The global rubber-coated magnet market is experiencing steady growth, driven by rising demand across automotive, electronics, industrial, and consumer goods sectors. According to Grand View Research, the global permanent magnet market—of which rubber-coated magnets are a key functional subset—was valued at USD 19.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.9% from 2023 to 2030. This growth is fueled by advancements in electric vehicles (EVs), increased adoption of energy-efficient motors, and the need for durable, corrosion-resistant magnetic components in harsh environments. Rubber-coated magnets, known for their protective layer that resists chipping, moisture, and wear, are increasingly preferred in assembly, automation, and mounting applications. As industries prioritize reliability and longevity in magnetic solutions, the role of specialized manufacturers capable of delivering high-performance rubber-bonded variants becomes more critical. Below are the top 10 rubber-coated magnet manufacturers at the forefront of innovation, scalability, and global supply.

Top 10 Rubber Coated Magnet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rubber Coated Magnets Factory, Manufacturers and Suppliers

Domain Est. 2015

Website: greatmagtech.com

Key Highlights: Excellent quality rubber coated magnets from ISO9001 and TS16949 certificated supplier, manufacturer and factory….

#2 Rubber Coated Magnet

Domain Est. 2013

Website: magnet-sdm.com

Key Highlights: A rubber coated magnet, also known as a rubber covered magnet, features a magnetic circuit encased in a protective rubber layer, designed to shield the magnet….

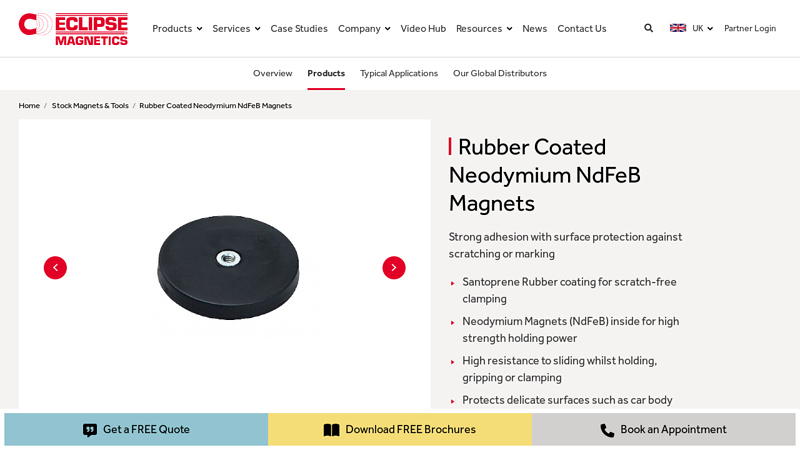

#3 Rubber coated Neodymium (NdFeb) Magnets

Domain Est. 2002

Website: eclipsemagnetics.com

Key Highlights: High power rubber coated Neodymium NdFeB Rare Earth magnets, great holding power, protect surfaces from scratching or marking….

#4 Rubber Coated Neodymium Magnets

Domain Est. 2003

Website: supermagnetman.com

Key Highlights: 6–7 day delivery 60-day returnsShop rubber coated magnets for high-friction grip. Great for prototyping holding systems, jigs, and fixtures where surfaces must stay protected….

#5 Rubber Coated Magnets

Domain Est. 2007

Website: first4magnets.com

Key Highlights: 4–6 day deliveryOur rubber coated magnets are designed to provide an incredible hold by increasing friction without marking or scratching surfaces….

