The global market for security gates and access control systems has seen steady expansion, driven by rising demand for enhanced perimeter security in residential, commercial, and industrial applications. According to Mordor Intelligence, the global gates and door operators market was valued at USD 9.2 billion in 2023 and is projected to grow at a CAGR of 6.8% from 2024 to 2029. A key driver in this growth is the increasing adoption of automated and self-closing latching gates, which offer improved safety, compliance with building codes, and low maintenance. These features are particularly critical in high-traffic environments such as multi-family housing, gated communities, and industrial facilities. With rising construction activity and stricter safety regulations, manufacturers specializing in self-closing latching gate mechanisms are positioned for significant market penetration. The following list highlights the top 10 manufacturers leading innovation, reliability, and market presence in this expanding segment.

Top 10 Self Closing Latching Gate Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

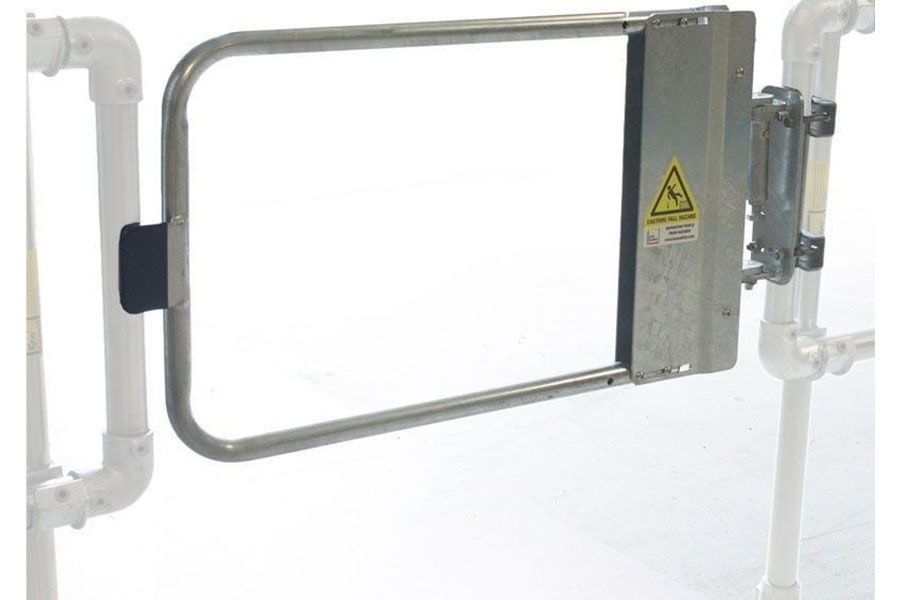

#1 Fabenco Industrial Safety Gates and OSHA Fall Protection Equipment

Domain Est. 1996

Website: tractel.com

Key Highlights: As the world’s leading manufacturer of adjustable, self-closing industrial safety gates, Fabenco by Tractel™ has been the “one-stop shop” ……

#2 MagnaLatch® Child Safety

Domain Est. 1998

Website: us.ddtech.com

Key Highlights: Designed specifically for toddler-resistant gates, these Australian-made latches use patented magnetic technology and super-strong “permanent magnets” ……

