The global rug making machine market is experiencing steady growth, driven by rising demand for automated textile manufacturing and increasing consumer preference for patterned and customized floor coverings. According to Mordor Intelligence, the textile machinery market—which includes rug making equipment—is projected to grow at a CAGR of over 5.2% from 2024 to 2029. Similarly, Grand View Research valued the global textile machinery market at USD 102.8 billion in 2023 and forecasts continued expansion, supported by technological advancements and the growing adoption of computerized and digitally controlled weaving and tufting systems. As the demand for efficient, high-precision rug production scales across both industrial and artisanal sectors, manufacturers are turning to innovative machine solutions that optimize speed, design flexibility, and material waste reduction. In this evolving landscape, a select group of manufacturers has emerged as leaders, combining engineering excellence with cutting-edge automation to meet the complex needs of modern rug producers worldwide.

Top 10 Rug Making Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

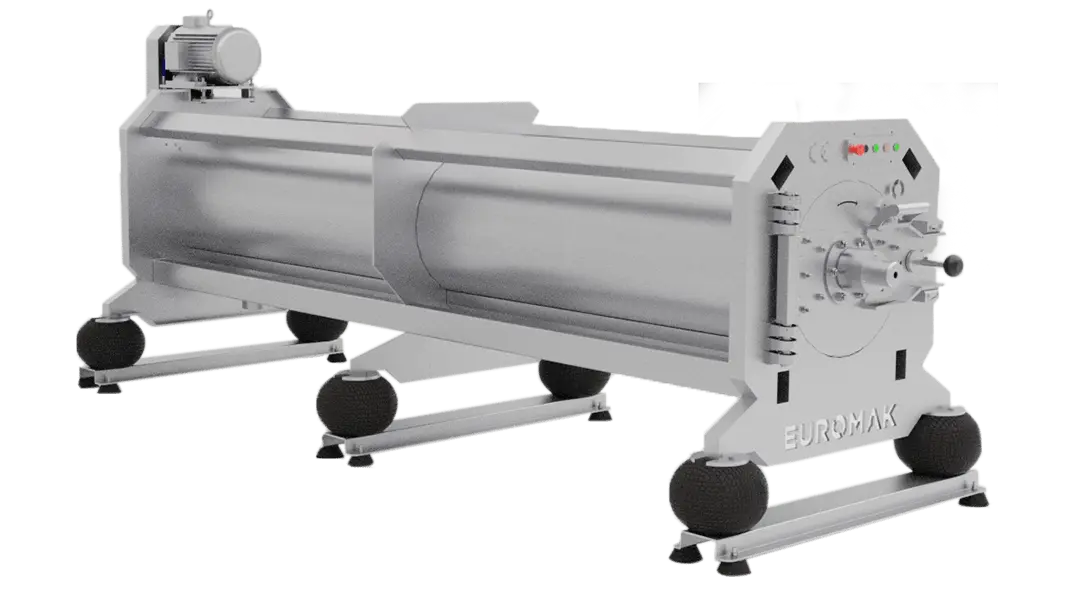

#1 Carpet Centrifuge Rug Spinner Machines

Domain Est. 2021

Website: euromakusa.com

Key Highlights: Euromak USA is the official North American distributor of Euromak, a globally recognized Turkish manufacturer of industrial carpet and rug cleaning equipment….

#2 Millstek

Domain Est. 2000

Website: millstek.com

Key Highlights: Millstek specialises in Hand Tufting (handtufting) equipment for area rugs, carpets and wall hangings from leading European Manufacturers….

#3 Automatic Custom Rug Carpet Tufting Machine

Domain Est. 2021

Website: tuftmachine.com

Key Highlights: Haochuan Group is a professional manufacturer of custom rug carpet Tufting Machine, mainly do rug tufting machine and also carpet tufting machine….

#4 Carpet weaving machines for any kind of carpet

Domain Est. 1996

Website: staubli.com

Key Highlights: Under the brand Schönherr Stäubli develops and produces high-quality double carpet rapier weaving machines. Rooted in tradition and based on more than 150 ……

#5 Carpet weaving machines

Domain Est. 1997

Website: vandewiele.com

Key Highlights: Introducing our carpet weaving machines, designed to elevate your manufacturing processes to unprecedented levels of efficiency and accuracy….

#6 Carpet Manufacturing Machines

Domain Est. 2005

Website: ategroup.com

Key Highlights: A.T.E. India brings a wide range of carpet manufacturing machines and hi-tech solutions for textile applications. To know more visit us now!…

#7 Rug Tufting Machines and Supplies

Domain Est. 2019

Website: tufttheworld.com

Key Highlights: 30-day returnsEverything you need to make professional and stunning rugs using our tufting supplies, including machines, cloth, yarn, and a community of creators like ……

