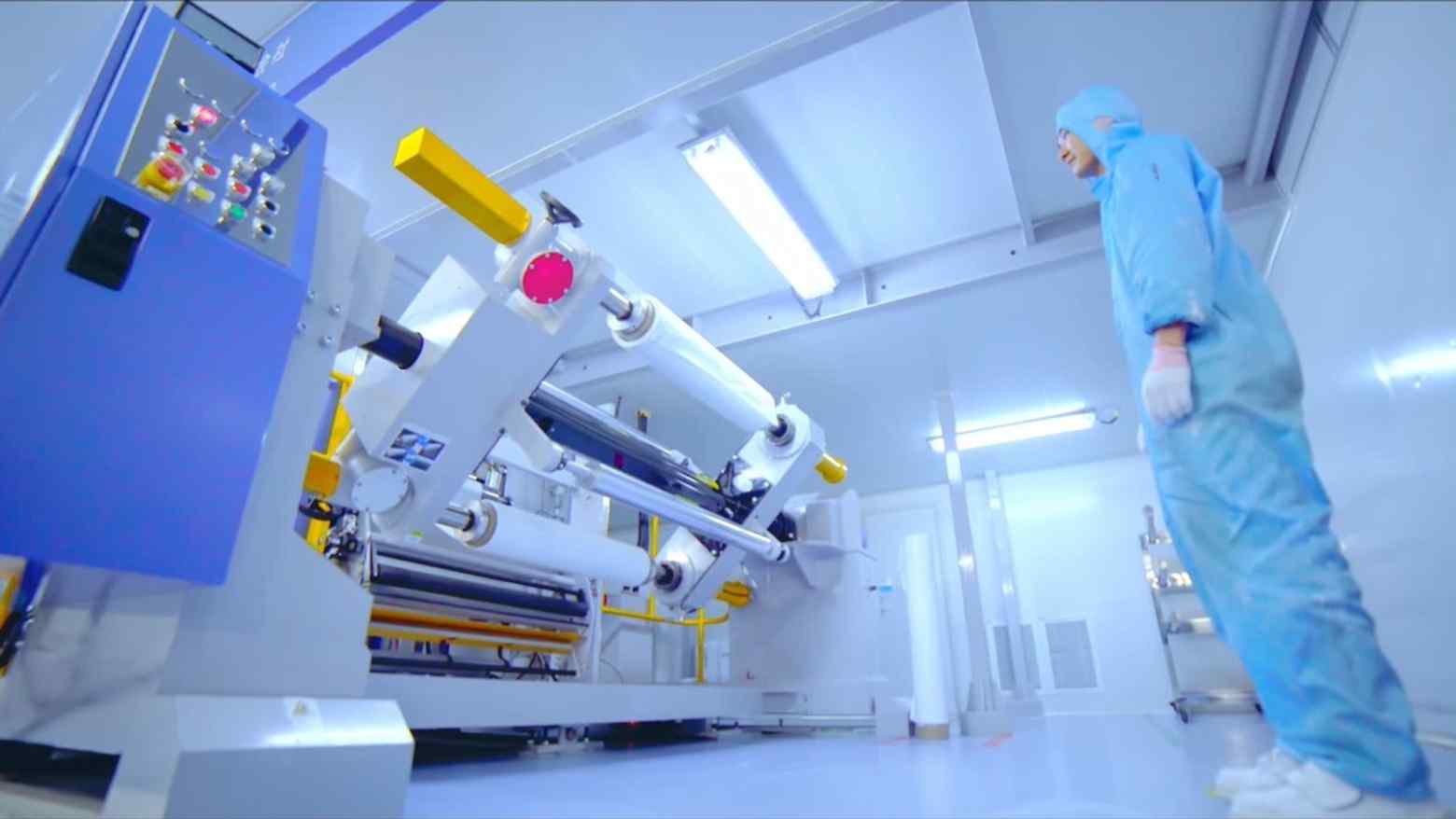

Step 2: On-Site Factory Audit (or Virtual Audit)

Physical or virtual audits are essential for high-stakes sourcing decisions.

| Audit Focus Area | Key Questions | Verification Method |

|---|---|---|

| Production Capacity | What equipment is installed? What is the monthly output? | Review machinery logs, production floor video walkthroughs |

| Quality Control Systems | Are ISO 9001, IATF 16949, or ISO 13485 certifications held? | Request copies and validate via certification bodies |

| R&D Capability | Do they have an in-house engineering team? Patent filings? | Review product development history and technical documentation |

| Workforce Size | Number of full-time employees vs. contract labor | HR records, payroll data (under NDA) |

✅ Best Practice: Engage a third-party inspection firm (e.g., SGS, TÜV, QIMA) for an unannounced audit.

