Introduction: Navigating the Global Market for ‘s banding’

Global buyers lose time and margin when stainless banding and seal choices don’t match the job, the joint, or the environment. You face inconsistent strength claims, mismatched tools, corrosion risks, and uneven supplier reliability across regions.

This guide gives you a practical buying path—clear specs, real performance checks, and a streamlined sourcing workflow—tailored for USA and Europe.

What this guide covers

– Product types and standards: stainless (304/316), galvanized, seal types and profiles, metric vs imperial sizing.

– Materials and corrosion performance: grade selection, environmental exposure, and post-galvanizing quality (Europe).

– Strength, sizing, and safety: working load, proof/test load, joint efficiency, elongation, and thickness-to-width guidance.

– Tooling and jointing: tensioners, cutters, seal applicators; seal-and-buckle vs band clamps; compatibility and service kits.

– Sourcing strategies: supplier vetting, quality documentation, sample testing, landed-cost and lead-time planning.

– Regional nuances: packaging, labeling, compliance (EU market expectations), and service norms.

By the end, you’ll specify the right banding solution with confidence—reducing failure, avoiding rework, and improving total cost of ownership.

Article Navigation

- Top 10 S Banding Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for s banding

- Understanding s banding Types and Variations

- Key Industrial Applications of s banding

- 3 Common User Pain Points for ‘s banding’ & Their Solutions

- Strategic Material Selection Guide for s banding

- In-depth Look: Manufacturing Processes and Quality Assurance for s banding

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘s banding’

- Comprehensive Cost and Pricing Analysis for s banding Sourcing

- Alternatives Analysis: Comparing s banding With Other Solutions

- Essential Technical Properties and Trade Terminology for s banding

- Navigating Market Dynamics and Sourcing Trends in the s banding Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of s banding

- Strategic Sourcing Conclusion and Outlook for s banding

- Important Disclaimer & Terms of Use

Top 10 S Banding Manufacturers & Suppliers List

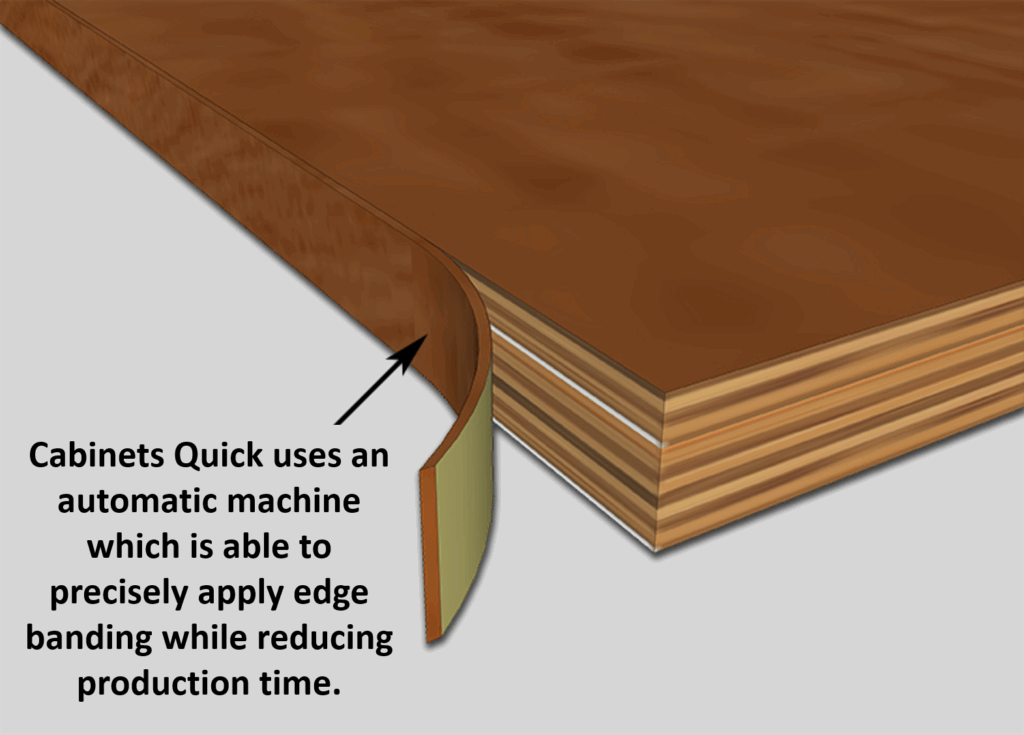

1. Stainless Steel Bands, Seals, & Strapping – Distribution International

Domain: distributioninternational.com

Registered: 2004 (21 years)

Introduction: 30-day returnsDistribution International supplies stainless steel banding & seals in common sizes with roll lengths and weights for bands depending on your needs….

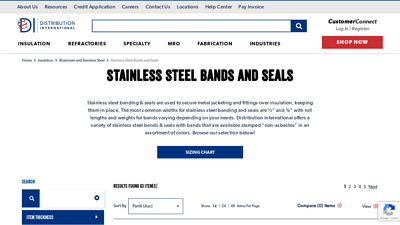

2. Steel Strapping

Domain: americanstrapping.com

Registered: 2002 (23 years)

Introduction: ASC strapping is available in a wide range of types, sizes, gauges and finishes to accommodate your strapping requirements….

3. Stainless Banding and Strapping Manufacturer and Supplier

Domain: permaband.com

Registered: 2001 (24 years)

Introduction: PermaBand is an American Manufacturer and Supplier of stainless steel banding, stainless steel buckles, stainless steel wing clips and stainless steel sign ……

Illustrative Image (Source: Google Search)

4. 7 Best Steel Strapping Manufacturers | Verified Market Research

Domain: verifiedmarketresearch.com

Registered: 2018 (7 years)

Introduction: 7 best steel strapping manufacturers are SMC Group, ArcelorMittal, FROMM, American Strapping Company, Walzen Strips, Empire Group India, ……

Understanding s banding Types and Variations

Understanding s banding Types and Variations

s banding in industrial applications typically refers to stainless steel band or strap systems used to fasten, bundle, or secure loads. In B2B contexts, buyers evaluate four primary decision drivers—material, tooling, dimensions, and accessories—and then tune performance through load profile and environmental constraints. Based on common product characteristics and the Amazon references, five common configurations emerge:

Illustrative Image (Source: Google Search)

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| 304 stainless band with ratchet tensioner and cutter (kit) | 304 stainless steel; widths commonly 3/4 in (≈19 mm); kits include ratchet/cutter, metal seals/buckles; 100 ft to 200 ft coils; sold as complete solutions | Palletizing, heavy-duty packaging, construction bundling, general-purpose industrial securing | Pros: corrosion resistance; all-in-one readiness; moderate price/availability; Cons: lower impact resistance vs. carbon; requires proper tensioner/seal selection to avoid slippage |

| 304 stainless band—coil only | 304 stainless steel; 3/4 in x ~95 ft roll in plastic case; coil-only option; often includes basic seals | Repairs, low-volume use, integrating into existing workflows | Pros: lightweight inventory; flexible procurement; Cons: no tools included; requires compatible seals/tensioners |

| 304 stainless banding with heavy-duty seals | 304 stainless steel; 3/4 in widths; heavy-duty pallet usage; 100 seals typically included in kits | High-cycle distribution, warehouse logistics, repeat pallet loads | Pros: faster strap-off with seals; higher throughput; Cons: seal/stamp cost; potential seal failure if misapplied |

| 304 stainless banding—200 ft coil | 304 stainless steel; 3/4 in x 200 ft coil; more footage per coil; often paired with seals | Longer-run palletizing, shipping yards, continuous bundling lines | Pros: fewer coil changes; lower per-foot procurement friction; Cons: larger spool storage; potential wastage if jobs are short |

| Heavy-duty kit with all accessories | 304 stainless steel; 3/4 in; includes tensioner tool, seals, hammer, gloves (varies); multi-use kit | Field operations, multi-site teams, mobile services | Pros: deploy anywhere; low setup friction; Cons: upfront price; glove/tool wear or loss over time |

Type 1: 304 Stainless Banding with Ratchet Tensioner and Cutter (Kit)

- Features: 304 stainless steel composition; common 3/4 in widths; lengths offered at 100 ft and 200 ft; kits commonly include a ratchet/cutter tool and 100 metal seals/buckles; marketed as heavy-duty, rust-resistant.

- Applications: Palletization for shipping and storage, construction bundling, and general industrial securing. Typical end-use includes pallets, crates, and equipment tie-downs where corrosion resistance and moderate cycle counts are required.

- Pros/Cons:

- Pros: Corrosion resistance suited to variable climates; all-in-one kits simplify purchase and setup; flexible widths and lengths support most SMB logistics needs.

- Cons: Lower impact resistance compared with coated carbon steel under severe shock; tool compatibility must be ensured to avoid slippage or seal under-tension.

