The global demand for precision-engineered industrial components continues to rise, driven by advancements in automation, automotive manufacturing, and heavy machinery. Among these components, Sapi cut plates—specialized steel plates used in high-stress applications such as construction equipment, mining machinery, and hydraulic systems—have seen sustained growth in demand due to their durability and performance under extreme conditions. According to a report by Grand View Research, the global construction machinery market size was valued at USD 193.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030, directly influencing the need for high-quality Sapi cut plates. Additionally, Mordor Intelligence forecasts the industrial machinery market to grow at a CAGR of over 4.6% during the same period, further underpinning the expanding supply chain for specialized metal components. As demand intensifies, manufacturers are enhancing production capabilities, investing in laser and plasma cutting technologies, and focusing on material traceability and compliance with international standards. This increasing market momentum has led to the emergence of key players excelling in precision, scalability, and innovation in Sapi cut plate manufacturing. Below are the top 9 manufacturers leading the industry through technological advancement and robust global supply networks.

Top 9 Sapi Cut Plates Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Body Armor Plates

Domain Est. 2000

Website: hesco.com

Key Highlights: SAPI Cuts with slightly less severe angles are a military cut now available for law enforcement and other use. Some users prefer Full Cut with no shoulder cut- ……

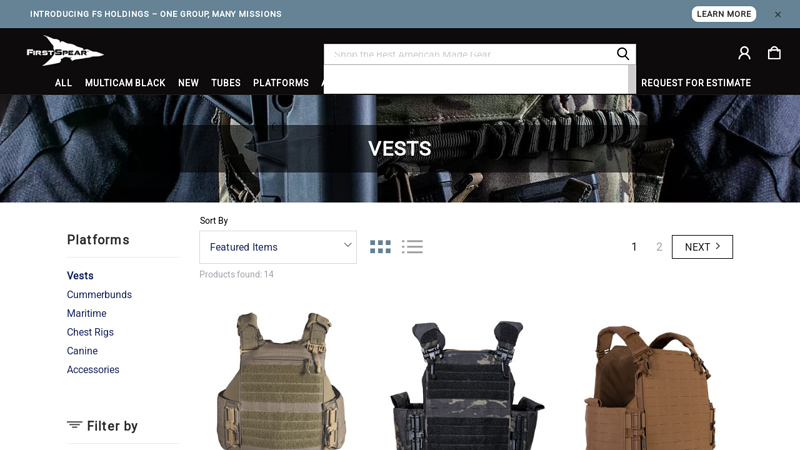

#2 Law Enforcement Slick Plate Carrier Vests

Domain Est. 2010

Website: first-spear.com

Key Highlights: First Spear American made plate carriers and law enforcement load carriage vests made to military specifications with the highest quality standards….

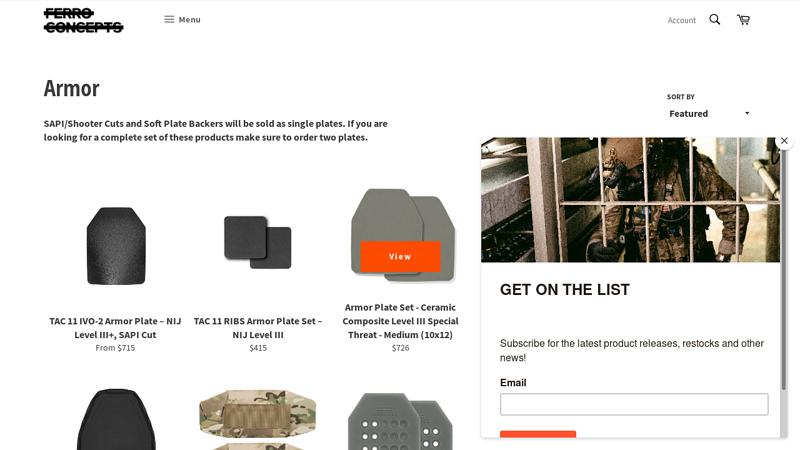

#3 Armor

Domain Est. 2011

Website: ferroconcepts.com

Key Highlights: SAPI/Shooter Cuts and Soft Plate Backers will be sold as single plates. If you are looking for a complete set of these products make sure to order two ……

