The global scaffolding platforms market is experiencing robust growth, driven by rising construction activities, infrastructure development, and stringent safety regulations. According to Grand View Research, the global scaffolding market size was valued at USD 12.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This upward trajectory is further supported by urbanization trends and increasing demand for modular and reusable scaffolding systems across commercial, industrial, and residential construction sectors. As the industry evolves, innovation in materials—such as aluminum and steel alloys—and advancements in system scaffolding designs are reshaping competitive dynamics. In this high-growth environment, leading manufacturers are scaling production, enhancing product safety and efficiency, and expanding their global footprint. Based on market share, product innovation, and geographic reach, the following ten companies have emerged as key players shaping the future of scaffolding platforms worldwide.

Top 10 Scaffolding Platforms Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Layher NA

Domain Est. 2005

Website: layherna.com

Key Highlights: As a leading scaffolding manufacturer USA & Canada, Layher NA offers superior industrial, commercial, and construction scaffolding systems….

#2 at Scafom

Domain Est. 2010

Website: scafom-rux.com

Key Highlights: The home of scaffolding. Scafom-rux is a scaffold manufacturer of various system scaffolds for industrial scaffolding as well as construction scaffolding….

#3 Bil-Jax® Scaffolding

Domain Est. 1996

Website: biljax.com

Key Highlights: Biljax scaffolding from a top U.S. manufacturer. Durable scaffold systems, staging, and supplies for all your project needs….

#4 Aluminum Ladder Manufacturer, Falcon Ladder & Scaffold

Domain Est. 1999

Website: falconladder.com

Key Highlights: Falcon Ladder & Scaffold has been a manufacturer of high quality ladders, scaffolding and aluminum products in the Okanagan of British Columbia, Canada, since ……

#5 Scaffold

Domain Est. 1998

Website: universalscaffold.com

Key Highlights: We manufacture the highest-quality scaffolding equipment and custom access products including complete scaffold engineering and CAD design services….

#6 Action Equipment and Scaffold Company

Domain Est. 2000

Website: actionscaffold.com

Key Highlights: Action Equipment and Scaffold Company sells, rents, erects and dismantles scaffolding, equipment and many accessories….

#7 Work Platforms

Domain Est. 2000

Website: vanguardmanufacturing.com

Key Highlights: The work platforms shown here are designed to be used with steel scaffolding. Showing all 6 resultsSorted by popularity. Sort by popularity, Sort by latest ……

#8 ScaffoldMart Scaffolding & Accessories

Domain Est. 2005

Website: scaffoldmart.com

Key Highlights: 3–12 day delivery 1-day returnsExplore our extensive range of scaffold frames, sets, safety accessories, and more designed to elevate your construction projects….

#9 Metaltech

Domain Est. 2011

Website: metaltech.co

Key Highlights: Products: Exterior Scaffolding, Portable Scaffolding, Aluminum Scaffolding, Temporary Fences, Fiberglass Series, Drywall, Ladders and step ladders….

#10 Aluminum Scaffolding

Domain Est. 2011

Website: affixscaffolding.com

Key Highlights: Buy aluminum scaffolding towers from the supplier of wide range of scaffold towers manufacture. Available aluminum scaffolding towers for sales and aluminum ……

Expert Sourcing Insights for Scaffolding Platforms

2026 Market Trends for Scaffolding Platforms

The global scaffolding platforms market is poised for significant transformation by 2026, driven by technological advancements, evolving safety regulations, and increasing construction activity worldwide. This analysis explores key trends expected to shape the scaffolding platforms industry in 2026, focusing on innovation, regional dynamics, sustainability, and market demand.

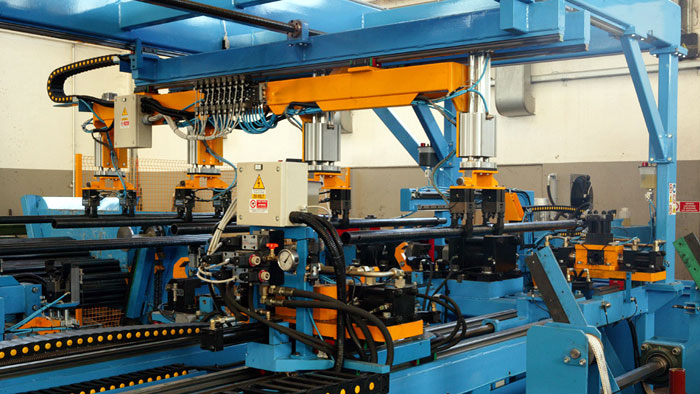

Technological Advancements and Smart Scaffolding

One of the most prominent trends in the 2026 scaffolding platforms market is the integration of smart technologies. Manufacturers are increasingly incorporating sensors, IoT (Internet of Things) connectivity, and real-time monitoring systems into scaffolding structures. These smart scaffolds can detect weight loads, structural integrity issues, environmental conditions (such as wind speed and tilt), and send alerts to supervisors via mobile applications. This shift enhances worker safety and enables predictive maintenance, reducing downtime and accident risks.

