The global sand and stone market continues to expand, driven by rising construction activity, infrastructure development, and urbanization—especially across Asia-Pacific, North America, and the Middle East. According to a 2023 report by Grand View Research, the global construction aggregates market, which includes sand, gravel, and crushed stone, was valued at USD 317.9 billion and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects steady growth in demand for industrial sand and stone, citing increased spending on residential and commercial infrastructure, as well as the expansion of the glass and semiconductor industries, which rely heavily on high-purity silica sand. With such momentum, identifying the leading manufacturers becomes critical for stakeholders across supply chains—from developers to government agencies. The following list highlights the top nine sand and stone producers worldwide, evaluated based on production capacity, market reach, sustainability initiatives, and technological innovation.

Top 9 Sand & Stone Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Vulcan Materials Company

Domain Est. 1996

Website: vulcanmaterials.com

Key Highlights: Vulcan Materials Company is the nation’s largest producer of construction aggregates—crushed stone, sand and gravel and a producer of construction materials ……

#2 Sand

Domain Est. 2005

Website: sand-stoneinc.com

Key Highlights: Sand-Stone, Inc. offers the best hardscape building materials and landscape supply materials for Contractors and Builders, as well as individual homeowners….

#3 Holliston Sand

Domain Est. 2005

Website: hollistonsand.com

Key Highlights: Filtration Sand Solutions. Holliston Sand is New England’s most established supplier of industrial sand and stone products for a wide variety of applications….

#4 Holliday

Domain Est. 1998 | Founded: 1928

Website: hollidaysand.com

Key Highlights: Since 1928, Holliday Sand & Stone has safely built its business to be the preferred source of quality sand, gravel, and crushed stone….

#5 Boston Sand and Gravel

Domain Est. 2000

Website: bostonsand.com

Key Highlights: Boston Sand & Gravel offers over 1000 concrete mix designs, including specialty mixes for winter concrete, slurry walls, drilled shafts, and LEED-approved ……

#6 The National Stone Sand & Gravel Association

Domain Est. 2001

Website: nssga.org

Key Highlights: We produce the materials that build America. NSSGA’s Blog on the Rocks is a collection of news, insights and perspectives all about the aggregates industry….

#7 Masonry

Domain Est. 2005

Website: sandbuildingmaterials.com

Key Highlights: Sand Building Materials is located in the San Fernando and Santa Clarita Valley with a wide variety of natural stone, boulders, block, brick, sand & gravel, ……

#8 Sand & Stone

Domain Est. 2022

Website: sand-and-stone.com

Key Highlights: Sand + Stone is a one-stop-shop of top-tier concrete solutions for residential homeowners and contractors alike—complete with install, financing options, and ……

#9 Premier Sand & Stone LLC

Domain Est. 2023

Website: premiersandandstone.com

Key Highlights: Premier Sand & Stone is the leading processor of high quality quartz aggregates used in the Pool, Golf and Sports Industries across the United States….

Expert Sourcing Insights for Sand & Stone

H2 2025–2026 Market Trends Analysis for Sand & Stone

As we approach the second half of 2025 and look ahead to 2026, the sand and stone (construction aggregates) market is poised for a period of strategic evolution driven by infrastructure demand, sustainability pressures, technological adoption, and geopolitical dynamics. Here’s a comprehensive analysis of key trends shaping the industry:

1. Infrastructure-Led Demand Surge

- Government Investment: The full impact of multi-year infrastructure bills (e.g., U.S. Bipartisan Infrastructure Law, EU Green Deal investments) will materialize in 2026, driving strong demand for aggregates in road construction, bridge rehabilitation, and public transit projects.

- Urbanization & Housing: Despite earlier economic headwinds, stabilized interest rates in late 2025 are expected to revive residential and commercial construction, particularly in high-growth regions, increasing demand for crushed stone and sand.

- Regional Disparities: Demand will remain strongest in North America, parts of Asia-Pacific (India, Southeast Asia), and the Middle East, while Western Europe may see moderate growth due to market maturity.

2. Sustainability & Regulatory Pressures Intensify

- Carbon Accountability: Regulatory frameworks such as the EU’s CBAM (Carbon Border Adjustment Mechanism) and U.S. state-level emissions targets will push aggregate producers to decarbonize. Adoption of low-carbon cement and reduced haul distances will become competitive advantages.

- Recycled Aggregates Growth: Driven by circular economy mandates and LEED certification requirements, the market share of recycled concrete and construction waste as substitutes for virgin sand and stone will expand, particularly in urban centers.

- Water & Land Use Scrutiny: Stricter environmental regulations on quarrying operations—especially sand mining near water bodies—will increase compliance costs and accelerate investment in closed-loop water systems and land rehabilitation.