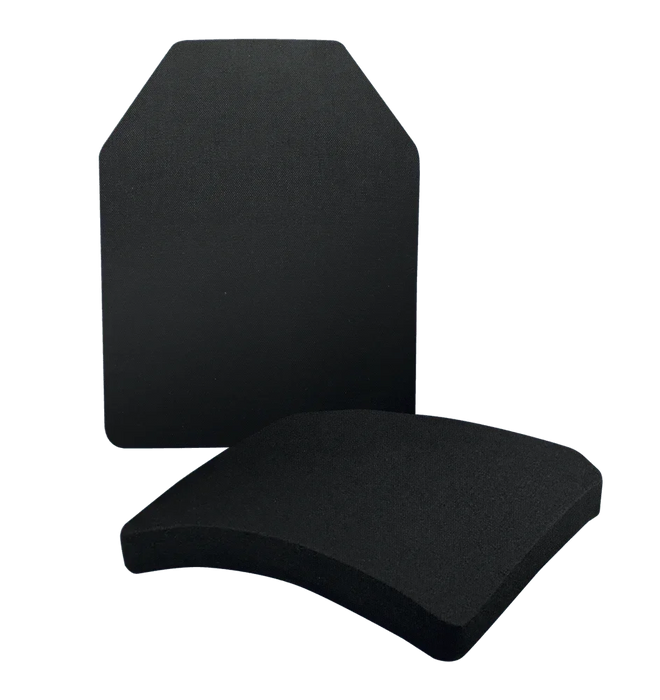

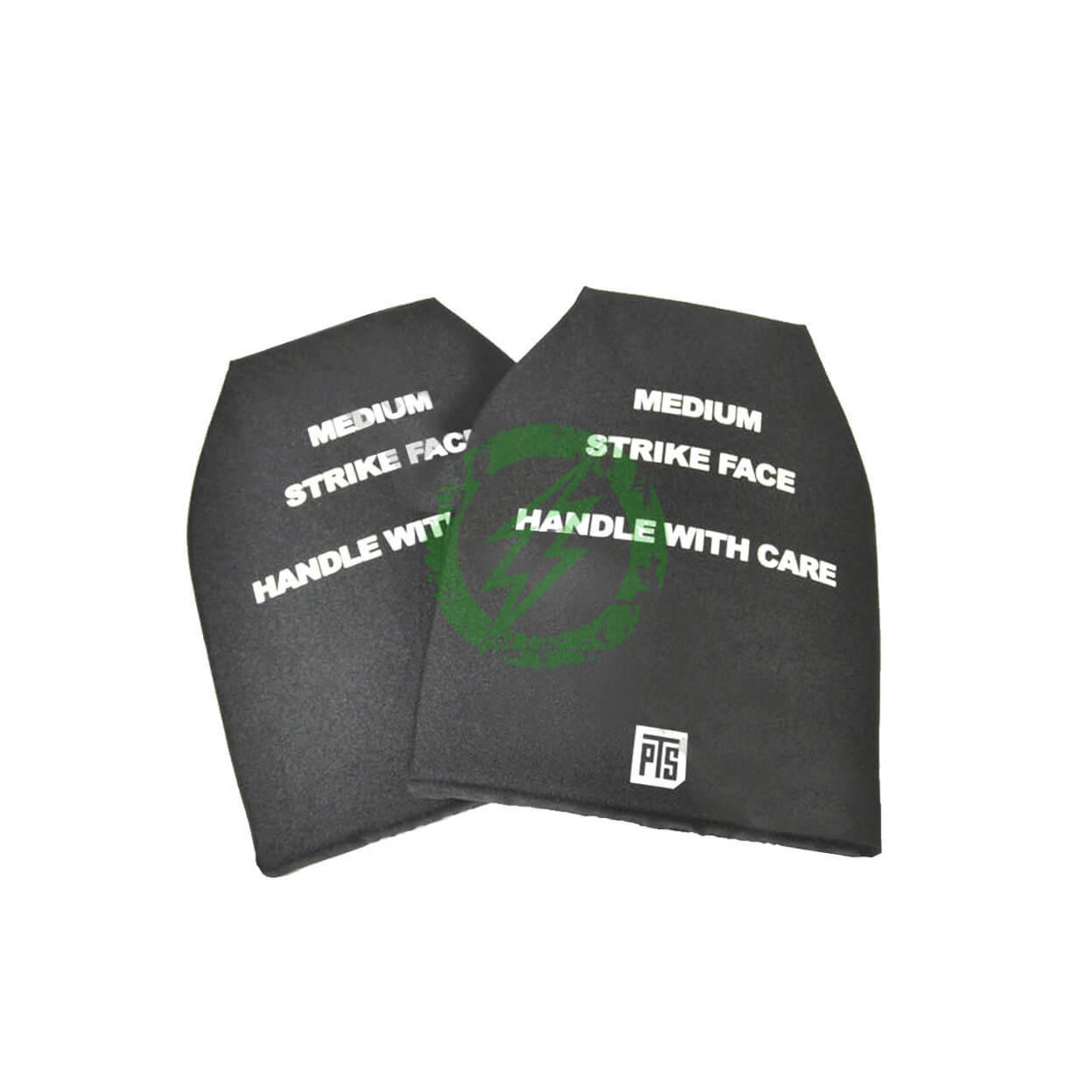

#4 Shop Ballistic SAPI Plates

Domain Est. 2015

Website: hoplitearmor.com

Key Highlights: Our SAPI (Small Arms Protective Inserts) plates come in a variety of levels, sizes and colors. Only hard plate armor can prevent penetration from rifle rounds….

