The global construction tools market has experienced steady growth over the past decade, driven by rising infrastructure development and increasing investments in commercial and residential construction. According to a report by Mordor Intelligence, the global hand tools market—encompassing specialized tools such as scaffolders wrenches—was valued at USD 11.47 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2029. This growth is further amplified by stringent safety regulations and the growing adoption of durable, ergonomically designed tools on construction sites. Scaffolders wrenches, in particular, play a critical role in scaffolding assembly due to their multi-functional design, combining a wrench, hammer, and pipe cutter in one robust tool. With increasing demand across Asia-Pacific, North America, and Europe, the manufacturing landscape has evolved to include both long-standing industry leaders and innovative regional players. Based on market presence, product quality, distribution reach, and user reviews, the following eight manufacturers stand out as the top producers of scaffolders wrenches in 2024.

Top 8 Scaffolders Wrench Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bil-Jax® Scaffolding

Domain Est. 1996

Website: biljax.com

Key Highlights: Biljax scaffolding from a top U.S. manufacturer. Durable scaffold systems, staging, and supplies for all your project needs….

#2 Scaffold Ratchet – No Pry Bar

Domain Est. 2020

Website: williams-industrial.com

Key Highlights: 1/2″ Drive with pinned 7/8″ 6-point socket, 2-1/4″ length. 36 tooth gear with 10 degree of engagement allows engagement in tight working areas….

#3 Scaffold Ratchets

Domain Est. 1997

Website: wrighttool.com

Key Highlights: Wright ratchets are well balanced providing substantial strength with minimal arc movement. Forged and Machined for Best Fit and Unyielding Strength….

#4 SALES OF TOOLS AND LEATHER HOLDERS:

Domain Est. 2005

Website: scaffoldworker.com

Key Highlights: … SCAFFOLD WRENCHS; LEATHER HOLDERS FOR TAPES, HAMMERS, PLIERS, LEVELS, KNIPEX. PLUS 2″ & 3″ TOOL BELTS, KLEIN BAG, SNAPS … THE USA —MOST ORDERS SHIP IN 1 WEEK – ……

#5 Scaffold Wrenches

Domain Est. 2012

Website: edmontonscaffolding.com

Key Highlights: Scaffold Wrenches. C$29.99Price. Style. Select Black Red Blue Green Yellow Silver Short Bent Silver. Quantity. Add to Cart 19/22….

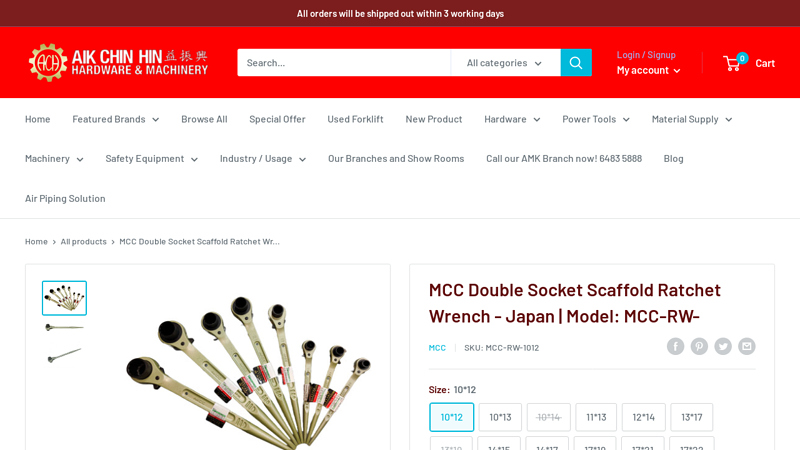

#6 MCC Double Socket Scaffold Ratchet Wrench

Domain Est. 2017

Website: aikchinhin.sg

Key Highlights: MCC Double Socket Scaffold Ratchet Wrench – Japan | Model: MCC-RW- Features Made in JAPAN Handle drop forged from special alloy steel with dodecagon (twelve ……