Type 2: 304 Stainless Banding—Coil Only

- Features: 304 stainless steel; 3/4 in width; ~95 ft coil length; typically provided in a plastic case; no tools included.

- Applications: Repairs, low-volume bundling, or integration into existing bundling lines where tensioners and seals are already on hand.

- Pros/Cons:

- Pros: Lower acquisition cost for small runs; compact storage; easy to match to existing toolsets.

- Cons: No tooling provided; requires separate procurement of seals and tensioners; potential mismatch risk if existing tools are not 3/4 in compatible.

Type 3: 304 Stainless Banding with Heavy-Duty Seals

- Features: 304 stainless steel; 3/4 in widths; kits include ~100 metal seals/buckles; positioned for heavy-duty pallet use and rust resistance.

- Applications: Palletizing and warehouse logistics where frequent cycles are expected, and seal consistency drives throughput.

- Pros/Cons:

- Pros: Seals speed strap-off and improve consistency; stainless resists rust; stock seals reduce time-to-secure per pallet.

- Cons: Ongoing seal consumption increases operating cost; incorrect seal selection or installation can reduce clamp force and cause failures.

Type 4: 304 Stainless Banding—200 ft Coil

- Features: 304 stainless steel; 3/4 in widths; 200 ft length coils often shipped with 100 steel buckles and a tensioner tool; targeted for heavy-duty pallet strapping in shipping and storage.

- Applications: Yards, shipping docks, and repeat workloads where longer coils minimize coil changes and downtime.

- Pros/Cons:

- Pros: Fewer coil changes and lower per-foot logistical friction; suited to continuous use cases; often paired with compatible seals/buckles.

- Cons: Larger spool footprint; potential overage waste on shorter runs; ensure storage conditions (dry, protected) to avoid edge damage.

Type 5: Heavy-Duty Kit with All Accessories

- Features: 304 stainless steel; 3/4 in widths; kits often include a tensioner tool, seals/buckles, a hammer, and cut-resistant gloves; marketed as complete pallet packaging or strapping solutions.

- Applications: Field operations, mobile teams, or multi-site deployments requiring portable, self-contained strapping kits.

- Pros/Cons:

- Pros: Rapid deployment; minimized need for separate accessory purchases; safer handling with gloves included.

- Cons: Higher upfront price; tools and PPE can be lost or wear over time; ensure compatibility of seals/tensioners with strap width.

Selection guidance: For USA and Europe, typical widths are 3/4 in; common coil lengths are ~95–100 ft and 200 ft. Align material grade (304 stainless steel) to your corrosion and sanitation requirements, and choose kit vs. coil based on whether tools and seals are already available in your operation.

Key Industrial Applications of s banding

Key Industrial Applications of S Banding

S banding (stainless steel strapping) supports heavy, repetitive, and hygiene‑critical fastening across sectors. Below are representative use cases and the material benefits that matter for procurement and operations.

| Industry/Segment | Representative Applications (S Banding) | Benefits That Matter |

|---|---|---|

| Logistics & Packaging | Unitizing pallets; bundling coils, pipe, and lumber; securing dunnage and slip‑sheets | High tensile strength and grip on mixed loads; resists rust and sharp edges; compatible with ratchet/tensioner tools for fast, consistent tension |

| Construction & Building | Anchoring scaffolding, formwork, and temporary bracing; bundling rebar, conduit, and site materials; cable management | Strong, non‑stretch fixation under vibration; corrosion‑resistant in wet or outdoor settings; predictable performance with standard buckles/seals |

| Utilities & Infrastructure | Securing cable trays, luminaires, and signage; grounding/bonding straps; fastening guy wires and hangers | Stable mechanical performance over long service; resists moisture and road salts; clean, low‑maintenance profile on infrastructure |

| Food & Beverage | Stainless banding for vats, tanks, conveyors; sealing stainless mesh carts/totes; hygienic equipment mounting | Smooth finish; corrosion resistance; compatible with frequent washdowns; low maintenance in HACCP environments (verify grade/seal compatibility per application) |

| Oil & Gas (upstream/midstream) | Securing insulation on pipes; anchoring guards and cable bundles; equipment tie‑downs | Withstands ambient corrosives; maintains tension across temperature cycles; dependable in field conditions |

| Marine & Offshore | Fastening guards, ladders, signage; cable harnessing on decks and bridges | Resists salt spray and chlorides; durable in wet, salty environments; reliable in marine atmospheres (select grade to suit environment) |

| Pulp & Paper | Bundle paper rolls and wire; secure guards; tie equipment sub‑assemblies | Maintains grip on pulp and paper products; corrosion resistance in humid mills; simple maintenance |

| HVAC & Energy | Cable harnessing; anchoring supports; equipment tie‑downs | Durable under vibration; corrosion‑resistant for rooftop and coastal sites; integrates with standard hardware and tools |

| Manufacturing & Fabrication | Tooling tie‑downs; fixture and jig attachments; securing pallets of finished goods | High repeatability with tensioners; minimal relaxation over time; secure in mixed packaging lines |

| Retail & Industrial Displays | Mounting signage and fixtures; securing carts and displays | Clean, finished appearance; reliable hold under public‑facing use |

| Waste Management & Recycling | Bale binding; container reinforcement; equipment tie‑downs | Abrasion resistance; maintains tension despite sharp/bulky loads; reduces downtime from corrosion or slippage |

Notes for buyers

– Standard widths and thicknesses (e.g., 3/4 in × ~0.030 in) are broadly available and compatible with common ratchet/tensioner tools and buckles/seals.

– For severe environments, specify the grade to match corrosivity (e.g., marine).

– Ensure buckles/seals are compatible with the strapping grade and application tension to achieve published performance.

3 Common User Pain Points for ‘s banding’ & Their Solutions

3 Common User Pain Points for Stainless Steel Banding & Their Solutions

Below are frequent B2B pain points when sourcing and applying stainless steel banding, followed by practical solutions that improve reliability and reduce operating costs.

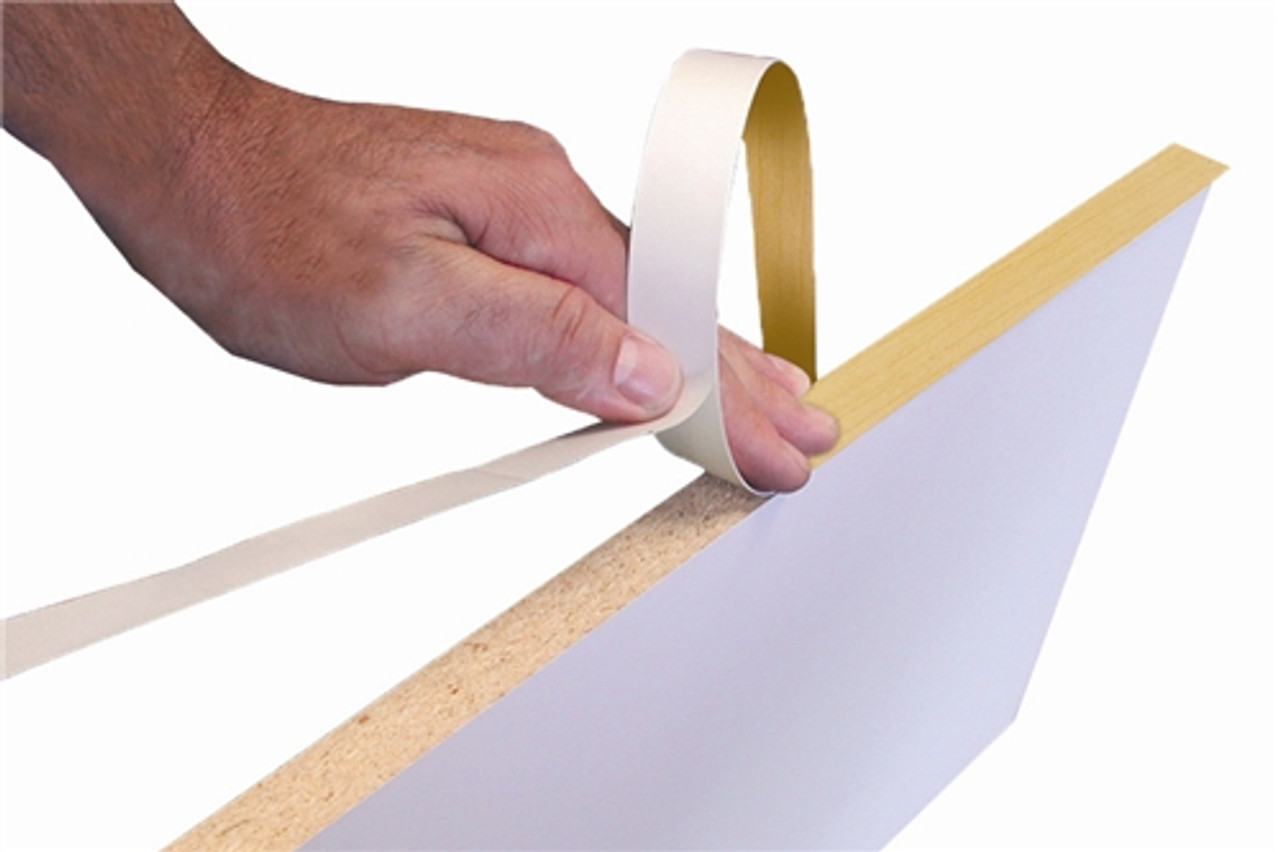

Illustrative Image (Source: Google Search)

Pain Point 1: Tool–Strap Compatibility and Consistent Tension

- Problem: Mismatched tensioners, cutters, or buckles lead to uneven tension, damaged seals, and frequent jams. Users end up re-tying or scrapping coils due to poor fit.