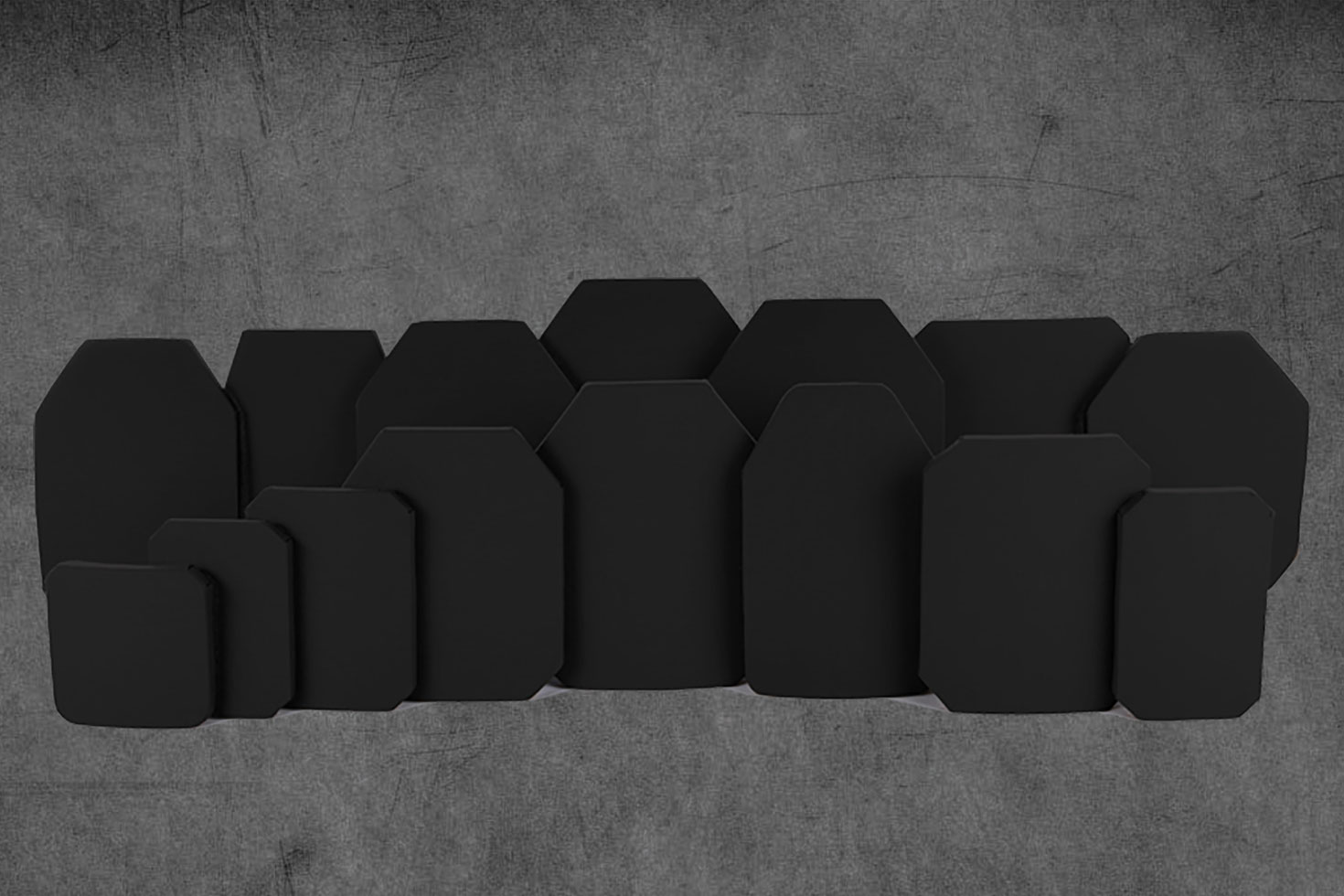

#5 Rifle Armor Plate Cuts and how they make a difference

Domain Est. 2017

Website: highcomarmor.com

Key Highlights: These plates come in different types of cuts: Full Cut, Shooters Cut, Swimmers Cut and Small Arms Protective Insert (SAPI)….

#6 SAPI Plates

Domain Est. 2019

Website: armorliteusa.com

Key Highlights: Our SAPI (Small Arms Protective Inserts) plates come in a variety of levels, sizes and colors. Only hard plate armor can prevent penetration from rifle rounds….

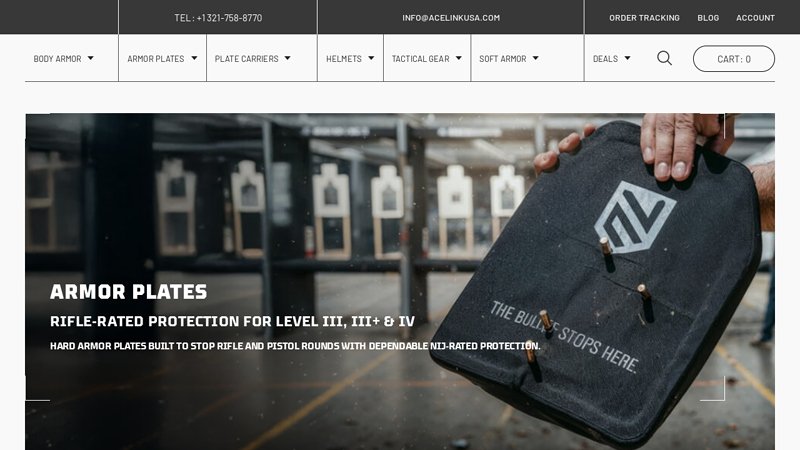

#7 Armor Plates

Domain Est. 2020

Website: acelinkarmor.com

Key Highlights: Typically, armor plates follow SAPI specifications and come in four sizes, small, medium, large, and extra-large. For most of the population, whether male or ……

#8 Shop LTC Plates

Domain Est. 2020

Website: apexarmorsolutions.com

Key Highlights: We have a wide selection of high end LTC plates, including elusive military and socom plates such as the 28534 ESAPI, 27919 SAPI or 28791 Less Than Overt….

#9 Body Armor GEN 2 Threat Level

Domain Est. 2020

Website: primearmor.us

Key Highlights: 11″x14″ – 5.4 lbs. In SAPI/ESAPI cut. This body armor has been tested according to NIJ 0101.06 standard in official NIJ laboratory. Plate has positive buoyancy, ……

Expert Sourcing Insights for Sapi Cut Plates

H2: Projected Market Trends for Sapi Cut Plates in 2026

While “Sapi Cut Plates” isn’t a widely recognized standard industry term, the most plausible interpretation points to high-quality, premium beef cuts derived from Sapi (cattle), specifically focusing on high-end or specialized cuts like those from Wagyu or other premium breeds. Analyzing the 2026 market trends for such premium beef plates requires examining broader forces shaping the global meat, foodservice, and luxury consumer goods sectors.

Here’s a breakdown of key projected trends for 2026:

1. Sustained Demand for Premiumization & Experience-Driven Consumption

- H2: Consumers, particularly in affluent markets (North America, Western Europe, parts of Asia), will increasingly prioritize quality, provenance, and unique dining experiences over volume. This fuels demand for premium cuts like Sapi plates (e.g., high-grade Wagyu ribeye, tomahawk, or specialized dry-aged steaks).