Additionally, modular and automated scaffolding systems are gaining traction. These systems allow for faster assembly and disassembly, reducing labor costs and project timelines—especially crucial in urban construction environments with tight schedules.

Sustainability and Eco-Friendly Materials

Sustainability is becoming a core consideration across the construction industry, and scaffolding platforms are no exception. By 2026, there is a growing demand for scaffolding made from recycled or recyclable materials, such as high-grade aluminum and composite alloys. These materials reduce the carbon footprint of construction projects and offer long-term cost benefits due to their durability and corrosion resistance.

Moreover, rental and leasing models are expected to expand, promoting a circular economy. Instead of purchasing scaffolding outright, contractors opt to rent equipment, which encourages manufacturers to design longer-lasting, reusable components and reduces overall material waste.

Stringent Safety Regulations and Compliance

Governments and regulatory bodies worldwide are tightening safety standards for construction work at heights. In 2026, compliance with updated safety codes—such as OSHA in the U.S., the Work at Height Regulations in the UK, and similar frameworks in Asia-Pacific and the Middle East—will be a critical driver of market growth. These regulations mandate the use of certified scaffolding platforms that meet specific load-bearing, stability, and fall protection requirements.

As a result, manufacturers are investing heavily in R&D to produce scaffolding that not only meets but exceeds safety benchmarks. Third-party certifications and digital compliance tracking will become standard features in premium scaffolding solutions.

Regional Market Dynamics

The Asia-Pacific region is expected to dominate the scaffolding platforms market by 2026, fueled by rapid urbanization, infrastructure development, and large-scale construction projects in countries like China, India, and Indonesia. High-rise building construction and government investments in transportation and smart cities are key growth catalysts.

Meanwhile, North America and Europe will see steady growth driven by renovation of aging infrastructure and strict safety enforcement. The Middle East, particularly Gulf Cooperation Council (GCC) countries, will also witness increased demand due to ongoing mega-projects linked to tourism and economic diversification initiatives.

Demand in Specialized Applications

Beyond traditional building construction, scaffolding platforms are finding expanded applications in offshore oil & gas, wind turbine maintenance, bridge rehabilitation, and industrial plant upgrades. These specialized sectors require customized, high-performance scaffolding solutions that can operate in extreme environments. By 2026, demand for such niche products is expected to rise, encouraging innovation in design and materials.

Conclusion

By 2026, the scaffolding platforms market will be characterized by smarter, safer, and more sustainable solutions. Technological integration, regulatory compliance, and regional construction booms will drive market expansion. Companies that embrace innovation, prioritize safety, and adapt to environmental concerns will be best positioned to capitalize on emerging opportunities in this dynamic sector.

Common Pitfalls When Sourcing Scaffolding Platforms (Quality, IP)

Sourcing scaffolding platforms involves significant risks if not managed carefully, particularly concerning product quality and intellectual property (IP) protection. Overlooking these aspects can lead to safety hazards, project delays, legal disputes, and reputational damage. Below are key pitfalls to watch for:

Poor Manufacturing Quality and Non-Compliance

Many suppliers, especially in low-cost regions, may offer scaffolding platforms that do not meet international safety standards (e.g., EN 12811, OSHA, or BS standards). Substandard materials, inadequate welding, or incorrect load ratings can result in structural failures, endangering workers and increasing liability. Always verify third-party certifications and conduct factory audits.

Lack of Traceability and Documentation

Reputable suppliers provide full traceability, including material test reports, CE marking, and compliance documentation. Sourcing from vendors who cannot supply these increases the risk of receiving counterfeit or non-compliant products, which may fail inspection or contribute to workplace incidents.

Intellectual Property Infringement

Some manufacturers replicate patented designs or branded components without authorization. Purchasing such infringing products—even unknowingly—can expose your company to legal action, customs seizures, or supply chain disruption. Always confirm the supplier’s right to produce the design and avoid “look-alike” products.

Inadequate Design Validation

Not all scaffolding platforms are engineered for the intended application. Suppliers may offer generic platforms unsuitable for specific load requirements, environmental conditions, or modular compatibility. Ensure designs are validated by a qualified engineer and match your project specifications.

Hidden Costs from Rework or Replacement

Low initial pricing can be misleading if platforms require modification, fail quality checks, or don’t integrate with existing systems. These hidden costs—combined with downtime—often outweigh savings. Insist on samples and performance testing before bulk orders.

Weak Contractual IP Protections

When custom designs are involved, failure to include clear IP clauses in contracts can result in loss of ownership or unauthorized replication by the supplier. Use well-drafted agreements that assign IP rights and include confidentiality and non-disclosure terms.

Avoiding these pitfalls requires due diligence, supplier vetting, and proactive risk management throughout the sourcing process.