- Scenario: Palletizing crew uses an off-brand tensioner with a 3/4″ 304 stainless steel coil. The tool’s grip geometry doesn’t match the buckle, causing seal slippage and uneven compression.

- Impact: Rework, damaged straps, slower throughput, and higher material waste.

- Solution: Standardize on:

- Width: 3/4″ coils (common in B2B kits).

- Grade: 304 stainless steel (good corrosion resistance for most indoor/outdoor applications).

- Tool set: Ratchet/cutter tensioner and matched buckles/seals sized for the strap profile.

- Training: Calibrate tension settings and follow the manufacturer’s cut/seal sequence.

- How to verify:

- Run pilot kits and track jams per 100 straps and seal slippage rate.

- Require suppliers to specify width, grade, and tool compatibility.

Pain Point 2: Rust Resistance and Corrosion Failures

- Problem: “Stainless” banding that isn’t true 304/316 degrades in moisture, chemicals, or outdoor conditions, leading to rust, brittleness, and premature failure.

- Scenario: A construction team uses banding in humid storage and finds pitting after a few weeks, compromising load security.

- Impact: Safety risks, unexpected replacements, and potential claims.

- Solution:

- Specify 304 stainless steel for general use; upgrade to 316 where chloride exposure is high.

- Confirm seal/buckle material matches the band grade to avoid galvanic mismatch.

- Verify documentation: product pages and supplier spec sheets listing grade and test standards.

- How to verify:

- Check brand pages for “304 Stainless Steel Strapping” statements and test reports if available.

- Document lot/batch traceability and store in dry areas.

Pain Point 3: Lead Times, Stock Levels, and Total Cost of Ownership (TCO)

- Problem: Kits go out of stock or show long delivery windows; buying low-price coils separately leads to hidden tool costs.

- Scenario: A 3/4″ × 95′ roll listing shows delayed delivery and “Only 20 left in stock,” forcing expedited orders or substitutions.

- Impact: Downtime, expedited shipping fees, and fragmented inventory.

- Solution:

- Keep a core kit (coil + tensioner + buckles/seals + PPE) on hand for fast rollout.

- Consolidate procurement: multi-pack coils or kits with documented delivery SLAs.

- Track TCO: combine kit price, shipping lead times, and expected reorders to compare suppliers.

- How to verify:

- Check current lead times and stock status on supplier pages.

- Use vendor scorecards for on-time delivery and availability.

Quick Reference: Typical Kit Components

| Component | Common Spec (from B2B listings) | Notes |

|---|---|---|

| Stainless steel strap | 304 grade; 3/4″ width; 95–100 ft coils | Good general corrosion resistance; choose 316 in high-chloride environments |

| Seals/buckles | 100–200 pcs per kit; 3/4″ profile | Match strap width and thickness to avoid slippage |

| Tensioner/cutter | Ratchet type with cutter | Ensures consistent tension and safe cuts |

| PPE | Cut-resistant gloves, sometimes hammer | Keep safety stock in dispatch areas |

| Delivery | 5–10+ business days typical; variable per supplier | Plan buffer stock based on SLA |

| Pricing indicators | Coils: ~$31; Kits: ~$80–$130 | Prices vary by contents, brand, and delivery |

Summary

- Standardize tool–strap compatibility for predictable tension.

- Demand grade verification (304/316) and matched components to prevent corrosion.

- Use supplier SLAs and buffer inventory to control lead times and TCO.

These actions improve uptime, reduce rework, and deliver consistent performance for USA/Europe operations.

Strategic Material Selection Guide for s banding

Strategic Material Selection Guide for S‑Banding

S‑banding, also called stainless steel strapping or metal banding, secures loads across industrial, construction, and logistics applications. The material choice sets the performance ceiling for break strength, corrosion resistance, and total cost of ownership.

Use this guide to map operating conditions to the right stainless grade.

Decision factors

- Environment: inland, coastal/marine, chemical exposure (chlorides, acids), or high humidity.

- Load and geometry: heavy pallets, rigid modules, vibration risk, cut‑through hazards, elongation limits.

- Temperature range: sub‑zero, ambient, elevated or intermittent heat.

- Corrosion and hygiene: presence of salt, fertilizers, caustic cleaners, or food/pharma requirements.

- Joint performance: seal type (buckled or welded) and its compatibility with the band grade.

- Life‑cycle and budget: purchase price vs. lifetime replacement, rework, or corrosion failures.

- Supply and availability: regional stock of widths (1/2″, 5/8″, 3/4″, 1″), thicknesses (0.015–0.030″), and seals.

Material options and when to choose each

- 304 (UNS S30400)

- Strengths: good corrosion resistance for general use; cost‑effective; widely available; compatible with buckled and crimp seals.

- Use when: inland or lightly corrosive environments, general packaging and industrial bundling, mild cleaners, moderate humidity, cost is a priority.

-

Watch out for: chloride stress corrosion cracking (SCC) in coastal or de‑icing exposure; avoid prolonged elevated temperatures where creep becomes relevant.

-

316 (UNS S31600)

- Strengths: superior chloride pitting and SCC resistance vs. 304; robust for marine/coastal and humid climates; compatible with buckled and crimp seals.

- Use when: coastal/marine, de‑icing salts, fertilizer handling, humid storage, chemical cleaning with salts.

-

Watch out for: price premium; ensure seals are 316 to avoid galvanic issues and mixed‑grade crevice corrosion at joints.

-

316L (UNS S31603)

- Strengths: lower carbon content (≤0.03%) improves weldability and reduces sensitization risk; same corrosion class as 316; compatible with welded seals and welded band loops.

- Use when: welded joints are preferred or required; frequent weld repairs or in‑field splicing; process industries where weld integrity is critical.

- Watch out for: slightly higher cost vs. 316; follow welding best practice to preserve corrosion resistance (interpass temperature, shielding gas, post‑weld passivation).

Material comparison summary

| Property | 304 (S30400) | 316 (S31600) | 316L (S31603) |

|---|---|---|---|

| Typical ultimate tensile strength (UTS) | 515–690 MPa | 515–690 MPa | 485–620 MPa |

| Typical yield strength (0.2% offset) | 205–310 MPa | 205–310 MPa | 170–310 MPa |

| Service temperature range (air) | −50 to ~300°C | −50 to ~300°C | −50 to ~300°C |

| Chloride pitting/SCC resistance | Low–Moderate (best inland) | High (coastal/industrial) | High (coastal/industrial) |

| Magnetism (work‑hardened) | May become magnetic near welds | May become magnetic near welds | May become magnetic near welds |

| Weldability (sensitization risk) | Good; avoid thick multi‑pass welds | Good; avoid thick multi‑pass welds | Excellent; lower carbon reduces sensitization |

| Seal compatibility | Buckled, crimp | Buckled, crimp | Buckled, crimp, welded (preferred) |

| Typical environment | Indoor, mild outdoor | Coastal/marine, salts | Coastal/marine, salts; welded joints |

| Cost trend | Low | Medium | Medium–High |

Notes:

– Ranges reflect typical annealed austenitic stainless sheet/band. Actual values vary by thickness, finish, and processing.

– 316/316L share similar corrosion performance; 316L is selected primarily for weld‑heavy designs or where sensitization is a concern.

Illustrative Image (Source: Google Search)

Practical selection criteria

- Marine/coastal, de‑icing, fertilizer handling, caustic cleaners: choose 316 or 316L to mitigate pitting and SCC; match seals to the band grade to reduce galvanic and crevice corrosion at joints.

- Inland logistics, warehouses, general bundling: 304 often suffices; ensure proper tension and seal set‑up to minimize loose bands.

- Vibration‑heavy or high‑cycle applications: prioritize robust seal geometry and tension retention; confirm strap thickness with joint efficiency to meet or exceed working load requirements.

- Food, pharma, cleanrooms: 316/316L combined with smooth finish and good hygiene practices; favor welded loops or sealed edges where practicable.

- Budget‑constrained projects: 304 can reduce CAPEX; validate expected service life to avoid hidden OPEX from early replacements.

Seals and joints

- Use seals of the same or higher alloy family as the band; mixed grades can drive crevice corrosion at the joint.