- Drivers: Rising disposable incomes among affluent segments, the growth of experiential dining (fine dining, high-end steakhouses, luxury hotels), and social media influence (showcasing premium food experiences).

- 2026 Impact: Continued strong demand for visually impressive, high-marbling (high BMS) Sapi plates. Expect focus on storytelling (origin, breed, farming practices) as a key differentiator.

2. Supply Chain Challenges & Price Volatility

- H2: The supply of ultra-premium Sapi cuts (especially authentic Wagyu) remains constrained by biological factors (long breeding/feeding times, limited global supply of purebred genetics) and geopolitical factors (trade policies, disease outbreaks like BSE concerns).

- Drivers: Limited global Wagyu herd sizes, high production costs (feed, labor, land), potential for trade disruptions, and climate change impacts on feed grain availability and pasture quality.

- 2026 Impact: Prices for genuine premium Sapi plates are expected to remain high and potentially increase further. This will intensify the battle for authentic supply and make “Wagyu” or “Japanese-style” labeling a critical (and potentially contentious) point. Premiumization will coexist with price sensitivity in broader markets.

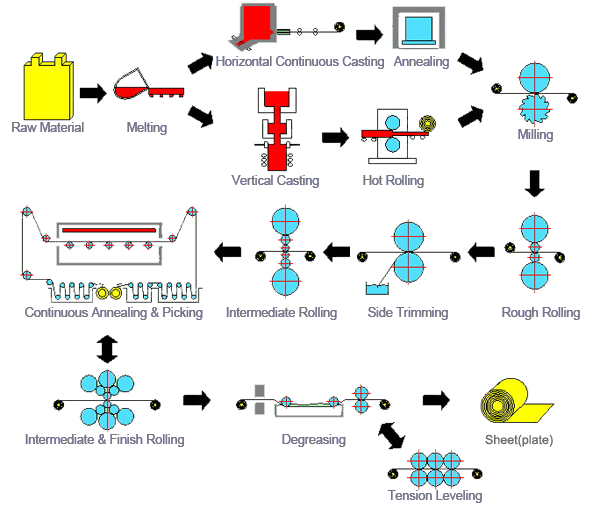

3. Technological Advancements in Production & Traceability

- H2: Technology will play an increasingly crucial role in both production efficiency and consumer trust for premium products.

- Drivers: Adoption of precision agriculture, DNA tracking for breed authentication, blockchain for transparent supply chain traceability, and advanced meat grading technologies (beyond visual assessment).

- 2026 Impact: Enhanced ability to verify the authenticity and origin of Sapi plates, crucial for combating fraud and justifying premium prices. Consumers will demand and expect verifiable proof of claims (e.g., “100% Fullblood Wagyu,” “Grass-Fed,” “Dry-Aged for X days”). Farms adopting these technologies gain a competitive edge.

4. Growing Focus on Sustainability & Ethical Sourcing

- H2: Environmental and ethical concerns will significantly influence purchasing decisions, even for premium products. “Sustainable luxury” is becoming a necessity.

- Drivers: Consumer awareness of beef’s environmental footprint (GHG emissions, land/water use), animal welfare standards, and regenerative agriculture practices.

- 2026 Impact: Premium Sapi plate producers and sellers will need to demonstrate strong ESG (Environmental, Social, Governance) credentials. Demand will rise for products certified by reputable bodies (e.g., verified regenerative, high animal welfare standards, carbon-neutral initiatives). Greenwashing will be heavily scrutinized.

5. Diversification of Premium Sources & “Wagyu-Style” Competition

- H2: While authentic Japanese Wagyu remains the pinnacle, the market for high-marbling beef will expand beyond Japan.

- Drivers: Successful breeding programs in Australia, USA, Canada, and Europe producing high-quality Wagyu or Wagyu-cross beef. Development of alternative premium cuts and finishing techniques.

- 2026 Impact: Increased competition in the “premium plate” segment. Consumers will have more choices beyond Japanese imports, potentially at different price points. Success will depend on consistent quality, effective branding, and clear communication of the product’s unique value proposition (e.g., “Australian Fullblood,” “American Akaushi,” “Dry-Aged Angus”).

6. E-commerce & Direct-to-Consumer (DTC) Growth

- H2: Online channels will become even more critical for reaching consumers seeking premium home dining experiences.

