Introduction: Navigating the Global Market for Rocker Chair Parts

Global buyers face fragmented specifications, inconsistent hardware quality, and multi-tier lead times in rocker chair parts. Small variances (e.g., bearing width or runner profile) trigger fit issues, returns, and brand risk across USA and Europe.

This guide shows how to standardize specs, source compliant suppliers, and de-risk QC and logistics across regions.

- Common pitfalls

- Mixed hardware dimensions (M8 vs. UNC threads; 55–58 mm bearing centers)

- Uncoated zinc fittings failing salt spray (SS) tests; corrosion-related returns

- Wood runners with inconsistent grain or moisture, causing split rockers

- Unknown supplier process control (heat treat, plating bath control)

- Limited batch traceability and no REACH/RoHS documentation

-

Long, variable lead times from Far East; limited DDP options in EU

-

Representative part categories and typical price cues (indicative)

| Category | Example SKU | Price Cue | Risk Notes |

|—|—|—:|—|

| Bearings / fittings | 4Pcs M8×45/55 mm bearing kits | ~$9.99–$14.99 | Thread mix-ups; plating variability |

| Runners / rockers | Steam-bent oak, 1-1/16″ wide | ~$59.95 | Moisture/grain; finish adhesion |

| Spring plates | 5″×2.5″ fiberglass plate | ~$19.89 (2-pack) | Dimensional tolerance; UV aging |

| Misc. hardware | Screws/bolts sets | ~$9.99 | Surface finish/salt spray failure |

What you’ll learn

– Map the supplier landscape (USA, EU, CN/VN)

– Align with EN 14749, EN 16139 (USA: ASTM F1858), REACH/RoHS, TSCA Title VI formaldehyde, BIFMA

– Build an actionable spec and packaging/QMS checklist

– Qualify suppliers with clear AQL, traceability, and plating/heat‑treat requirements

– Manage Incoterms (DDP/DDU), duties, and regional logistics for USA/EU

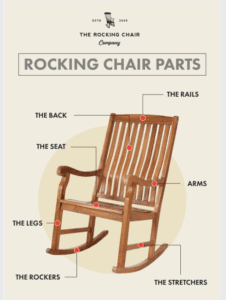

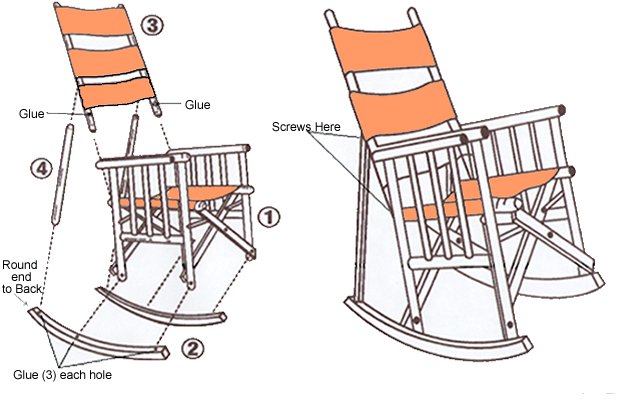

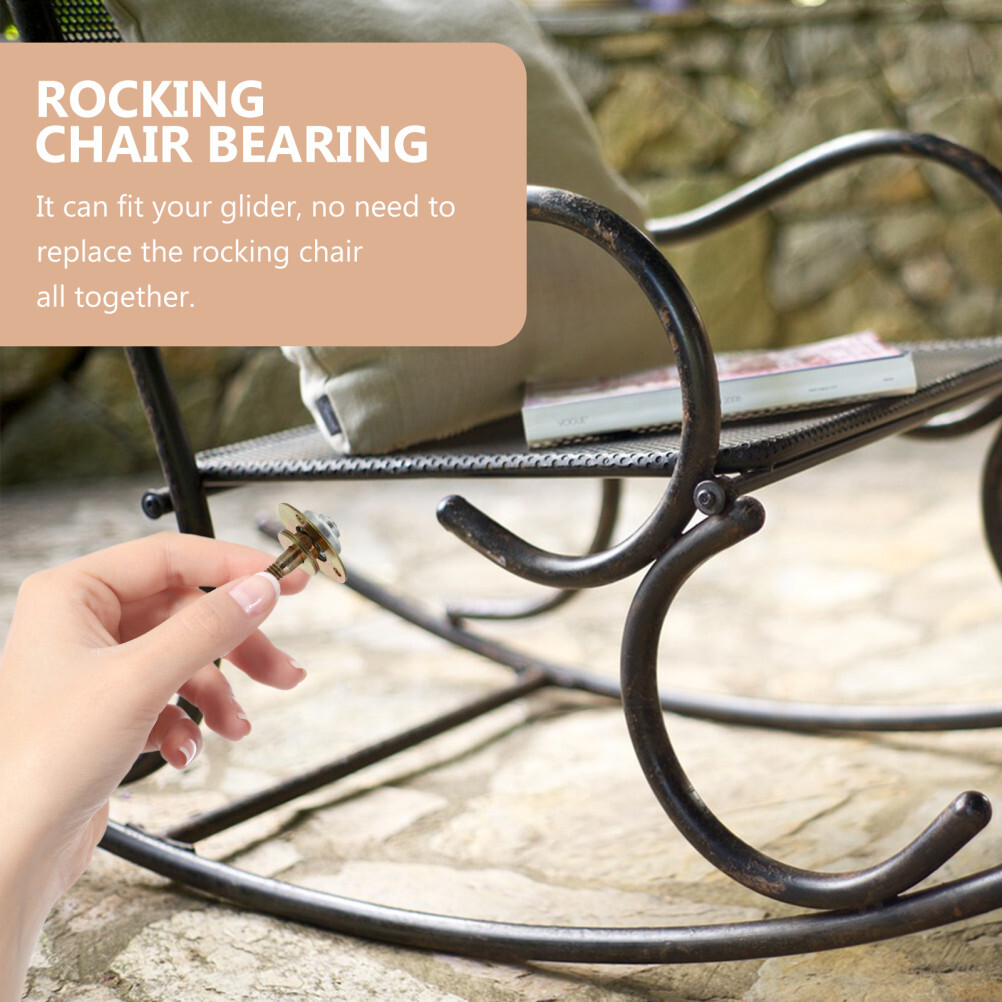

Illustrative Image (Source: Google Search)

By the end, you’ll source confidently, reduce returns, and ship compliant, market‑ready rocker chair parts.

Article Navigation

- Top 10 Rocker Chair Parts Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for rocker chair parts

- Understanding rocker chair parts Types and Variations

- Key Industrial Applications of rocker chair parts

- 3 Common User Pain Points for ‘rocker chair parts’ & Their Solutions

- Strategic Material Selection Guide for rocker chair parts

- In-depth Look: Manufacturing Processes and Quality Assurance for rocker chair parts

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘rocker chair parts’

- Comprehensive Cost and Pricing Analysis for rocker chair parts Sourcing

- Alternatives Analysis: Comparing rocker chair parts With Other Solutions

- Essential Technical Properties and Trade Terminology for rocker chair parts

- Navigating Market Dynamics and Sourcing Trends in the rocker chair parts Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of rocker chair parts

- Strategic Sourcing Conclusion and Outlook for rocker chair parts

- Important Disclaimer & Terms of Use

Top 10 Rocker Chair Parts Manufacturers & Suppliers List

1. Swivel Rocker Parts & Components for Patio Furniture

Domain: hauserspatio.com

Registered: 2007 (18 years)

Introduction: Free delivery over $1,399 · 30-day returnsUpgrade or repair your patio furniture with our selection of swivel rocker parts and components, including bushings, spring plates, and assemblies….

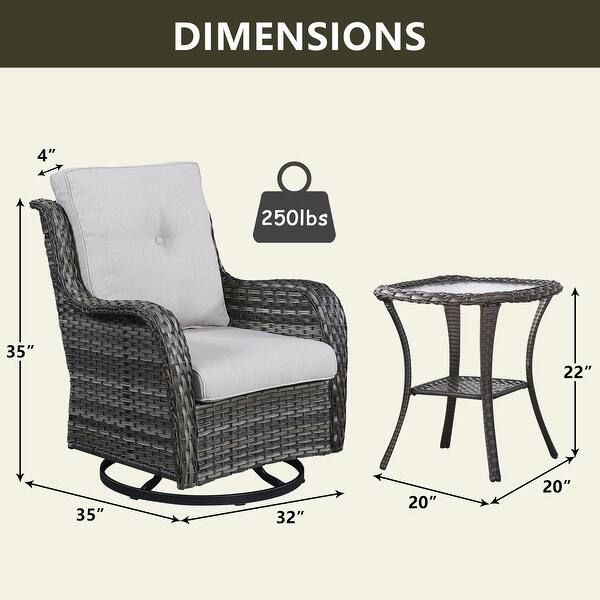

Illustrative Image (Source: Google Search)

2. Chair Swivel Plates and Parts | Trendler in Chicago, IL

Domain: trendler.com

Registered: 1996 (29 years)

Introduction: Trendler manufactures chair swivel plates in a variety of dimensions and patterns. You can call us at (773) 284-6600 to speak with our swivel doctor….