- For welded loops, 316L is the recommended grade to preserve weld corrosion resistance.

- Validate the strap thickness/seal capacity pairing for your tension and width to avoid peel or joint failure.

This section provides a B2B‑ready framework to align grade selection with environment, load, and joint method—balancing performance, availability, and total cost in USA and Europe markets.

In-depth Look: Manufacturing Processes and Quality Assurance for s banding

Key points overview

– Precise material selection and incoming verification based on alloy grade, thickness tolerance, and coil quality.

– Controlled forming and slitting to achieve tight dimensional and edge-quality controls.

– Assembly (cut-to-length, seal/buckle pairing, packaging) aligned with end-use safety factors.

– Quality assurance across the entire process, anchored in ISO 9001–compliant QMS with relevant ISO and AWS norms.

– Traceability and documentation that meet B2B expectations in USA and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for S Banding

Process flow (Prep → Forming → Assembly → QC)

| Process step | What’s done | Critical checks | Key outcomes |

|---|---|---|---|

| Prep | Grade verification (e.g., 304/316); coil inspection; deburring/pickling (where applicable); storage in dry, clean areas to prevent contamination. | Incoming material certs; dimensional and surface checks; contamination controls. | Consistent material integrity; predictable forming behavior. |

| Forming | Precision rolling to target thickness; slitting to specified widths; edge preparation; coil wind-up; optional passivation for corrosion resistance. | Width, thickness, and camber tolerances; edge quality (no burrs/lacerations); surface finish; batch logging. | Dimensionally stable strap with repeatable performance and handling safety. |

| Assembly | Cut-to-length operations; pairing with certified seals/buckles; tool verification; packaging per market (USA/EU) standards. | Length accuracy; hardware compatibility; packaging labeling; moisture/chemical exposure prevention. | Ready-to-use banding solutions suitable for pallets, infrastructure, and industrial applications. |

| Quality control (QC) | Tensile and elongation testing; corrosion checks (salt spray); seal performance; packaging integrity; calibration traceability to ISO/IEC 17025 standards. | Test validity and repeatability; nonconformance handling; records and Certificates of Conformance (CoCs). | Verified strength, durability, and regulatory compliance. |

Alloy and material selection

| Alloy | Typical applications | Notes for USA/EU markets |

|---|---|---|

| 304 (UNS S30400) | General industrial banding and packaging; construction support. | Broadly available; good corrosion resistance under typical environments. |

| 316 (UNS S31600) | Marine, coastal, and chemically exposed environments. | Higher pitting resistance; preferred where chlorides are present. |

Selection is guided by environment, load profile, and regulatory context. Buyers in USA and Europe can expect grade selection to be matched to duty cycle and exposure conditions.

Assembly hardware compatibility

| Hardware | Type | Typical material | Use case |

|---|---|---|---|

| Seals | Painted/sealed; crimp-on | Stainless or coated carbon; stainless preferred for corrosion-sensitive uses. | Mechanical locking; permanent or semi-permanent bundling. |

| Buckles | Roll-over or clamp style | Stainless or coated carbon | Adjustable bundling; reusable systems. |

Assembly matches strap width/thickness to rated seal/buckle capacity to avoid underperformance. Coatings or corrosion-resistant hardware are specified for higher exposure environments.

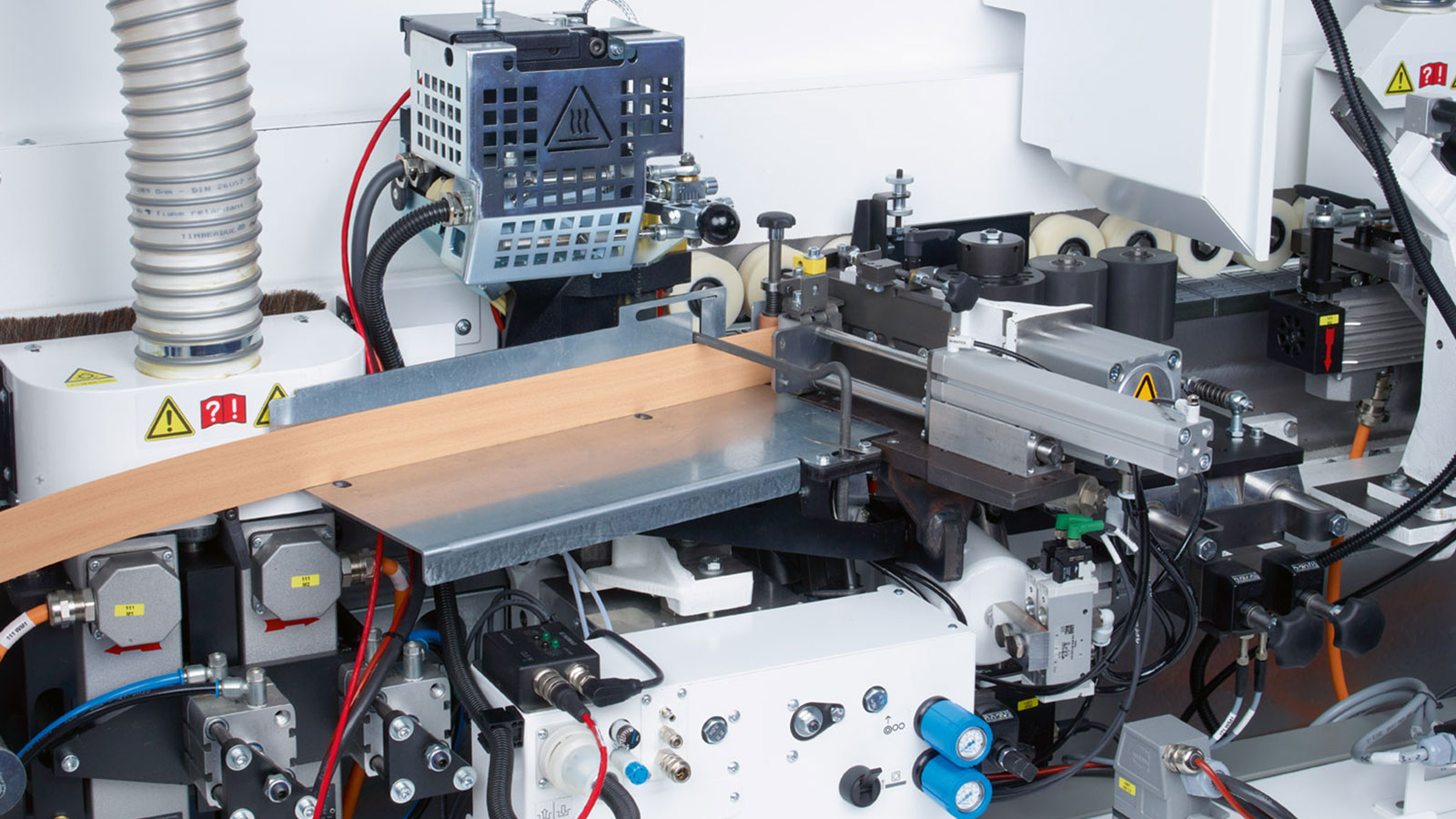

Illustrative Image (Source: Google Search)

Quality assurance: tests, standards, and documentation

| Test / check | Purpose | Standards (examples) | Frequency |

|---|---|---|---|

| Tensile testing | Verify strap strength; confirm mechanical limits. | ISO 6892-1 (metallics), AWS D1.1 (where weld or welding performance is relevant). | First article; lot testing; periodic verification. |

| Elongation (tensile ductility) | Ensure strap can absorb load variance without brittle failure. | ISO 6892-1 (as above). | Same as tensile. |

| Corrosion (salt spray/fog) | Assess resistance to rust and pitting, especially for coastal/industrial exposure. | ISO 9227; product-specific acceptance criteria agreed with customers. | Development and lot sampling. |

| Hardware performance (seal/buckle) | Confirm locking integrity under typical installation loads. | ISO standards for product quality systems (e.g., sampling per ISO 2859-1); internal performance protocols. | Lot sampling; first article. |

| Dimension and edge quality | Ensure fit, handling safety, and product consistency. | ISO 11082 (dimensions for strap widths) and other relevant ISO dimension standards. | Every lot/slit slit; in-process checks. |

| Surface treatment | Verify passivation/pickling quality to reduce free-iron contamination. | ISO 13056 (passivation of stainless steel fasteners and related parts). | Process validation and periodic audits. |

| Packaging integrity | Prevent moisture ingress and mechanical damage in transit. | ISO 2233 (package, crate and package components—moisture protection) for export packaging. | Each shipment or lot. |

| Calibration & traceability | Ensure measurement validity across all tests and inspections. | ISO/IEC 17025 (laboratory competency) via calibrated instruments; traceability to national/international standards. | Ongoing; annual audits. |

Factory-level quality management

- ISO 9001–compliant QMS covering process control, corrective and preventive actions, and customer communication.