- Drivers: Convenience, wider product selection, subscription models for premium meats, and the normalization of high-value online food purchases.

- 2026 Impact: Premium Sapi plate suppliers will invest heavily in sophisticated e-commerce platforms with exceptional packaging (cryovac, dry ice), reliable cold chain logistics, and engaging content (recipes, provenance stories). DTC allows for higher margins and direct customer relationships.

Conclusion for 2026:

The market for premium Sapi Cut Plates in 2026 will be characterized by resilient demand driven by experiential luxury consumption, but operating within a landscape of supply constraints, price sensitivity for some segments, and heightened demands for authenticity, sustainability, and transparency. Success will belong to producers and distributors who can:

- Guarantee Authenticity & Provenance: Utilizing technology for traceability.

- Demonstrate Sustainability & Ethics: Integrating verifiable ESG practices.

- Leverage Technology: For efficient production, grading, and direct consumer engagement.

- Master DTC & E-commerce: Delivering premium experiences seamlessly to the home.

- Navigate Geopolitics & Supply Chain Risks: Ensuring reliable access to high-quality genetics and feed.

While challenges exist, the fundamental appeal of an exceptional, high-quality beef plate ensures a strong, albeit competitive, market for genuine premium Sapi cuts in 2026.

Common Pitfalls When Sourcing Sapi Cut Plates (Quality & IP)

Sourcing Sapi Cut Plates—often referring to intricately carved or laser-cut plates made from natural stone like marble, travertine, or onyx, inspired by traditional Javanese Sapi (cow) motifs—can be challenging. Buyers frequently encounter issues related to both quality and intellectual property (IP). Being aware of these pitfalls is crucial for ensuring value, authenticity, and legal compliance.

Quality-Related Pitfalls

Inconsistent Material Quality

Suppliers may use lower-grade stone with visible flaws such as cracks, pits, or inconsistent coloration. Sourcing from regions with lax quality control can result in plates that are structurally weak or aesthetically uneven, undermining durability and design integrity.

Poor Craftsmanship and Finishing

Hand-carved or machine-cut details may lack precision, especially if labor costs are minimized. Common issues include uneven edges, chipped surfaces, or模糊 (blurred) engravings. Inadequate polishing can leave surfaces rough or discolored, affecting both appearance and usability.

Inaccurate Sizing and Dimensional Variability

Mass-produced or poorly supervised batches often exhibit dimensional inconsistencies. Plates may not fit intended installations or display unevenly when used in tiling or decorative arrangements.

Inadequate Sealing and Treatment

Natural stone is porous and requires proper sealing to resist stains and moisture. Many suppliers skip or skimp on sealing processes, leading to premature degradation—especially problematic in humid or high-traffic environments.

Misrepresentation of Stone Type

Some suppliers falsely label lower-cost stones (e.g., resin composites or low-grade marble) as premium materials like Crema Marfil or Emperador. This misrepresentation affects both aesthetic authenticity and long-term performance.

Intellectual Property and Ethical Pitfalls

Unauthorized Use of Traditional Designs

Sapi motifs are culturally significant in Javanese art and architecture. Sourcing from manufacturers that reproduce these designs without community engagement or fair compensation can constitute cultural appropriation and violate ethical sourcing standards.

Lack of Design Originality and IP Infringement

Many suppliers copy patented or trademarked patterns from established designers or brands. Buyers risk legal liability if they import or sell plates that infringe on registered intellectual property, particularly in markets with strict IP enforcement (e.g., EU, US).

No Certifications or Provenance Documentation

Reputable sourcing should include proof of ethical labor practices and legal material origin. Absence of certifications (e.g., from artisan cooperatives or sustainability programs) may indicate exploitative labor or environmentally harmful extraction methods.

Counterfeit or Fake Artisan Claims

Some vendors falsely market mass-produced items as “handcrafted by local artisans.” This not only misleads consumers but also undermines genuine artisan communities who depend on authentic recognition and fair trade.

Conclusion

To avoid these pitfalls, buyers should conduct thorough due diligence: request material samples, verify supplier credentials, demand design usage rights, and partner with ethical, transparent manufacturers. Ensuring both quality and IP compliance protects brand reputation, supports cultural integrity, and delivers lasting value.