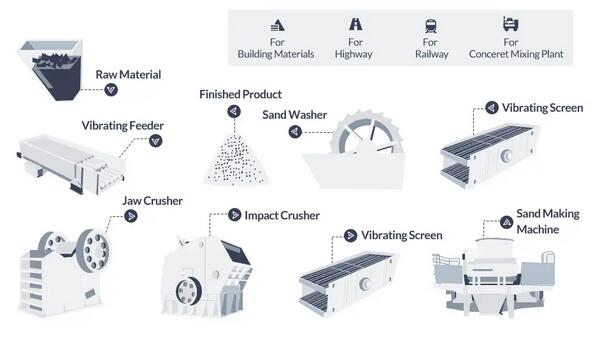

3. Technological Innovation & Operational Efficiency

- Smart Quarrying: Wider adoption of IoT sensors, drone surveys, and AI-driven predictive maintenance will optimize extraction efficiency, reduce downtime, and improve safety in quarries.

- Automation & Electrification: Pilot programs for electric and autonomous haul trucks will scale in 2026, cutting fuel costs and emissions. Major players will invest in fleet electrification to meet ESG goals.

- Digital Supply Chains: Blockchain and digital twin technologies will enhance traceability of materials, improving transparency for clients concerned with sustainability and compliance.

4. Geopolitical & Supply Chain Resilience

- Localization of Supply: Ongoing supply chain disruptions and trade uncertainties will encourage construction firms to source aggregates regionally, reducing dependence on long-haul transport.

- Sand Scarcity Concerns: Global awareness of “sand mafias” and ecological damage from illegal sand mining will lead to tighter international controls, potentially increasing prices for river and marine sand. This will benefit land-based quarry operators.

- Competition for Resources: Rising demand from emerging technologies (e.g., high-purity silica for semiconductors and solar panels) may create competition for specific sand grades, influencing long-term pricing and diversification strategies.

5. Consolidation & Strategic Partnerships

- Market Consolidation: Mid-sized operators will face margin pressure due to capital intensity of compliance and tech upgrades, leading to increased M&A activity. Larger firms will acquire regional players to secure reserves and logistics networks.

- Vertical Integration: Aggregates companies will deepen integration with downstream segments—such as concrete production and asphalt plants—to capture more value and stabilize demand.

Strategic Outlook for Sand & Stone Companies in 2026

- Winners will be those investing early in sustainability, digital transformation, and localized logistics.

- Risk Areas include regulatory non-compliance, exposure to high-carbon operations, and reliance on volatile transportation fuels.

- Opportunities lie in recycled materials, value-added products (e.g., engineered aggregates), and serving green infrastructure projects.

In conclusion, H2 2025–2026 will be a transformative period for the sand and stone industry, where environmental stewardship, technological agility, and strategic foresight will define market leadership. Companies that align operations with long-term sustainability and infrastructure trends will be best positioned for growth.

Common Pitfalls When Sourcing Sand & Stone: Quality and Intellectual Property Issues

Sourcing sand and stone for construction, landscaping, or industrial applications involves more than just finding a supplier with competitive pricing. Critical pitfalls related to material quality and intellectual property (IP) can significantly impact project outcomes, legal compliance, and long-term costs. Understanding these risks is essential for informed procurement decisions.

Quality-Related Pitfalls

1. Inconsistent Material Specifications

Sand and stone vary widely in grain size, composition, durability, and color. A common mistake is failing to define precise technical specifications (e.g., gradation, compressive strength, moisture content). Suppliers may deliver substandard or inconsistent batches, leading to structural weaknesses, poor workability, or aesthetic discrepancies in finished projects.

2. Contamination and Impurities

Low-quality sand may contain silt, clay, organic matter, or salts, especially if sourced from unregulated or illegal operations. These impurities compromise concrete strength, increase water demand, and cause long-term durability issues like cracking or efflorescence.

3. Lack of Certification and Testing

Procuring materials without third-party testing or compliance certifications (e.g., ASTM, EN, or local standards) exposes projects to performance risks. Suppliers may claim compliance without providing verifiable documentation, leading to non-conforming materials on-site.

4. Geographic and Environmental Variability

Natural stone and sand characteristics depend heavily on their geological source. Changes in quarry locations—even within the same region—can result in variations in color, texture, and performance. Overlooking this variability leads to mismatches in design expectations.

5. Unreliable Supply Chain and Logistics

Inadequate logistics planning or reliance on unstable suppliers can result in delays, stockouts, or damage during transport. Poor handling may degrade material quality (e.g., segregation of aggregate sizes or moisture absorption in sand).

Intellectual Property-Related Pitfalls

1. Unauthorized Use of Branded or Patented Materials

Some specialty aggregates or engineered stone products are protected by patents or trademarks. Sourcing counterfeit or unlicensed versions—even unknowingly—can lead to IP infringement claims, project stoppages, or liability for damages.

2. Misrepresentation of Origin or Branding

Suppliers may falsely represent materials as coming from a prestigious or certified quarry (e.g., “imported Italian marble” or “river-washed sand”) to justify higher prices. This mislabeling not only affects quality but may constitute false advertising or trademark violations.