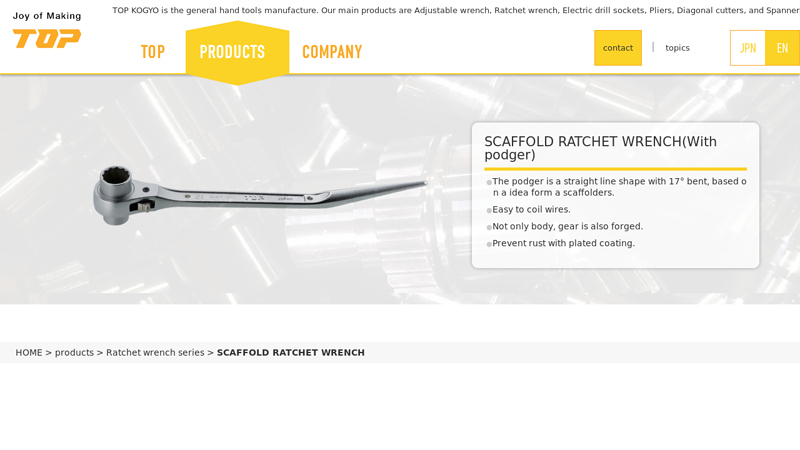

#7 SCAFFOLD RATCHET WRENCH

Website: toptools.co.jp

Key Highlights: SCAFFOLD RATCHET WRENCH(With podger). The podger is a straight line shape with 17° bent, based on a idea form a scaffolders. Easy to coil wires….

#8 Hand tools

Website: layher.co.nz

Key Highlights: Layher offers a range of hand tools that have been specially designed and engineered for use with scaffolding systems….

Expert Sourcing Insights for Scaffolders Wrench

H2: 2026 Market Trends for Scaffolders Wrench

The global market for scaffolders wrenches—specialized tools used in construction and maintenance for assembling and disassembling scaffolding systems—is expected to undergo notable shifts by 2026, driven by evolving construction practices, safety regulations, technological advancements, and regional economic developments. Here’s an analysis of key trends shaping the scaffolders wrench market in 2026:

-

Increased Demand from Urbanization and Infrastructure Growth

Rapid urbanization, particularly in Asia-Pacific (China, India, and Southeast Asia) and Africa, is fueling large-scale infrastructure projects. Governments are investing heavily in transportation, residential, and commercial developments, directly increasing the need for safe and efficient scaffolding systems—and by extension, high-quality scaffolders wrenches. This sustained construction activity is expected to boost wrench demand through 2026. -

Stringent Safety Regulations Driving Tool Standardization

Regulatory bodies such as OSHA (U.S.), HSE (UK), and EU-OSHA are enforcing stricter safety standards for working at heights. These regulations emphasize the use of durable, reliable tools that reduce the risk of accidents. Scaffolders wrenches made from high-grade materials (e.g., drop-forged steel) and compliant with ISO or ANSI standards are becoming preferred, pushing manufacturers to focus on certified, ergonomic, and anti-slip designs. -

Growth in Rental and Modular Scaffolding Systems

The rise of modular and prefabricated scaffolding systems—valued for faster setup and reusability—is influencing wrench design. These systems often require specialized wrenches for quick coupling and disassembly. As rental markets for scaffolding expand, especially in Europe and North America, demand for standardized, durable wrenches compatible with multiple systems is increasing. -

Technological Integration and Smart Tools

While still in early stages, the construction industry’s digital transformation is beginning to affect hand tools. By 2026, some manufacturers are expected to introduce “smart” scaffolders wrenches with embedded sensors to monitor torque, usage frequency, or maintenance needs. Though not yet mainstream, such innovations may gain traction in high-safety environments like nuclear plants or offshore construction. -

Sustainability and Material Innovation

Environmental concerns are prompting manufacturers to explore sustainable production methods and recyclable materials. Lightweight yet durable alloys and corrosion-resistant coatings are being adopted to extend tool lifespan and reduce environmental impact. Additionally, companies are emphasizing sustainable packaging and energy-efficient manufacturing to meet ESG (Environmental, Social, and Governance) goals. -

Regional Market Dynamics

- Asia-Pacific: Dominates market growth due to massive construction booms in India and Southeast Asia. Local manufacturers are gaining ground, offering cost-effective alternatives to Western brands.

- North America & Europe: Mature markets with steady demand, driven by infrastructure renewal, renovation projects, and strict safety compliance. Premium and ergonomic wrenches are favored.