Logistics & Compliance Guide for Sapi Cut Plates

Overview

This guide outlines the essential logistics and compliance requirements for the transportation, handling, storage, and regulatory adherence related to Sapi Cut Plates. These plates are precision-engineered metal components typically used in industrial, automotive, or construction applications. Ensuring proper logistics and compliance procedures is critical for product integrity, safety, and adherence to international standards.

Packaging and Handling

Sapi Cut Plates must be packaged to prevent damage during transit. Use moisture-resistant wrapping, edge protectors, and non-slip pallets. Secure stacking and shrink-wrapping are required to prevent shifting. Handling should be conducted using appropriate lifting equipment (e.g., forklifts with padded forks) to avoid surface scratches or deformation. Always follow handling guidelines provided in the product datasheet.

Transportation Requirements

Transport Sapi Cut Plates via covered, dry freight vehicles to protect against weather and contamination. Ensure cargo is evenly distributed and properly secured using straps or load locks. For international shipments, comply with IMDG (for sea), ADR (for road in Europe), or 49 CFR (for US domestic) regulations if applicable. Temperature-controlled transport is recommended for coated or sensitive-grade plates.

Storage Conditions

Store Sapi Cut Plates in a dry, well-ventilated indoor area away from direct sunlight and moisture. Maintain ambient temperatures between 10°C and 30°C (50°F–86°F). Plates should be stored flat on level, clean pallets, with adequate spacing for air circulation. Avoid prolonged storage on concrete floors; use protective underlay if necessary. Rotate stock using FIFO (First In, First Out) methodology.

Regulatory Compliance

Sapi Cut Plates must comply with relevant regional and international standards, including but not limited to:

– ISO 9001 (Quality Management)

– ISO 14001 (Environmental Management)

– REACH and RoHS (for material restrictions in the EU)

– ASTM or EN standards for material composition and mechanical properties

Ensure all documentation (Material Test Reports, Certificates of Compliance, SDS if applicable) accompanies each shipment. Export documentation (e.g., commercial invoice, packing list, certificate of origin) must be accurate and complete.

Customs and Import/Export

For cross-border shipments, classify Sapi Cut Plates under the correct HS Code (e.g., 7326.90 for other articles of steel). Verify import duties, tariffs, and licensing requirements for the destination country. Use licensed freight forwarders experienced in metal product logistics. Provide all required documentation to avoid customs delays.

Traceability and Documentation

Each batch of Sapi Cut Plates must be traceable through a unique batch/lot number. Maintain logs for production date, material source, inspection results, and shipping details. Digital tracking systems (e.g., ERP or WMS) are recommended to ensure full supply chain visibility and support audit readiness.

Safety and Environmental Considerations

Adhere to OSHA (US), COSHH (UK), or equivalent workplace safety regulations during handling. Provide personnel with appropriate PPE (gloves, safety glasses, steel-toe boots). Recycle packaging materials where possible and dispose of any metal swarf or waste in compliance with local environmental laws.

Conclusion

Proper logistics and compliance practices ensure the quality, safety, and regulatory acceptance of Sapi Cut Plates throughout the supply chain. Regular training, documentation audits, and process reviews are essential to maintain high standards and customer trust. Always consult the latest version of this guide and relevant regulatory updates before shipment or storage.

Conclusion for Sourcing SAPI Cut Plates

In conclusion, sourcing SAPI (Small Arms Protective Insert) cut plates requires a careful balance between protection, mobility, comfort, and compliance with recognized ballistic standards. The choice of cut—such as Swimmer, Shooter, or OG (Original Government) cut—significantly impacts both the wearer’s range of motion and level of coverage, making it essential to align the selection with the intended operational use, whether for military, law enforcement, or civilian defense applications.

Key factors in the sourcing process include verifying ballistic certification (e.g., NIJ standards), selecting appropriate materials (ceramic/composite vs. polyethylene), and ensuring compatibility with carrier systems. Additionally, considerations such as weight, durability, lead time, and supplier reliability play a crucial role in making a cost-effective and mission-ready procurement decision.

Ultimately, sourcing SAPI cut plates from reputable, certified manufacturers ensures optimal protection and performance. A well-informed selection process—based on thorough evaluation of operational needs, quality assurance, and end-user requirements—will enhance personal safety and operational effectiveness in high-risk environments.