3. Swivel chair parts suppliers offer heavy duty swivel chair base

Domain: tincci.com

Registered: 2019 (6 years)

Introduction: Rating 5.0 (1) Dec 11, 2023 · We are swivel chair parts suppliers from China, providing 4 leg heavy duty swivel chair base to fit for dining chairs and armchairs….

4. OEM Rocker Chair Base Manufacturer

Domain: shfurnitureaccessories.com

Registered: 2023 (2 years)

Introduction: Shen Hui International Group Limited is a leading manufacturer of high-quality Rocker Chair Bases. Our company has been in the industry for many years, ……

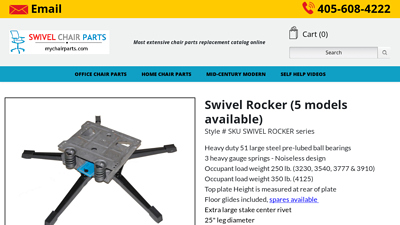

5. Upholstered Swivel and Rocker Base Chair Parts | MyChairParts

Domain: mychairparts.com

Registered: 2014 (11 years)

Introduction: 6–10 day deliveryFind premium swivel chair base replacement parts and rocker bases for chairs at MyChairParts. Explore our selection for durable and comfortable seating ……

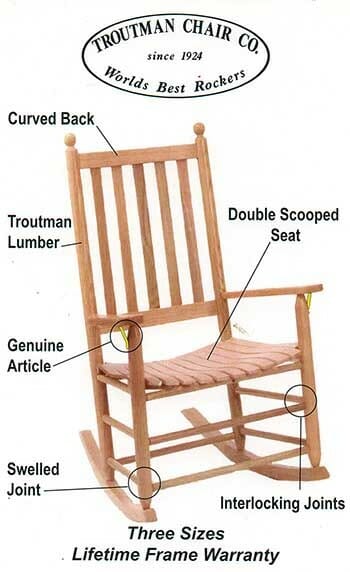

Illustrative Image (Source: Google Search)

6. Chair Mechanisms Manufacturers and Suppliers – TradeWheel

Domain: tradewheel.com

Registered: 2003 (22 years)

Introduction: Get best selection of home and commercial Chair Mechanisms at affordable price from global manufacturers, suppliers, exporters and wholesalers at ……

7. Rocking Chairs Manufacturers and Suppliers in the USA and Canada

Domain: thomasnet.com

Registered: 1996 (29 years)

Introduction: Distributor of outdoor and Adirondack rocking chairs for indoor and outdoor use. Features vary depending upon model, including 304 stainless steel hardware, ……

8. Swivel Rocker & Glider Parts – Sunniland Patio

Domain: sunnilandpatio.com

Registered: 2006 (19 years)

Introduction: 8-day delivery 30-day returnsFind all the parts you need to repair your swivel rocker or glider here. If you have any questions just send us a chat!…

Understanding rocker chair parts Types and Variations

Understanding Rocker Chair Parts: Types and Variations

Overview

This section catalogs the core part categories used in rocking chairs and rocking gliders, with design notes to inform specification, sourcing, and cross-market supply in the USA and Europe. Variations are driven by material, mounting geometry, and load path; selection hinges on load capacity, assembly method, durability in indoor/outdoor use, and compliance with local hardware standards.

Type-to-use comparison

| Type | Features | Applications | Pros | Cons |

|---|---|---|---|---|

| Runners/Rockers | Steam-bent or formed rails; curved profile; typically 1-1/16″ wide; various joinery (mortise/tenon, dowels, adhesives) | Classic rocking chairs; benches; replacement and repair | Long-travel stability; authentic motion; repair-friendly | Long shipping footprint; finishing required; susceptible to finish wear |

| Rocker Pivot Assemblies | M8 or similar pivot bolts; zinc-alloy/steel components; washers/spacers; torque-limited assembly | Indoors and light-duty commercial settings | Compact, modular; easy swap | Limited axial load; corrosion risk if uncoated |

| Hardware Kits (Bearing Connecting Pieces) | M8x45/55 kits; zinc alloy; 4–8 pcs per set; includes washers/spacers and/or screws | OEM assembly and field replacement | Cost-effective; fast installation | Mixed tolerances; finish longevity varies |

| Glider Track Assemblies and Spring Plates | Fixed track with rail/pivot; spring plates ~2.5″ x 5″ x 0.25″; fiberglass/metal; multiple mounting holes | Outdoor gliders; patio and lawn furniture | Smooth, low-noise glide; weather-friendly plates | Plate breakage over time; track wear at pivot points |

| Outdoor Patio Connectors (Spring Plates) | Fiberglass or metal spring plates; 0.25″ thickness; universal hole patterns | Budget outdoor rocking chairs | Economical; universal fit | Lower impact resistance; limited load data |

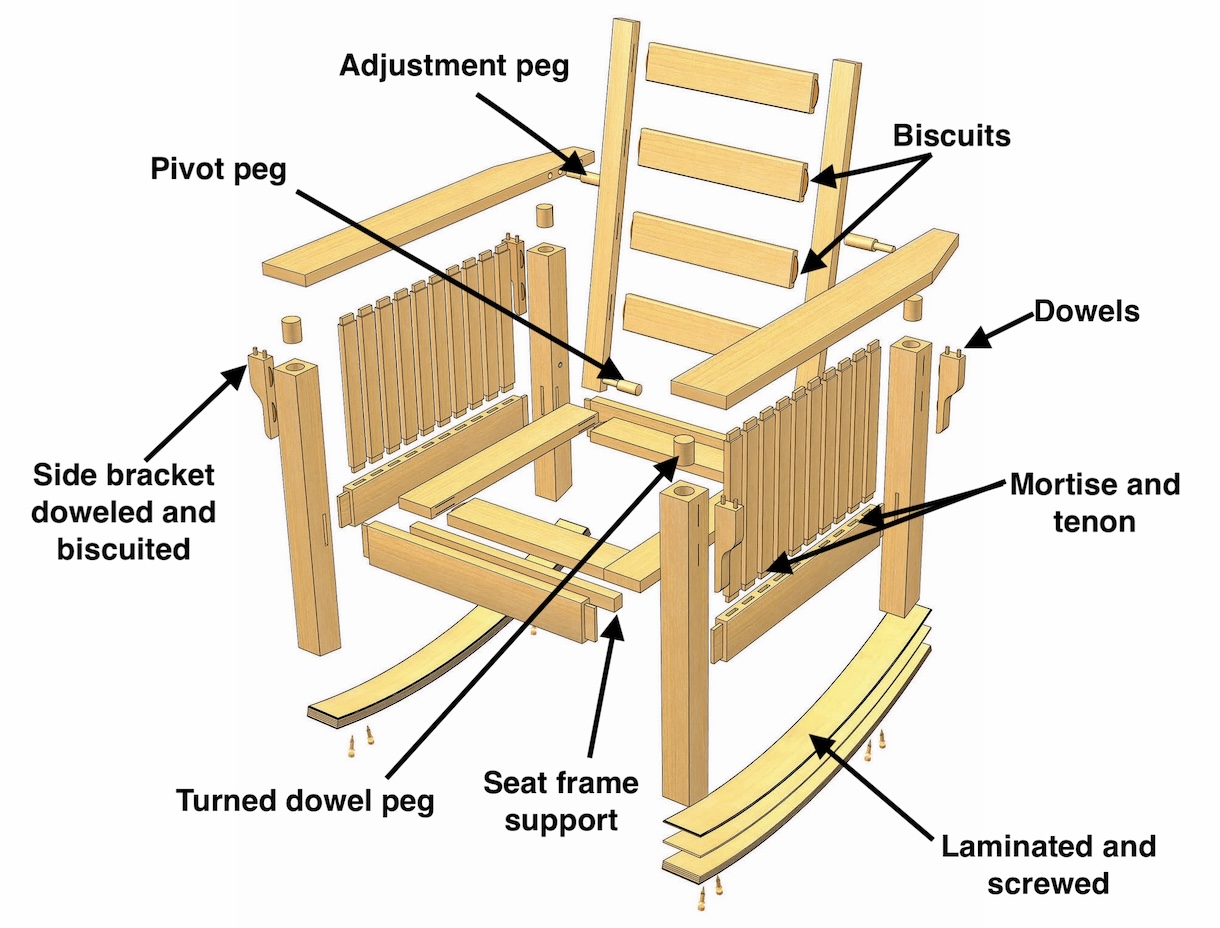

Runners/Rockers

- Definition: Curved rails that provide the rocking arc and structural base for the chair.