- ISO 14001 environmental controls for waste, chemicals, and energy management (aligned with EU sustainability expectations).

- Document control and full batch traceability from raw material certificates to end-of-line inspections and shipment.

Regulatory and sustainability considerations (USA and Europe)

- REACH/RoHS: Materials and coatings comply with EU registration, evaluation, authorization, and restriction of chemicals (REACH) and restrictions on hazardous substances (RoHS).

- Conflict minerals: Responsible sourcing declarations per Dodd-Frank §1502 or EU Regulation 2017/821, as applicable.

- Packaging waste: Compliance with EU Packaging and Packaging Waste Directive; use of recyclable/renewable materials where feasible.

- AQL sampling: Acceptance quality limit (AQL) sampling plans applied to inspections per ISO 2859-1, with customer-specified critical, major, and minor defect definitions.

Packaging and logistics controls

- Packaging designed to protect against moisture, abrasion, and contamination; export crates and wrap conforming to ISO 2233 where applicable.

- Labeling with alloy grade, dimensions, lot ID, coil length, and applicable compliance marks for USA/EU destinations.

- Shipping and documentation aligned with carrier and country-specific requirements, with certificates and declarations readily available to B2B buyers.

Summary

Manufacturing of s banding for USA and Europe is governed by robust process controls: validated incoming materials, precision forming and edge prep, careful assembly with compatible hardware, and a comprehensive QA framework anchored in ISO standards. ISO 9001–compliant systems, ISO/IEC 17025–aligned calibration, relevant ISO test methods, and regulatory compliance (REACH, RoHS, conflict minerals, packaging waste) ensure reliability, traceability, and market fit. This disciplined approach delivers a consistent, corrosion-aware banding solution that meets the operational and regulatory expectations of professional B2B buyers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘s banding’

Practical Sourcing Guide: A Step-by-Step Checklist for Stainless Steel Banding

Use this checklist to source stainless steel banding for palletization, construction, and general heavy-duty strapping. Steps are aligned for USA and Europe (compliance, shipping lanes, and supplier discovery).

1) Define requirements

- Application: palletization, industrial bundling, cable/pipe support, HVAC, signage, or other.

- Performance: load profile, duty cycle, shock/cyclic loads, and risk tolerance.

- Environment: indoor vs outdoor; UV exposure; moisture; salt; chemicals; temperature extremes.

- Corrosion: select grade (304 for general use; 316/316L where chlorides/salts or chemical exposure require higher corrosion resistance).

- Standard & approval: verify regional compliance and acceptance criteria (e.g., ISO standards, UN ECE R43 for sign hardware in EU; chain-of-custody for stainless if relevant).

2) Specify product fundamentals

- Width and thickness: common widths 1/2″, 5/8″, 3/4″, 1″; thickness typically in bands’ per-foot strength—match to your load and hardware capacity.

- Length and packaging:

- Coil formats (e.g., 95’–100′ per coil are typical on B2C/B2B kits; bulk rolls allow longer continuous runs).

- Per-pack count (e.g., 1 coil per box vs. bulk pallet).

- Edge and finish: smooth/rolled edges preferred for safer handling; coating optional for noise/corrosion management.

- Buckles/seals and tools: select mechanically compatible buckles (buckle width must match band width); ensure tensioner/cutter fits the profile.

3) Build your shortlist

- Channels:

- Commercial kits (e.g., Amazon) for testing, pilots, or low-volume needs.

- Industrial distributors and manufacturers for bulk, repeat orders, and SLA support.

- What to gather: datasheets, test certificates, edge safety, corrosion data, tool compatibility, inventory availability, lead time, Incoterms, payment terms.

4) Validate supplier fit

- Quality and consistency:

- Request MTC (Mill Test Certificate) for stainless grade; confirm corrosion claims (e.g., 304 vs 316/316L).

- Ask for sample coils to verify thickness/edge quality and tension in your application.

- Commercial terms:

- MOQ, lead time, inventory depth, standard packaging (coil in plastic case or boxed; quantities per carton/pallet).

- Incoterms and shipping lanes (USA vs EU), delivery reliability.

- Warranty/return policy; price valid window; escalation process for stockouts.

- Tooling support:

- Availability and lead time of compatible tensioners/cutters/buckles/seals.

- Spares and consumables strategy to avoid tool downtime.

5) Compare value, not just price

- Cost breakdown: band price + buckles/seals + tools + shipping + expected scrap/loss + re-tensioning frequency.

- Total cost of ownership (TCO):

- Fewer re-tension events, lower breakage rates, and reduced injury risk can outweigh lower unit prices.

- Consider safety and compliance—some applications require cut-resistant gloves and proper tools.

- Risk: stockout probability, SLA coverage, multi-source options, lead-time predictability.

6) Run a pilot and qualify

- Pilot scope:

- 2–3 coil lots from 2 suppliers; test in a controlled subset of jobs/environments.

- Acceptance criteria:

- Tension holding over test period; edge safety; compatibility with tools and buckles; rework/returns <= agreed threshold.

- Decision gate:

- Approve, reject, or require corrective action; update specs, tooling, or processes accordingly.

7) Contract and scale

- Contract essentials:

- Specifications (grade, width, thickness, length), packaging, labeling, QA documentation (MTCs).

- Incoterms (e.g., DDP/DAP for USA/EU), lead time, stock cover, safety stock levels.

- Payment terms, price valid period, indexation clauses, escalation path.

- Quality remedies (rejection/returns), on-time delivery SLAs, audit rights.

- Onboarding:

- Standardize SKU coding; update inventory and reorder points; train teams on edge safety and proper tool use.

- Maintain a vendor scorecard and quarterly business review cadence.

Quick reference snapshot (Amazon channel context)

- Typical kit content:

- 304 stainless steel banding coil (often 3/4″ x ~95’–100′).

- Steel buckles/seals (often 100 pcs), ratchet/cutter tensioner tool, sometimes hammer and gloves.

- Example price points (USD):

- Coil-only: ~$30.99 (3/4″ x 95′).

- Complete kits with tools/buckles: ~$79.39–$129.99 (100 ft banding).

- Delivery timing (USA):

- Often within 3–14 days depending on seller and region.

- Selection notes:

- Kits are cost-effective for pilots/low-volume; bulk sourcing via industrial channels lowers unit cost and secures supply.

8) Due diligence questions to ask suppliers

- Grade and certification:

- Is the band 304, 316, or 316L? Can you provide MTCs and lot traceability?

- Mechanical and edge performance:

- Thickness, minimum breaking strength, edge finish (smooth/rolled), cut risk and PPE recommendations.

- Compatibility:

- Buckle/seal dimensions and tolerances; tool torque ranges; available replacement parts.

- Inventory and service:

- Current stock (coils and hardware), lead time, shipping lanes (USA/EU), SLA for replenishment.

- Commercials:

- MOQ, packaging (coils per carton/pallet), labeling, Incoterms, payment terms, return policy.

Use this checklist to streamline specification, vendor selection, pilot qualification, and contract management. Adjust compliance checks to your facility’s standards and regulatory requirements, and always pair banding with compatible tools and seals to ensure performance and safety.

Comprehensive Cost and Pricing Analysis for s banding Sourcing

Comprehensive Cost and Pricing Analysis for Stainless Steel (s) Banding Sourcing

What you’ll pay: price benchmarks and units of value

The price for stainless steel banding depends on strip width, grade (304/316), roll length, and whether tooling (tensioner) or seals/buckles are included. To make sourcing decisions comparable across suppliers, normalize to $/ft and $/ft incl. seals.

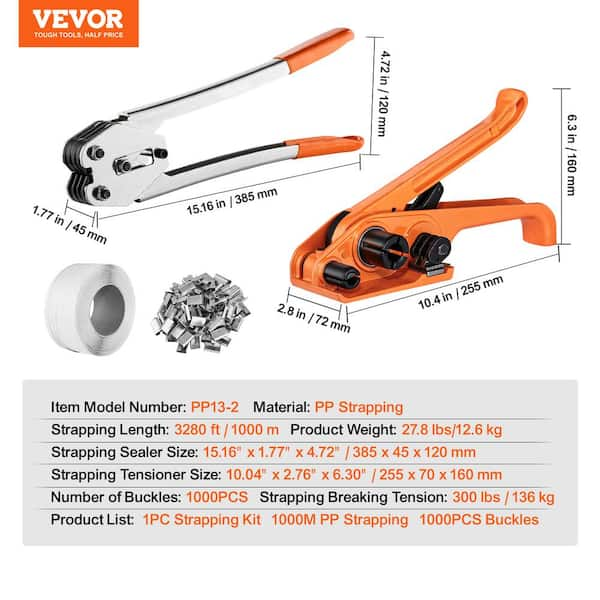

Illustrative Image (Source: Google Search)

Table: Normalized price benchmarks from current retail listings (USD, Amazon.com)

| Option | Width | Length | Includes tools/seals | Total price | Unit price ($/ft) | Unit incl. seals ($/ft) | Notes |

|---|---|---|---|---|---|---|---|

| 3/4″ x 95′ coil (304) | 0.75 in | 95 ft | No | $30.99 | $0.33 | n/a | Coil only |

| 3/4″ x 100′ kit (VEVOR) | 0.75 in | 100 ft | Tensioner + seals | $79.39 | $0.79 | $0.54 | Kit includes 100 seals; $/ft assumes 2 seals per ft |

| 3/4″ x 100′ kit (FoundGo) | 0.75 in | 100 ft | Tensioner + seals | $85.99 | $0.86 | $0.61 | Kit includes ~100 seals |

| 3/4″ x 200′ kit (FoundGo) | 0.75 in | 200 ft | Tensioner + seals | $109.99 | $0.55 | $0.37 | Better $/ft due to longer roll |

Key takeaways:

– For banding coil only, benchmark price is roughly $0.30–$0.35/ft at retail for 3/4″ x 100′ 304 stainless.

