The global PVC piping systems market, driven by increasing demand in residential, commercial, and infrastructure applications, is projected to grow at a CAGR of 5.8% from 2023 to 2030, according to Grand View Research. With sanitation and plumbing infrastructure expanding rapidly across developing regions and urban centers, the demand for reliable, corrosion-resistant components like sanitary tee PVC fittings has surged. These fittings—essential in DWV (Drain, Waste, and Vent) systems for their leak-proof junctions and ease of installation—represent a critical segment within the broader PVC plumbing market. As sustainability and cost-efficiency become key decision drivers, leading manufacturers are investing in high-performance, long-life PVC formulations compliant with international standards. This growing market momentum, supported by steady urbanization and government-backed water infrastructure initiatives, has intensified competition among producers. Based on production capacity, product compliance, innovation, and global reach, the following eight companies have emerged as the top sanitary tee PVC manufacturers shaping the industry’s future.

Top 8 Sanitary Tee Pvc Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Prince Pipes

Domain Est. 2000

Website: princepipes.com

Key Highlights: Prince Pipes specialises in manufacturing world class plumbing, sewerage & drainage piping systems for both residential and commercial applications….

#2 JM Eagle™

Domain Est. 2007

Website: jmeagle.com

Key Highlights: JM Eagle · Delivering life’s essentials through the most eco-friendly plastic pipe products on the market. · Express Service Trucks (ESTs) Deliver within 24 hours ……

#3 IPEX Inc.

Domain Est. 2009

Website: ipexna.com

Key Highlights: IPEX Inc. manufactures advanced PVC & CPVC piping systems for several applications for the Canadian market. Learn more….

#4 3″ PVC DWV Street Sanitary Tee

Domain Est. 1996

Website: ussupply.com

Key Highlights: In stockThe PVC DWV sanitary street tee features a spigot x hub x hub connection and a flowing sweep to aid in the evacuation of waste and used fluids….

#5 Advanced Drainage Systems

Domain Est. 2000

Website: adspipe.com

Key Highlights: Advanced Drainage Systems provides high-performing, durable pipe and innovative stormwater management solutions. Discover our industry-leading products ……

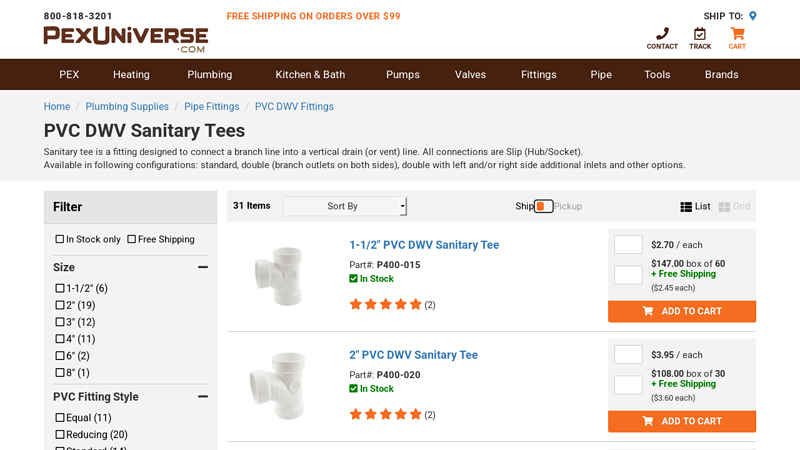

#6 PVC DWV Sanitary Tee Fittings

Domain Est. 2009

Website: pexuniverse.com

Key Highlights: Free delivery over $99 · 30-day returnsEqual and reducing, single and double sanitary tees in sizes from 1-1/2” to 8”. Slip (Hub/Socket) connections on all outlets. Made in the US…

#7 Sanitary Tees On IPEX

Domain Est. 2009

Website: bim.ipexna.com

Key Highlights: Browse Sanitary Tees in the IPEX catalog including Sanitary Tee H x H x H,Sanitary Tee Sp x H x H,Sanitary Tee Sp x Sp x H,Sanitary Tee Sp x Sp x Sp,Double ……

#8 Sanitary Tee ( All Hub ) Products

Domain Est. 2012

Website: lessoamerica.com

Key Highlights: LESSO Sanitary Tee ( All Hub ) Products | LESSO America products can be used in plumbing and irrigation. High-quality, affordable and easy to install….

Expert Sourcing Insights for Sanitary Tee Pvc

H2: Projected Market Trends for Sanitary Tee PVC in 2026

The global market for Sanitary Tee PVC fittings is expected to experience steady growth by 2026, driven by increasing demand in residential, commercial, and industrial construction sectors. This analysis highlights key trends shaping the Sanitary Tee PVC market in the coming years.

