The global ladder and scaffold equipment market is experiencing steady growth, driven by rising construction activities, increased focus on workplace safety, and regulatory compliance across industrial and residential sectors. According to Grand View Research, the global ladders market size was valued at USD 5.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further amplified by the expanding infrastructure and renovation projects in both developed and emerging economies. With height-related safety becoming a top priority, demand for specialized equipment—such as roof ladder platforms—has surged among roofing professionals, maintenance crews, and utility service providers. As a result, manufacturers are investing in innovation, durability, and compliance with OSHA and ANSI standards to meet evolving industry needs. In this competitive landscape, the following ten companies have emerged as leading manufacturers of roof ladder platforms, distinguished by product quality, safety certifications, customer reviews, and market presence.

Top 10 Roof Ladder Platform Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Aluminum Fixed Access Ladders

Domain Est. 1997

Website: okeeffes.com

Key Highlights: Fixed Roof access ladders that are permanently attached to the building or structure offer safe and easy access to rooftops, mezzanines, loading docks and more….

#2 Industrial Ladders – Prefabricated, Modular Metal Stairs

Domain Est. 2010

Website: erectastep.com

Key Highlights: Fixed Ladders and Ladder Platforms Erectastep’s patented, bolt-together design uses 5 modular components to create unlimited stair and access configurations….

#3 Height Adjustable Steel Ladder System

Domain Est. 2012

Website: safesmartaccess.com

Key Highlights: SafeSmart Access is proud to be the global leading manufacturer and supplier of high quality height adjustable steel ladder system….

#4 Werner Ladder

Domain Est. 1996

Website: wernerco.com

Key Highlights: Werner is the world leader in the manufacturing and distribution of ladders, climbing equipment, fall protection and ladder accessories….

#5 Cotterman

Domain Est. 1996 | Founded: 1925

Website: cotterman.com

Key Highlights: Quality ladders made in the USA since 1925 with locations in Michigan, Georgia, Texas and California waiting to serve you….

#6 Louisville Ladder

Domain Est. 1997

Website: louisvilleladder.com

Key Highlights: Work safely around electricity with the toughest, strongest, and most tested fiberglass ladders on the market. See Platform Ladders….

#7 Ladder Systems

Domain Est. 1998

Website: roofcurb.com

Key Highlights: Our ladders are available for both internal and external mount for accessing the roof. In addition, RCS works very hard to be your well-informed source….

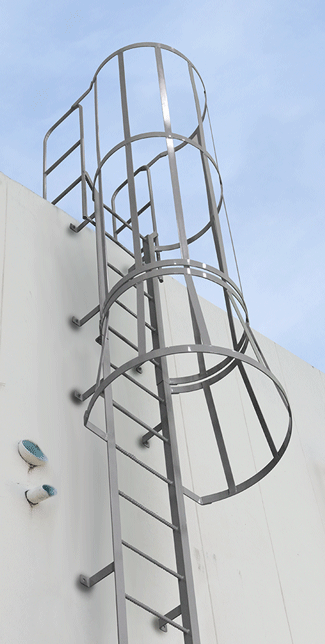

#8 Cages & Platforms

Domain Est. 2000

Website: alacoladder.com

Key Highlights: All platforms come in standard mill finish. Our aluminum platform ladders at Alaco Ladder Company meet the following OSHA standards: 1917.118(e)(2)(iii)….

#9 Ladderport

Domain Est. 2004

Website: ladderport.com

Key Highlights: From roof hatches to ladder stabilization and lifting equipment, LadderPort provides innovative solutions to make rooftop access safer, more efficient, ……

#10 Kattsafe

Domain Est. 2019

Website: kattsafe.com

Key Highlights: At Kattsafe (formerly FIXFAST USA) we design and manufacture industry-leading, high-spec products for height safety and access systems that deliver maximum ……

Expert Sourcing Insights for Roof Ladder Platform

H2: Market Trends for Roof Ladder Platforms in 2026

The global market for roof ladder platforms is poised for significant transformation by 2026, driven by advancements in construction safety regulations, rising demand for rooftop installations, and the growing emphasis on worker safety. This analysis explores key trends shaping the industry over the forecast period.