Logistics & Compliance Guide for Scaffolding Platforms

This guide outlines key logistics considerations and compliance requirements for the safe and legal transportation, handling, and use of scaffolding platforms. Adherence ensures worker safety, regulatory compliance, and operational efficiency.

Regulatory Standards and Compliance

Scaffolding platforms must comply with national and international safety standards. In the U.S., OSHA (Occupational Safety and Health Administration) standards under 29 CFR 1926 Subpart L govern scaffolding use in construction. Key requirements include:

- Platforms must support their own weight plus at least four times the intended load (OSHA 1926.451(a)(1)).

- Guardrails or personal fall arrest systems are required for platforms over 10 feet in height.

- All components must be inspected before each shift for damage, corrosion, or deformation.

- Scaffolds must be erected, dismantled, and modified by trained and competent personnel.

Additionally, manufacturers must comply with standards such as ANSI/ASSE A10.8 and EN 12811 (Europe) for design and performance.

Transportation and Handling Logistics

Proper logistics planning is essential for the safe transport and handling of scaffolding platforms:

- Load Securing: Platforms and components must be secured on transport vehicles using straps, chains, or load locks to prevent shifting during transit. Follow FMCSA (Federal Motor Carrier Safety Administration) guidelines for cargo securement.

- Stacking and Packaging: Store and stack platforms evenly to avoid warping or damage. Use protective padding between layers if applicable.

- Weight Distribution: Ensure even weight distribution on trailers or trucks to maintain vehicle stability.

- Handling Equipment: Use forklifts, cranes, or pallet jacks with appropriate load capacity. Never drag or drop components to prevent structural damage.

Site Delivery and Receiving Procedures

Effective site logistics begin with proper receiving and storage:

- Delivery Verification: Inspect delivered platforms against packing slips and purchase orders. Check for visible damage or missing components.

- Designated Storage Area: Store scaffolding platforms off the ground, on level surfaces, and under cover when possible to prevent corrosion and water damage.

- Access and Safety: Keep storage areas clear of obstructions and ensure easy access for assembly crews while maintaining safe walkways.

Assembly and Installation Compliance

Only trained personnel should assemble scaffolding platforms following manufacturer instructions and OSHA guidelines:

- Foundation Requirements: Install on stable, level ground. Use base plates or mud sills on soft or uneven surfaces.

- Component Compatibility: Never mix components from different manufacturers unless certified as compatible.

- Tie-Ins and Bracing: Install tie-ins and cross-bracing at specified intervals to prevent sway or collapse.

- Platform Integrity: Ensure platforms are fully planked with no gaps over 1 inch and secured to prevent movement.

Inspection and Maintenance Protocols

Regular inspection and maintenance are critical for ongoing compliance:

- Pre-Use Inspection: Conduct daily checks by a competent person before each work shift.

- Periodic Inspection: Perform formal inspections every 7 days when in continuous use.

- Post-Incident Inspection: Re-inspect after any event that may affect structural integrity (e.g., impact, storm).

- Maintenance Records: Keep logs of inspections, repairs, and component replacements.

Training and Documentation

All personnel involved in scaffolding operations must receive proper training:

- Competent Person Training: Required for individuals responsible for inspection and oversight (OSHA 1926.454).

- User Training: Workers must be trained on fall hazards, proper use, load limits, and emergency procedures.

- Documentation: Maintain records of training, inspections, and equipment certifications.

Disposal and Recycling

At end-of-life, dispose of scaffolding platforms responsibly:

- Assess for Reuse/Recycling: Metal components (steel, aluminum) are often recyclable.

- Hazardous Material Handling: Remove any contaminated materials (e.g., paint with lead) per EPA regulations.

- Certified Disposal: Use licensed waste management providers for proper disposal.

Adhering to this logistics and compliance guide ensures the safe, legal, and efficient use of scaffolding platforms across all project phases.

Conclusion on Sourcing Scaffolding Platforms

Sourcing scaffolding platforms requires a strategic approach that balances safety, quality, cost-efficiency, and compliance with industry standards. After evaluating suppliers, materials, and product specifications, it is evident that selecting reliable manufacturers or vendors is critical to ensuring structural integrity and worker safety on construction sites. Prioritizing suppliers with proven certifications (such as OSHA, EN, or AS/NZS compliance), robust testing procedures, and a track record of timely delivery minimizes project risks and delays.

Additionally, considering factors such as modularity, load capacity, ease of assembly, and durability enhances long-term usability and return on investment. Whether sourcing locally or internationally, conducting thorough due diligence, requesting product samples, and reviewing customer feedback can significantly improve decision-making.

Ultimately, a well-informed sourcing strategy not only supports operational efficiency and regulatory compliance but also contributes to a safer working environment. Establishing strong partnerships with reputable suppliers ensures consistent access to high-quality scaffolding platforms, supporting project success across multiple job sites and timelines.