The global roll shaper machine market is witnessing steady expansion, driven by rising demand for precision-formed metal components across construction, automotive, and manufacturing sectors. According to a report by Mordor Intelligence, the Cold Roll Forming Machine Market was valued at USD 2.37 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029. This growth is fueled by increasing industrial automation, the need for energy-efficient production processes, and the surge in infrastructure development—particularly in emerging economies. As manufacturers prioritize accuracy, speed, and low operational costs, the demand for advanced roll shaping technology continues to climb. In this evolving landscape, selecting the right equipment from leading manufacturers becomes critical for maintaining competitive advantage. Based on market presence, innovation, global footprint, and customer feedback, here are the top 8 roll shaper machine manufacturers shaping the industry’s future.

Top 8 Roll Shaper Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rollshape

Domain Est. 2010

Website: vacuactiv.com

Key Highlights: A versatile, modern and fully automatic massage device. Rollshape rollmassage make full use of the available technology with quiet operation and efficiency ……

#2 Body Space®

Website: bodyspace.eu

Key Highlights: We are European manufacturer of innovative body shaping devices. As pioneers in the industry, we’ve combined cardio training with Vacuum and InfraRed biohacking ……

#3 Roll Shaper · Machine for sale · Studio Figura International

Domain Est. 2008

Website: rollshaper.com

Key Highlights: Roll Shaper ❤️ a massage device that supports the lymphatic system, relaxation, and body health ☎️ Order now! – Studio Figura International….

#4 RollStar Rollshaper

Domain Est. 2014

Website: vacuactivus.com

Key Highlights: Lymphatic drainage massage is a gentle technique designed to stimulate the lymphatic system, promoting the removal of toxins and reducing swelling….

#5 Roller Original

Domain Est. 2017

Website: rolleroriginal.com

Key Highlights: Free delivery over $699The Roller Original EVO III Pro is a unique body massager and body former that our partner, BS-Systems has engineered and produced in the Czech Republic ……

#6 Body Roll Studio

Domain Est. 2019

Website: bodyrollstudio.com

Key Highlights: Body Roll Studio machines combine the healing effects of slimming and lymphatic drainage massages. Lymphatic drainage massages help relieve muscle tension….

#7 Body Rolling by Active Roll

Domain Est. 2024

Website: activerollsa.com

Key Highlights: The Active Roll Body Rolling Machine revolutionizes lymphatic drainage by enhancing the body’s natural detoxification process….

#8 Roll Shaper America

Website: wellnesszonedistributor.com

Key Highlights: Roll Shaper America is your source for lymphatic massage devices. We’re the official U.S. distributor of infrared Roll Shapers by Studio Figura….