-

Rising Construction Activities in Emerging Economies

Rapid urbanization and infrastructure development in regions such as Asia-Pacific, Latin America, and Africa are projected to significantly boost the demand for PVC plumbing components, including Sanitary Tees. Countries like India, Indonesia, and Nigeria are witnessing a surge in affordable housing and sanitation projects, directly increasing the need for cost-effective and durable piping solutions. -

Growing Emphasis on Sustainable and Low-Maintenance Materials

PVC remains a preferred material due to its corrosion resistance, lightweight nature, and long service life. As sustainability becomes a priority, manufacturers are investing in eco-friendly PVC formulations and recycling technologies. By 2026, the market is likely to see increased adoption of recyclable and lead-free PVC fittings, aligning with global environmental regulations. -

Innovation in Product Design and Performance

Ongoing advancements in PVC compound engineering are enhancing the thermal and pressure resistance of sanitary tees. Innovations such as solvent-weld and push-fit designs are improving installation efficiency, reducing labor costs, and minimizing leak risks. These features are expected to drive preference for PVC over traditional materials like cast iron or metal alloys. -

Expansion of Sanitation Infrastructure

Government-led initiatives to improve public health and sanitation—such as India’s Swachh Bharat Mission and similar programs in Southeast Asia and Sub-Saharan Africa—are accelerating the deployment of modern drainage and sewer systems. Sanitary Tee PVC fittings, essential in DWV (Drain, Waste, and Vent) systems, are benefiting from this infrastructure push. -

Competitive Market Landscape and Regional Production Growth

The market is becoming increasingly competitive, with key players expanding production capacities and distribution networks in high-growth regions. Local manufacturing is reducing dependency on imports and lowering costs, further stimulating market penetration. Strategic partnerships and mergers among PVC piping companies are also expected to intensify by 2026. -

Impact of Regulatory Standards and Building Codes

Stricter building codes related to plumbing safety and hygiene are favoring the use of standardized PVC fittings. Compliance with international standards (e.g., ASTM, ISO, and DIN) is becoming a market differentiator, pushing manufacturers to improve quality control and certification processes.

In conclusion, the Sanitary Tee PVC market in 2026 will be shaped by infrastructural growth, technological innovation, and regulatory support. With favorable macroeconomic trends and rising awareness of efficient plumbing solutions, the demand for PVC sanitary fittings is poised for sustained expansion globally.

Common Pitfalls When Sourcing Sanitary Tee PVC (Quality and IP)

Sourcing Sanitary Tee PVC fittings—especially for critical plumbing and drainage applications—requires attention to both material quality and intellectual property (IP) considerations. Failure to address these aspects can lead to system failures, regulatory non-compliance, or legal risks. Below are common pitfalls to avoid:

Poor Material Quality and Non-Compliance with Standards

One of the most frequent issues when sourcing Sanitary Tee PVC is receiving substandard products that do not meet required industry standards such as ASTM D2665, ISO 15493, or local plumbing codes. Low-quality PVC may contain excessive fillers, inconsistent wall thickness, or poor impact resistance, leading to cracking, leaks, or premature failure. Always verify certifications, request test reports, and conduct material inspections to ensure compliance.

Counterfeit or Unbranded Products

The market is flooded with counterfeit or unbranded PVC fittings that mimic reputable brands but lack performance reliability. These products often bypass quality control and may not be traceable. Sourcing from unauthorized suppliers increases the risk of receiving non-genuine items. Always procure from authorized distributors and verify product authenticity through batch numbers, holograms, or manufacturer verification tools.

Inadequate Intellectual Property Due Diligence

When developing or sourcing proprietary plumbing systems, there’s a risk of infringing on existing patents or trademarks—especially with design-specific fittings like sanitary tees. Using a design or manufacturing process protected by IP rights without permission can lead to legal disputes, injunctions, or financial penalties. Conduct thorough patent searches and consult legal experts to ensure freedom to operate.

Lack of Traceability and Documentation

Reputable PVC fittings come with traceable documentation, including material test reports, compliance certificates, and lot numbers. Suppliers who cannot provide this documentation may be sourcing from unregulated manufacturers. Insist on full traceability to protect against liability in case of system failures or recalls.

Inconsistent Dimensional Accuracy

Poorly manufactured sanitary tees may have inconsistent socket dimensions or misaligned centers, leading to improper jointing and potential leaks. This is especially critical in pressurized or gravity-fed waste systems. Request samples and perform dimensional checks using calibrated tools before placing large orders.

Failure to Consider Environmental and Chemical Resistance

Not all PVC formulations are suitable for every application. Some sanitary tees may degrade when exposed to certain chemicals, UV light, or extreme temperatures. Ensure the PVC compound used is appropriate for the intended environment—such as Schedule 40 for standard drainage or CPVC for higher temperature resistance.

Overlooking Supplier Reliability and Long-Term Support

Choosing suppliers based solely on price often leads to long-term issues. Unreliable suppliers may deliver inconsistent quality, lack technical support, or go out of business, leaving you without replacement parts or warranty coverage. Prioritize suppliers with a proven track record, strong customer service, and stable supply chains.

By proactively addressing these pitfalls—focusing on verified quality, regulatory compliance, and IP integrity—buyers can ensure the safe, legal, and efficient use of Sanitary Tee PVC fittings in their projects.

Logistics & Compliance Guide for Sanitary Tee PVC Fittings

This guide outlines the essential logistics considerations and compliance requirements for handling, transporting, and distributing Sanitary Tee PVC fittings in commercial and industrial applications.