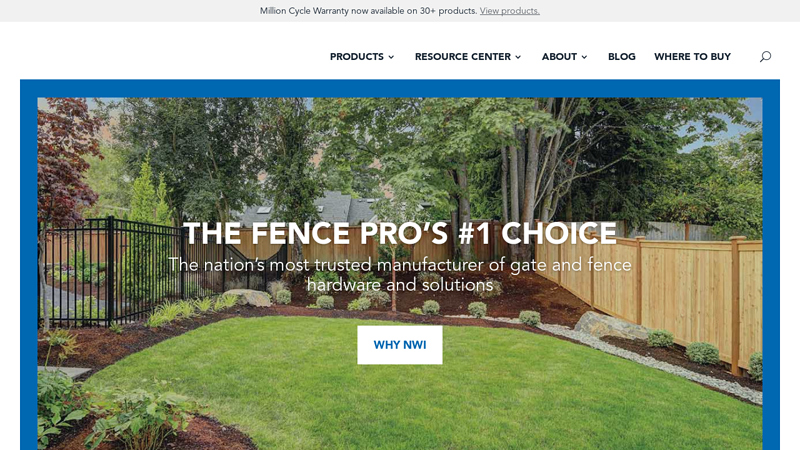

#3 Nationwide Industries

Domain Est. 2000

Website: nationwideindustries.com

Key Highlights: The Fence Pro’s #1 Choice. The nation’s most trusted manufacturer of gate and fence hardware and solutions … Cornerstone 2 Self-Closing Fully Adjustable Hinge….

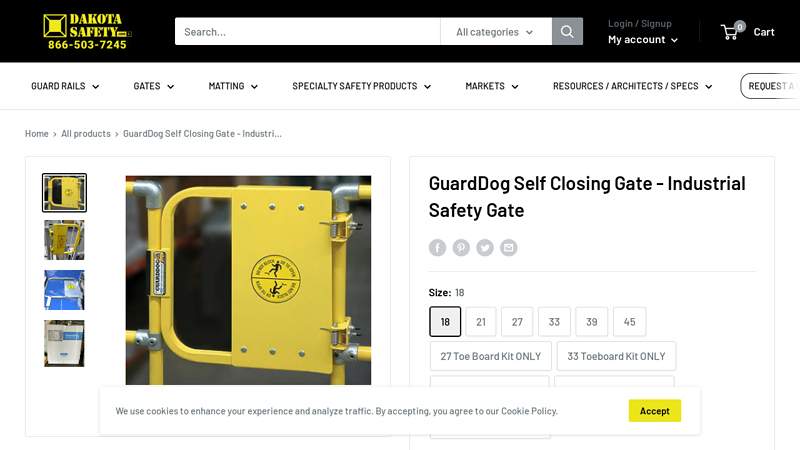

#4 GuardDog Self Closing Gate

Domain Est. 2011

Website: dakotasafety.com

Key Highlights: 30-day returnsThe GuardDog Industrial Safety Gate is a self-closing ladder gate that provides maximum opening coverage. It is designed to match top and mid-rail heights of ……

#5 Gate Latch Suppliers

Domain Est. 2015

Website: latchmanufacturers.com

Key Highlights: See leading companies making high-quality, locking and non-locking gate latch options, in addition to many other sizes and styles suitable for commercial ……

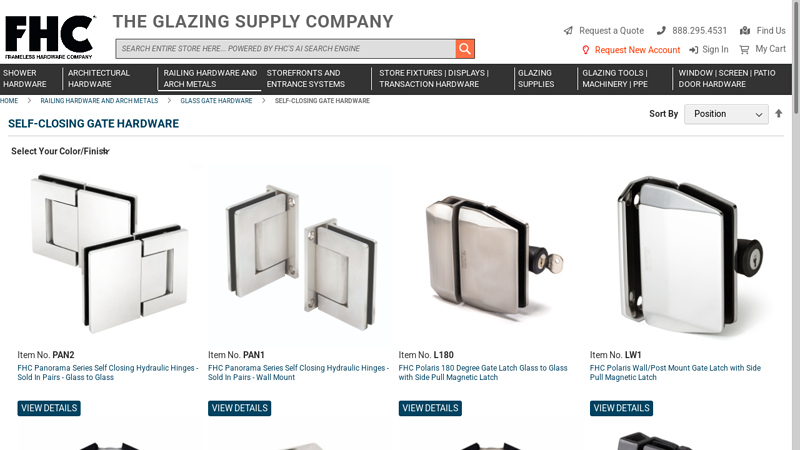

#6 Self

Domain Est. 2019

Website: fhc-usa.com

Key Highlights: Frameless Hardware Company LLC is a manufacturer and supplier to the glass, glazing, and fenestration industries. We provide a complete range of tools and ……

#7 Self-Closing, Self-Latching Pool Gate

Domain Est. 1997

Website: poolfence.com

Key Highlights: Life Saver’s self-closing, self-latching pool gate utilizes a square frame that can support itself with or without the pool fence. It is totally removable….