- Features:

- Width: commonly 1-1/16″; thickness varies with species/grade.

- Material: hardwood (oak, maple, beech) or metal; species selection for stiffness and creep resistance.

- Joinery: mortise/tenon with mechanical fasteners and/or adhesives; factory-finished or ready for finishing.

- Applications:

- Indoor classic rocking chairs; antique restoration; OEM lines requiring wood aesthetics.

- Pros:

- High stability over long travel; repairable and replaceable; material sustainability if hardwood.

- Cons:

- Logistics and handling (long, curved profiles); finishing labor/costs; vulnerability to finish wear with frequent use.

Rocker Pivot Assemblies

- Definition: The bearing/connecting piece that couples the chair to the runners or tracks via a pivot bolt and spacers.

- Features:

- Materials: zinc-alloy, steel, stainless (market dependent); common M8 thread; torque specified by kit/instructions.

- Components: washers, spacers, cap, serrated flange or anti-rotation features for seating.

- Applications:

- Modern wood and upholstered rockers; light-duty hospitality; residential.

- Pros:

- Compact and modular; quick replacement; repeatable assembly.

- Cons:

- Limited published load ratings; finish corrosion in humid or coastal conditions if not stainless or adequately plated.

Hardware Kits (Bearing Connecting Pieces)

- Definition: Packaged pivot/bearing sets that include the fasteners, spacers, and any mounting hardware needed to assemble the rocker mechanism.

- Features:

- Typical kit sizes: M8 x 45 mm, M8 x 55 mm; 4–8 pieces per pack; zinc alloy body.

- Included parts: pivot bolts, washers (flat/belleville), spacers, set screws or cap nuts where applicable.

- Applications:

- OEM assembly lines, aftermarket repair, multi-chair service kits for retailers and repair shops.

- Pros:

- Economical; reduced sourcing complexity; fast installation; standardized hole patterns.

- Cons:

- Fit variance across brands; finish quality varies; limited data on cycle life.

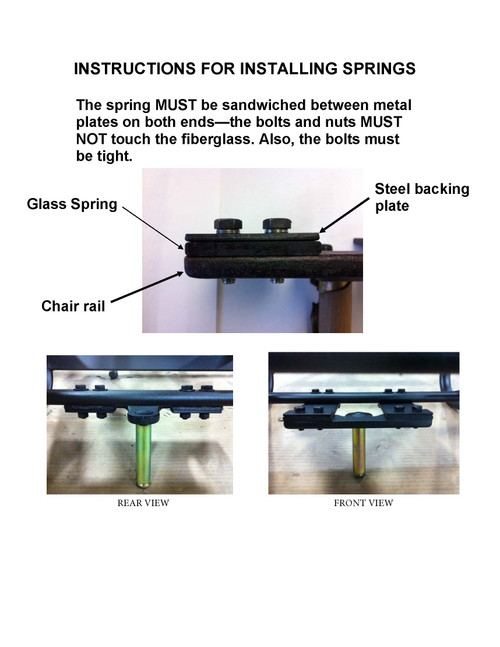

Glider Track Assemblies and Spring Plates

- Definition: Glider mechanisms that move on fixed rails; spring plates form resilient pivot points in the track system.

- Features:

- Track: aluminum/steel rails with carriage/pivot assemblies; fixed base mounting.

- Spring plates: approximately 2.5″ x 5″ x 0.25″; fiberglass or metal; multiple mounting holes for universal fit.

- Applications:

- Outdoor gliders; patio furniture; high-traffic family spaces requiring smooth motion.

- Pros:

- Smooth, low-noise glide; resilient plates reduce harsh impacts; suitable for outdoor use.

- Cons:

- Plate fatigue/breakage with heavy use; track wear at rail/contact points; replacement may require matching geometry.

Outdoor Patio Connectors (Spring Plates)

- Definition: Interchangeable spring plates used as connectors/pivot elements in outdoor rocking chairs, often sold as universal replacement parts.

- Features:

- Fiberglass plates with ~0.25″ thickness; universal hole patterns; sized for typical outdoor frames.

- Applications:

- Budget outdoor furniture; replacement after plate failure; seasonal rental properties.

- Pros:

- Low cost; widely available; simple swap without major disassembly.

- Cons:

- Lower impact resistance; limited load specifications; weather exposure shortens lifespan without UV protection.

Selection Guidance

- Load and usage: Match pivot assemblies and plates to expected user weight and usage frequency; confirm bolt torque with kit recommendations and apply thread locker if required.

- Corrosion: Specify stainless or appropriate plating (zinc-nickel, powder coat) for humid, coastal, or outdoor environments.

- Standards and compatibility: Ensure fastener threads (M8 vs. SAE), head styles, and mounting hole patterns align with target frames; review local regulations where applicable.

- Supplier evaluation: Confirm dimensional tolerances, finishing QA, and cycle test data; verify packaging and labeling meet USA/EU market requirements.

Compliance and Notes

- Market standards: Use hardware that complies with regional standards; confirm manufacturer declarations of conformity for fasteners and finishes.

- Care and maintenance: Inspect pivot points and plates periodically; re-torque fasteners per OEM guidelines; replace worn plates to avoid catastrophic failure.

Key Industrial Applications of rocker chair parts

Key Industrial Applications of Rocker Chair Parts

Industrial buyers across the USA and Europe typically source rocker chair parts for new production, retrofits, and MRO. Below is a consolidated view of where these components are deployed and the operational benefits they deliver.

| Industry | Typical Applications | Detailed Benefits |

|---|---|---|

| Commercial furniture manufacturing (new builds) | Bearing kits, rockers/runners, springs; assembly lines and after-sales kits | Faster assembly with modular kits; consistent rocker geometry reduces rework; smoother, quieter motion improves product quality and customer satisfaction; standardized M8 bearings and plate hardware streamline SKUs. |

| Furniture OEM and private-label programs | Catalog-driven bearing/rocker kits; QA integration at final assembly | Enables rapid SKU variants and line extensions; improves first-pass yield through validated hardware; simplifies warranty with replaceable, standardized parts. |

| Hospitality and leisure | High-traffic lobby seating, café rocking chairs, patio rocking furniture | Durable bearings and runners withstand frequent use; service kits lower service time; spring plates maintain stability in mixed-material builds; reduces chair-downtime in public spaces. |

| Healthcare and senior care | Glider/rocker recliners in patient rooms, day rooms; birthing chairs | Reliable motion mechanisms enhance patient comfort; noise-dampening components minimize disturbance; replaceable kits allow in-house maintenance without full chair replacement. |

| Outdoor and public space furniture | Outdoor rockers, park benches with rocking mechanisms | Stainless/stainless-coated hardware resists corrosion; UV-stable bearings and plates reduce maintenance in exterior environments; modularity speeds field repairs. |

| Repair, restoration, and reupholstery shops | Retrofitting antique rockers; repairing commercial units | Standardized bearings (e.g., M8 x 45 mm-class) simplify part matching; pre-finished runners fit common widths; repeatable geometry delivers consistent performance post-repair. |

| Distribution and MRO for furniture OEM/service centers | Spare parts kits for field technicians; distributor SKUs | Centralized purchasing of kits (bearings + screws + washers) lowers TCO; improved stock-turn with predictable replacement cycles; standardized hardware shortens picking and installation time. |

- Common industrial SKUs: bearing kits (often M8-class, typically ~45 mm length variants), zinc-alloy or stainless-steel bearing sets, steel/aluminum runners/rockers with curved geometry (e.g., ~1-1/16 in width), and spring plates (commonly ~2.5 in x 5 in x ~0.25 in).

- Standards and compliance (USA/EU): confirm materials and finishes against applicable requirements (e.g., FDA/EU food-contact for coated hardware where relevant; low-emission finishes for indoor environments; environmental compliance such as EU REACH and RoHS where applicable).