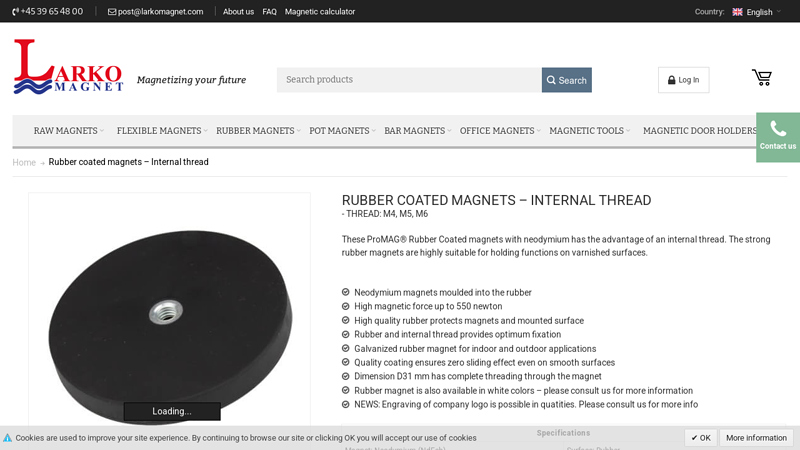

#6 Rubber coated magnets

Domain Est. 2014

Website: larkomagnet.com

Key Highlights: Rubber coated magnets with internal thread from Larko Magnet are produced of quality materials only, to ensure long durability and correct magnetic strength ……

#7 Neodymium (Rare Earth) Rubber Coated Magnets

Domain Est. 2016

Website: amfmagnets.com

Key Highlights: 30-day returnsStrong Neodymium rare earth mounting magnets with durable rubber coating which resists corrosion & protects easily scratched surfaces….

#8 Rubber Coated Magnets

Domain Est. 2018

Website: weizhongmagnetics.com

Key Highlights: These rubber-coated magnets are designed to provide an effective solution for organizing and mounting items such as cables, hoses, and pipes. They are an ……

#9 Rubberized Magnets

Domain Est. 2021

Website: tymagnets.com

Key Highlights: Rubberized magnets are magnets wrapped in a rubber shell. They are usually made of NdFeB magnets, iron sheets, and rubber shells. This structure can avoid ……

#10 Rubberized Neodymium Magnets

Domain Est. 2022

Website: wzmagnetics.com

Key Highlights: WZ Magnetics manufacture completely full range of Rubber Coated Pot Magnets for holding & Fasterning without drilling and weldings….

Expert Sourcing Insights for Rubber Coated Magnet

H2: Projected Market Trends for Rubber Coated Magnets in 2026

The global market for rubber coated magnets is expected to experience steady growth by 2026, driven by rising demand across various industrial and consumer sectors. Key trends shaping the market include technological advancements, increasing applications in green energy and automotive industries, and a growing emphasis on corrosion-resistant and durable magnetic solutions.

-

Expansion in Automotive and Electric Vehicle (EV) Applications

As the automotive industry shifts toward electrification, rubber coated magnets are increasingly used in motors, sensors, and sealing systems. Their resistance to vibration, moisture, and corrosion makes them ideal for EV components. By 2026, the integration of these magnets in battery systems and onboard electronics is projected to accelerate, particularly in regions with strong EV adoption policies such as Europe and China. -

Growth in Consumer Electronics and Home Appliances

The durability and safety offered by rubber coated magnets make them a preferred choice in consumer products such as smartphones, laptops, refrigerators, and smart home devices. With continued innovation in compact and efficient device design, demand for these magnets in precision applications is expected to rise. -

Adoption in Renewable Energy Systems

Rubber coated magnets are finding increased use in wind turbines and solar power equipment due to their ability to perform reliably in harsh outdoor environments. By 2026, expanding investments in renewable infrastructure are anticipated to boost demand, particularly in emerging markets. -

Regional Market Shifts

Asia-Pacific is expected to remain the largest market, led by manufacturing hubs in China, Japan, and South Korea. North America and Europe will see growth due to stringent environmental regulations and increased R&D spending. Meanwhile, Latin America and Africa are emerging as potential growth regions, driven by industrialization and infrastructure development. -

Material and Manufacturing Innovations

Advancements in coating technologies—such as eco-friendly rubber compounds and improved adhesion techniques—are enhancing product lifespan and performance. Manufacturers are also adopting automated production methods to improve consistency and reduce costs, supporting scalability. -

Sustainability and Regulatory Pressures

Environmental regulations are pushing manufacturers to develop recyclable and lead-free rubber coatings. By 2026, compliance with global standards such as RoHS and REACH will be a key differentiator in the market, influencing supply chain decisions and product design.