Expert Sourcing Insights for Roll Shaper Machine

H2: Market Trends for Roll Shaper Machines in 2026

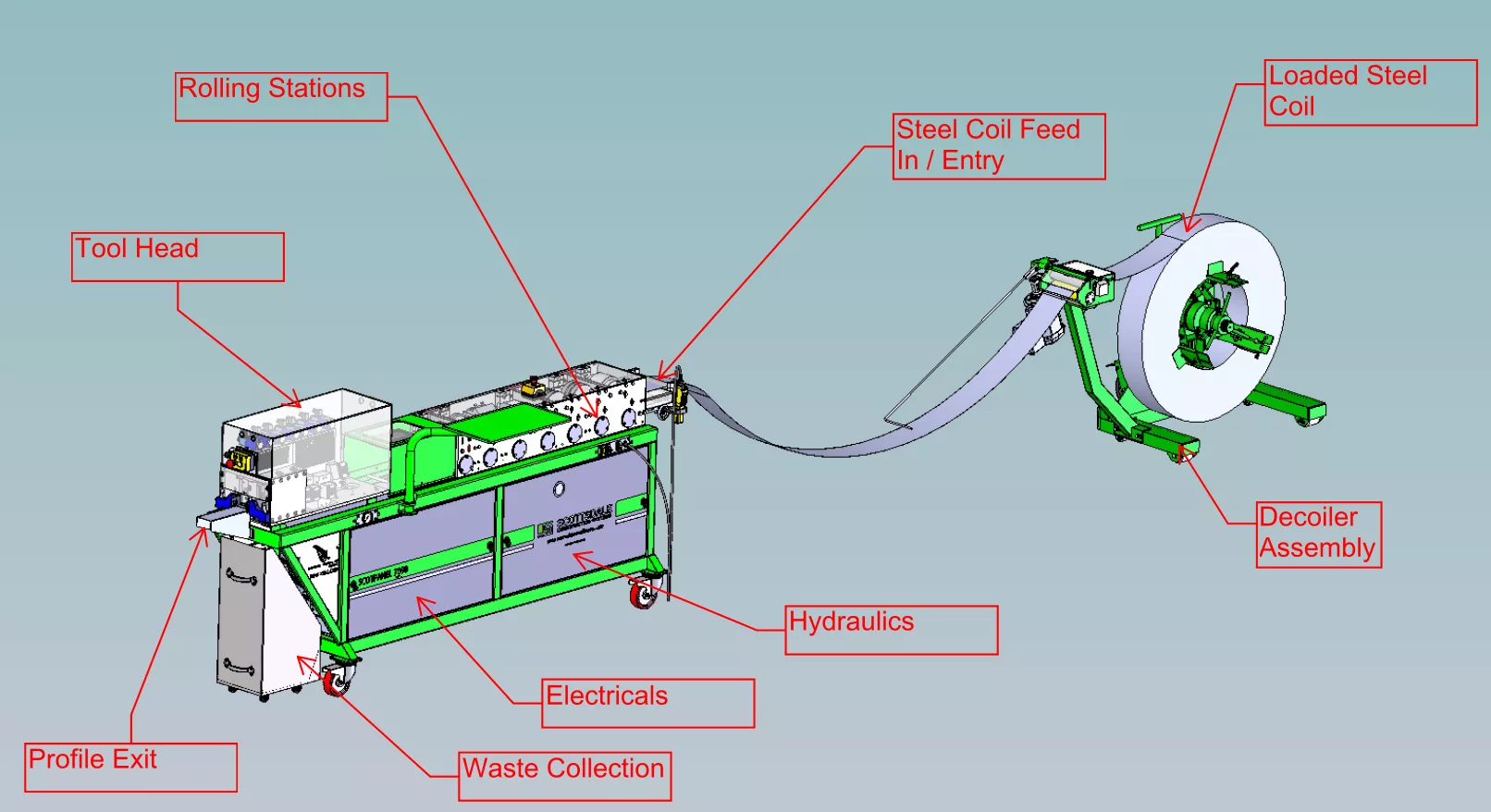

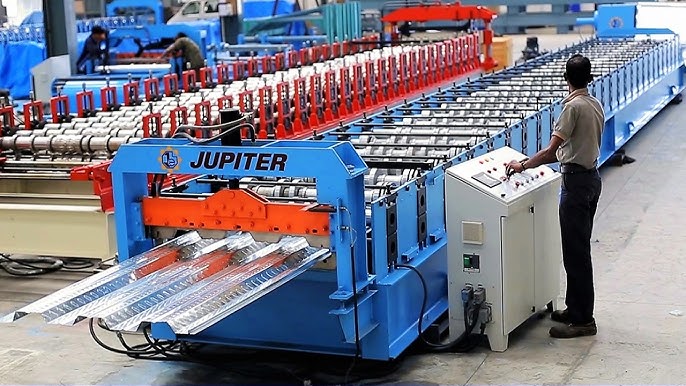

The global roll shaper machine market is poised for significant transformation by 2026, driven by advancements in automation, rising demand from construction and automotive sectors, and a growing emphasis on energy efficiency and precision manufacturing. As industries continue to adopt lean production methods and smart factory technologies, roll forming machines—critical in shaping metal coils into consistent cross-sectional profiles—are evolving to meet new performance and sustainability standards.

One of the most prominent trends shaping the 2026 landscape is the integration of Industry 4.0 technologies. Roll shaper machines are increasingly being equipped with IoT-enabled sensors, real-time monitoring systems, and AI-driven predictive maintenance algorithms. This shift allows for greater operational efficiency, reduced downtime, and improved product consistency, particularly in high-volume production environments across North America, Europe, and Asia-Pacific.

Additionally, the construction industry’s continued expansion—especially in emerging economies—fuels demand for lightweight, durable steel profiles used in roofing, wall panels, and structural supports. This has led to increased investment in versatile, high-speed roll forming machines capable of producing customized profiles with minimal changeover time.

