The global rotary tool accessories market is experiencing steady expansion, driven by rising demand across construction, metalworking, and DIY sectors. According to Grand View Research, the global rotary tool market was valued at USD 762.8 million in 2022 and is projected to grow at a CAGR of 4.3% from 2023 to 2030, fueled by advancements in cordless technology and increasing adoption in both professional and home workshops. As one of the leading power tool brands, DeWalt benefits from this upward trend, with a growing ecosystem of manufacturers producing compatible rotary tool accessories designed for durability and precision. These accessories—from grinding stones and cutting wheels to sanding drums and polishing pads—are essential for enhancing the versatility of DeWalt rotary tools. Below are the top 5 manufacturers producing high-performance rotary tool accessories optimized for use with DeWalt systems, selected based on product innovation, market presence, and user performance data.

Top 5 Rotary Tool Accessories Dewalt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

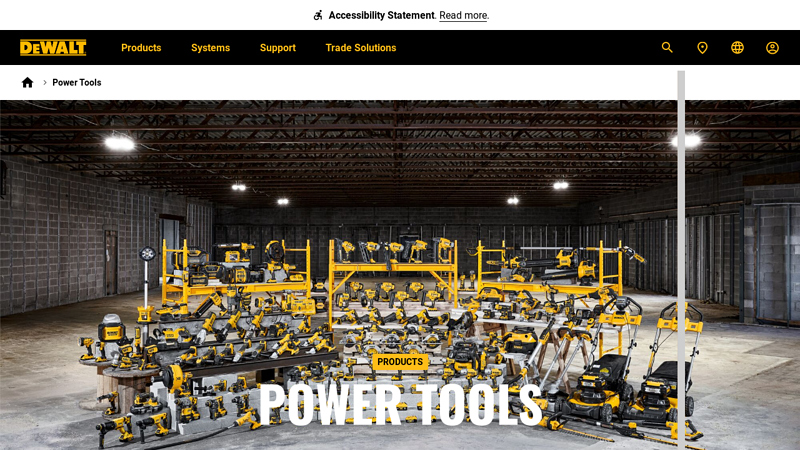

#1 Power Tools – Cordless & Electric

Domain Est. 1997

Website: dewalt.com

Key Highlights: Browse DEWALT power tools across a variety of use cases and job types, including cutting, grinding, sawing, riveting, sanding and more….

#2 DEWALT

Domain Est. 2009

Website: stanleyblackanddecker.com

Key Highlights: DEWALT launches its first line of portable electric power tools and accessories … tools feature compact designs with power and features needed for the job site….

#3 Authorized Tool Outlet

Domain Est. 2016

Website: authorizedtooloutlet.com

Key Highlights: Free delivery over $199 30-day returnsAuthorized Tool Outlet is the premier source for professional power tools, accessories, hand tools, and equipment manufactured by DeWalt….

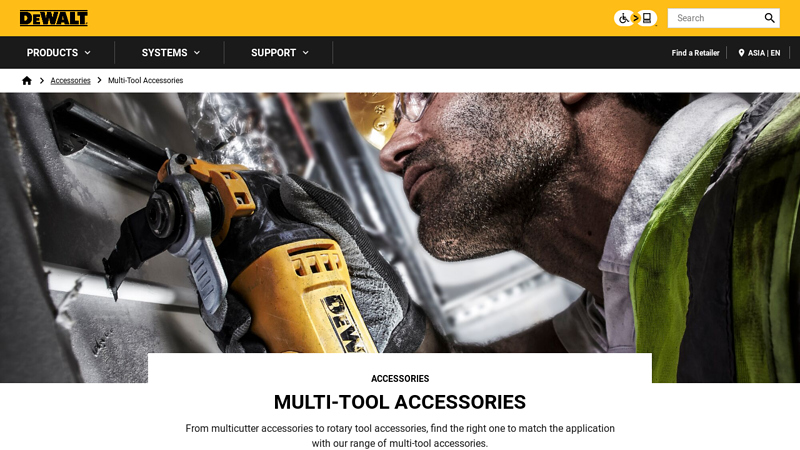

#4 Multi

Website: asia.dewalt.global

Key Highlights: From multicutter accessories to rotary tool accessories, find the right one to match the application with our range of multi-tool accessories….