– Kits improve $/ft because tooling and seals are bundled, though the real value is in time saved and fewer separate SKUs.

– Longer rolls compress $/ft; the 200 ft kit improves unit economics compared with two 100 ft kits.

Material cost drivers to watch:

– Grade and thickness: 316/201 cost more/less than 304; thicker gauges add weight and cost.

– Width: 1/2″ typically costs less per foot but may require more wraps; 3/4″ is common for palletization and heavier bundling.

– Surface: Smooth vs. embossed can change friction and seal performance; embossed sometimes commands a premium.

– Core size and packaging: Longer, larger-diameter coils reduce core and handling costs per foot.

Cost breakdown approach for procurement

Use a simple template to structure pricing, whether evaluating retail kits or wholesale quotes.

Illustrative Image (Source: Google Search)

Cost breakdown template

| Component | What to include | How to estimate |

|---|---|---|

| Materials | Banding coil (grade, width, length), seals/buckles (type, finish), any wax or edge protection | Convert retail $/ft or request wholesale $/lb and convert using coil weight. |

| Tooling | Tensioner, cutter, hammer, gloves | Either amortize over projects or treat as one-off CapEx. |

| Logistics (domestic) | Freight to your facility (parcel or LTL), handling | Add actual freight quote; parcel often $15–$35 per order; LTL tiered by pallet count and zone. |

| Logistics (imports) | Ocean/air freight, drayage, customs clearance, duties/VAT, last-mile | For USA: 25% duty (HTS 7326.90.8590). For EU: 2.5% duty + 22%–25% VAT on CIF + duty + handling. Freight dominates transit time/cost; consolidate loads to improve unit rates. |

| Compliance & risk | Supplier QC (salt spray test, break strength), documentation, claims handling | Quantify as a % of material cost to reflect returns, rework, and downtime risk. |

| Labor | Banding application time | USA average ~$22–$26/hr; EU ~€17–€25/hr depending on country. A typical pallet band takes ~60–120 seconds; factor in fatigue and safety requirements. |

Estimating materials from wholesale pricing:

– If quote is $X per lb for 3/4″ x 100′ x 0.030″ 304 coil, compute:

– Coil weight (lb) ≈ length(ft) × width(in) × thickness(in) × 0.29 (density factor).

– Example: 100′ × 0.75″ × 0.030″ × 0.29 ≈ 0.6525 lb; at $8.50/lb, coil ≈ $5.55; seals add $0.01–$0.03/ft based on vendor.

– Retail coil pricing converts to $22–$35/lb at short lengths—typically higher than wholesale. Consolidate and buy longer coils to reduce effective $/lb.

Logistics snapshot for USA and EU

- Domestic USA:

- Parcel: $15–$35 per order (retail kits often free ship thresholds; wholesale requires quotes).

- LTL: Tiered by pallet count (1–3+ pallets) and distance; request zone-based quotes from carriers.

- EU import:

- Ocean freight dominates cost/time; consolidate to container or shared LTL.

- Add 2.5% duty and 22%–25% VAT on CIF value (goods + freight + insurance + duties). Budget for customs handling fees.

- Supplier terms:

- FOB vs DDP (Delivered Duty Paid) impacts landed cost planning; confirm Incoterms early.

Labor: the often-overlooked cost driver

Band application costs depend on strap configuration, load stability, and operator tool proficiency. Using a ratchet tensioner reduces cycles per joint; heavier/ wider strap reduces wraps.

Illustrative scenario (per 100 pallets/day; assume 2 bands/pallet; ~120 sec per band)

Illustrative Image (Source: Google Search)

- Labor time: 100 pallets × 2 bands × 120 sec = 6.7 hours

- Labor cost: USA ≈ 6.7 hr × $22–$26 = $147–$174/day; EU ≈ 6.7 hr × €17–€25 = €114–€168/day

- Incremental options to reduce time: pre-cuts, standardized seal count, better tensioner ergonomics, training.

How to read offers and plan benchmarks

- Convert to $/ft and $/ft incl. seals to compare apples-to-apples.

- Strip out tools: if a kit includes tensioner, amortize tool cost to get banding+seals-only $/ft.

- Consider length: longer rolls improve unit cost and reduce changeovers.

- Check seals per foot: most kits include ~2 seals/ft for 3/4″ width; align this with your application to avoid waste.

Practical tips to reduce cost without compromising quality

- Standardize on one width and grade (e.g., 3/4″ 304) to simplify purchasing and reduce dead stock.

- Buy longer rolls (100–200+ ft) to improve $/ft; avoid frequent roll changes for high-volume lines.

- Negotiate duty exemptions for EU via AEO/simplified customs when viable; ensure supplier classification is accurate.

- Compare wholesale vs retail: verify coil weight (thickness), confirm seal type (stainless vs carbon steel), and request samples for salt spray testing.

- Bundle logistics: consolidate shipments to improve freight per foot; explore LTL agreements if palletizing in-house.

- Use DDP quotes from EU suppliers to simplify budgeting; otherwise, model duty + VAT to avoid unexpected costs.

- Track actual application time by job type; invest in better tensioners or fixtures if manual time > 120 sec/band.

- Optimize seal count: many applications perform well with 1 seal/ft on light bundling; reserve 2 seals/ft for transit-critical loads.

- Maintain tool maintenance: regular inspection and cleaning of ratchets reduces downtime and rework.

When to choose retail kits vs wholesale sourcing

- Choose retail kits:

- Low volume, urgent replenishment, or initial trials.

- Need rapid onboarding (pre-bundled tools + seals).

- Value convenience and free ship thresholds over $/ft.

- Choose wholesale:

- Stable demand (pallets/day, bundles/month).

- Willingness to maintain tooling and logistics planning.

- Opportunity to reduce cost per foot and secure consistent quality across rolls.

A quick procurement check-list

- Unit conversion: $/ft and $/ft incl. seals for every quote.

- Grade/width/thickness: confirm and test sample strength and seal performance.

- Seals/buckles: type and finish; check seal-to-strap compatibility.

- Freight terms: Incoterms, transit time, customs handling; budget for duty/VAT.

- Quality docs: salt spray hours, break strength, batch traceability.

- Trial run: measure banding time and rework rates on representative loads.

- Inventory policy: roll lengths, reorder points, safety stock, vendor lead times.

Benchmark guidance:

– Expect retail coil-only pricing around $0.30–$0.35/ft for 3/4″ x 100′ 304 stainless.

– Expect banding+seals in kits around $0.35–$0.65/ft depending on length and vendor.

– Wholesale quotes should materially undercut retail on coil cost; ensure you model seals, freight, and tooling to compare effectively.

Alternatives Analysis: Comparing s banding With Other Solutions

Alternatives Analysis: Comparing s banding With Other Solutions

For B2B uses (palletizing, bundling, anchoring, building services), the most common s banding alternatives are:

– Galvanized steel strapping (steel band)

– Polyester (PET) strapping

Below is a technical comparison table followed by a focused analysis.

| Attribute | s banding (Stainless Steel) | Galvanized Steel | Polyester (PET) |

|---|---|---|---|

| Corrosion resistance | Excellent; stainless 304/316 resists rust, chemicals, and moisture | Moderate; zinc coating offers basic protection but can corrode in salt/air, cut edges are vulnerable | Good; inherently corrosion-resistant (no rust), unaffected by moisture |

| Tensile strength | High | High | Moderate–High (typically less than steel) |

| Toughness (impact/shock) | High; absorbs shock without fracturing | High | Moderate; can crack under heavy shock or low temperatures |

| Elongation (stretch) | Low (elastic recovery is limited) | Low | Moderate–High (elongates to absorb shock; can relax under sustained load) |

| Temperature use | Wide range; performs in sub-zero to high-temp environments | Broad range; zinc can degrade at higher temperatures | Moderate; heat can reduce strength; cold can increase brittleness (formulations vary) |

| Edge safety/handling | Sharp edges; requires gloves and careful handling | Sharp edges; requires gloves and careful handling | Softer edges; lower risk of cuts |

| Reusability | Reusable if sealed properly; seal removal can damage band | Similar to stainless for reuse | Often single-use; re-tensioning can be unreliable after initial setting |

| Typical use cases | Heavy-duty outdoor bundling, anchor strapping, harsh environments | Indoor/outdoor general strapping; cost-conscious applications | Light–medium duty packaging, unitizing loads, automated systems |

| Price signals (consumer retail) | Coils ~$30.99 (3/4” x 95’, 304); kits ~$85–$130 with tensioner/seals (varies by size/brand) | Generally lower than stainless for the same spec | Generally lower than stainless for comparable duty; automated equipment cost is separate |

| Compliance and hygiene | Non-magnetic grades available; food-safe options | Coatings may limit food contact | Food-grade grades available; widely used in packaging |

Focused Analysis

- If your application is outdoors, humid, chemical exposure, or long-service life is required, s banding (stainless) is the most resilient choice. It avoids corrosion pitfalls that can cause steel failures, especially where zinc protection is compromised.