In summary, the rubber coated magnet market in 2026 will be characterized by strong demand from high-tech and sustainable industries, geographic diversification, and ongoing innovation in materials and manufacturing. Companies that invest in R&D and sustainable practices are likely to gain a competitive edge.

Common Pitfalls When Sourcing Rubber-Coated Magnets (Quality and IP)

Sourcing rubber-coated magnets can present several challenges related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure reliable supply and avoids legal or performance issues.

Poor Rubber Coating Quality

One of the most frequent quality issues is substandard rubber coating. This includes inconsistent thickness, pinholes, bubbles, or poor adhesion. Such defects compromise the magnet’s corrosion resistance and mechanical protection, leading to premature failure—especially in humid or abrasive environments. Low-quality rubber may also degrade quickly under UV exposure or temperature fluctuations.

Inadequate Magnet Performance Verification

Suppliers may overstate magnetic strength (e.g., pull force, gauss rating) or use lower-grade magnetic materials (e.g., substituting ferrite for neodymium). Without independent testing or material certifications, buyers risk receiving magnets that fail to meet application requirements, resulting in product malfunctions or safety concerns.

Lack of Compliance and Certification

Rubber-coated magnets used in consumer or industrial products may need to comply with safety and environmental standards (e.g., RoHS, REACH, FDA for food contact). Sourcing from suppliers without proper documentation risks non-compliance, legal liability, and market access issues.

Insufficient IP Protection and Risk of Design Copying

When providing custom designs or specifications to suppliers—especially overseas manufacturers—there’s a significant risk of intellectual property (IP) infringement. Without robust legal agreements (e.g., NDAs, IP ownership clauses), suppliers may replicate or sell your design to competitors. Patent, trademark, or design rights may also be difficult to enforce internationally.

Inconsistent Dimensional Tolerances

Poor manufacturing controls can lead to variations in size, shape, or coating thickness. Even minor deviations can affect fit and performance in precision applications, leading to assembly issues or reduced effectiveness.

Supply Chain Transparency and Traceability Issues

Many suppliers source raw materials from multiple sub-tier vendors without full traceability. This lack of transparency makes it difficult to verify material origins, ensure consistent quality, or respond to quality failures. It also increases the risk of counterfeit or recycled materials being used.

Hidden Costs from Rework or Failures

Initially lower prices may be offset by higher costs due to rejected batches, field failures, or the need for secondary quality checks. Poor-quality magnets can damage a brand’s reputation and lead to costly recalls or warranty claims.

Limited Technical Support and Communication Barriers

Working with suppliers who lack engineering expertise or have poor communication (e.g., language barriers, time zone differences) can delay problem resolution and increase the risk of misunderstandings around specifications or quality expectations.

To mitigate these risks, conduct thorough supplier audits, require material and performance certifications, protect IP through legal agreements, and consider third-party testing or on-site inspections during production.

Logistics & Compliance Guide for Rubber Coated Magnets

Rubber coated magnets are widely used in industrial, automotive, and consumer applications due to their enhanced durability, corrosion resistance, and reduced risk of chipping or scratching surfaces. However, their transport and handling involve specific logistics and compliance considerations, primarily due to the magnetic properties of the core material. This guide outlines key requirements for safe and compliant shipping and handling.

Classification and Regulatory Compliance

Rubber coated magnets contain permanent magnetic material (typically neodymium, ferrite, or samarium cobalt), which subjects them to international transport regulations. The rubber coating does not eliminate magnetic field emissions.

- IMDG Code (Maritime): Classified under Class 9 – Miscellaneous Dangerous Goods, UN 2807, “Magnetized Material”. Shipment requires evaluation of magnetic field strength.

- IATA DGR (Air): Regulated under Class 9, UN 2807. Air transport is strictly controlled due to potential interference with aircraft navigation systems.

- 49 CFR (U.S. Ground): Subject to DOT hazardous materials regulations as magnetized material (UN 2807, Class 9).

Key Compliance Requirement: The magnetic field at a distance of 2.1 meters (7 feet) from any point on the assembled package must not exceed 0.159 A/m (0.002 Gauss) to qualify for exemption from Class 9 labeling under IATA and IMDG.

Packaging Requirements

Proper packaging is critical to ensure safety and regulatory compliance.