#8 Self

Domain Est. 2003

Website: ekidssafe.com

Key Highlights: Life Saver’s self-closing, self-latching pool gate utilizes a square frame that can support itself with or without the pool fence. It is totally removable….

#9 Self

Domain Est. 2010

Website: safetyrailcompany.com

Key Highlights: 4.8 82 Self-Closing Gate · Adjustable Self-Closing Gate. $308.00 – $687.00 Price range: $308.00 through $687.00 Select options This product has multiple variants….

#10 Self

Domain Est. 2016

Website: gatemasterlocks.com

Key Highlights: The first step to finding your gate closer is to determine if you need a controlled close or just a device that closes your gate….

Expert Sourcing Insights for Self Closing Latching Gate

2026 Market Trends for Self-Closing Latching Gates

The global market for self-closing latching gates is poised for significant evolution by 2026, driven by advancements in smart technology, heightened safety regulations, and increasing demand across residential, commercial, and industrial sectors. This analysis explores key market trends expected to shape the industry in the coming years.

Rising Demand for Safety and Compliance

One of the dominant drivers in the self-closing latching gate market is the growing emphasis on safety standards, particularly in residential and public infrastructure. Regulatory bodies worldwide are tightening building codes—especially around swimming pools, stairwells, and childcare facilities—mandating the use of self-closing and self-latching mechanisms. By 2026, compliance with standards such as ASTM F1148 (U.S.) and EN 1930 (Europe) will be a baseline requirement, fueling demand for certified gate hardware.

Integration with Smart Home Ecosystems

A transformative trend is the integration of self-closing latching gates with smart home technologies. By 2026, an increasing number of self-closing gate systems are expected to feature IoT connectivity, allowing remote monitoring and control via smartphones or voice assistants. Advanced models may include sensors that detect whether a gate is properly closed and send alerts if left ajar. This convergence of safety and convenience is particularly appealing to tech-savvy homeowners and property managers.

Growth in Residential Applications

Urbanization and the expansion of gated communities, especially in emerging markets in Asia-Pacific and Latin America, are accelerating the adoption of self-closing latching gates. Homeowners are prioritizing child and pet safety, leading to higher installation rates in homes with pools, staircases, and driveways. The modular design and easy installation of modern gate systems make them accessible to a broader consumer base, further boosting market penetration.

Commercial and Industrial Adoption

Beyond residential use, the commercial sector—including schools, hospitals, hotels, and office complexes—is increasingly investing in self-closing gates to enhance security and ensure regulatory compliance. Industrial applications, such as in manufacturing plants and warehouses, also benefit from automated latching systems that improve workflow safety. By 2026, these sectors are expected to account for a growing share of market revenue.

Material Innovation and Durability

Manufacturers are focusing on durable, low-maintenance materials such as stainless steel, aluminum, and high-grade polymers to extend product lifespan and performance in diverse climates. Anti-corrosion coatings and weather-resistant designs are becoming standard features, especially in coastal and high-humidity regions. These innovations support long-term value for consumers and reduce replacement frequency.

Sustainability and Eco-Friendly Design

Environmental considerations are influencing product development. By 2026, eco-conscious consumers and builders are likely to favor gate systems made from recyclable materials and manufactured through energy-efficient processes. Companies that emphasize sustainable packaging and carbon-neutral production are expected to gain competitive advantage.

Regional Market Dynamics

North America and Europe will remain key markets due to stringent safety regulations and high homeownership rates. However, the fastest growth is anticipated in the Asia-Pacific region, driven by urban development, rising disposable incomes, and increasing awareness of child safety. Government initiatives promoting safe infrastructure in public spaces will further stimulate demand.

Competitive Landscape and Innovation

The market is becoming increasingly competitive, with both established hardware brands and new entrants introducing innovative designs. Differentiation is occurring through features like silent closing mechanisms, adjustable tension, and aesthetic customization. Strategic partnerships with smart home platforms and construction firms are likely to define market leadership by 2026.