-

Middle East & Africa: Growth fueled by megaprojects (e.g., NEOM in Saudi Arabia, urban developments in UAE), creating sustained demand for reliable tools.

-

E-Commerce and Distribution Channels

Online B2B platforms and construction equipment marketplaces are becoming key sales channels. By 2026, digital procurement is expected to account for a growing share of wrench sales, enabling faster delivery, product comparisons, and access to global suppliers. -

Competitive Landscape and Brand Differentiation

Leading players such as Gedore, Bahco, and Stanley Hand Tools are investing in R&D to differentiate their products through ergonomics, durability, and customization. Niche brands are emerging with specialized wrenches for unique scaffolding systems (e.g., Ringlock, Cuplock), fostering product diversification.

Conclusion

By 2026, the scaffolders wrench market will be shaped by a confluence of regulatory pressure, infrastructural expansion, and technological adaptation. While the core function of the tool remains unchanged, market success will increasingly depend on compliance, durability, and alignment with modern construction workflows. Companies that innovate in design, sustainability, and distribution are poised to capture greater market share in this essential segment of the construction tools industry.

Common Pitfalls When Sourcing Scaffolders Wrenches (Quality and Intellectual Property)

Sourcing scaffolders wrenches—specialized tools used in scaffolding assembly and disassembly—can be deceptively complex. While they may appear simple, choosing the wrong supplier or product can lead to serious safety risks, compliance issues, and legal complications. Below are common pitfalls related to quality and intellectual property (IP) that buyers should be aware of.

Poor Material Quality and Workmanship

Many low-cost scaffolders wrenches are manufactured using substandard steel or improper heat treatment processes. This results in tools that are prone to bending, cracking, or breaking under stress—posing significant safety hazards on job sites. Look for wrenches made from forged alloy steel with proper tempering and surface finishes. Avoid suppliers who cannot provide material certifications or testing reports.

Lack of Compliance with Safety Standards

Reputable scaffolders wrenches should comply with regional safety and engineering standards such as EN 1755 (Europe) or ANSI/ISEA standards (USA). Sourcing non-compliant tools can expose contractors and suppliers to liability in the event of accidents. Always verify that the product meets required certifications and carries appropriate markings (e.g., CE, UKCA).

Inconsistent Dimensional Accuracy

Even slight variations in jaw size or handle length can render a wrench ineffective or unsafe for specific scaffold couplers. Inconsistent tool dimensions from batch to batch suggest poor quality control. Request sample testing and insist on documented quality assurance processes from manufacturers.

Misrepresentation of Brand or Origin

Some suppliers falsely claim that their wrenches are made by well-known brands or in specific countries (e.g., “German-engineered” or “UK-made”) to command higher prices. This misrepresentation undermines trust and may indicate broader ethical or quality concerns. Conduct due diligence on supplier claims and, if possible, visit manufacturing facilities.

Intellectual Property (IP) Infringement

Many established brands hold registered designs, trademarks, or patents on their wrench designs (e.g., unique jaw configurations or ergonomic handles). Sourcing generic copies that closely mimic these designs can lead to IP infringement, resulting in shipment seizures, legal action, or reputational damage. Always ensure that the design is either licensed or in the public domain.

No Warranty or After-Sales Support

Low-quality suppliers often offer no warranty or traceability. If a wrench fails, there may be no recourse for replacement or investigation. Reputable suppliers provide clear warranty terms and support channels, which reflect confidence in their product quality and manufacturing integrity.

Failure to Verify Supply Chain Transparency

Without visibility into the full supply chain, buyers risk sourcing wrenches produced under unethical labor conditions or with untraceable materials. This can lead to reputational risks and non-compliance with corporate social responsibility (CSR) policies. Request documentation on factory audits and chain-of-custody when possible.

By recognizing these pitfalls, procurement professionals can make safer, legally compliant, and more reliable sourcing decisions when acquiring scaffolders wrenches.

Logistics & Compliance Guide for Scaffolders Wrench

This guide outlines the key logistics and compliance considerations for the safe and legal handling, transportation, storage, and use of a scaffolders wrench—an essential hand tool used in scaffolding construction and maintenance.

