The global roll threading machines market is experiencing steady expansion, driven by rising demand for precision threading solutions across construction, automotive, and industrial manufacturing sectors. According to Grand View Research, the global thread rolling machines market was valued at USD 1.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by the increasing preference for cold-forming techniques, which offer superior thread strength, reduced material waste, and higher production efficiency compared to traditional cutting methods. With automation and smart manufacturing on the rise, leading manufacturers are investing in advanced CNC-controlled roll threading systems to meet stringent quality standards and evolving industry needs. As the market becomes more competitive, identifying top-performing manufacturers with proven innovation, global reach, and technical expertise has become crucial for procurement professionals and OEMs seeking reliable supply chain partners.

Top 10 Roll Threading Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CJWinter

Domain Est. 1997

Website: cjwinter.com

Key Highlights: CJWinter manufactures thread rolls not only for our premier line of attachments, but also to fit attachments for all manufacturers, including Fette, Reed, ……

#2 Kinefac

Domain Est. 1997

Website: kinefac.com

Key Highlights: As a world leader in precision metal forming technology, Kinefac specializes in thread rolling machines, spline forming equipment, and more….

#3

Domain Est. 1999

Website: superiorthread.com

Key Highlights: Superior Thread Rolling is an aerospace parts manufacturer with a variety of thread rolling, CNC machining, and quality testing capabilities….

#4 Thread Rolling Manufacturer

Domain Est. 2002

Website: smartmachinery.com

Key Highlights: SMART Machinery thread rollers and pointing machines were the first secondary operation machines on the market able to utilize low maintenance, ……

#5

Domain Est. 2003

Website: rolledthreads.com

Key Highlights: Rolled Threads Unlimited is the industry’s leading rolled threads manufacturer. We offer a product line of unmatched quality & craftsmanship….

#6 Thread Rolling Precision Services

Domain Est. 2004

Website: tuttlemfg.com

Key Highlights: Tuttle Manufacturing is a custom manufacturer offering thread rolling services for turned, screw machined, and headed parts. Read more here….

#7 Fette Tools

Domain Est. 2012

Website: fette-tools.com

Key Highlights: FETTE TOOLS is the leading distributor for Fette threading products, providing unmatched service and technology….

#8 Keystone Threaded Products

Domain Est. 1997

Website: keystonethreaded.com

Key Highlights: We have unparalleled roll threading capabilities and can create a wide variety of threading products, from Acme threaded bars to specialty forms….

#9 Landis

Domain Est. 2016

Website: landis-solutions.com

Key Highlights: For the last 120 years, Landis has been setting global standards for excellence in high volume thread rolling and thread cutting applications….

#10 Rollwalztechnik Abele + Höltich GmbH

Founded: 1982

Website: rollwalztechnik.de

Key Highlights: Since 1982 we have been designing, producing and supplying machines, tools and dies to meet the most highly specialised and customised requirements of thread ……