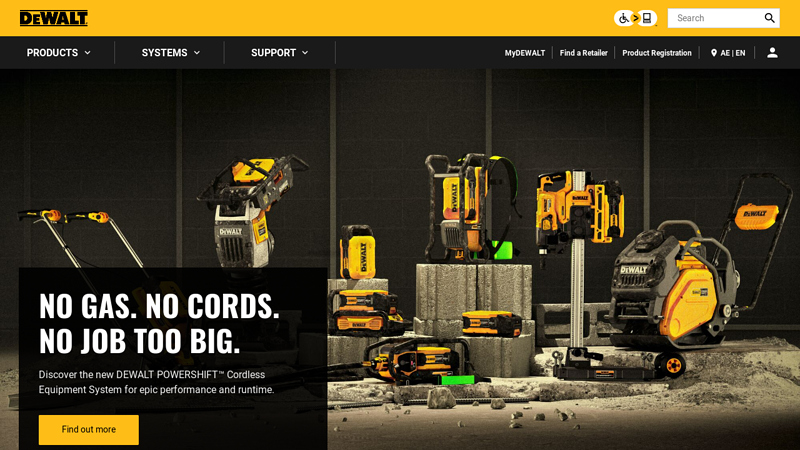

#5 Power Tools

Website: dewalt.ae

Key Highlights: Find information on DEWALT construction solutions – built for professionals and relied upon to deliver in the toughest jobsite conditions….

Expert Sourcing Insights for Rotary Tool Accessories Dewalt

H2: 2026 Market Trends for DeWalt Rotary Tool Accessories

The market for DeWalt rotary tool accessories is poised for notable evolution by 2026, shaped by technological innovation, shifting consumer demands, and broader industry dynamics. As a leading brand in the power tool sector, DeWalt is expected to maintain a competitive edge through strategic product development and market responsiveness. Key trends influencing the rotary tool accessories segment include:

-

Increased Demand for Precision and Versatility

By 2026, end-users in both professional trades and DIY markets will increasingly prioritize precision, adaptability, and ease of use. DeWalt rotary tool accessories are likely to feature enhanced designs—such as quick-change mechanisms, improved heat resistance, and multi-material compatibility—to serve applications ranging from engraving and grinding to cutting and polishing. -

Integration with Cordless Ecosystems

With the continued rise of cordless power tools, DeWalt’s expansion of its 20V MAX and 60V FLEXVOLT platforms will extend to rotary accessories optimized for battery efficiency. Accessories designed to minimize load and maximize runtime will appeal to mobile professionals and contractors seeking productivity on job sites without access to power outlets. -

Focus on Durability and Longevity

Market expectations for tool life and performance are rising. DeWalt is anticipated to invest in advanced materials—like carbide-tipped bits, diamond abrasives, and reinforced shanks—to reduce wear and increase the service life of accessories. This focus supports sustainability goals and aligns with the professional user’s demand for reliable, long-term investments. -

Smart Tool Integration and IoT Readiness

While still emerging, the integration of smart technology into accessories could gain traction by 2026. DeWalt may explore sensor-enabled accessories or companion apps that track usage patterns, wear levels, or recommend optimal speeds for specific attachments—enhancing user experience and tool safety. -

E-Commerce and Direct-to-Consumer Growth

Online retail platforms will continue to dominate tool and accessory sales. DeWalt is expected to strengthen its digital presence with targeted marketing, bundled kits, and educational content (e.g., video tutorials) to guide consumers in selecting the right rotary accessories for their projects. -

Sustainability and Packaging Innovation

Environmental concerns will influence packaging and manufacturing practices. DeWalt may adopt recyclable packaging and promote repairability or recycling programs for worn accessories, aligning with corporate sustainability goals and appealing to eco-conscious consumers. -

Competition and Market Expansion

While DeWalt holds a strong position, competition from brands like Bosch, Milwaukee, and Makita will drive innovation. To maintain market share, DeWalt may expand its accessory lineup to include niche products—such as compact attachments for tight spaces or specialized bits for composites and new building materials.