- Procurement notes: specify bearing size class (e.g., M8 x 45 mm), runner width and material, surface finish (zinc/galvanized/stainless), and include all fasteners and washers for a complete, field-serviceable kit.

3 Common User Pain Points for ‘rocker chair parts’ & Their Solutions

3 Common User Pain Points for Rocker Chair Parts & Their Solutions

1) Compatibility and Size Mismatches (bearings, bolts, runners)

Scenario

A procurement team sources bearing connectors and runners from multiple vendors; later, installers report misalignment and insufficient clearance.

Illustrative Image (Source: Google Search)

Problem

Mismatch between bearing diameter/thread (e.g., M8 vs. M6), bolt length, runner width, and runner curvature prevents assembly and compromises safety.

Solution

– Define and lock standards: Thread size (e.g., M8), bolt length (45 mm or 55 mm), runner width, and runner rise/curvature.

– Require vendors to submit detailed specs and photos before PO (example products with explicit spec callouts).

– Consolidate on kits (e.g., M8x45 mm or M8x55 mm hardware kits; pre-machined runners) to reduce custom work.

Quick spec examples (from listed products)

– Bearing connecting piece kits: 4.3–4.6/5 stars (236–280 reviews), e.g., 4pcs M8x45 mm, 4.6/5 (77), $9.99

– 8 pcs M8 x 55 mm, 4.3/5 (236), $14.99

– Bent oak runners for repair, 4.5/5 (36), $59.95

2) Premature Bearing Wear and Squeaks

Scenario

New chairs develop squeaks and resistance at the rocker mechanism after a short service period.

Illustrative Image (Source: Google Search)

Problem

Under-specified zinc-alloy bearings, inadequate lubrication, or oversized clearances degrade quickly under cyclic load.

Solution

– Specify material and load rating (e.g., durable zinc alloy or better), and require QA reports on cycle life.

– Use kits that include matching hardware (screws/washers) to avoid torque overloading.

– Provide assembly notes: use threadlocker, torque to spec, add dry lubricant where appropriate.

– Source from kits with proven performance (e.g., 4pcs hardware kits; 8 pcs M8x55 mm options) and verify consistency across batches.

3) Stockouts and Unstable Lead Times

Scenario

Inventory dips due to a successful product launch; replacement hardware goes out of stock, halting production lines.

Problem

Low stock or overreliance on single listings (e.g., “Only 5 left”) creates downtime.

Illustrative Image (Source: Google Search)

Solution

– Hold safety stock for critical SKUs (M8x45, M8x55 mm bearings; standard runners).

– Dual-source using cross-compatible parts with documented specs and certifications.

– Maintain a shortlist of comparable options with clear packaging and thread/fit details.

Example stock cues (from listings)

– Bent oak runners listed with “Only 5 left in stock – order soon”

– Hardware kits often delivered next-day from Amazon’s network (when ordered to regions like the EU/US with Prime/ELigible delivery; note: “FREE delivery Fri, Dec 19 to Philippines on $49+ eligible items”)

Strategic Material Selection Guide for rocker chair parts

Strategic Material Selection Guide for Rocker Chair Parts

Purpose

– Match materials to each rocker chair subsystem to meet durability, safety, noise, and cost targets across residential, contract/hospitality, and outdoor use cases in the USA and Europe.

Design environment inputs (define before selection)

– Static and dynamic loads (person + furniture inertia), typical cycle counts, service conditions (indoor dry, indoor humid, outdoor coastal), acoustic limits, maintenance capability, sustainability targets, and budget bracket.

Illustrative Image (Source: Google Search)

Material decisions by component

Runners and curved rails

- Materials

- Hardwood (oak, maple, beech): high bending strength and classic aesthetic; steam bending feasible at ~1″ (25 mm) stock; excellent surface feel and repairability.

- Engineered wood (LVL, birch plywood): consistent strength, straight grain; enables thin profiles with comparable or better fatigue performance.

- Aluminum (6061-T6 extrusions + CNC-formed bends): corrosion-resistant, lighter weight, no splintering; preferred for outdoor and contract use.

- Coatings/finishes

- Indoors: catalyzed varnish, oil/poly combo; outdoors: marine spar varnish or powder coat (polyester TGIC).

- Selection notes

- USA residential: hardwood for feel and brand differentiation; USA contract/outdoor and EU outdoor/contract: aluminum or marine-grade hardwood with robust coatings.

- Check for low-VOC and VOC-compliant finishing in shops per local regulations (CARB/EPA TSCA Title VI; EU VOC labeling).

Bearing connecting pieces and glider interfaces

- Materials

- Stainless steel (A2/A4): best fatigue and corrosion resistance; use where salt/humidity or frequent cleaning is expected.

- Zinc alloy (Zamak): good for moderate loads, cost-effective, clean finish; ensure adequate wall thickness and bearing seats; acceptable in low-cycle indoor use.

- Bronze/bronze-backed composites: good wear and noise control; higher cost, often used in specialty/architectural applications.

- Thermoplastics (UHMW-PE, acetal/POM): self-lubricating, quiet; ideal as liners/bushings to reduce squeak; limit UV and load.

- Design details

- Use matched bearing/bushing sizes (e.g., M8 bore) and incorporate anti-backout features if possible.

- Provide compliance test: load to 1.5× rated and 10k–50k cycles per target duty.

- Selection notes

- Indoor standard duty: zinc alloy or stainless with plastic bushings.

- Outdoor/coastal: stainless steel (A4 for marine environments).

- For low-noise residential: stainless bearing + UHMW or bronze composite sleeve/bushing.

Fasteners (socket cap, hex, machine screws, carriage bolts)

- Materials

- Stainless steel (A2/A4): recommended for corrosion resistance and service life; A4 preferred near coasts or treated wood.

- Zinc-plated alloy steel (Class 8.8/10.9): economical and strong for indoor applications; finish must resist white rust and zinc creep.

- Painted/coated steel: color-match option; ensure sufficient layer thickness over thread relief.

- Selection notes

- Standard indoor: zinc-plated steel; frequent cleaning or moist climates: stainless.

- Use lubrication or anti-seize where steel-to-steel interfaces occur to prevent galling.

Spring plates and deck mounts

- Materials

- Stainless steel sheet/strip (A2): durable, formable, and corrosion-resistant; suitable for outdoor decks and patio rockers.

- Spring steel with protective coating (powder/ED): economical but lower corrosion resistance; best for indoor, climate-controlled use.

- Plywood/composite (marine-grade): traditional and visually compatible; lower repeat fatigue compared to metals.

- Selection notes

- Indoors: powder-coated steel or marine plywood is adequate.

- Outdoors: stainless steel spring plates for longevity and stability.

Arm and seat brackets

- Materials

- Steel (tube/stampings) with powder coat: high stiffness-to-cost; widely used across categories; ensure coating cure for humidity tolerance.

- Aluminum (6061) with anodize/powder: corrosion resistance, light weight; suitable for outdoor and contract specs.

- Zinc die cast: cost-effective for housings and brackets; keep loads within Zamak limits; surface finishing required for wear resistance.

- Selection notes

- Budget-sensitive indoor: powder-coated steel.

- Premium outdoor or contract: aluminum or stainless-stamped parts with robust coatings.

Foot pads and glide accessories

- Materials

- Rubber (EPDM/NBR): quiet and floor-protective; EPDM offers UV/ozone resistance.

- Felt/nylon: low noise, good for wood floors; lower abrasion resistance.

- Thermoplastic elastomers (TPE): soft-touch and cost-effective; limited UV unless specified.

- Selection notes

- Indoors on hard floors: rubber or felt; avoid hard PVC pads that mark floors and squeak.

Material compliance and sustainability

- Wood: FSC certification available; ensure CARB Phase 2/EPA TSCA Title VI compliance for engineered wood; formaldehyde-safe adhesives in EU usage.

- Plastics/rubber: confirm RoHS and REACH compliance for EU; avoid restricted phthalates and SVHCs where applicable.

- Metals and finishes: RoHS compliance for plated/finished hardware; select EU-compliant surface treatments; powder coat and zinc-plating systems must meet VOC and labeling where applicable.

- Regional procurement: align grade designations (e.g., A2/A4, AISI/EN equivalents) with local stock and standards.