Expert Sourcing Insights for Roll Threading

H2: 2026 Market Trends for Roll Threading

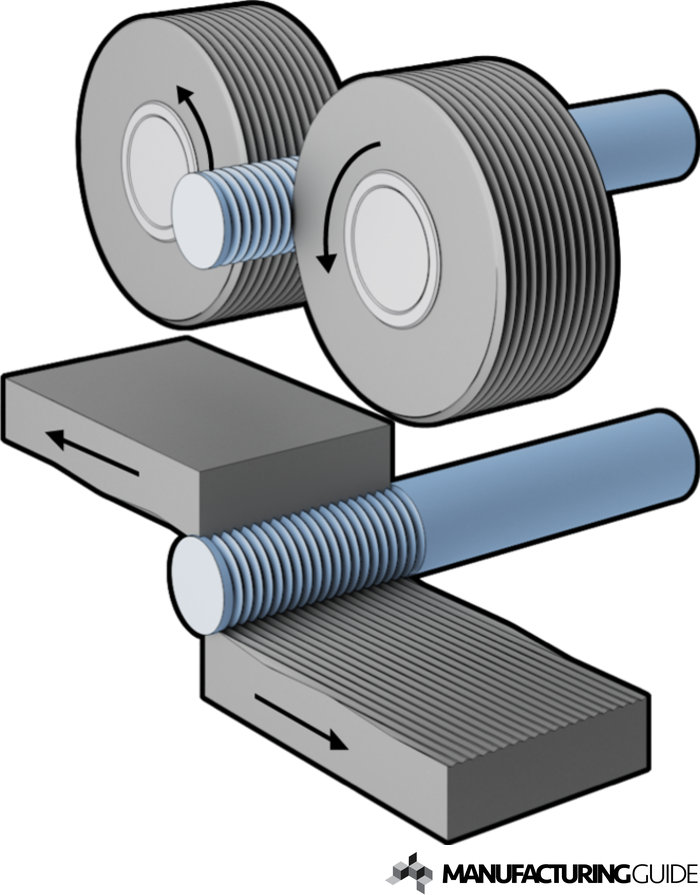

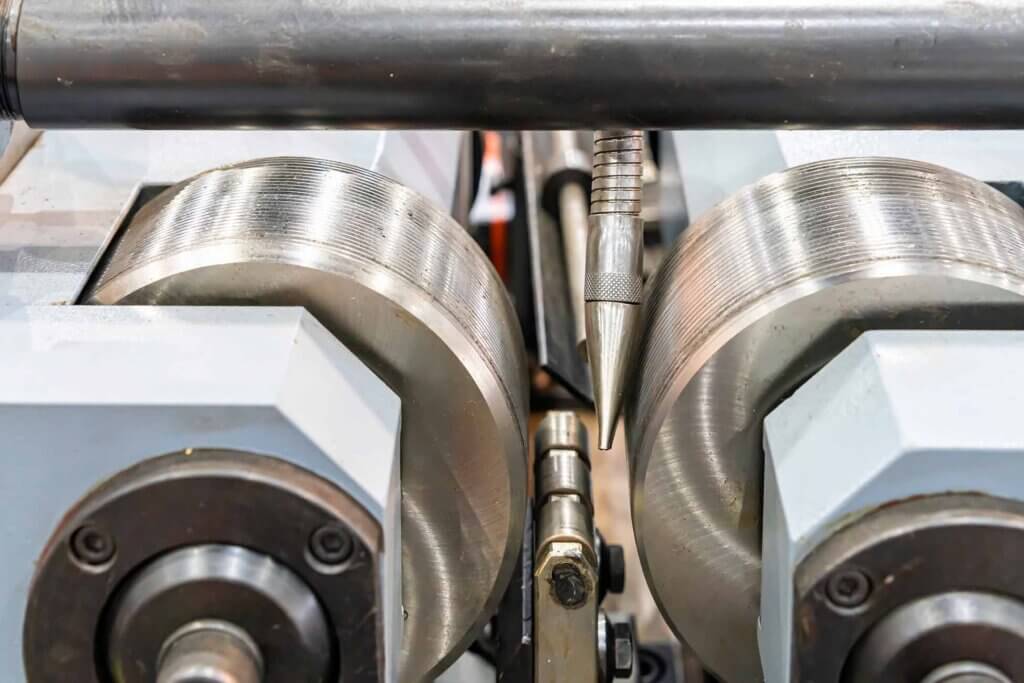

The roll threading market is poised for significant transformation by 2026, driven by technological advancements, evolving industrial demands, and a growing emphasis on sustainability. Roll threading, a cold-forming process used to create threads on bolts, screws, and other fasteners, continues to gain preference over traditional cutting methods due to its efficiency, precision, and material savings. The following key trends are expected to shape the roll threading landscape in 2026:

1. Rising Demand from Automotive and Aerospace Sectors

The automotive and aerospace industries remain primary drivers of roll threading adoption. With the push toward lightweight vehicles and fuel-efficient aircraft, manufacturers are increasingly using high-strength materials such as alloy steels and titanium—materials well-suited for roll threading. The growth of electric vehicles (EVs) will further boost demand, as EV powertrains and battery systems require precision-engineered fasteners produced efficiently through roll threading.

2. Technological Integration and Automation

By 2026, roll threading machines are expected to feature higher levels of automation and integration with Industry 4.0 technologies. Smart threading systems equipped with IoT sensors, real-time monitoring, and AI-driven predictive maintenance will enhance production efficiency and reduce downtime. CNC-controlled roll threading machines will dominate the market, offering improved repeatability and adaptability for complex threading profiles.

3. Focus on Sustainability and Material Efficiency

As global manufacturing shifts toward sustainable practices, roll threading’s inherent advantages—such as minimal material waste and reduced energy consumption compared to cutting processes—will become more valuable. Companies aiming for circular economy goals will favor roll threading for its ability to produce strong, durable threads without removing material, aligning with green manufacturing standards.

4. Expansion in Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, will see increased investment in manufacturing infrastructure, directly benefiting the roll threading market. Local production of machinery, construction equipment, and consumer electronics will drive demand for cost-effective and high-volume fastener production, where roll threading excels.