- If you are cost-driven and the environment is moderate (indoor, infrequent moisture), galvanized steel delivers steel performance at lower upfront cost. Be prepared to manage potential corrosion at cut edges or under abrasion.

- If you are primarily palletizing goods with less extreme duty, or if automated strapping machinery is preferred, PET strapping can reduce cost and tooling complexity. Be mindful of strength limits, temperature sensitivity, and the fact that many PET applications are single-use.

Essential Technical Properties and Trade Terminology for s banding

Essential Technical Properties and Trade Terminology for S Banding

S banding refers to stainless steel strapping (also written “S-banding”). It is used for bundling, palletizing, securing loads, and general-purpose fastening where high strength and corrosion resistance are required. Typical B2B widths on the US/EU market are 1/2 in, 5/8 in, 3/4 in, and 1 in; common lengths are 100 ft and 200 ft per coil/roll.

Illustrative Image (Source: Google Search)

Core technical properties to specify

| Category | Key parameters | Typical values or options | Notes |

|---|---|---|---|

| Material grade | Stainless steel family and grade | 304/304L (18-8), 316/316L; 201 as lower-cost alternative (Asia) | For severe environments or coastal/marine use, prefer 316/316L. Always verify grade on the product page (Amazon listings often specify 304). |

| Coating | Finish/coating | Uncoated (bright annealed); PVC-coated | PVC coatings add wear resistance and protection; note reduced bend capacity vs uncoated. |

| Width x Thickness (WxT) | Standard widths | 1/2 in (12.7 mm); 5/8 in (15.9 mm); 3/4 in (19.0 mm); 1 in (25.4 mm) | Check product page for exact thickness and total thickness when PVC-coated. |

| Length | Coil/roll length | 100 ft, 200 ft (many kits) | Longer coils reduce splices; ensure fitment with your tensioner. |

| Finish | Surface finish | Bright annealed (non-magnetic to weakly magnetic), polished, embossed/smooth options | Embossing can improve grip; finish affects appearance and scratch concealment. |

| Edge condition | Deburred vs cut | Deburred edge reduces cut hazards | Safer handling; some applications prefer cut-edge for cost. |

| Temperature range | Service temperature | ~−50 to +150 °C (PVC coated); up to ~+400 °C for uncoated austenitic | Performance declines at very low temperatures; consult datasheet for cryogenic or higher-temperature service. |

| Magnetism (304/316) | Magnetic response | Non-magnetic to slightly magnetic depending on cold work | Slight magnetism does not indicate corrosion performance. |

| Compliance | Typical standards and references | Material per ASTM A666/A240 (flat products). Strap and seals often aligned to ISO 14310/EN 12195 (for straps/seals used as cargo securing). | Markings vary by supplier; always verify on the product page. |

| Tool compatibility | Strap/seal/tool matching | Use compatible seals (e.g., 300-series stainless) and tensioners for the band width | Tool set often included in kits (100 ft and 200 ft kits common on Amazon). |

If an exact design value is critical (e.g., breaking strength, proof load, elongation, clamp force), obtain the supplier’s datasheet before committing to purchase. Many product pages (e.g., Amazon) will state only grade, width, length, and included accessories.

Trade terminology (B2B)

| Term | Meaning (B2B) | Notes |

|---|---|---|

| MOQ | Minimum order quantity | Common to be one carton/box or 1–5 coils per SKU. |

| Lead time | Time from PO to shipment | Often 1–3 weeks for stocked widths; longer for special finishes. |

| OEM | Original equipment manufacturer (custom branding) | Coil labels, packaging, and seal design can be customized (e.g., your logo). |

| Custom size | Non-standard W x T or finish | 316/316L and special coatings often require custom orders. |

| Packaging | Palletizing, strapping, and wrap | 100/200 ft coils are typical; check if coils come in a plastic case. |

| QA/QC | Quality assurance/control | Common checks: grade verification (XRF), thickness, tensile testing, seal shear testing. |

| Certificates | Documentation provided | Material certificates (MTCs), ROHS/REACH compliance statements, etc. Always request and verify. |

| Price unit | Quotation unit | Typically per coil or per carton (with net and gross weight). |

| Incoterms | Trade terms (FOB, CIF, DAP, DDP) | Clarify freight, insurance, and delivery responsibilities. |

| HS code | Commodity classification | Stainless strap is commonly classified under heading 7326; confirm locally (US/EU codes differ by product form). |

| Payment | Terms and methods | Often T/T 30–60 days for established accounts; credit card for small orders on Amazon listings. |

| Samples | Trial material | Expect small fees for custom coil samples; lead time for sampling 1–2 weeks. |

| Warranty/Returns | After-sales | Specify return window, condition requirements, and who pays return freight. |

| Compliance | Standards, directives | REACH and ROHS apply to coatings such as PVC; verify declaration on the product page. |

| Logistics | Carriers and freight | US: UPS/FedEx for small kits; LTL/TL for bulk. EU: courier for small; palletized shipping for bulk. |

| Origin | Manufacturing location | Many coils made in Asia; ask about regional stocking (US/EU). |

Practical buying notes (USA/EU):

– Width/length commonly supplied: 1/2 in, 5/8 in, 3/4 in, 1 in; 100 ft and 200 ft lengths are standard among kits on platforms like Amazon.

– For heavy-duty outdoor use or harsh environments, specify 316/316L stainless and stainless seals; verify grade on the product page before purchase.

– For best value: unembossed bright annealed coils are typically lower cost; embossed or PVC-coated versions are premium options.

If you need specific mechanical values (tensile strength, elongation, seal performance) or custom dimensions/coatings, request the supplier’s datasheet and confirm MOQ, lead time, and payment terms in writing.

Navigating Market Dynamics and Sourcing Trends in the s banding Sector

Navigating Market Dynamics and Sourcing Trends in the Stainless Steel Banding (s‑banding) Sector

Market conditions in stainless steel banding reflect the broader stainless chain—raw materials, manufacturing capacity, logistics, and B2B buyer behavior. For U.S. and European buyers, the priorities are stable supply, total cost of ownership, and compliance with safety, corrosion, and procurement standards.

Illustrative Image (Source: Google Search)

Material and grade landscape

- 304 (18–8) dominates retail and mid‑duty B2B sourcing due to its balanced corrosion resistance and cost. 316L is preferred where chloride exposure, coastal conditions, or aggressive chemicals are present.

- Thicknesses of 0.030–0.038 in (0.76–0.97 mm) and widths of 3/4 in (19.05 mm) are common, aligning with widely stocked seals and tools.

- Finish options include unpolished (mill) and polished (Type 2 per EN 12166). Polishing can improve corrosion resistance and visual inspection.

Table: Typical product snapshots (market scan)

| Item (example) | Grade | Dimensions (in) | Length | Typical price (USD) | Features noted |

|---|---|---|---|---|---|

| Coil (roll) | 304 | 3/4 x 0.030–0.038 | ~95–100 ft | ~$31 (coil), ~$22+ (used/new) | Plastic case; corrosion‑resistant |

| Coil + ratchet tensioner/cutter + seals | 304 | 3/4 x 0.030–0.038 | 100 ft | ~$130 | Tool bundle; blue tray; stock limits |

| 200 ft kit with 100 seals and tensioner | 304 | 3/4 | 200 ft | ~$110 | Heavier bundle; extended lead times |

| Banding kit + seals (generic) | 304 | 3/4 | 100 ft | ~$85–$120 | Often includes gloves/hammer; coupons |

Note: Prices fluctuate; listings often change frequently. Products highlighted as “Overall Pick” by major marketplaces typically meet 4+ star ratings and high purchase volumes with low returns.

Pricing drivers

- Raw materials: Nickel and chromium prices drive stainless coil costs. Regional premiums and energy costs affect final bands and tooling price levels.

