The global sealing tent market has seen steady expansion in recent years, driven by rising demand across industries such as construction, emergency response, environmental remediation, and industrial maintenance. According to a 2023 report by Grand View Research, the global industrial tent and temporary structure market size was valued at USD 3.8 billion and is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is fueled by increased infrastructure development, the need for rapid deployment shelters, and the scalability of reusable temporary enclosures. As applications for sealing tents expand—from containment solutions in hazardous material removal to climate-controlled worksites—the demand for high-performance, durable, and customizable designs has intensified. In this evolving landscape, a select group of manufacturers have distinguished themselves through innovation, quality, and global reach. Based on market presence, product diversity, and technological advancements, here are the top nine sealing tent manufacturers shaping the future of temporary containment and protective enclosures.

Top 9 Sealing Tent Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tents

Domain Est. 2004

Website: seamseal.com

Key Highlights: At Seam Seal International we have a proven and reliable knowledge on almost all types of tents and tent fabrics and supply many of the renowned manufacturer’s….

#2 Tents 101: Seam Taping vs. Seam Sealing

Domain Est. 1995

Website: cascadedesigns.com

Key Highlights: To prevent infiltration, tent manufacturers have three options: seam taping, seam sealing, and creating a strong seam construction itself….

#3 Protecting the Essential

Domain Est. 1996

Website: trelleborg.com

Key Highlights: For over a century, we have pioneered applied polymer engineering, growing from a rubber manufacturer into a world leader in engineered polymer ……

#4 Tarptent

Domain Est. 2001

Website: tarptent.com

Key Highlights: Tarptent is a premium collection of ultralight, mobile shelters that shed everything from flying bugs to summer snow….

#5 Seam Sealing Service

Domain Est. 2002

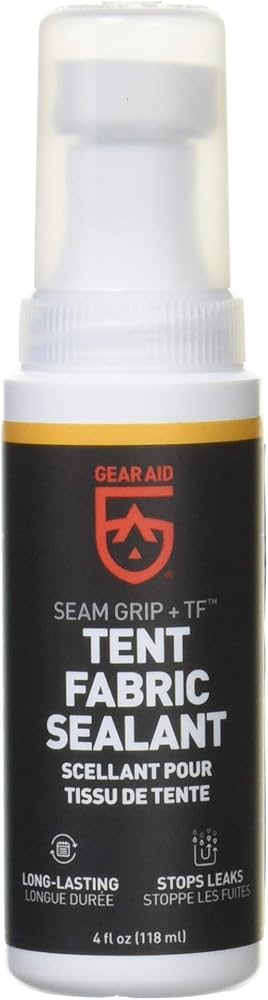

#6 Seam Grip TF Tent Fabric Sealant

Domain Est. 2005

Website: gearaid.com

Key Highlights: Use Seam Grip TF tent fabric sealant to waterproof a tent floor, rain fly, or tarp when the old polyurethane coating wears off….

#7 GEAR AID

Domain Est. 2011

Website: sierramadreresearch.com

Key Highlights: 4-day delivery 30-day returnsThis clear sealant dries to a flexible rubber that works on all silicone-treated gear including nylon tarps and ultralight backpacks….

#8 Tent Seam Sealing

Domain Est. 2016

Website: argalioutdoors.com

Key Highlights: Start sealing at the top of your tent seams and work your way down. · You do not need a lot of seam sealer to waterproof your tent. Use a small bead of silicone ……

#9 Seal Seams 101

Domain Est. 2019

Website: pomoly.com

Key Highlights: Sealing the seams of your tent is crucial to prevent water from seeping through the tiny needle holes created during the manufacturing process….

Expert Sourcing Insights for Sealing Tent

H2: 2026 Market Trends for Sealing Tents

The global sealing tent market is poised for significant transformation by 2026, driven by advancements in material science, rising demand for temporary and modular infrastructure, and growing applications across industries such as oil and gas, construction, emergency response, and environmental remediation. The following analysis outlines key trends shaping the sealing tent market in 2026 under the H2 framework—highlighting Hygiene, Hazard Containment, High-Performance Materials, and Hybrid Deployment Models.

1. Hygiene: Increased Focus on Controlled Environments

With heightened global awareness of contamination control—spurred by recent public health crises—sealing tents are increasingly utilized in sterile and hygienic environments. By 2026, demand is rising for sealing tents equipped with HEPA filtration systems, UV-C sterilization, and positive/negative pressure controls. These features are critical in pharmaceutical manufacturing, hospital decontamination zones, and biotech labs, where air quality and particulate control are paramount. The integration of IoT-enabled air quality sensors allows real-time monitoring, further enhancing hygiene standards.