5. Advancements in Tooling Materials and Coatings

Roll threading dies and tools are expected to incorporate advanced materials such as high-speed steel (HSS), carbide, and ceramic composites with specialized coatings (e.g., TiN, DLC). These improvements will extend tool life, allow for higher threading speeds, and improve performance with harder materials—reducing operational costs and boosting productivity.

6. Customization and Multi-Functional Machines

Manufacturers will increasingly demand flexible roll threading solutions that can handle a variety of thread types (e.g., metric, UNC, UNF, buttress) and diameters on a single machine. Multi-axis and modular roll threading systems will gain popularity, enabling small-batch customization without sacrificing throughput.

In conclusion, the 2026 roll threading market will be characterized by innovation, automation, and sustainability. Companies that embrace digital integration, expand into high-growth sectors, and invest in advanced tooling will be best positioned to capitalize on these evolving trends.

Common Pitfalls in Sourcing Roll Threading: Quality and Intellectual Property Risks

Poor Quality Control and Inconsistent Thread Dimensions

One of the most frequent issues when sourcing roll threading—especially from low-cost or inexperienced suppliers—is inconsistent thread quality. Roll threading relies on precise cold-forming processes, and deviations in pressure, tool alignment, or material hardness can result in undersized threads, incomplete thread forms, or surface defects. Without stringent quality control protocols (such as regular thread pitch and major/minor diameter inspections), these flaws may not be detected until failure occurs in the field, leading to assembly issues or structural weaknesses.

Use of Substandard Tooling and Equipment

The quality of rolled threads heavily depends on the condition and precision of the threading dies and machinery. Some suppliers may use worn or low-grade tooling to cut costs, resulting in poor thread finish, dimensional inaccuracies, or reduced fatigue strength in the final product. Sourcing from manufacturers that do not maintain or calibrate their equipment regularly increases the risk of receiving components that fail to meet engineering specifications.

Inadequate Material Selection and Hardness Control

Roll threading requires materials with appropriate ductility and hardness to form threads without cracking or galling. If a supplier uses materials outside the recommended hardness range (typically 25–32 HRC for many steels), thread deformation or work hardening issues can arise. Sourcing without verifying material certifications or heat treatment processes exposes buyers to performance risks, especially in high-stress applications.

Lack of Process Documentation and Traceability

Reputable roll threading suppliers should provide full process documentation, including tooling specifications, machine settings, and inspection records. A common pitfall is sourcing from vendors who lack traceability, making it difficult to diagnose quality issues or ensure consistency across production batches. This is particularly critical in regulated industries like aerospace or medical devices.

Intellectual Property (IP) Infringement Risks

Roll threading tooling and processes can be protected by patents or proprietary know-how. Sourcing from unauthorized or unlicensed manufacturers—especially in regions with lax IP enforcement—risks using patented techniques without permission. This could lead to legal liability, supply chain disruptions, or forced redesigns if infringement is discovered post-production.

Unverified Supplier Claims and Certifications

Some suppliers may claim compliance with industry standards (e.g., ISO, ASME) or possess certifications (e.g., ISO 9001) without undergoing rigorous audits. Failing to independently verify these claims can result in sourcing from facilities that do not meet required quality management practices, increasing the likelihood of defects and non-conformance.

Insufficient Communication on Thread Standards and Finishes

Misunderstandings about thread standards (e.g., UNF vs. UNC, metric vs. imperial), tolerances (6g, 6H), or required surface finishes can lead to mismatched components. Poor communication or lack of technical expertise on the supplier’s side may result in parts that are technically “correct” but functionally incompatible with mating components.

Overlooking Secondary Processes and Post-Threading Operations

Roll threading is often followed by operations like cleaning, coating, or heat treatment. If these are outsourced or poorly coordinated, residual stresses, contamination, or hydrogen embrittlement can compromise thread integrity. Sourcing without understanding the full production workflow increases the risk of undetected downstream failures.

Logistics & Compliance Guide for Roll Threading

Roll threading is a cold-forming process used to create threads on pipes, rods, and fasteners without removing material. Proper logistics and compliance management are essential to ensure product quality, worker safety, and adherence to industry regulations. This guide outlines key considerations across the supply chain and regulatory landscape.

Supply Chain & Material Logistics

Efficient logistics begin with sourcing and handling raw materials. For roll threading operations, this typically involves steel rods, bars, or pipes delivered in bulk.

- Material Specifications: Ensure incoming stock meets required grades (e.g., ASTM A307, A193, A325) and dimensional tolerances.

- Inventory Management: Maintain FIFO (First In, First Out) practices to prevent material degradation, especially for corrosion-prone metals.