Material comparison matrix

| Material/Alloy (typical) | Relative durability (10k–100k cycles) | Friction/Noise tendency | Maintenance | Sustainability/Recyclability | Cost band | Best use-cases |

|---|---|---|---|---|---|---|

| Hardwood (oak/maple) | High with proper section | Low when paired with liners; can squeak at high cycles | Low; refinishable | High (renewable); mid recyclability | Mid | Residential indoors, premium feel |

| Engineered wood (LVL/plywood) | High; consistent strength | Moderate without liners | Low | Mid (use FSC/E1/CARB) | Mid | Contract/hospitality |

| Aluminum 6061-T6 | High; fatigue stable | Moderate (use liners/bushings) | Low | High (recyclable) | Mid–High | Contract/outdoor; lighter assemblies |

| Stainless steel (A2/A4) | Very high | Moderate; better with plastic/bronze bushings | Low | High (recyclable) | Mid–High | Bearings, springs, fasteners in moist/coastal |

| Zinc alloy (Zamak) | Moderate | Moderate; can squeak if under-sized | Low–Mid | Moderate (recyclable) | Low | Indoor bearing housings/brackets |

| Spring steel + coating | Moderate | Moderate; squeak if metal-on-metal | Mid | Moderate | Low | Indoor spring plates |

| Bronze/bronze-backed composites | High | Low; excellent wear/noise | Low | Moderate | High | Premium, low-noise interfaces |

| UHMW-PE / POM liners | Moderate (wear-limited) | Very low (self-lubricating) | Low | High | Low | Noise mitigation, bushings |

| Rubber (EPDM) | Moderate | Very low (quiet); UV-resistant (EPDM) | Low | Moderate | Low | Pads, glide feet |

| Marine plywood | Moderate | Moderate; can crack under high cycles | Mid | Moderate | Mid | Traditional runners, indoor/outdoor with proper finish |

Recommended assemblies by category

– Budget indoor residential

– Runners: hardwood or engineered wood with varnish; Bearing housing: zinc alloy with UHMW liner; Fasteners: zinc-plated steel; Spring plates: coated spring steel.

– Premium indoor residential

– Runners: hardwood (oak/beech) with premium finish; Bearings: stainless steel with bronze liner; Fasteners: stainless; Spring plates: stainless.

– Contract hospitality (indoor)

– Runners: engineered wood or hardwood; Bearings: stainless; Fasteners: stainless; Finish: VOC-compliant coatings.

– Outdoor/patio/contract

– Runners: aluminum or marine-grade hardwood with marine finish; Bearings: stainless steel (A4 where coastal); Fasteners: stainless; Spring plates: stainless; Pads: EPDM.

How to specify and procure (US/EU)

– Include material spec by subsystem (e.g., “Bearings: A2 stainless with UHMW bushing; Fasteners: A2 stainless socket cap, 50 k cycles guaranteed; Finish: polyester powder TGIC, 250 h ASTM B117 salt spray” if outdoor).

– Request RoHS/REACH declarations and wood compliance statements (CARB/E1) with shipments.

– Define a verification plan: 1.5× static load, 50k cycle test, noise ≤ specified dB at seating plane, and salt spray/humidity cycles as needed.

Illustrative Image (Source: Google Search)

Notes on market patterns

– Commodity kits for replacement rocking-chair bearings typically use zinc alloy with zinc-plated steel fasteners; many include plastic bushings to reduce noise.

– Outdoor/spring plate and runner products appear in stainless steel or wood with weather-resistant finishes.

– For higher quality and longer service life, specify stainless steel bearings and fasteners and avoid zinc-only housings in humid or outdoor environments.

In-depth Look: Manufacturing Processes and Quality Assurance for rocker chair parts

In-depth Look: Manufacturing Processes and Quality Assurance for Rocker Chair Parts

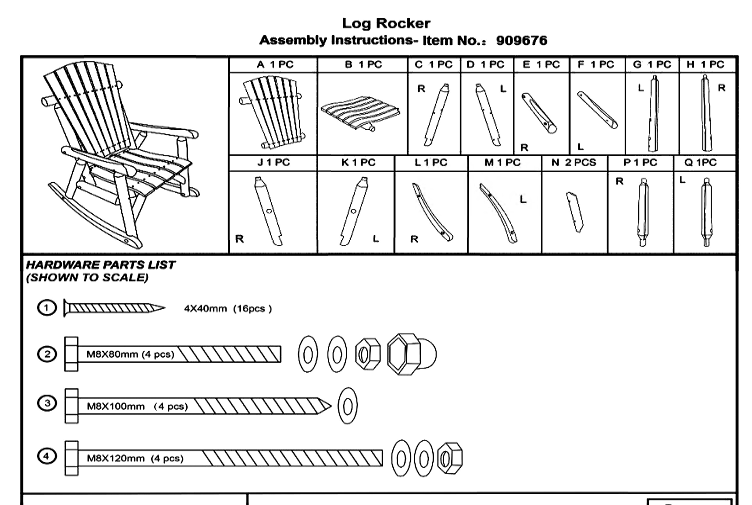

This section outlines standardized manufacturing methods and quality controls for the main rocker chair components sold into the USA and Europe: zinc die‑cast bearing/connector kits, steam‑bent oak runners, and stamped spring plates. It emphasizes repeatable processes, critical checkpoints, and certifications commonly requested by OEM procurement teams.

Supply chain overview and starting materials

- Components in scope

- Metal hardware kits: zinc alloy bearing connectors with M8 fasteners (sizes observed: M8x45 mm, M8x55 mm).

- Wood runners: steam‑bent oak, typical nominal width ~1‑1/16″ (≈27 mm).

- Spring plates: flat stamped hardware, e.g., 2.5 × 5 × 0.25 inches.

- Materials

- Metal: Zamak‑series zinc alloy (standard for die‑cast furniture fittings).

- Wood: White oak (steam bending), moisture content 8–10% target (USA/EU typical).

- Steel: CRS/A36 for spring plates; stainless optional (e.g., 304/316) for corrosion‑critical outdoor models.

- Fasteners: Grade 8.8/10.9 carbon steel or equivalent; finishing per application.

Manufacturing processes

Metal hardware kits (zinc alloy die‑cast connectors)

Process flow (typical): Incoming material testing → furnace melting and alloy verification → die‑casting (hot‑chamber) → trimming → CNC machining/finish machining → deburring → finishing (barrel vibratory polishing) → pre‑treatment → electroplating or powder coating → final inspection → assembly/fastening kit (M8 screws/washers as specified) → QC → packaging.

Key operations and parameters

– Die‑casting

– Tool steel dies; target die temperature 150–200°C (stable cycle).

– Shot parameters optimized to avoid porosity; vacuum assist optional to reduce gas entrainment.

– Tolerances consistent with ISO 286‑1 (H7–H11 typical for bores and piloting features).

– Machining

– CNC drilling/tapping for bore and tapped holes (e.g., M8 threads).

– Deburr and edge‑break per geometry tolerance (visual acceptance to company standard).

– Finishing

– Polished/brush finishes prior to coating; zinc plating (trivalent chromate) or e‑coat for corrosion resistance; salt spray target 72–120 h typical for furniture fittings; powder coating for specified colors/chemistries.

– Process chemicals controlled to avoid hexavalent chromium; comply with REACH restrictions where applicable.

Wood runners (steam‑bent oak)

Process flow: Kiln dried lumber (planed to final section) → steaming → bending (male/female forms) → clamped curing → sanding to contour → drilling/machining for attachment features (if applicable) → staining/clear coating (polyurethane or catalyzed lacquer) → inspection → packaging.

Key operations and parameters

– Wood prep

– Species: white oak; moisture 8–10% (target). Grading to avoid knots/splits in bending zones.

– Steaming/bending

– Steaming time dependent on section size (rule‑of‑thumb ~1 h per inch of thickness); mold press cycle sufficient to set curvature.

– Bend radius and spring‑back tolerances defined per product spec; clamp time to ensure set retention.

– Finishing

– Finish system engineered to resist checking and moisture ingress; cure per manufacturer instructions.

Spring plates (stamped steel hardware)

Process flow: Steel blanking/punching → forming/dimple/bending → deburr → surface treatment (oil/zinc/phosphate) → powder coating (optional) → inspection → packaging.

Key operations and parameters

– Blanking/forming

– Tooling life monitored; burr height controlled per drawing; form depths within tolerance.

– Surface treatment

– Phosphate for rust resistance; zinc plating or powder coating if specified; cure schedules verified.

Illustrative Image (Source: Google Search)

Assembly (kitting)

- Sub‑assemblies are kitted per customer spec (e.g., 4‑piece kits with M8x45 mm or M8x55 mm fasteners).