#8 iMakeRugs

Domain Est. 2020

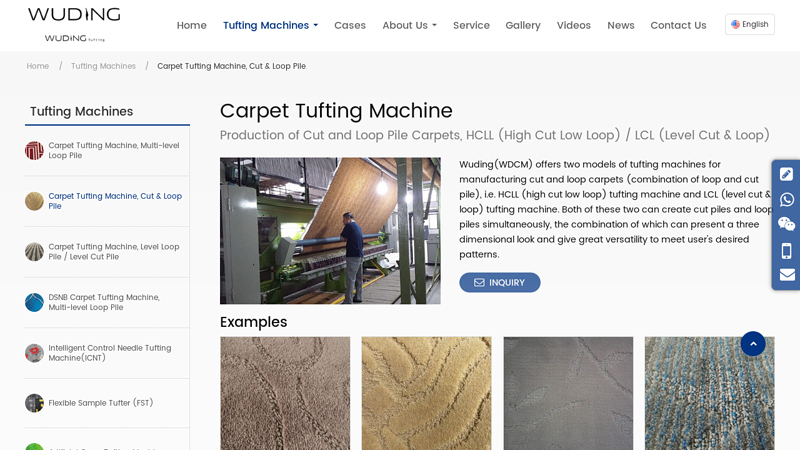

#9 Production of Cut and Loop Pile Carpets, HCLL …

Domain Est. 2021

Website: carpet-machinery.com

Key Highlights: WDCM offers two models of tufting machines for manufacturing cut and loop carpets, i.e. HCLL (high cut low loop) and LCL (level cut & loop), ……

#10 Tufting Robot

Website: efab.de

Key Highlights: ROBOTIC TUFTING MACHINE · Advanced robotic tufting machine for the production of fashionable tufted carpets and custom-made artificial grass….

Expert Sourcing Insights for Rug Making Machine

H2: 2026 Market Trends for Rug Making Machines

The global rug making machine market is anticipated to undergo significant transformation by 2026, driven by technological innovation, evolving consumer preferences, and shifting manufacturing dynamics. This analysis explores key trends shaping the industry landscape in the lead-up to 2026.

1. Automation and Smart Manufacturing Integration

A dominant trend in the rug making machine sector is the increasing adoption of automation and Industry 4.0 technologies. By 2026, manufacturers are expected to integrate IoT-enabled machinery, AI-driven design software, and real-time monitoring systems into rug production lines. These advancements enhance precision, reduce waste, and improve operational efficiency. Automated tufting, weaving, and finishing machines are becoming standard in large-scale production facilities, particularly in regions with rising labor costs.

2. Sustainable and Eco-Friendly Production

Sustainability is a growing imperative influencing machine design and functionality. Rug making machines in 2026 are likely to emphasize energy efficiency, reduced water consumption (especially in dyeing and finishing processes), and compatibility with recycled and biodegradable fibers. Machine manufacturers are responding to environmental regulations and consumer demand by developing low-emission systems and closed-loop water recycling technologies.

3. Customization and On-Demand Manufacturing

The trend toward personalized home decor is fueling demand for flexible rug making machines capable of small-batch and custom production. Digital tufting and jacquard weaving machines equipped with user-friendly CAD/CAM interfaces allow designers and small businesses to create bespoke patterns efficiently. This shift supports a growing market for made-to-order rugs, particularly in e-commerce and direct-to-consumer models.

4. Growth in Emerging Markets

Asia-Pacific, especially countries like India, China, and Turkey, will continue to be key growth regions for rug making machines due to their established textile industries and increasing domestic and export demand. Investments in modernizing traditional handcraft sectors with semi-automated machines are expected to expand production capacity and improve product consistency.

5. Advancements in Material Compatibility

Machine manufacturers are engineering rug making systems to handle a broader range of materials, including synthetic blends, natural fibers, and innovative composites such as PET from recycled plastics. By 2026, versatility in material processing will be a critical competitive advantage, enabling producers to meet diverse market needs—from durable commercial rugs to luxury handmade-style floor coverings.

6. Consolidation and Strategic Partnerships

The rug making machine industry is likely to see increased consolidation, with larger manufacturers acquiring niche technology providers to expand their product portfolios. Strategic partnerships between machine builders and textile innovators will accelerate the development of next-generation solutions, such as 3D-knitted rugs or antimicrobial surface treatments integrated during manufacturing.

In summary, the 2026 rug making machine market will be defined by smarter, greener, and more adaptable technologies. Companies that invest in innovation, sustainability, and digital integration will be best positioned to capitalize on evolving global demand.

Common Pitfalls When Sourcing Rug Making Machines (Quality and Intellectual Property)

Sourcing rug making machines, especially from international or unfamiliar suppliers, involves significant risks related to both machine quality and intellectual property (IP) concerns. Overlooking these pitfalls can lead to production delays, substandard output, legal disputes, and financial losses.

Poor Machine Quality and Performance

One of the most frequent issues when sourcing rug making machines is receiving equipment that fails to meet promised performance standards. Buyers may encounter machines constructed with substandard materials, leading to frequent breakdowns, inconsistent rug quality, and high maintenance costs. Machines may also lack essential safety features or fail to comply with local industry regulations. Additionally, inadequate after-sales support—such as unavailable spare parts, poor technical guidance, or delayed service—can severely disrupt operations. To mitigate this, conduct thorough due diligence: request live demonstrations, check references, inspect machines in person if possible, and ensure clear warranty and service agreements are in place.