3. Design IP Infringement in Custom Stonework

When sourcing custom-cut stone or patterned stone products for architectural features, there’s a risk of receiving pieces that replicate protected designs. Contractors or designers may inadvertently use materials featuring copyrighted patterns or patented laying techniques, exposing the project to legal action.

4. Lack of Documentation for Traceability and Compliance

In regulated markets, proving the legal and ethical origin of stone (e.g., conflict-free or sustainably sourced) is increasingly important. Failure to obtain proper documentation may violate environmental regulations or green building standards (e.g., LEED), risking certification loss or reputational damage.

Mitigation Strategies

- Define clear material specifications and require test reports for each batch.

- Audit suppliers and conduct site visits to quarries or processing facilities.

- Verify certifications (e.g., ISO, CE, or industry-specific standards).

- Include IP warranties in contracts, requiring suppliers to confirm materials do not infringe on third-party rights.

- Maintain detailed sourcing records to ensure traceability and defend against IP claims.

Avoiding these pitfalls requires due diligence, clear contractual terms, and proactive quality control—ensuring that both the physical and legal foundations of your project remain solid.

Logistics & Compliance Guide for Sand & Stone

This guide outlines essential logistics procedures and compliance requirements for the transportation, handling, and regulatory adherence related to sand and stone materials. Proper execution ensures safety, environmental protection, legal compliance, and operational efficiency.

Transportation & Handling Procedures

Ensure all sand and stone shipments are transported using appropriate vehicles such as dump trucks, hopper trailers, or bulk carriers designed for aggregate materials. Secure loads properly to prevent spillage during transit in accordance with local road safety regulations. Use tarps or covers where required by law or environmental conditions. On-site, implement safe unloading protocols, including designated dumping zones, exclusion areas for personnel, and proper equipment operation (e.g., front-end loaders, conveyors) to minimize dust and material degradation.

Regulatory Compliance

Adhere to all federal, state, and local regulations governing the extraction, transportation, and sale of sand and stone. Key compliance areas include:

- Environmental Permits: Maintain valid permits for quarrying, dredging, or mining operations. Comply with reclamation plans and erosion control measures.

- DOT Regulations: Follow Department of Transportation (DOT) guidelines for vehicle weight limits, load securement, and hazardous material classification (if applicable).

- Air Quality Standards: Implement dust suppression methods (e.g., water spraying, chemical binders) to meet Clean Air Act or local air quality mandates.

- Water Protection: Prevent sediment runoff into waterways by using silt fences, retention basins, and stormwater pollution prevention plans (SWPPP) where required.

Documentation & Recordkeeping

Maintain accurate records for traceability and audit readiness. Required documentation includes:

- Bills of lading for all shipments

- Material safety data sheets (MSDS/SDS), if applicable

- Weigh tickets and quality test reports (e.g., gradation, moisture content)

- Permits and compliance certifications (e.g., NPDES, MSHA)

- Driver and vehicle inspection logs

Retain records for a minimum of three years or as required by jurisdiction.

Safety & Training

All personnel involved in sand and stone logistics must complete safety training programs covering:

- Hazard communication (HazCom)

- Confined space entry (if applicable)

- Equipment operation and lockout/tagout (LOTO)

- Fall protection and traffic control in active work zones

Conduct regular safety audits and toolbox talks to reinforce best practices and ensure ongoing compliance.

Customer & Delivery Requirements

Verify delivery specifications with customers prior to shipment, including:

- Material type, size, and grade

- Quantity and delivery timeline

- Site access restrictions and unloading instructions

- Special handling or environmental conditions (e.g., freeze-thaw resistance)

Provide clear communication channels for delivery updates and issue resolution.

By following this guide, Sand & Stone operations can ensure reliable logistics performance while maintaining full regulatory compliance and workplace safety.

Conclusion for Sourcing Sand & Stone:

Sourcing sand and stone is a critical component in construction, infrastructure development, and landscaping projects. The successful procurement of these materials depends on several key factors, including material quality, proximity to the project site, environmental regulations, and sustainability practices. Locally available sources help reduce transportation costs and carbon emissions, while ensuring compliance with regional environmental and mining regulations safeguards long-term ecological balance.

It is essential to conduct thorough site assessments, engage with reliable suppliers, and verify the consistency and suitability of materials for specific applications—whether for concrete production, road base, or decorative purposes. Moreover, with increasing environmental concerns, sustainable sourcing methods, such as using recycled aggregates or exploring alternative materials, are becoming vital.

In conclusion, effective sourcing of sand and stone requires a balanced approach that considers economic efficiency, environmental responsibility, and material performance. By prioritizing sustainable practices and strategic supplier partnerships, stakeholders can ensure a reliable supply chain that supports both project success and environmental stewardship.