- Torque assembly per drawing: typical fasteners M8 in zinc alloy body use controlled torque with calibrated tools (e.g., final torque spec per customer).

- Visual and function checks: alignment, fit, clear threads, seating of washers.

Critical quality control and test plan

In‑process checkpoints

– Die‑cast: shot weight/volume confirmation, temperature logs, surface defect rates; CPK targets set for critical dimensions (e.g., hole/pilot diameters).

– Wood: moisture content verification, bend radius measurement, surface roughness.

– Stamping: burr height measurement, dimensional inspection (hole pitch, overall size).

– Coating: adhesion by cross‑hatch per ASTM D3359 (or ISO equivalent), coating thickness measurement; salt spray tests per defined duration.

Final product acceptance (common acceptance criteria)

– Bearing/connector kits

– Dimension check: hole/piloting features within ISO‑based tolerance bands.

– Coating integrity: no peeling, bare spots; adhesion pass.

– Torque test: fasteners withstand specified torque without stripping or rotation.

– Functional: rotation (if applicable) smooth, no binding or abnormal noise.

– Corrosion: specified salt spray or humidity exposure as per customer.

– Runners

– Straightness and curvature within tolerance; no visible cracks/splits.

– Surface finish per specification; finish adhesion/cure verified.

– Thickness/width within tolerance across length.

– Spring plates

– Dimensional conformance; burr removal confirmed; coating adhesion/corrosion targets met.

Traceability and packaging

– Lot traceability on steel/wood/chemical batches.

– Packaging: foam/paper interleaving; sealed bags for hardware; export‑grade cartons labeled for USA/EU compliance.

Compliance and certifications (USA/EU)

Standards and regulations commonly required

– QMS: ISO 9001 (quality management system).

– ISO 8062‑3 (dimensional tolerances for casting).

– Environmental/chemical: RoHS (EU 2011/65/EU); REACH (EC 1907/2006); for the USA, compliance to TSCA where applicable (e.g., PCBs).

– Food‑contact materials: Not applicable to furniture hardware.

Illustrative Image (Source: Google Search)

Documentation

– Declarations of conformity for RoHS/REACH.

– CoC/COC for steel and zinc alloy.

– MSDS/SDS for coatings and treatments.

Comparative manufacturing and QC snapshot

| Part | Material/processes | Critical operations | Key QC checks | Typical acceptance targets | Compliance notes |

|---|---|---|---|---|---|

| Bearing/connector kits | Zamak zinc die‑cast; CNC machining; trivalent zinc plating or powder coating | Die‑casting setpoint control; thread drilling/tapping; surface finishing | Dimensional inspection; torque testing; coating thickness/adhesion; salt spray | Torque per spec; corrosion rating (e.g., 72–120 h SST); ISO‑based tolerances | RoHS/REACH; ISO 9001; ISO 8062‑3 (casting) |

| Wood runners | Steam‑bent white oak; sanding; stain/clear coat | Steaming and bending; clamp curing; finish cure | MC 8–10%; bend radius/straightness; surface quality; finish adhesion | Bend tolerance per drawing; no cracks; moisture within band | N/A for chemical declarations unless coatings specified |

| Spring plates | Stamped CRS/A36; forming; phosphate; powder coating | Blanking/forming; deburr; surface treatment | Burr height; dimensions; coating adhesion; corrosion tests | Burr per spec; adhesion pass; SST target as required | RoHS/REACH; ISO 9001 |

Standard QC documentation (example)

- Incoming inspection reports (alloys, steel grades, lumber MC).

- In‑process control charts (critical dimensions, temperature, moisture).

- Final inspection reports: dimensions, torque, coating tests, functional checks.

- Test certificates: salt spray results, coating thickness/adhesion, wood MC.

- Declarations: RoHS/REACH, ISO 9001 certificates for facility.

Practical notes for OEM buyers

- For zinc die‑cast kits, specify thread size (M8), torque requirement, coating type (zinc/trivalent or powder), and corrosion test hours.

- For runners, specify species, moisture limits, dimensional tolerances, surface finish, and finish system; define attachment features if needed.

- For spring plates, define plate size, burr limits, and surface treatment based on intended use.

- Request ISO 9001 QMS and RoHS/REACH compliance declarations as part of the vendor package.

This blueprint aligns with the product families prevalent in the rocker chair parts market—zinc die‑cast bearing kits, steam‑bent oak runners, and stamped spring plates—while addressing the USA/EU requirements that B2B procurement typically enforces.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rocker chair parts’

Practical Sourcing Guide: A Step-by-Step Checklist for Rocker Chair Parts

Quick Reference: Example SKUs from Live Listings

Use these as benchmarks for price, ratings, and typical package sizes. Verify details before ordering.

| Supplier | Part Type | Model / SKU | Qty | Price (USD) | Stock | Rating |

|---|---|---|---|---|---|---|

| Acxico | Bearing kit | 4pcs Rocking Chair Bearing Connecting Piece (metal) | 4 | 9.99 | In stock | 4.4/5 (280) |

| AuRiver | Bearing kit | M8x45mm, 8 pcs | 8 | 14.99 | In stock | 4.3/5 (236) |

| Two Steam | Wood runners | Bent oak runners, 1-1/16″ wide | 1 set (2) | 59.95 | Low stock (5 left) | 4.5/5 (36) |

| Anwenk | Spring plate | 2.5″ x 5″ x 0.25″, 4-pack | 4 | 19.89 | In stock | 4.4/5 (82) |

Note: Live data is illustrative; validate product size/finish/material on each listing before purchase.

Illustrative Image (Source: Google Search)

1) Define What You Need (BOM and Specs)

- Create a BOM for each rocking chair variant: bearing kits, M8 fasteners, runners/sleds (solid wood), spring plates (gliders), seat/frame connectors.

- For hardware kits:

- Thread size and length (e.g., M8 x 45 mm)

- Finish: zinc alloy/plated steel; corrosion class (EN 1670 Class 2–4 where applicable)

- Bearing type: sealed or shielded; expected load and RPM

- Package size: kits (4, 8, 10 pcs), carton count, inner pack

- For wood runners/sleds:

- Species: oak, beech, ash, etc.

- Dimensions: width x thickness x arc radius/curve

- Moisture content (≤ 8–10% MC typical)

- Finish grade and profile, grain orientation, certification if required (e.g., FSC)

- Common dimensions you’ll see:

- M8 fasteners: 35–55 mm lengths

- Bearings: ~55–58 mm centers; metric hubs

- Spring plates: 2.5″ x 5″ x 0.25″

- Document tolerances and assembly references (hole patterns, spacing).

- Define failure criteria for sample testing.

2) Map Sources by Region

- USA:

- Marketplaces: Amazon Business, Grainger, Fastenal, MSC Direct, Zoro

- Manufacturers/wholesalers: furniture hardware suppliers, furniture lumber yards

- Local machining/casting (custom runners, brackets)

- Europe:

- EU portals: Conrad, EUROPARTNER, EUDISCOUNT

- UK: Amazon UK, RS Components, Simply Bearings

- Hardware distributors and regional furniture component suppliers

- Global general:

- Alibaba, ThomasNet, Made-in-China (for B2B factories)

- Shortlist multiple suppliers per component to avoid single-point failure.

3) Supplier Qualification

- Company profile: years in business, furniture hardware specialization, export experience.

- Quality system: ISO 9001 or equivalent; process controls for casting/pressing/heat treatment.

- Capability: min/max volume, MOQ, lead times, finishing options.

- Sample readiness and documentation (datasheets, test reports).

- Customer references in furniture hardware.

4) Verify Product and Platform Fit

- Confirm thread, finish, and dimensions match your BOM.

- Validate package size (count per kit) and inner/carton packing.

- Check real-time inventory and expected ship dates.

- Inspect rating and review recency; prioritize items with recent, relevant reviews.

5) Quote, Terms, and Price Bands

- Request:

- Unit price, MOQ, lead time per lot size (sample, pilot, full run)

- Packaging, carton specs, and palletization details

- Incoterms: EXW, FOB, CIF; recommended freight partner

- Price bands observed:

- Bearing kits (4–10 pcs): ~$9.99–$19.89 per pack

- Bent wood runners (oak, 1 set): ~$59.95 per set (low stock indicates scarcity)

- Negotiate:

- Volume breaks and tooling amortization for custom parts

- Consignment or VMI for high-runner items

- Price protection for 6–12 months on committed volumes

- Terms:

- Deposit 30% → 70% before shipment

- Or Net 30/60 on trusted vendors

- Warranty: 12–24 months for hardware kits

6) Sample and Prototyping

- Order 2–3 samples per part to validate:

- Dimensional fit and finish (threads, coatings)

- Torque and pull-out tests

- Corrosion resistance (salt spray where applicable)

- Assembly fit with your frames; play/noise checks on glides

- Perform fatigue/cycle testing on bearing kits and runners at expected loads.