2. Hazard Containment: Regulatory Push and Industrial Safety

Stringent environmental and occupational safety regulations are accelerating adoption of sealing tents for hazardous material containment. In sectors like asbestos abatement, chemical remediation, and nuclear decommissioning, sealing tents serve as critical barriers to prevent cross-contamination. By 2026, governments in North America and Europe are expected to enforce stricter containment protocols, driving demand for certified, leak-tested sealing systems. The market is responding with tents compliant with OSHA, EPA, and ISO standards, featuring airtight zippers, welded seams, and modular airlocks.

3. High-Performance Materials: Innovation in Durability and Flexibility

Material innovation is a cornerstone of 2026 sealing tent advancements. Manufacturers are investing in fluoropolymers (e.g., PTFE-coated fabrics), silicone-impregnated textiles, and nanocomposite membranes that offer superior resistance to UV degradation, extreme temperatures, and chemical exposure. These materials extend product lifespan and reduce maintenance costs. Additionally, lightweight yet robust fabrics enable faster deployment and improved portability—key for remote or disaster-stricken areas. Sustainability trends are also pushing development of recyclable and low-VOC materials.

4. Hybrid Deployment Models: Integration with Modular and Smart Infrastructure

The future of sealing tents lies in hybrid applications that integrate with modular buildings, temporary cleanrooms, and smart site management systems. By 2026, sealing tents are increasingly designed as part of larger temporary infrastructure ecosystems—featuring plug-and-play connectivity with HVAC units, power sources, and digital monitoring platforms. AI-powered deployment planning tools optimize tent sizing and layout based on environmental data. Remote operation via mobile apps and cloud-based dashboards enhances operational efficiency, especially in large-scale industrial projects.

Conclusion

By 2026, the sealing tent market will be defined by a convergence of safety, technology, and sustainability. The H2 trends—Hygiene, Hazard Containment, High-Performance Materials, and Hybrid Deployment—reflect a shift from basic containment solutions to intelligent, adaptable systems. Companies that prioritize innovation in these areas will gain competitive advantage, while end-users benefit from safer, smarter, and more efficient temporary enclosures. As global infrastructure demands evolve, sealing tents will play an increasingly vital role in enabling resilient and responsive operational environments.

Common Pitfalls When Sourcing Sealing Tents: Quality and Intellectual Property Issues

Sourcing sealing tents—often used in cleanrooms, isolation units, or for containment in industrial and healthcare settings—can present several challenges, particularly concerning product quality and intellectual property (IP) rights. Below are common pitfalls to watch for in these two critical areas.

Quality-Related Pitfalls

1. Substandard Materials and Construction

Many suppliers, especially from low-cost manufacturing regions, may use inferior materials to reduce costs. This includes non-compliant fabrics, weak seams, or inadequate zippers and seals that fail under pressure or repeated use. Poor construction can compromise the tent’s ability to maintain proper sealing and environmental control.

2. Inconsistent Manufacturing Standards

Lack of adherence to international quality standards (e.g., ISO 13485 for medical devices or ISO 9001) can result in inconsistent product quality between batches. Without proper quality control processes, defects may go undetected until deployment, leading to operational failures.

3. Misleading or Unverified IP Ratings

Suppliers may claim high Ingress Protection (IP) ratings (e.g., IP67) without third-party certification. These claims can be exaggerated or entirely false. Without independent testing reports, buyers risk acquiring tents that do not meet required environmental protection levels.

4. Absence of Performance Testing Data

Reputable sealing tents should come with documented performance data, including leak tests, pressure resistance, and durability under specific conditions. Sourcing from suppliers who cannot provide verifiable test results increases the risk of receiving ineffective or unsafe products.

Intellectual Property-Related Pitfalls

1. Infringement of Patented Designs

Some suppliers may copy patented sealing mechanisms, frame structures, or deployment systems without authorization. Purchasing such products—even unknowingly—can expose the buyer to legal risk, especially if the tent is used in regulated industries or exported to IP-strict jurisdictions.

2. Lack of IP Documentation and Transparency

Suppliers may be unwilling or unable to provide proof of IP ownership or licensing agreements. This opacity raises red flags about the legitimacy of the product and can lead to supply chain disruptions if legal action is taken against the manufacturer.

3. Grey Market or Counterfeit Goods

Sealing tents with well-known brand designs may be counterfeit or produced in unauthorized facilities. These often mimic legitimate products but lack quality assurance and IP compliance. Buyers may face not only performance issues but also reputational and legal consequences.

4. Inadequate Contractual IP Protections

Procurement contracts that fail to include IP warranties, indemnification clauses, or clear ownership terms leave buyers vulnerable. If a third party asserts IP infringement, the buyer may be held liable without recourse against the supplier.

Mitigation Strategies

- Conduct thorough due diligence on suppliers, including factory audits and requests for certification.

- Require independent test reports for IP ratings and performance metrics.

- Verify IP status through patent databases and request documentation from suppliers.