Sustainability is another key driver. Manufacturers are focusing on energy-efficient motors, reduced material waste through precision control systems, and recyclable material compatibility. Regulatory pressures and corporate ESG (Environmental, Social, and Governance) goals are accelerating this trend, making eco-friendly roll shapers a competitive differentiator.

Finally, the automotive and electric vehicle (EV) sectors are creating new opportunities. As EV manufacturers seek lightweight, high-strength components to improve battery efficiency and vehicle performance, roll forming is being adopted for chassis parts, battery enclosures, and structural reinforcements. This demand is pushing innovation in high-tensile steel and aluminum roll forming technologies.

In summary, by 2026, the roll shaper machine market will be characterized by smart manufacturing integration, sector-specific customization, sustainability initiatives, and strong growth in construction and advanced transportation industries. Companies that invest in digitalization, flexibility, and green technologies are expected to lead the next phase of market evolution.

Common Pitfalls When Sourcing Roll Shaper Machines (Quality and Intellectual Property)

Sourcing a roll shaper machine—especially from international or unfamiliar suppliers—presents several risks that can impact production efficiency, product quality, and legal compliance. Two of the most critical areas of concern are machine quality and intellectual property (IP) protection. Being aware of these common pitfalls helps mitigate risks and ensures a reliable, long-term investment.

Poor Build Quality and Substandard Components

One of the most frequent issues when sourcing roll shaper machines, particularly from low-cost manufacturers, is compromised build quality. Suppliers may use inferior materials or cut corners in machining and assembly to reduce costs. This results in machines that wear out quickly, require frequent maintenance, or fail to maintain precise tolerances. Poor alignment, weak frame structures, or low-grade rollers can lead to inconsistent shaping, increased downtime, and higher total cost of ownership.

Inadequate Calibration and Precision

Roll shaper machines require high precision to ensure uniform shaping across long runs. Machines sourced from unreliable vendors may lack proper calibration during manufacturing or fail to maintain accuracy under production loads. Without documented quality control processes or performance testing, buyers risk receiving equipment that cannot meet production specifications, leading to wasted materials and rework.

Lack of Quality Assurance and Testing Documentation

Reputable manufacturers provide detailed quality assurance documentation, including material certifications, alignment reports, and performance test results. Many low-tier suppliers either omit this documentation or provide falsified reports. Without verifiable data, buyers have no assurance that the machine meets engineering standards or will perform as expected in real-world conditions.

Hidden Intellectual Property Infringement

A significant legal risk when sourcing roll shaper machines—especially from regions with lax IP enforcement—is inadvertently purchasing machines that infringe on patented technologies. Some manufacturers replicate designs, control systems, or roll forming methodologies protected by patents without authorization. Buyers using such machines may face legal action from IP holders, even if they were unaware of the infringement, leading to costly litigation, machine seizure, or production halts.

Use of Counterfeit or Unlicensed Software and Controls

Modern roll shapers often rely on proprietary software for CNC controls, diagnostics, and automation. Some suppliers install pirated or unlicensed versions of industrial software to cut costs. This not only violates software licensing agreements but can also result in poor performance, lack of updates, and cybersecurity vulnerabilities. In the event of an audit or legal challenge, the end user may be held liable for using unlicensed software.

Insufficient Technical Support and Spare Parts Availability

Even if a machine initially meets quality standards, poor after-sales support can undermine its long-term value. Many overseas suppliers offer limited technical assistance or fail to maintain inventories of spare parts. When critical components fail, delays in sourcing replacements can halt production for extended periods. Additionally, lack of documentation or training increases the risk of improper operation and accelerated wear.

Misrepresentation of Capabilities and Specifications

Some suppliers exaggerate machine capabilities—such as maximum material thickness, forming speed, or precision tolerances—to win contracts. Without independent verification or on-site testing, buyers may discover post-delivery that the machine cannot handle their production requirements. This misalignment leads to costly retrofits, delays, or the need to purchase additional equipment.

Failure to Secure IP Ownership in Custom Designs

When commissioning a custom roll shaper machine, buyers often assume they own the design and associated IP. However, without a clear contractual agreement, the supplier may retain rights to the design, limiting the buyer’s ability to replicate, modify, or service the machine independently. This can result in vendor lock-in and increased costs for future upgrades or repairs.