- Shielding: Use ferromagnetic materials (e.g., steel plates or containers) around the magnets to contain the magnetic field and meet field strength limits.

- Separation: Individual magnets should be spaced or isolated using non-magnetic spacers to prevent attraction during transit, which can cause damage or injury.

- Immobilization: Secure magnets within packaging using foam, cardboard dividers, or molded inserts to prevent movement.

- Outer Packaging: Use strong, rigid containers (e.g., double-wall corrugated boxes or wooden crates) capable of withstanding stacking and handling.

- Marking & Labeling: If classified as dangerous goods (UN 2807, Class 9), packages must display:

- Proper shipping name: “Magnetized Material”

- UN number: UN 2807

- Class 9 hazard label

- Orientation arrows (if applicable)

- Shipper/consignee information

Note: Packages that meet the magnetic field threshold may be shipped as non-regulated, but documentation should confirm field measurements.

Documentation

Accurate documentation is essential for customs clearance and regulatory compliance.

- Safety Data Sheet (SDS): Provide an up-to-date SDS, typically under Section 14 (Transport Information), specifying UN number, proper shipping name, hazard class, and packaging group (if applicable).

- Shipper’s Declaration for Dangerous Goods: Required for air and sea shipments if classified as Class 9.

- Commercial Invoice & Packing List: Include detailed description, quantity, net/gross weight, and material composition (e.g., NdFeB core with rubber coating).

- Test Report: Include a magnetic field measurement certificate confirming compliance with 0.002 Gauss at 2.1 meters (if claiming exemption).

Handling and Storage

- Personnel Safety: Warn handlers about pinch hazards due to strong magnetic attraction. Keep magnets away from pacemakers, credit cards, and electronic devices.

- Storage: Store away from sensitive equipment. Stack packages securely and avoid placing near ferromagnetic materials.

- Temperature: Rubber coatings may degrade under extreme temperatures. Store and transport within manufacturer-recommended temperature ranges (typically -20°C to +80°C).

Environmental and End-of-Life Considerations

- Recycling: Neodymium and other rare earth elements are valuable and recyclable. Encourage end-user recycling programs.

- Disposal: Follow local regulations for disposal of magnets containing hazardous materials (e.g., heavy metals). Do not incinerate.

- RoHS & REACH Compliance: Confirm that both the magnetic core and rubber coating comply with relevant EU directives (e.g., no restricted substances like lead, cadmium, or certain phthalates).

Special Considerations for International Shipments

- Country-Specific Regulations: Some countries impose additional restrictions on magnetic materials or rare earth elements. Verify import requirements.

- Customs Delays: Improper classification or missing documentation can lead to delays. Clearly declare contents and provide compliance evidence.

- Insurance: Declare accurate value and specify magnetic content to ensure proper coverage.

By adhering to these guidelines, shippers and handlers can ensure the safe, compliant, and efficient transport of rubber coated magnets across global supply chains. Always consult with a certified dangerous goods safety advisor (DGSA) when in doubt.

Conclusion for Sourcing Rubber-Coated Magnets

Sourcing rubber-coated magnets requires a strategic approach that balances quality, cost, durability, and supplier reliability. These specialized magnets offer enhanced protection against corrosion, reduced surface damage, and improved grip, making them ideal for applications in industries such as automotive, electronics, manufacturing, and consumer goods.

After evaluating various suppliers, material specifications, coating types (e.g., neoprene, PVC, EPDM), and performance requirements, it is clear that selecting the right rubber-coated magnet involves understanding both technical needs and operational environments. Key considerations include magnetic strength, coating thickness, temperature resistance, and compatibility with target surfaces.

To ensure long-term success, it is recommended to partner with suppliers who provide consistent quality, customization options, and compliance with relevant industry standards. Conducting sample testing, assessing lead times, and negotiating favorable terms will further enhance supply chain efficiency.

In conclusion, effective sourcing of rubber-coated magnets hinges on thorough supplier vetting, clear technical specifications, and ongoing performance evaluation—ensuring reliable, cost-effective, and durable magnetic solutions for diverse industrial and commercial applications.