- Storage Conditions: Store materials in dry, covered areas to prevent rust and surface defects that can compromise threading quality.

- Just-in-Time (JIT) Delivery: Coordinate with suppliers to minimize on-site inventory and reduce handling, especially in high-volume production environments.

Equipment & Process Compliance

Roll threading machines must be maintained and operated in accordance with manufacturer guidelines and industry standards.

- Machine Calibration: Conduct regular calibration and preventive maintenance to ensure thread accuracy and consistency (e.g., pitch diameter, thread form).

- Tooling Inspection: Inspect dies and rolls frequently for wear or damage; replace according to schedule or performance metrics.

- Process Validation: Perform periodic quality checks using thread gauges (GO/NO-GO), optical comparators, or coordinate measuring machines (CMMs).

- Standard Operating Procedures (SOPs): Document and enforce SOPs for setup, operation, and changeover to ensure repeatability and compliance with ISO 9001 or equivalent quality systems.

Safety & Environmental Compliance

Worker safety and environmental responsibility are critical in roll threading facilities.

- Personal Protective Equipment (PPE): Require operators to wear safety glasses, gloves, and hearing protection due to high-pressure operations and metal shavings (burr, not chips, since roll threading is chipless).

- Machine Guarding: Install and maintain physical guards on roll threading equipment to prevent contact with moving parts.

- Lubricant Management: Use approved threading lubricants and implement containment systems to prevent spills. Recycle or dispose of used lubricants in compliance with EPA or local environmental regulations.

- Noise Control: Monitor noise levels and implement engineering or administrative controls if exposure exceeds OSHA limits (e.g., 85 dB over 8 hours).

Quality Assurance & Regulatory Standards

Adherence to industry standards ensures threaded components are fit for purpose and meet customer expectations.

- Thread Standards: Follow recognized standards such as ASME B1.1 (Unified Inch Screw Threads), ISO 68-1 (ISO general-purpose screw threads), or NPT/NPTF for pipe threads.

- Inspection & Documentation: Maintain traceability through batch records, material certifications (e.g., MTRs), and inspection reports.

- Non-Destructive Testing (NDT): Perform visual, dimensional, and functional testing; use magnetic particle or ultrasonic testing when required for critical applications.

- Certifications: Maintain compliance with ISO 9001, API Q1 (for oil & gas), or other sector-specific quality management systems.

Shipping & Final Product Handling

Proper packaging and documentation are essential to preserve thread integrity and ensure regulatory compliance during transport.

- Thread Protection: Use thread protectors (plastic or metal caps) to prevent damage during handling and shipping.

- Packaging Standards: Secure loads to prevent shifting; use corrosion-inhibiting wraps or VCI (Vapor Corrosion Inhibitor) paper for long-term storage or overseas shipping.

- Labeling & Marking: Clearly mark products with traceability data (heat number, size, grade, manufacturer ID) per ASTM, ASME, or customer specifications.

- Export Compliance: For international shipments, comply with ITAR, EAR, or other export control regulations if applicable, especially for defense or aerospace applications.

Training & Personnel Compliance

Qualified personnel are vital to maintaining quality and safety.

- Operator Certification: Ensure staff are trained and certified on roll threading machines and safety protocols.

- Continuous Improvement: Conduct regular training on quality updates, equipment changes, and regulatory developments.

- Audit Preparedness: Maintain training records and conduct internal audits to prepare for customer or third-party assessments.

By integrating these logistics and compliance practices, organizations can ensure reliable roll threading operations, regulatory adherence, and customer satisfaction across industrial sectors.

Conclusion for Sourcing Roll Threading:

Sourcing roll threading requires a strategic approach that balances quality, cost, lead time, and supplier reliability. After evaluating potential suppliers, it is evident that selecting a manufacturer with proven expertise in precision thread rolling, robust quality control processes, and the capability to handle the required materials and volumes is critical. Domestic sourcing may offer advantages in communication, shorter lead times, and easier quality oversight, while overseas options—particularly in regions with mature manufacturing ecosystems—can provide significant cost savings if managed with strong supply chain oversight.

Investing time in supplier qualification, including audits, sample testing, and review of certifications (such as ISO), will mitigate risks related to product consistency and compliance. Additionally, establishing long-term partnerships with reliable suppliers can lead to improved pricing, capacity allocation, and collaborative innovation.

In conclusion, the optimal sourcing strategy for roll threading should align with overall business objectives—prioritizing quality and reliability for critical applications, while leveraging cost-effective solutions for high-volume, less mission-critical components. A well-executed sourcing plan not only ensures product performance and durability but also enhances supply chain resilience and competitiveness.