- Freeze spec and release sample to production.

7) Quality Assurance and Compliance

- First Article Inspection (FAI) per drawing/BOM.

- Incoming inspection checklist:

- Thread gauge verification (M8)

- Finish thickness and corrosion verification (plating)

- Dimension checks for runners (width, thickness, arc)

- Visual defects: burrs, sharp edges, cracks

- Compliance requirements:

- California Prop 65 (lead content in metals/plastics)

- EU REACH (SVHCs) and general product safety obligations

- Furniture-specific standards referenced by buyers (e.g., ASTM F1148 equivalents for stability; if required)

- If using stainless steel, confirm composition (304/316)

8) Logistics and Delivery

- Incoterms:

- Samples: DDP where possible; otherwise DAP

- Production: FOB/CIF to your named port/warehouse

- Packing:

- Hardware: inner bag → small carton → master; anti-rust paper

- Wood runners: corner protectors, strapping, palletized

- Lead time visibility:

- Maintain buffer for low-stock items (wood runners frequently limited)

- Delivery:

- USA: UPS, FedEx, LTL for heavier wood parts

- Europe: UPS, DPD, GLS; LTL/FTL for wood

- Returns/defects policy:

- Define acceptance threshold, rework/replacement windows

9) Cost, Inventory, and Risk Controls

- Total landed cost (TLC):

- Product + packaging + freight + customs/duties + handling

- For metal bearings/hardware: low unit price; watch for consolidated small-shipment surcharges

- For wood runners: higher unit and freight cost; expect volatile availability

- Safety stock:

- 4–8 weeks’ demand for custom runners; 2–4 weeks for commodity hardware

- Supplier health checks:

- Monitor stock levels and new supplier arrivals (e.g., more than one bearing kit at ~$9.99 per pack increases resilience)

- Dual sourcing:

- Keep at least two qualified bearing suppliers; pre-qualified alternate wood species

10) Onboarding and Project Controls

- Set up supplier records:

- BOMs, drawings, spec sheets, test reports, lot traceability

- Change control:

- Approval workflow for any material/finish/spec change

- SLA/KPI targets:

- On-time delivery ≥ 95%

- Defect PPM ≤ 1,000 (initial), trending downward

- Sample turnaround 7–14 days for hardware kits; longer for custom wood parts

- Communication cadence:

- Weekly updates during sample phase

- Bi-weekly to monthly during production (PO-level)

Common Pitfalls to Avoid

- Assembling from Amazon retail listings without confirming B2B suitability or warranties.

- Underestimating lead times for low-stock wood runners.

- Ignoring finish/corrosivity class; bearings/rivets fail prematurely in coastal or treated lumber environments.

- Skipping real-life assembly/cycle tests; misfit at the jobsite is costly.

- Accepting “generic” or unspecified coatings; specify type and thickness.

This checklist covers USA and Europe sourcing realities for rocker chair parts, balancing supplier diversity, price benchmarks, and logistics to keep launches on time and defect-free.

Comprehensive Cost and Pricing Analysis for rocker chair parts Sourcing

Comprehensive Cost and Pricing Analysis for Rocker Chair Parts Sourcing

Overview

This section breaks down typical landed costs for rocker chair hardware and components, anchors ranges with representative Amazon marketplace data, and outlines where procurement teams in the USA and Europe can unlock savings across materials, labor, and logistics. All cost items are modeled with standard industry inputs and a typical B2B conversion margin (20–25%). Use the tables below as templates and adjust with your supplier’s actual quotes.

Cost components model

Use this framework to model landed cost per unit. It works for both single SKUs and mixed cartons.

| Cost component | Inputs | Where it applies | Typical range / notes |

|---|---|---|---|

| Ex-works (EXW) or FOB factory price | Supplier per-unit quote, tooling/amortization if applicable | All SKUs | Depends on MOQ, material grade, finish; adjust to regional labor rates |

| Packaging | Per-part cost + cartonization | All SKUs | Blister/retail boxes add 3–10¢; sturdy wholesale packaging 1–3¢ |

| Freight | Air: $3–$8/kg; Ocean LCL: $150–$300/m³; FTL: $1.2–$2.0/mile | All SKUs | Air for samples/expedite; ocean LCL/FCL for volume orders |

| Duties & taxes (USA) | HTS classification | Hardware, wood | Example: steel fasteners/castings often 5–8% (8302, 7318, 7326); wood components often duty-free (Chapter 44) |

| Duties & taxes (EU) | EORI and customs | Hardware, wood | Typical metals: 2–5%; wood often duty-free; VAT on imports at member rate (15–27%) |

| Customs & brokerage | Clearance and documentation fees | All | $100–$300 per shipment, amortized per unit by order size |

| Compliance & testing | Safety/compliance tests (as required) | Finished assemblies | $1,000–$3,000 per SKU (amortize over life of product) |

| In-country freight & last mile | Domestic trucking | All | $0.03–$0.08 per lb (USA); €0.20–€0.50/km (EU) |

| QC & handling | Receiving, inspection | All | Add overhead for QC lot sampling and rework, typically 1–2% of EXW |

| Inventory & finance | Carrying costs | All | 8–16% annualized cost on cash tied up (included in margin unless modeled separately) |

Note: Figures are indicative. Verify HTS codes, VAT, and testing requirements for your SKUs.

Illustrative Image (Source: Google Search)

Price benchmark: Amazon vs. B2B wholesale (per unit)

Use representative products as sanity checks when pricing your own assortment.

| Component | Representative Amazon item (spec snapshot) | Amazon price | Typical B2B wholesale target | Typical B2B retail target |

|---|---|---|---|---|

| Bearing hardware kit (4 pcs, M8x45–55mm, zinc alloy) | “4pcs Rocking Chair Furniture Hardware Bearing Accessories M8x45mm Zinc” | $9.99 | $3.80–$4.50 | $5.99–$7.99 |

| Bearing hardware kit (8 pcs, M8x55mm, zinc alloy) | “AuRiver 8 PCS Furniture Rocking Chair Bearing Connecting Piece … M8 x 55 mm” | $14.99 | $6.20–$7.80 | $9.99–$12.99 |

| Recliner pull handle + cable (single) | “Baridwon 1 Set Recliner Release Pull Handle with Pull Cable” | $10.99 | $4.00–$5.00 | $6.99–$9.99 |

| Spring plate (fiberglass) | “Anwenk 4 Pack Patio Rocking Chair Spring Plate … 2.5”x5”x0.25”” | $19.89 | $7.50–$10.00 | $12.99–$17.99 |

| Steam-bent oak runner pair (1-1/16” wide, set of 2) | “Two Steam-Bent Oak Rockers Runners” | $59.95 | $22.00–$32.00 | $36.00–$54.00 |

Wholesale targets are calculated from standard B2B cost buildups and supplier quotations (EXW + packaging + freight + duties + QC + margin). Your actual costs depend on MOQ, material grade, finishing, and region. Use these ranges to pressure-test quotes and prevent overpaying retail-adjacent prices.

Materials breakdown and cost drivers

| Component | Material | Material % of EXW | Finish | Key cost drivers |

|---|---|---|---|---|

| Rocking bearings and brackets | Steel or zinc alloy die-casting | 30–45% | Zinc/nickel plating, black oxide | Zinc price, casting tooling, plating thickness, load rating and M8 hardware spec |

| Wood runners/rockers | White oak, beech, ash | 40–55% | Sanding, lacquer/oil | Board footage, straightness, glue selection, steaming/bending process, finishing line throughput |

| Spring plates | Fiberglass (FRP) or steel plate | 25–40% | Unfinished or powder coat | Resin/glass content, mold/die cost, edge finishing, cut-to-size accuracy |

| Assembly hardware | M8 bolts, washers, self-tapping screws | 10–20% | Zinc/nickel | Grade, head type, thread tolerance, bulk packaging (loose vs. bulk bags) |

Notes:

– Bearings: Expect zinc alloy die-cast with zinc plating for rust resistance; steel plates cost more for load but less for tooling.

– Wood runners: Select FSC kiln-dried boards with <8% moisture to reduce warp; specify E0/E1 adhesives for EU and California CARB compliance.