Conclusion

To avoid these pitfalls, buyers should conduct thorough due diligence, including factory audits, third-party inspections, and legal review of IP clauses in procurement contracts. Engaging reputable suppliers with proven track records, transparent manufacturing processes, and strong IP compliance is essential for ensuring both quality and legal safety when sourcing roll shaper machines.

Logistics & Compliance Guide for Roll Shaper Machine

Overview

This guide provides essential information for the safe and compliant transportation, handling, import/export, and installation of Roll Shaper Machines. Adhering to these guidelines ensures regulatory compliance, minimizes risks, and supports efficient logistics operations.

Packaging & Crating Requirements

Roll Shaper Machines must be securely packaged to prevent damage during transit. Use weather-resistant, wooden export crates that meet ISPM-15 standards for international shipments. Include internal bracing, foam padding, and corner protectors to secure moving parts and sensitive components. Clearly label crates with handling instructions (e.g., “Fragile,” “Do Not Invert,” “Keep Dry”).

Transportation & Handling

Use flatbed trucks or containerized shipping (20’ or 40’ HC) depending on machine size. Ensure proper lifting points are used during loading/unloading—never lift by control panels, rollers, or auxiliary parts. Forklifts must engage only at designated points with appropriate capacity. Confirm ground stability at delivery site and use skids or rollers for on-site movement.

Import/Export Documentation

Prepare all required international trade documentation, including:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Technical Specifications (for customs classification)

For exports, verify export control classifications (e.g., ECCN) under relevant regulations such as the EAR (Export Administration Regulations). Importers must comply with local customs codes (e.g., HS Code 8462.21 or similar for metal forming machinery).

Regulatory Compliance

Ensure the Roll Shaper Machine meets applicable safety and environmental standards in the destination country:

– CE Marking (for EU markets) per Machinery Directive 2006/42/EC

– UKCA Marking (for UK markets)

– UL/CSA Certification (for North America)

– Compliance with local electrical codes (e.g., NEC in USA, IEC standards internationally)

Include necessary technical files, EC Declarations of Conformity, and user manuals in the local language.

Customs Clearance & Duties

Engage a licensed customs broker to facilitate clearance. Accurately declare the machine’s value, country of origin, and technical specifications to avoid delays or penalties. Be prepared to pay applicable import duties, VAT, or GST based on the destination’s tariff schedule. Retain all documentation for audit purposes.

Installation & Site Preparation

Verify that the installation site meets machine requirements:

– Adequate floor load capacity

– Proper power supply (voltage, phase, frequency)

– Sufficient space for operation and maintenance

– Environmental controls (temperature, humidity, dust)

Ensure only qualified personnel perform installation and initial calibration. Follow the manufacturer’s installation manual and conduct safety checks before commissioning.

Safety & Training Compliance

Provide operators and maintenance staff with training on safe operation, emergency procedures, and lockout/tagout (LOTO) protocols. Maintain training records and ensure compliance with OSHA (USA), HSE (UK), or equivalent workplace safety regulations.

Environmental & Disposal Regulations

Dispose of packaging materials (e.g., wood, plastic, foam) in accordance with local waste management regulations. For end-of-life machine disposal, follow WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Recycle metal components and properly handle any hazardous materials (e.g., hydraulic fluids).

Support & Warranty Logistics

Register the machine with the manufacturer to activate warranty coverage. Keep shipping labels, delivery receipts, and installation reports for warranty claims. For service support, provide machine serial number, location, and detailed issue descriptions to streamline logistics for spare parts and technician dispatch.

Conclusion for Sourcing a Roll Shaper Machine:

After a thorough evaluation of technical specifications, supplier capabilities, cost considerations, lead times, and after-sales support, sourcing a roll shaper machine requires a strategic balance between quality, performance, and cost-efficiency. It is essential to select a supplier that not only meets the technical requirements of the production process—such as precision, speed, material compatibility, and customization—but also offers reliable service, training, and maintenance support.

Investing in a high-quality roll shaper machine from a reputable manufacturer ensures improved product consistency, reduced downtime, and long-term operational efficiency. Additionally, considering factors such as energy consumption, ease of integration into existing production lines, and future scalability will contribute to sustainable manufacturing growth.

Ultimately, the successful sourcing of a roll shaper machine hinges on due diligence, clear communication with suppliers, and aligning the machine’s capabilities with specific production goals. A well-informed decision will enhance productivity, maintain product quality, and support the overall competitiveness of the manufacturing operation.