Tool Specifications and Identification

Ensure each scaffolders wrench meets recognized industry standards (e.g., ANSI, OSHA, or EN for international use). Verify that the wrench is clearly marked with:

– Manufacturer name or logo

– Material grade and heat treatment certification

– Size and type (e.g., double-ended adjustable, fixed spanner)

– Compliance with safety standards (e.g., ASME B107.400)

Maintain an inventory log with serial numbers (if applicable) and inspection dates for traceability.

Transportation Requirements

When transporting scaffolders wrenches:

– Store wrenches in durable tool bags, roll-up organizers, or lockable containers to prevent damage and loss.

– Secure tools during transit to avoid movement that could cause injury or damage.

– Comply with transportation regulations (e.g., DOT in the U.S.) when shipping in bulk; declare tools appropriately if shipped via courier or freight.

– Avoid exposure to moisture, extreme temperatures, or corrosive environments during transit.

Storage and Handling

Store scaffolders wrenches in a clean, dry, and secure location:

– Use labeled tool racks or storage cabinets to prevent misplacement.

– Keep away from chemicals, solvents, or moisture to prevent corrosion.

– Do not leave tools on scaffold platforms overnight unless secured and protected from weather.

– Implement a “clean as you go” policy to maintain tool integrity and worksite safety.

Safety and Compliance Standards

Adhere to relevant safety and compliance regulations:

– OSHA 29 CFR 1926 Subpart L (Scaffolds): Requires tools to be secured when used at height to prevent falling object hazards.

– Personal Protective Equipment (PPE): Wear cut-resistant gloves when handling wrenches, especially after prolonged use.

– Tool Tethering: Use lanyards or tool holsters when working at height to prevent dropped objects—complying with ANSI/ISEA 121-2018 standards.

– Regular inspection: Check for cracks, deformation, or excessive wear before each use.

Inspection and Maintenance

Implement a routine inspection and maintenance program:

– Conduct pre-use visual checks for damage or wear.

– Perform documented monthly inspections by a competent person.

– Remove damaged wrenches from service immediately and tag as “Do Not Use.”

– Clean wrenches regularly with a dry cloth; apply light oil to prevent rust.

– Do not modify wrenches (e.g., grinding, heating, or extending handles), as this compromises structural integrity and voids compliance.

Training and Documentation

Ensure all scaffold workers are trained in:

– Proper use of scaffolders wrenches for tightening couplers and fittings.

– Safety protocols, including tool tethering and drop prevention.

– Inspection procedures and reporting damaged tools.

Maintain training records and include tool safety in site-specific safety plans (SSSP) or job hazard analyses (JHA).

International and Environmental Considerations

For cross-border projects:

– Verify that wrenches meet local standards (e.g., CE marking in the EU, UKCA in the UK).

– Account for customs documentation when shipping tools internationally.

– Follow environmental guidelines for disposal of damaged tools—recycle metal components where possible.

Incident Reporting and Audits

Establish procedures for:

– Reporting lost, damaged, or malfunctioning wrenches.

– Investigating tool-related incidents (e.g., dropped tools, injuries).

– Conducting periodic audits of tool inventories, storage conditions, and compliance with safety protocols.

By following this guide, scaffolding teams can ensure efficient logistics, regulatory compliance, and a safer working environment.

Conclusion on Sourcing Scaffolders’ Wrenches

In conclusion, sourcing scaffolders’ wrenches requires a balanced consideration of quality, durability, cost-effectiveness, and supplier reliability. These specialized tools are critical for the safety and efficiency of scaffolding operations, making it essential to procure wrenches made from high-grade materials such as forged steel, with enhanced features like dual functionality (wrench and hammer), anti-slip grips, and compliance with safety standards.

After evaluating potential suppliers, it is recommended to establish partnerships with reputable manufacturers or distributors known for consistent product quality and timely delivery. Factors such as bulk pricing, warranty options, and customization availability should also be taken into account to meet specific project needs. Additionally, prioritizing suppliers with certifications (e.g., ISO, ANSI, or OSHA compliance) ensures adherence to industry safety and reliability standards.

Ultimately, a strategic sourcing approach—focused on long-term value rather than upfront cost—will enhance worksite safety, reduce tool replacement frequency, and support overall operational efficiency in scaffolding projects.