-

Increased Focus on Workplace Safety and Regulatory Compliance

Governments and occupational health agencies worldwide are tightening safety standards for working at heights. By 2026, stricter enforcement of OSHA (U.S.), Work at Height Regulations (UK), and similar frameworks in Europe and Asia-Pacific is expected to mandate the use of certified roof ladder platforms on commercial and industrial construction sites. This regulatory push is a primary driver for market growth, especially in mature economies. -

Growth in Rooftop Solar Installations

The surge in renewable energy adoption, particularly solar photovoltaic (PV) systems, is creating sustained demand for safe access solutions. Roof ladder platforms provide secure staging areas for solar panel installation and maintenance. As countries accelerate clean energy targets under climate agreements, the solar sector’s expansion will directly boost demand for specialized ladder platforms designed for rooftop use. -

Technological Advancements and Smart Integration

By 2026, manufacturers are increasingly integrating smart features into roof ladder platforms, such as anti-slip sensors, load monitoring systems, and IoT-enabled stability alerts. These innovations enhance safety and operational efficiency. Lightweight composite materials and modular designs are also gaining traction, improving portability and adaptability across roof types. -

Urbanization and Infrastructure Development

Rapid urbanization in emerging markets—including India, Southeast Asia, and parts of Africa—is fueling construction activity. High-rise residential and commercial buildings require reliable fall protection systems. Roof ladder platforms are becoming standard equipment, especially in projects emphasizing worker safety and compliance with green building certifications. -

Shift Toward Rental and Shared Equipment Models

A growing number of contractors are opting to rent rather than purchase roof ladder platforms. Equipment rental services are expanding, offering cost-effective and flexible access to certified platforms. This trend is particularly strong in short-term projects and among small-to-medium enterprises (SMEs), supporting market penetration without high upfront costs. -

Regional Market Dynamics

North America and Europe are expected to maintain leadership in market value due to strong safety regulations and high construction standards. However, the Asia-Pacific region is projected to witness the highest growth rate, driven by industrial expansion and urban infrastructure development. China, Japan, and South Korea are investing heavily in smart and sustainable construction, further boosting demand. -

Sustainability and Eco-Friendly Materials

Environmental concerns are influencing product design. By 2026, manufacturers are increasingly using recyclable aluminum and reducing carbon footprints in production. Sustainable sourcing and end-of-life recyclability are becoming competitive differentiators in the market.

Conclusion

The roof ladder platform market in 2026 will be shaped by a convergence of regulatory, technological, and environmental factors. As safety becomes non-negotiable and rooftop activities increase across industries, demand for reliable, innovative access solutions will continue to rise. Companies that invest in compliance, smart features, and sustainable design will be best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing a Roof Ladder Platform (Quality, IP)

Sourcing a roof ladder platform involves significant risks related to both product quality and intellectual property (IP). Failing to address these pitfalls can lead to safety hazards, legal liabilities, and reputational damage. Below are key challenges to watch for:

Poor Material and Build Quality

Many suppliers, especially low-cost manufacturers, use substandard materials such as thin-gauge aluminum or inferior steel that compromise structural integrity. This can lead to platform failure under load, posing serious safety risks to workers. Additionally, inadequate welding, poor finish, and lack of corrosion resistance reduce the product’s lifespan and reliability in harsh environments.

Inconsistent Manufacturing Standards

Roof ladder platforms must meet strict safety and engineering standards (e.g., OSHA, ANSI, EN). Sourcing from suppliers without certified quality management systems (e.g., ISO 9001) increases the risk of non-compliant products. Inconsistent tolerances, faulty assembly, or missing safety features such as non-slip surfaces or secure locking mechanisms are common issues.

Lack of Product Testing and Certification

Reputable platforms undergo rigorous load testing, fatigue testing, and third-party certification. Some suppliers provide falsified or incomplete test reports. Always verify certifications with accredited bodies and request independent test data to confirm compliance with regional safety regulations.

Intellectual Property Infringement

Roof ladder platforms often incorporate patented designs, such as unique locking mechanisms or folding systems. Sourcing from manufacturers that copy branded designs can expose your company to IP litigation. Always conduct due diligence on suppliers to ensure they have legitimate rights to the design or offer original engineering.

Inadequate Documentation and IP Transparency

Suppliers may fail to provide technical drawings, material specifications, or IP ownership documentation. This lack of transparency makes it difficult to verify authenticity or defend against infringement claims. Insist on clear contractual terms regarding IP ownership and design rights before placing orders.

Counterfeit or Rebranded Products

Some suppliers rebrand off-spec or counterfeit platforms as OEM-equivalent, misleading buyers about quality and origin. This often includes fake logos, misleading certifications, or copied packaging. Conduct factory audits and use trusted sourcing channels to mitigate this risk.