- Packaging and tooling: Ratchet tensioners and cutters add material and labor cost; bulk kits carry a premium relative to coils but reduce transaction overhead.

- Logistics and timing: Free delivery windows and “order soon” flags imply variable stock levels; longer shipping windows (10–20 days) can indicate spot inventory or replenishment cycles.

Table: Pricing components (qualitative view)

| Component | Impact on price | Typical variability (qualitative) | Buyer note |

|---|---|---|---|

| Raw material (304/316L coil) | High | Medium–High | Nickel/chromium exposure affects coil premiums |

| Tooling (ratchet/cutter) | Medium | Low–Medium | Bundles add value but increase line item costs |

| Packaging and accessories | Low | Low | Gloves, hammers increase freight and handling |

| Shipping lead time | Low–Medium (indirect cost) | Medium–High | Lead times drive expediting and stock carry cost |

Sourcing strategies

- Standardize to 304 with 316L exceptions for corrosive environments.

- Specify thickness, width, and finish (Type 2) upfront; insist on EN 13431 compliance (minimum breaking force criteria).

- Source coils and seals together to match width and gauge; avoid cross‑supplier mismatches.

- Verify ASTM A666/A240 or equivalent material properties on request; request mill certificates for lot traceability.

- Confirm tooling compatibility (tensioner/cutter); evaluate total cost of ownership rather than per‑unit price.

- Use reputable suppliers for safety and efficiency; prioritize products with consistent ratings, low return rates, and “Overall Pick”/“Amazon’s Choice” signals only after technical validation.

Sustainability and material handling

- Stainless banding is 304/316L steel: durable, fully recyclable, and does not require surface coatings that add VOCs or plastic waste.

- Polished finishes can extend service life and reduce rework, lowering lifecycle waste and transport emissions.

- Reusable plastic cases for coils minimize single‑use packaging.

Quality, performance, and lead times

- 304 offers broad utility for general packaging and construction applications; 316L is the standard for saltwater, road‑salt environments, and chemical exposure.

- Typical lead times range from 5–10 days for in‑stock items to 10–20 days for extended shipping; “Only 20 left” flags signal constrained availability.

- Buyers should monitor stock status and delivery windows; bulk kit pricing may be favorable, but lead time and stock levels can offset logistics savings.

Compliance and supplier selection checklist

- Grades: 304 for standard duty; 316L for corrosive/chloride exposure.

- Standards: EN 13431 compliance; ASTM A666/A240 for mechanical properties.

- Specs: Thickness 0.030–0.038 in; width 3/4 in; finish: unpolished or Type 2 polished.

- Tooling: Ratchet tensioner and cutter verified for band thickness and width.

- Documentation: Mill certificates, lot traceability, and packaging case details.

- Logistics: Stock proximity (U.S./EU), delivery windows, and packaging sustainability.

In short: standardize to 304, reserve 316L for harsher conditions, align tools and seals to width/thickness, and benchmark true total cost and lead times. This approach stabilizes cost and availability while ensuring performance and compliance in the s‑banding supply chain.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of s banding

Frequently Asked Questions (FAQs) for B2B Buyers of Stainless Steel Banding

1) What stainless steel grades and finishes are available?

- Common grades:

- 304/304L: general-purpose, corrosion-resistant for most environments.

- 316/316L: superior corrosion resistance for coastal, marine, or chemically exposed applications.

- 201: economy grade with lower corrosion resistance; use where exposure is mild.

- Finishes:

- Polished (Type 2): smoother, less edge catch; often preferred for cable bundling and clean installations.

- Mill (Type 1): standard finish for heavy-duty strapping; cost-effective.

2) What widths, thicknesses, and tensile strengths are typical?

- Widths: 1/2″ (12.7 mm), 5/8″ (15.9 mm), 3/4″ (19 mm), 1″ (25.4 mm), 1-1/4″ (31.8 mm).

- Thicknesses: 0.015″ (0.38 mm), 0.020″ (0.50 mm), 0.025″ (0.63 mm), 0.030″ (0.76 mm), 0.035″ (0.89 mm).

- Tensile strength (typical):

- 304/304L: ~75,000 psi (515 MPa).

- 316/316L: ~70,000 psi (480 MPa).

- 201: ~60,000 psi (414 MPa).

- Typical coil lengths: 100 ft and 200 ft; bulk coils and custom slitting available.

3) How do I select the right seal/buckle and what coatings are offered?

- Seal types:

- Wing seals (painted steel): lower initial tension; fastest, lowest cost.

- Code 1 or Regular seals (stainless or galvanized steel): higher tension and grip; recommended for critical loads.

- Coatings:

- Painted/sealed buckles: reduce minor galvanic interaction and improve handling; do not change strap grade or inherent corrosion resistance.

- Uncoated (plain) buckles: most economical; suitable where galvanic concerns are minimal.

4) What certifications and compliance can I expect?

- Stainless steel banding is generally compliant with REACH (SVHC) and RoHS; material declarations (RoHS/REACH) are available on request.

- Certificates available:

- Mill Test Certificates (MTC) or Material Test Report (MTR) confirming grade and mechanical properties.

- Documentation provided as PDF; printed copies on request.

- EU-specific: compliance and origin documentation; customs tariff code guidance available.

5) How is stainless steel banding priced and what affects cost?

- Pricing is usually per foot for coils or per kit for bundled solutions (band + seals + tools).

- Cost drivers:

- Grade (316 > 304 > 201).

- Thickness and width (thicker/wider = higher cost per foot).

- Finish and surface quality.

- Quantity (economies of scale in bulk).

- Logistics (freight, palletization, destination in USA/EU).

- Kits can combine tooling (tensioner/cutter/seals) with the band coil; they are convenient for initial procurement.

6) What are the MOQs and lead times for USA and Europe?

- MOQs:

- Coils: typically 50–200 coils (size-dependent) for bulk orders.

- Seals/buckles: commonly 1,000–5,000 pcs per size.

- Kits: 10–50 units depending on tool stock.

- Lead times:

- USA: stock items 1–2 weeks; bulk/custom slitting 3–6 weeks.

- Europe: stock items 1–2 weeks; bulk/custom 4–8 weeks depending on warehouse location and finish.

- Exact lead times vary by spec; confirm at time of order.

7) What packaging and labeling are provided?

- Packaging:

- Coils: individually boxed or in plastic cases; strapped and palletized for shipment.

- Seals: boxed or bagged with barcode labels.

- Labeling:

- SKU, width, thickness, grade, length, batch/lot, and compliance indicators on each carton or coil label.

- Tooling:

- Standard ratchet tensioners and cutters available; optional cut-resistant gloves included in some kits.

8) How should I specify and install banding correctly?

- Specify with: grade, finish, width, thickness, tensile strength, coil length, seal type, buckle type and finish, quantity, desired documents (MTC/RoHS/REACH), and destination.

- Installation tips:

- Choose the correct seal/buckle for your width and load.

- Tension to manufacturer-recommended levels; avoid over-tension to prevent strap damage.

- Use compatible tensioner/cutter; apply a double-overlap where required by your application.

- Inspect for sharp edges on cut ends; deburr if necessary.

- Wear cut-resistant gloves during installation for safety.

Strategic Sourcing Conclusion and Outlook for s banding

Strategic Sourcing Conclusion and Outlook

Stainless steel banding delivers superior value where strength, corrosion resistance, and reliability matter. Across North American and European operations, 304/316 stainless outperforms galvanized and plastic alternatives in harsh, wet, and outdoor environments, reducing downtime and rework while extending service life. With widths of 3/4 inch, 0.030–0.035 inch thickness, and 1,200–1,500 lb break strength when properly sealed, it is the preferred solution for heavy-duty bundling, pipe support, and load securement in construction, utilities, packaging, and transportation.

Total cost of ownership (TCO) advantages accrue from:

– Durability and fewer replacements

– Reduced safety incidents via proven tools (tensioner/cutter)

– Consistent performance with standardized buckles and seals (AISI 304/316)

– Compliance with relevant standards and environmental exposure

– Predictable sourcing through kit or coil formats

Typical 100 ft kit price bands on commodity marketplaces have recently ranged from ~$80 to ~$130 depending on inclusions (tensioner, cutter, buckles, gloves, case). For high-volume procurement, expect lower unit costs and better payment terms.

Short‑term outlook (2025): Expect price volatility tied to nickel and steel inputs; lead times may stretch during supply disruptions. Strategic mitigations include:

– Multi‑sourcing and buffer stock for critical widths (e.g., 3/4 inch)

– Annual indexing contracts with price collars

– Supplier audits for quality (magnetization, thickness tolerance, buckle strength)

– Tool‑standardization to improve ergonomics and safety

– Packaging and logistics optimization (coils vs. kits) for freight efficiency

Illustrative Image (Source: Google Search)

Action: Qualify at least one US and one EU distributor, align specs across sites, and consolidate purchase orders. This stabilizes cost, enhances safety, and supports sustainability goals with long‑lived materials.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.