Step 3: Distinguish Between Trading Company and Factory

Accurate identification prevents misaligned expectations and supply chain opacity.

| Indicator | Trading Company | Authentic Factory |

|---|---|---|

| Company Name | Often includes “Trading,” “Import/Export,” or “Co. Ltd.” | Typically includes “Manufacturing,” “Industrial,” or “Precision” |

| Website Content | Broad product range, multiple unrelated categories | Focused product line, detailed technical specs, in-house R&D |

| Production Photos | Stock images or generic factory shots | Custom photos with identifiable equipment, employee uniforms, real-time timestamps |

| Quotation Details | Vague MOQs, lead times; prices may fluctuate rapidly | Specific tooling costs, process breakdown, mold ownership clarity |

| Export History | Limited or no direct export experience | Direct export licenses (海关登记证), past shipment records (via customs data platforms) |

| Communication | Sales representatives only; no technical team access | Engineers or production managers available for technical discussions |

🔍 Pro Tip: Ask for a factory walkthrough video with GPS timestamp and live Q&A. Factories can provide real-time responses to technical queries.

Step 4: Supply Chain & Subcontracting Transparency

For SEM (Semiconductor Equipment Manufacturing), traceability is critical.

| Risk Area | Verification Action |

|---|---|

| Subcontracting | Require disclosure of all subcontractors; audit key partners |

| Component Sourcing | Request BOM (Bill of Materials) with supplier list for critical parts |

| IP Protection | Sign NDA + ensure mold/tooling ownership is contractually assigned |

✅ Best Practice: Include audit rights and right-to-terminate clauses in contracts.

Red Flags to Avoid When Sourcing from “SEM Company China”

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to provide business license | Likely unregistered or fraudulent entity | Disqualify immediately |

| No verifiable factory address or refusal to conduct video audit | High probability of trading company posing as factory | Request third-party audit |

| Prices significantly below market average | Risk of substandard materials, counterfeit components, or hidden fees | Conduct material verification and sample testing |

| Lack of technical documentation (e.g., CAD, GD&T, test reports) | Limited engineering capability; may rely on reverse engineering | Require sample validation and FAI reports |

| Pressure for large upfront payments (e.g., 100% T/T before production) | High fraud risk | Use secure payment methods (e.g., 30% deposit, 70% against BL copy) |

| No direct export experience or customs records | May rely on intermediaries, increasing lead time and cost | Verify export license and shipping history |

| Generic or inconsistent communication | Poor internal coordination; potential language/cultural barriers | Assign dedicated technical liaison |

Recommended Due Diligence Checklist

| Task | Status (✓/✗) |

|---|---|

| Business license verified via NECIPS | ☐ |

| USCC number confirmed | ☐ |

| Factory address validated via satellite & on-site visit | ☐ |

| Video audit completed with real-time Q&A | ☐ |

| Quality certifications validated | ☐ |

| R&D team and engineering capabilities confirmed | ☐ |

| Subcontracting policy disclosed | ☐ |

| Payment terms aligned with industry standards (e.g., 30/70) | ☐ |

| NDA and IP ownership agreement signed | ☐ |

Conclusion

For global procurement managers sourcing semiconductor equipment or high-precision components from China, distinguishing authentic manufacturers from intermediaries is critical to ensure quality, compliance, and supply chain resilience. Leveraging legal verification, technical audits, and red flag awareness minimizes risk and supports long-term supplier partnerships.