Limited After-Sales Support and Warranty

Low-quality suppliers may offer weak or unenforceable warranties and lack technical support. This becomes critical when safety defects emerge or maintenance is needed. Ensure warranty terms are clear, and the supplier can provide spare parts and service over the product’s lifecycle.

Avoiding these pitfalls requires thorough supplier vetting, independent quality inspections, and legal review of IP rights. Investing in reputable manufacturers with proven compliance and transparent practices ensures both safety and legal protection.

Logistics & Compliance Guide for Roof Ladder Platform

This guide outlines essential logistics considerations and compliance requirements for the safe and legal handling, transportation, installation, and use of roof ladder platforms.

Product Classification and Regulatory Compliance

Roof ladder platforms are classified as workplace access and fall protection equipment. They must comply with relevant national and international safety standards such as OSHA (Occupational Safety and Health Administration) regulations in the U.S., EN 131 standards in Europe, and applicable ANSI (American National Standards Institute) guidelines. Ensure all units meet load capacity, material strength, and design requirements specified under these standards. Units should be certified and accompanied by a Declaration of Conformity.

Transportation and Handling

Roof ladder platforms must be transported securely to prevent damage. Use vehicles with adequate tie-down points and secure the platform with straps or chains to prevent shifting during transit. Avoid overloading transport vehicles and ensure weight distribution complies with local road regulations. When handling manually, use appropriate lifting equipment or trained personnel to prevent injury. Platforms should be stored horizontally in a dry, protected area to avoid warping or corrosion.

Installation Requirements

Installation must be performed by qualified personnel following manufacturer instructions and site-specific risk assessments. The platform must be securely anchored to the roof structure using approved fasteners and supports capable of withstanding anticipated loads, including live loads (workers and tools) and environmental loads (wind, snow). Installers must verify roof integrity and ensure compatibility with the building’s structural system. Temporary fall protection must be used during installation.

Load Capacity and Usage Restrictions

Each roof ladder platform has a defined maximum load capacity, clearly marked on the unit. This includes the combined weight of personnel, tools, and materials. Exceeding this limit is a violation of safety standards and can lead to structural failure. Only trained personnel should use the platform, and all users must follow fall protection protocols, including the use of harnesses and lifelines where required.

Inspection and Maintenance

Regular inspection is mandatory. Conduct pre-use visual checks for damage, corrosion, loose fasteners, or wear. Perform thorough inspections by a competent person at least annually, or more frequently in harsh environments. Maintain a log of all inspections and repairs. Any damaged component must be repaired or replaced using manufacturer-approved parts before the platform is returned to service.

Documentation and Recordkeeping

Maintain comprehensive documentation including product manuals, compliance certificates, installation records, inspection logs, maintenance history, and training records for personnel. These documents must be readily accessible for audits, safety inspections, or incident investigations. Proper recordkeeping is required under OSHA and other regulatory frameworks.

Training and Worker Safety

All personnel involved in the handling, installation, or use of roof ladder platforms must receive documented training on safe practices, fall protection, equipment limitations, and emergency procedures. Training should be refreshed periodically and whenever new equipment or procedures are introduced. Only trained and authorized workers should access or operate the platform.

Environmental and Site-Specific Considerations

Evaluate site conditions including weather exposure, roof slope, surrounding obstacles, and proximity to power lines. Install warning signs and barriers to prevent unauthorized access. In high-wind or inclement weather, suspend use of the platform. Ensure the platform design accounts for local environmental loads and complies with municipal building codes and permitting requirements.

Conclusion for Sourcing Roof Ladder Platform

Sourcing a roof ladder platform requires a strategic approach that balances safety, durability, compliance, and cost-effectiveness. After evaluating various suppliers, materials, and design specifications, it is evident that selecting a high-quality, standards-compliant platform—constructed from robust materials such as aluminum or galvanized steel—is essential for ensuring worker safety and long-term usability. Prioritizing platforms that meet OSHA and ANSI/ASSP A14 standards not only ensures regulatory compliance but also reduces liability risks.

Additionally, factors such as ease of installation, portability, load capacity, and compatibility with existing ladder systems must be carefully considered to maximize functionality across different job sites. Engaging with reputable suppliers who provide warranties, technical support, and customization options further enhances value and reliability.

In conclusion, a well-sourced roof ladder platform contributes significantly to workplace safety, operational efficiency, and compliance. Investing time in thorough supplier vetting and product evaluation will yield long-term benefits, ultimately supporting a safer and more productive working environment.