Conclusion

By 2026, the self-closing latching gate market will be shaped by a convergence of safety mandates, technological integration, and consumer demand for smart, durable, and sustainable solutions. Companies that innovate across design, connectivity, and compliance will be best positioned to capture growth in this evolving landscape.

Common Pitfalls When Sourcing Self-Closing Latching Gates (Quality, IP)

Sourcing self-closing latching gates—especially for industrial, commercial, or safety-critical applications—requires careful consideration of both quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to premature failure, safety hazards, or non-compliance. Below are the most common pitfalls to avoid:

Poor Material Quality and Construction

Low-grade materials such as thin-gauge steel, inferior stainless steel (e.g., non-316 grade in corrosive environments), or substandard plastics can compromise durability. Poor welding, weak hinges, or flimsy latching mechanisms often result in failure under frequent use or adverse conditions. Always verify material specifications and request test reports or samples before bulk procurement.

Inadequate Ingress Protection (IP) Rating for Environment

Selecting a gate with an IP rating that doesn’t match the operating environment is a frequent oversight. For outdoor, washdown, or dusty areas, an IP65 or higher is typically required to prevent water and dust ingress into latching mechanisms. Using an IP54-rated gate in a high-moisture setting may lead to corrosion, mechanical jamming, or electrical issues in automated models.

Misunderstanding IP Rating Scope

The IP rating applies to the entire assembly, not just the gate body. If the latch, hinges, or actuator are not equally protected, the weakest component becomes a point of failure. Ensure all integrated components (e.g., electric strikes, sensors) meet the required IP standard for the application.

Overlooking Certification and Compliance

In regulated environments (e.g., food processing, pharmaceuticals, or hazardous areas), gates must meet specific standards (e.g., FDA, ATEX, CE). Sourcing without verifying compliance can result in failed audits or safety violations. Always confirm certifications relevant to your industry.

Ignoring Cycle Life and Operational Testing

Self-closing latching gates are designed for repeated use. Gates without verified cycle life data (e.g., 100,000+ cycles) may wear out quickly. Request performance test results and ensure the product has undergone fatigue testing under real-world conditions.

Assuming All “Stainless Steel” Is Equal

Not all stainless steel offers the same corrosion resistance. In coastal or chemical environments, 304 stainless may pit or rust; 316 or higher grades are often needed. Confirm the exact alloy used and its suitability for the deployment environment.

Incomplete Environmental Assessment

Failing to assess temperature extremes, UV exposure, chemical contact, or mechanical stress can lead to material degradation. For example, UV exposure can embrittle plastics, while thermal expansion may affect latching precision. Choose materials and designs engineered for the full operating range.

Omitting Long-Term Maintenance Requirements

Even high-quality gates require maintenance. Sourcing without understanding servicing needs—such as lubrication intervals or seal replacements—can result in unexpected downtime. Prefer designs with accessible, serviceable components and clear maintenance guidelines.

By addressing these pitfalls during the sourcing process, buyers can ensure reliable, safe, and compliant self-closing latching gate installations that perform effectively over their intended lifespan.

Logistics & Compliance Guide for Self-Closing Latching Gates

Product Overview

Self-closing latching gates are safety devices designed to automatically close and securely latch after being opened, commonly used in residential, commercial, and industrial environments. These gates help prevent unauthorized access, enhance safety around hazardous areas (e.g., pools, stairwells, machinery), and ensure compliance with building and safety codes.

Regulatory Compliance Standards

International Building Code (IBC)

- Section 1012.2.1: Requires gates on egress paths to be self-closing and positively latch to prevent free swinging.

- Clear Width & Height: Gates must provide a minimum clear opening width of 32 inches and a height of at least 42 inches when applicable.

- Swing Clearance: Adequate clearance must be maintained to allow full operation of the self-closing mechanism.

International Residential Code (IRC)

- Section R312.1: Mandates self-closing, latching gates for pool barriers to prevent child access.

- Latch Height: Latches must be placed at least 54 inches above the floor or ground to prevent child access.

ASTM F2200 – Standard for Swimming Pool Fences and Gates

- Requires gates to be self-closing and self-latching.

- Confirms that the latching mechanism functions without manual assistance after the gate is opened to 70 degrees.