Intellectual Property Infringement Risks

Sourcing machines from certain regions may expose buyers to intellectual property (IP) violations, particularly if the equipment copies patented technologies or designs from established manufacturers. Using such machines can result in legal action against the buyer, even if unintentional, including product seizures, fines, or reputational damage. Some suppliers may also use pirated software or control systems, which can introduce cybersecurity vulnerabilities or operational instability. To avoid IP pitfalls, verify the supplier’s legitimacy, request documentation proving original design rights or licensing agreements, and consider consulting legal experts familiar with international IP laws before finalizing procurement.

Logistics & Compliance Guide for Rug Making Machines

Overview

Importing or exporting rug making machines requires careful planning and adherence to international logistics and regulatory standards. This guide outlines key considerations for the safe, legal, and efficient transportation and compliance of rug making machinery across borders.

Packaging and Crating Requirements

Rug making machines are typically heavy, delicate, and composed of precision components. Proper packaging is essential to prevent damage during transit.

– Use robust wooden crates with internal bracing and anti-vibration materials.

– Apply moisture-resistant wrapping to prevent corrosion, especially for sea freight.

– Clearly label crates with handling instructions (e.g., “Fragile,” “This Side Up,” “Do Not Stack”).

– Include a detailed packing list inside and outside the crate, listing machine components and serial numbers.

Transportation Mode Selection

Choose the most suitable transportation method based on cost, delivery timeline, and machine size.

– Sea Freight: Recommended for large, heavy machines; cost-effective for full container loads (FCL) or less than container loads (LCL).

– Air Freight: Suitable for urgent shipments or smaller machines; faster but significantly more expensive.

– Road/Rail: Used for regional or domestic transport; ensure vehicles are equipped for heavy machinery.

Customs Documentation

Complete and accurate documentation is required to clear customs in both origin and destination countries.

– Commercial Invoice (detailing value, parties, and terms of sale)

– Packing List

– Bill of Lading (for sea) or Air Waybill (for air)

– Certificate of Origin

– Import/Export Licenses (if required)

– Technical Specifications Sheet (to determine HS Code and duties)

HS Code Classification

The Harmonized System (HS) code determines import duties and regulatory requirements.

– Typical HS Code for rug making machines: 8447.90 (Other machines for making textile fabrics).

– Confirm the exact code with local customs authorities, as classifications may vary by country and machine function.

Import Duties and Taxes

Research applicable tariffs, VAT, and other fees in the destination country.

– Duties vary by country; some offer reduced rates under trade agreements.

– Use a customs broker to calculate total landed costs and ensure correct payment.

Regulatory Compliance

Ensure the machine meets safety and technical standards in the destination market.

– Electrical Standards: Comply with local voltage, plug types, and safety certifications (e.g., CE in Europe, UL in the U.S.).

– Machine Safety: Adhere to directives such as the EU Machinery Directive 2006/42/EC or OSHA standards in the U.S.

– Environmental Regulations: Comply with RoHS (Restriction of Hazardous Substances) if applicable.

Installation and After-Sales Support

Plan for post-delivery logistics.

– Arrange for qualified technicians to handle machine uncrating, installation, and commissioning.

– Provide user manuals in the local language.

– Offer remote or on-site training and maintenance support.

Risk Management and Insurance

Protect against loss or damage during transit.

– Purchase all-risk cargo insurance covering the full value of the machine.

– Specify coverage for loading, transit, and unloading phases.

– Retain documentation for potential claims.

Conclusion

Successfully shipping rug making machines requires coordination between logistics providers, customs brokers, and compliance experts. By following this guide, businesses can minimize delays, reduce costs, and ensure safe delivery while meeting all regulatory obligations. Always consult local authorities and industry experts for jurisdiction-specific requirements.

Conclusion on Sourcing a Rug Making Machine

Sourcing a rug making machine is a strategic decision that requires careful consideration of production needs, budget, machine capabilities, and long-term business goals. After evaluating various types of machines—such as hand tufting guns, automated tufting machines, jacquard looms, and CNC carpet cutters—it is clear that the optimal choice depends on factors like production volume, design complexity, material type, and labor availability.

For small-scale or artisanal producers, hand or semi-automatic machines offer flexibility and lower upfront costs, while large-scale manufacturers benefit from fully automated systems that ensure consistency, speed, and efficiency. Additionally, sourcing from reputable suppliers, preferably with technical support and warranty coverage, is crucial to ensure machine reliability and minimize downtime.

Emerging trends such as digital design integration, eco-friendly production methods, and smart manufacturing technology also influence machine selection. Investing in a future-ready machine not only enhances productivity but also supports sustainable and innovative rug production.

In conclusion, a well-researched sourcing strategy—balancing cost, capability, scalability, and support—will empower businesses to improve quality, meet market demands, and maintain a competitive edge in the evolving textile and home décor industry.