In summary, the 2026 market for DeWalt rotary tool accessories will be defined by smarter, more durable, and user-centric designs, supported by digital engagement and sustainability initiatives. As the DIY and professional power tool markets converge in expectations, DeWalt’s ability to innovate across form, function, and ecosystem integration will determine its continued leadership in this segment.

Common Pitfalls When Sourcing Rotary Tool Accessories for Dewalt (Quality and IP Concerns)

Logistics & Compliance Guide for Rotary Tool Accessories (DeWalt)

Product Identification & Specifications

Ensure all DeWalt rotary tool accessories (e.g., grinding stones, cutting wheels, sanding drums, polishing pads) are clearly identified by model number, part number, and product description. Maintain accurate technical data sheets including dimensions, compatible shank sizes (e.g., 1/8″, 1/4″), maximum RPM rating, and material composition (e.g., silicon carbide, aluminum oxide, diamond-coated).

Packaging & Labeling Requirements

Package all accessories securely to prevent damage during transit. Use DeWalt-approved packaging with tamper-evident seals where applicable. Labels must include:

– DeWalt brand logo and product name

– Part/model number

– Safety warnings (e.g., “Wear eye protection,” “Use at or below maximum RPM”)

– Country of origin

– CE, UKCA, or other regional compliance marks as required

– Barcode for inventory tracking

Regulatory Compliance

Rotary tool accessories must comply with relevant regional safety and environmental regulations. Key standards include:

– EU/EEA: Comply with the Machinery Directive 2006/42/EC and carry the CE mark. Ensure conformity with EN standards for abrasive products (e.g., EN 13236).

– UK: Adhere to UKCA marking requirements post-Brexit; maintain compliance with GB standards equivalent to EN norms.

– USA/Canada: Follow OSHA and ANSI B7.1 safety guidelines for the use and performance of abrasive wheels. No specific federal certification required, but adherence ensures safety and liability protection.

– RoHS & REACH: Confirm accessories contain no restricted hazardous substances (e.g., lead, cadmium) above permitted levels.

Import & Export Documentation

Prepare complete shipping documentation for international logistics, including:

– Commercial invoice with HS code (e.g., 8207.40 for interchangeable tools)

– Packing list detailing quantities and weights

– Certificate of Origin

– Safety Data Sheet (SDS), if applicable (e.g., for accessories with coatings or binders of concern)

Ensure compliance with export control regulations and avoid restricted destinations per DeWalt’s global trade policies.

Storage & Handling

Store accessories in a dry, temperature-controlled environment away from direct sunlight and moisture to prevent degradation (especially for bonded abrasives). Use FIFO (First In, First Out) inventory rotation. Handle packages with care to avoid impact damage—inspect for cracks or deformation before distribution.

Transportation & Distribution

Ship via approved freight carriers with experience in handling industrial goods. Use appropriate cushioning and secure palletization to prevent shifting. For air freight, verify that no hazardous materials (e.g., certain bonded chemicals) are present that would restrict transport under IATA regulations.

Quality Assurance & Traceability

Implement batch/lot tracking for all accessories to enable rapid recall if non-compliance or defects are identified. Conduct periodic audits of supplier quality management systems and perform random sampling for performance and safety testing in accordance with DeWalt’s QA protocols.

End-of-Life & Environmental Responsibility

Support DeWalt’s sustainability initiatives by ensuring packaging is recyclable. Provide guidance to customers on proper disposal of used accessories, particularly those containing bonded resins or metallic compounds, in accordance with local waste regulations.

In conclusion, sourcing rotary tool accessories for DeWalt requires careful consideration of compatibility, quality, and supplier reliability. Ensuring that the accessories are specifically designed or verified to work with DeWalt rotary tools will maximize performance, safety, and tool longevity. Opting for genuine DeWalt accessories or reputable third-party alternatives that meet industry standards can provide effective results without compromising on durability. Additionally, comparing prices, reading customer reviews, and purchasing from authorized distributors or trusted retailers can help secure the best value and peace of mind. By taking a strategic and informed approach to sourcing, users can enhance the versatility and efficiency of their DeWalt rotary tools across a wide range of applications.