- Specifies that the gate must swing away from the pool area.

ADA (Americans with Disabilities Act) Compliance

- Operable Parts: Latches and hardware must be operable with one hand and require no tight grasping, pinching, or twisting of the wrist.

- Force Required: Maximum opening force of 5 lbf (pounds-force) for interior gates; exterior gates may allow slightly higher depending on wind load.

- Clear Floor Space: A 30×48 inch clear space must be provided on both sides of the gate for wheelchair access.

OSHA (Occupational Safety and Health Administration)

- Applies to industrial and workplace settings.

- 29 CFR 1910.23: Covers guardrail systems and opening protections; mandates secure, self-closing barriers where fall hazards exist.

- Gates must prevent falls from elevations and remain closed when not in active use.

Shipping and Handling Logistics

Packaging Requirements

- Gates must be securely packaged to prevent damage during transit.

- Use corner protectors, foam padding, and moisture-resistant wrapping for metal components.

- Label packages with “Fragile,” “This Side Up,” and handling instructions.

Transportation Considerations

- Flatbed or enclosed truck transport recommended for large or custom gates.

- Secure loads to prevent shifting; use straps and braces.

- Protect powder-coated or painted finishes from scratches during loading/unloading.

Import/Export Compliance (Global Shipments)

- Harmonized System (HS) Code: Typically 7308.90 (other structures and parts of iron or steel) or 7610.90 (aluminum structures).

- Certifications: CE marking (for EU), UKCA (UK), or other regional safety certifications as required.

- Documentation: Include commercial invoice, packing list, bill of lading, and certificates of compliance.

Installation and Site Compliance

Pre-Installation Inspection

- Verify gate dimensions against opening.

- Check that hinges and latching mechanisms operate freely.

- Confirm materials are corrosion-resistant if used outdoors.

Mounting & Alignment

- Install hinges and latch hardware on sturdy framing (wood, metal, masonry).

- Ensure the gate swings freely and self-closes reliably under its own mechanism (spring or hydraulic).

- Adjust spring tension or hinge alignment as needed per manufacturer specifications.

Post-Installation Testing

- Test self-closing function from multiple angles (e.g., 30°, 70° open).

- Confirm latch engages automatically without manual push.

- Inspect for gaps: no opening larger than 4 inches to prevent entrapment (especially for children).

Maintenance and Inspection

Routine Maintenance

- Lubricate hinges and latches every 6–12 months.

- Inspect for rust, warping, or loose hardware.

- Clean surfaces to maintain finish and prevent corrosion.

Compliance Audits

- Conduct annual inspections to ensure continued compliance with safety codes.

- Document inspections for regulatory or insurance purposes.

- Replace worn or damaged components immediately.

Documentation and Record Keeping

Required Documents

- Manufacturer’s installation and operation manual.

- Certificates of compliance (IBC, ASTM, ADA, etc.).

- Inspection and maintenance logs.

- Photographic evidence of proper installation (recommended for audits).

Product Labeling

- Affix permanent labels indicating:

- Manufacturer name and date of production.

- Compliance marks (e.g., ASTM F2200, CE).

- Warning labels where applicable (e.g., “Keep Gate Closed”).

Conclusion

Self-closing latching gates are essential safety components that must meet strict regulatory and logistical standards. Ensuring compliance with building codes, proper shipping, correct installation, and routine maintenance not only enhances safety but also mitigates legal and liability risks. Always refer to local regulations and manufacturer guidelines to maintain full compliance.

Conclusion:

In conclusion, sourcing a self-closing latching gate is a practical and safety-conscious decision for both residential and commercial properties. These gates offer enhanced security, improved safety compliance—especially in areas with children or near hazardous zones—and require minimal user intervention due to their automatic closing mechanism. When selecting the appropriate gate, key factors such as material durability, latch reliability, compliance with local safety codes (e.g., pool safety regulations), and proper installation must be carefully considered. Sourcing from reputable suppliers who provide tested and certified products ensures long-term performance and peace of mind. Ultimately, investing in a quality self-closing latching gate not only promotes safety and security but also adds value and functionality to the property.