- Include strong IP indemnification clauses in sourcing agreements.

- Work with legal and technical experts when entering new markets or scaling procurement.

Avoiding these pitfalls ensures that sealing tents perform as intended while minimizing legal and operational risks.

Logistics & Compliance Guide for Sealing Tent

Overview

A Sealing Tent is a temporary, controlled environment used primarily in industrial, pharmaceutical, or hazardous material handling settings to contain contaminants during maintenance, construction, or decontamination activities. Proper logistics and compliance are essential to ensure operational safety, regulatory adherence, and environmental protection.

Regulatory Compliance

Environmental Protection Regulations

Sealing Tents must comply with environmental regulations such as the U.S. Environmental Protection Agency (EPA) standards under the Clean Air Act and Resource Conservation and Recovery Act (RCRA), especially when used for asbestos abatement, lead paint removal, or handling volatile organic compounds (VOCs). Local and national air quality regulations may require emission controls, air filtration (e.g., HEPA filters), and proper waste disposal procedures.

Occupational Health & Safety Standards

Compliance with Occupational Safety and Health Administration (OSHA) standards is mandatory. Key regulations include:

– 29 CFR 1910.134 – Respiratory Protection

– 29 CFR 1910.120 – Hazardous Waste Operations and Emergency Response (HAZWOPER)

– 29 CFR 1926.57 – Ventilation in construction environments

Personnel working within or near the Sealing Tent must be trained, equipped with personal protective equipment (PPE), and monitored for exposure risks.

Containment and Decontamination Protocols

The tent must maintain negative pressure to prevent the spread of contaminants. Airflow must be continuously monitored using manometers or pressure gauges. Decontamination procedures, including entry/exit protocols (e.g., decon chambers), must be documented and followed rigorously.

Transportation and Logistics

Packaging and Handling

Sealing Tents are typically made from durable, flexible materials such as polyethylene or PVC-coated fabrics. When transported:

– Roll or fold the tent carefully to avoid tears

– Store in protective bags or containers labeled with handling instructions

– Avoid exposure to extreme temperatures or direct sunlight during transit

Shipping Requirements

- Ensure all components (tent material, frame, seals, filters) are inventoried and secured

- Use freight carriers experienced in handling hazardous or sensitive industrial equipment

- Include compliance documentation (e.g., safety data sheets, containment protocols) with the shipment

On-Site Setup and Installation

- Conduct a site assessment to ensure structural support and environmental stability

- Assemble the frame and seal all joints using appropriate tapes or clamps

- Verify integrity through smoke tests or pressure differential checks

- Install HEPA filtration units and connect to exhaust systems as required

Documentation and Reporting

Pre-Operation Checklist

- Confirm permits and regulatory approvals are in place

- Verify personnel training and PPE availability

- Inspect tent and components for damage

- Test air monitoring and filtration systems

Operational Records

Maintain logs for:

– Daily air quality readings

– Filter change schedules

– Personnel entry/exit times

– Waste generated and disposal manifests

Post-Project Decommissioning

- Decontaminate the tent and equipment according to protocol

- Dispose of contaminated materials through licensed hazardous waste handlers

- Conduct final clearance testing (e.g., air sampling)

- Submit closure reports to regulatory agencies if required

International Considerations

For cross-border operations, ensure compliance with:

– REACH and CLP regulations (EU)

– Health and Safety Executive (HSE) guidelines (UK)

– Transport regulations such as ADR (Europe) for hazardous materials

Verify local requirements for containment, worker safety, and waste handling before deployment.

Conclusion

Effective logistics and strict compliance are critical when deploying a Sealing Tent. Adherence to environmental, safety, and transportation regulations ensures the protection of workers, the public, and the environment. Maintain detailed documentation and conduct regular audits to support continuous compliance.

Conclusion for Sourcing Sealing Tents

In conclusion, sourcing sealing tents requires a comprehensive approach that balances quality, cost, technical specifications, and supplier reliability. These specialized tents are critical for maintaining contamination control in sensitive environments such as cleanrooms, pharmaceutical manufacturing, and biological research facilities. Therefore, selecting the right supplier involves evaluating factors such as material durability, ease of installation, compliance with industry standards (e.g., ISO classifications), and customization capabilities.

Thorough due diligence—comprising supplier audits, sample testing, and review of certifications—ensures that the procured sealing tents meet operational requirements and regulatory expectations. Additionally, considering logistical aspects such as lead times, after-sales support, and warranty terms contributes to long-term efficiency and risk mitigation.

By leveraging market research, comparative analysis, and stakeholder input, organizations can make informed sourcing decisions that enhance environmental control, ensure product integrity, and support compliance. Ultimately, a strategic sourcing process for sealing tents leads to improved operational performance, reduced contamination risks, and a better return on investment.