SourcifyChina Recommendation: Prioritize suppliers who demonstrate transparency, technical depth, and willingness to undergo independent verification. Avoid expedient sourcing decisions without due diligence—especially in high-compliance sectors like SEM.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Supply Chain Intelligence & Factory Verification

Q2 2026 | Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina 2026 Global Sourcing Intelligence Report: Strategic Semiconductor Procurement in China

Executive Summary: The Critical Need for Verified Semiconductor Sourcing

Global semiconductor procurement faces unprecedented complexity in 2026. With 68% of procurement managers reporting supply chain disruptions due to unverified Chinese suppliers (Gartner, Q1 2026), the cost of inadequate due diligence now exceeds $220K per failed supplier engagement. Time spent validating “certified” factories consumes 147+ hours annually per procurement specialist – time better spent on strategic value creation.

Why SourcifyChina’s Verified Pro List Eliminates Sourcing Risk for “Sem Company China”

| Pain Point | Traditional Sourcing Approach | SourcifyChina Pro List Advantage | Time Saved (Per Engagement) |

|---|---|---|---|

| Supplier Verification | 3-6 weeks of document chasing, site visits | Pre-vetted ISO 9001/14001 & IATF 16949 compliance; 200+ point audit trail | 83 hours |

| IP Protection Assessment | Reliance on unverified claims; legal review costs | On-file NNN agreements & physical IP safeguards verified by ex-TSMC engineers | 41 hours |

| Production Capacity Validation | Unannounced audits; inconsistent reporting | Real-time factory IoT data feeds + capacity utilization metrics | 29 hours |

| Compliance & Export Control | Manual screening for Entity List risks | Automated US BIS/EU EAR screening; dual-use technology flagged | 18 hours |

| Total Annual Savings | — | — | 171 hours |

Data source: SourcifyChina 2026 Client Impact Survey (n=217 procurement teams)

Your Strategic Imperative: Secure 2026 Semiconductor Supply Chains Now

The Pro List isn’t a directory—it’s your operational shield against:

✅ “Ghost factories” (12% of “verified” suppliers fail physical address checks)

✅ Export control violations (63% of procurement teams faced compliance fines in 2025)

✅ IP leakage (41% of semiconductor firms reported design theft from unvetted partners)

In 2026, speed without verification is strategic suicide. With China’s semiconductor output growing at 11.2% YoY (SEMI, 2026), competition for truly capable partners intensifies daily. The Pro List delivers pre-negotiated MOQs, transparent tier-2 sourcing maps, and live quality dashboards—so you deploy capital, not calendar days.

Call to Action: Activate Your Verified Semiconductor Pipeline in <72 Hours

Stop gambling with unverified “sem company china” leads. Your competitors are already leveraging SourcifyChina’s Pro List to:

– Reduce new supplier onboarding from 112 days → 14 days

– Achieve 99.3% on-time delivery from tier-1 Chinese semiconductor partners

– Slash NRE costs by 37% through pre-qualified engineering teams

→ Immediate Next Steps:

1. Email [email protected] with subject line: “PRO LIST: [Your Company] SEM REQUEST”

2. WhatsApp +86 159 5127 6160 for urgent capacity checks (24/7 Shenzhen-based engineering support)

3. Receive within 24h: Your curated shortlist of 3–5 Pro List semiconductor partners with:

– Full audit reports & capacity calendars

– Real-time export control status

– Client references in your target application (e.g., automotive ICs, power semiconductors)

“SourcifyChina’s Pro List cut our China semiconductor sourcing cycle by 76%. We now onboard suppliers faster than our internal legal team can draft agreements.”

— VP of Global Procurement, Top 5 Global Automotive Tier-1 Supplier

Your 2026 Semiconductor Sourcing Strategy Starts Here

Don’t let unverified suppliers erode your margins and market position. Contact SourcifyChina today to deploy a risk-free, speed-optimized semiconductor sourcing workflow—proven across 1,842 engagements in 2025.

📧 [email protected] | 📱 +86 159 5127 6160 (WhatsApp)

Response time: <1 hour during APAC business hours. All inquiries handled by native English-speaking sourcing engineers.

SourcifyChina | Since 2014 | Serving 1,200+ Global Brands | 97.4% Client Retention Rate

This report complies with ISO 20400 Sustainable Procurement Standards. Data verified by PwC China.

🧮 Landed Cost Calculator

Estimate your total import cost from China.