Product Overview

Sanitary Tee PVC fittings are T-shaped piping components made from polyvinyl chloride (PVC) designed specifically for sanitary drainage, waste, and vent (DWV) systems. These fittings feature a smooth interior finish and are engineered to facilitate efficient flow and reduce clog formation in plumbing systems.

Regulatory Compliance

Sanitary Tee PVC fittings must comply with national and international standards to ensure safety, performance, and environmental responsibility.

Material Standards

- ASTM D2665: Standard specification for PVC plastic DWV fittings.

- NSF/ANSI 14: Covers plastic piping system components and related materials.

- NSF/ANSI 61: Ensures material safety for components in contact with drinking water (if applicable).

- CSA B181 Series (Canada): Equivalent standards for PVC DWV fittings in Canadian markets.

Certification Requirements

- Products must bear certification marks from recognized bodies such as NSF, UL, or IAPMO.

- Documentation including test reports and certificates of compliance must be available upon request.

- Compliance with local building codes (e.g., IPC – International Plumbing Code, UPC – Uniform Plumbing Code) is mandatory for installation.

Packaging and Labeling

Proper packaging and labeling are essential for product integrity and regulatory compliance.

Packaging Specifications

- Fittings should be packed in sturdy corrugated cardboard boxes or shrink-wrapped bundles on pallets.

- Use protective materials (e.g., edge protectors, void fill) to prevent damage during transit.

- Pallets must be secured with strapping or stretch wrap to prevent shifting.

Labeling Requirements

- Include product name, size (e.g., 2″ x 2″ x 2″), material (PVC), standard compliance (e.g., ASTM D2665), and manufacturer details.

- Add handling symbols (e.g., “Fragile,” “This Side Up”) per ISTA standards.

- Include batch/lot number and manufacturing date for traceability.

- For international shipments, labels must be in the destination country’s official language(s).

Storage Conditions

Maintain optimal storage environments to prevent material degradation.

- Store in a dry, well-ventilated area away from direct sunlight and extreme temperatures (ideally 40°F to 100°F / 4°C to 38°C).

- Keep fittings off the ground using pallets or racks to avoid moisture absorption and contamination.

- Avoid stacking beyond manufacturer-recommended height limits to prevent deformation.

- Separate from chemicals, oils, and solvents that may cause PVC degradation.

Transportation Guidelines

Ensure safe and efficient transport of Sanitary Tee PVC fittings.

Domestic Shipping (U.S. & Canada)

- Use enclosed trucks or containers to protect from weather and UV exposure.

- Secure loads with straps or nets to prevent shifting during transit.

- Follow FMCSA regulations for commercial vehicle safety and load securement.

International Shipping

- Comply with IMDG Code if shipped by sea (PVC is generally non-hazardous but verify classification).

- Use ISPM 15-compliant wooden pallets for international destinations.

- Provide accurate Harmonized System (HS) code: typically 3917.33 (Plastic tubes, pipes, and hoses fittings, rigid, of PVC).

- Prepare commercial invoice, packing list, and certificate of origin as required.

Import/Export Documentation

Ensure all necessary paperwork is complete to avoid customs delays.

- Commercial Invoice

- Bill of Lading / Air Waybill

- Packing List

- Certificate of Origin

- Test Reports and Compliance Certificates (e.g., NSF, ASTM)

- Import permits (if required by destination country)

Environmental and Safety Considerations

- PVC is recyclable; provide disposal guidelines to customers in accordance with local regulations.

- Avoid incineration without proper emission controls due to potential dioxin release.

- Safety Data Sheets (SDS) should be available, although PVC fittings are generally inert and non-toxic under normal use.

Quality Assurance and Traceability

- Implement a lot-tracking system to enable recalls if necessary.

- Conduct periodic audits of suppliers and logistics partners.

- Retain compliance documentation for a minimum of 5–7 years, depending on jurisdiction.

Conclusion

Adhering to this logistics and compliance guide ensures that Sanitary Tee PVC fittings are handled, stored, and distributed in a manner that meets regulatory requirements, maintains product quality, and supports safe installation in plumbing systems. Regular training for logistics personnel and updated compliance monitoring are recommended to maintain standards across the supply chain.

Conclusion for Sourcing PVC Sanitary Tees

In conclusion, sourcing PVC sanitary tees requires a careful evaluation of material quality, compliance with industry standards (such as ASTM D2665 or ISO 16428), supplier reliability, and cost-effectiveness. These fittings play a critical role in drainage, waste, and vent (DWV) systems, where performance, durability, and leak-free connections are essential. By prioritizing certified manufacturers, ensuring compatibility with existing plumbing systems, and considering long-term maintenance and environmental conditions, businesses and contractors can make informed procurement decisions. Establishing strong relationships with reputable suppliers and conducting regular quality assessments further ensure consistent product performance and project success. Ultimately, a strategic and quality-focused approach to sourcing PVC sanitary tees contributes to the efficiency, safety, and longevity of plumbing installations.