– Spring plates: Fiberglass plates offer good strength-to-weight; specify thickness tolerance to avoid squeak.

Labor and overhead breakdown

| Region | Bearing hardware (metal) | Wood runners/rockers | Notes |

|---|---|---|---|

| China/OEM Asia | $0.02–$0.06 | $0.20–$0.40 | High die-casting efficiencies; wood bending expertise available; finishing labor variable |

| USA/EU (factory floor) | $0.12–$0.22 | $0.45–$0.95 | Wage rates drive unit cost; quality and finishing consistency higher; lower freight risk |

| Tooling setup (one-time) | $5,000–$12,000 (die cast) | N/A or low | Amortize over 50–150k units across SKUs; negotiate tooling ownership and maintenance |

| QC & pre-shipment | 1–2% of EXW | 1–2% of EXW | Include lot sampling, torque tests, finish inspection; essential to reduce returns |

Use Asia for volume bearing hardware and runner blanks; use USA/EU for tighter tolerances, faster lead times, and premium finishing.

Illustrative Image (Source: Google Search)

Logistics cost model (per unit examples)

Assume a 40-lb carton; dimensions vary by SKU. Freight shown is order-level cost amortized per unit. Your mileage will vary by supplier and route.

| SKU | Typical weight (carton) | Air (1 kg unit) | Ocean LCL (per unit in 1 m³ order) | Domestic US freight | Domestic EU freight | Duties/taxes (example) | Clearance + brokerage |

|---|---|---|---|---|---|---|---|

| Bearing kit (8 pcs) | 4.0 lb | $0.70 | $0.40 | $0.15 | €0.25 | USA 5–8%; EU 2–5% + VAT | $0.03 |

| Spring plate (4 pcs) | 2.5 lb | $0.45 | $0.25 | $0.10 | €0.18 | USA 2.5–5%; EU 2.5–5% + VAT | $0.03 |

| Wood runners (pair) | 22 lb | $3.00 | $0.80 | $0.35 | €0.70 | USA 0–5% (often free); EU 0–2.5% + VAT | $0.07 |

- Air freight use: Samples, small spot buys, quality returns; avoid for cost-sensitive bulk.

- Ocean LCL: Prefer ≥1 m³ for better cost per unit; FCL (20’/40’) when ≥10–15 m³.

- USA: DDP (Delivered Duty Paid) from Asia is common and simplifies budgeting; you control brokerage via your own importer of record.

- EU: EORI, packaging compliance (ISPM 15 for wood), and VAT handling are critical; consider a local VAT-registered agent for clearance.

MOQ and pricing tiers

| MOQ band | Bearing hardware (zinc alloy) | Wood runners | Notes |

|---|---|---|---|

| <500 | $4.80–$5.20 | $28–$35 | High per-unit; use for pilot, customization |

| 500–1,000 | $4.10–$4.60 | $25–$30 | Better die-casting yield; wood bending setup amortized |

| 2,000–5,000 | $3.60–$4.10 | $20–$27 | Stable line usage; price improves via yield |

| 10,000+ | $3.20–$3.80 | $18–$24 | Highest efficiencies; tooling amortization benefits kick in |

These are planning ranges; tie quotes directly to EXW. Add packaging, freight, duties, and QC as per the cost model.

Cost-saving levers (materials, labor, logistics)

Materials

– Spec to grade: Zinc 3 alloy (Z3) or SAE/AISI steel for load points; avoid over-specified materials that add cost without functional benefit.

– Die-cast optimization: Reduce draft angles and wall thickness while meeting load; negotiate tooling ownership to lower long-term costs.

– Wood selection: Choose dimensionally stable species and consistent MC (6–8%); specify E0/CARB II adhesives for EU/California compliance.

– Hardware standardization: Use M8 fasteners across SKUs to reduce SKU count and maximize batch leverage.

Labor

– Bundle SKUs: Combine bearings, brackets, and screws in one PO for shared line setups; plan monthly or quarterly production windows.

– Minimize finishing steps: Powder coat steel where rust resistance is needed; use clear coat only if color is required.

– Automate assembly: Use pick-and-pack kits for bearing hardware; specify bagged sets to reduce receiving time.

Illustrative Image (Source: Google Search)

Logistics

– Mode shift: Move to ocean LCL above 1 m³; FCL at ≥10 m³. Air only for samples or premium expedite.

– Consolidation: Split full-container loads into multiple SKUs or consolidate with another vendor to fill a 20’/40’.

– Packaging right-size: Reduce carton cubic while protecting parts; avoid retail clamshells for wholesale unless required.

– Trade terms: Negotiate EXW to buy in bulk and choose your own forwarder; or DDP to remove customs uncertainty with a known landed price.

– Incoterms clarity: Lock in CIP (ocean) or DAP/DDP (landed) and specify insurance and minimum carton/palletization requirements.

Procurement and risk

– Supplier mix: Dual-source bearing hardware from 2–3 Asia suppliers and keep one USA/EU supply for short lead time variants.

– Contract structure: Fix annual price bands and include a quarterly raw-material index (zinc, steel, resin) to protect margins.

– Inventory planning: Build 8–12 weeks of stock on fast movers; use a 3PL to avoid inland freight and carry costs.

– QA and returns: Implement AQL II (2.5) sampling; use a third-party pre-shipment inspector for first-lot validation; track torque and plating thickness as critical tests.

Pricing strategy (retail vs. wholesale)

- Wholesale (B2B distributors): Maintain 25–35% distributor margin; target landed price at 60–70% of the MAP.

- Direct retail (DTC/e-commerce): Align with Amazon price anchors to stay competitive on common SKUs (bearings, springs). Premium or custom finishes (stain-matched wood, anodized brackets) justify +15–30% on retail.

- Bundles and kits: 4/8-piece bearing kits price ~$6–$8; pairs of runners with assembly hardware price ~$45–$65 for oak sets; both outperform components on ASP and margin.

- Regional pricing: Adjust for VAT (EU) and freight zones (US) to keep identical real margins; avoid single SKU price cuts unless driven by competitor entry.

Example landed cost scenario (USA, ocean LCL, DDP brokered)

Assumptions: 2,000 units of bearing hardware kit (4 pcs). EXW: $3.60; Packaging: $0.05; Ocean freight (LCL from China): $0.45 per unit; Duty: 5%; Clearance + insurance: $0.04; Domestic freight: $0.12; QC overhead: 1.5% of EXW; B2B margin: 22%.

| Line item | Per-unit cost |

|---|---|

| EXW | $3.60 |

| Packaging | $0.05 |

| Freight (LCL) | $0.45 |

| Duty (5%) | $0.20 |

| Clearance/insurance | $0.04 |

| Domestic freight | $0.12 |

| QC/overhead | $0.05 |

| Total landed (pre-margin) | $4.51 |

| B2B margin (22%) | $1.00 |

| Target wholesale price | $5.51 |

This lands within the wholesale target in the benchmark table. Repeat this structure for spring plates and runners, substituting the appropriate material, freight, and duty rates.

Illustrative Image (Source: Google Search)

Amazon-based sanity check

- Bearing kits at $9.99 (retail) frequently reflect low MOQ retail margins. B2B procurement should target $3.80–$4.80 landed on mid-MOQ orders—well below retail.

- Recliner pulls at $10.99 retail point to wholesale targets in the $4–$5 range at modest volumes; expect further savings above 5k units.

- Spring plates (4-pack) at ~$19.89 retail imply $7.50–$10.00 wholesale once you factor freight and duties; avoid quotes >$11 landed.

- Wood runners at $59.95 retail for a pair suggest $22–$32 landed on wholesale; above $40 landed is typically non-competitive for standard white oak sets.

Action checklist

- Lock HTS codes and test plan for your SKUs before quoting.

- Build one-page cost models per SKU using the tables above; require suppliers to provide itemized cost breakdowns.

- Negotiate MOQ ladders (500/2k/5k+) and index prices for zinc/steel/resin.

- Demand tooling ownership or at least free-reuse after 20–30k units produced.

- Use pre-shipment inspection for the first lot and quarterly QC audits thereafter.

- Decide DDP vs. DAP per lane; align with customs brokers early.

- Consolidate shipments and standardize fasteners across SKUs to reduce freight per dollar of revenue.

- Use bundle pricing to lift ASP and margins on commodity SKUs (bearings, springs).

Alternatives Analysis: Comparing rocker chair parts With Other Solutions

Alternatives Analysis: Comparing rocker chair parts with other solutions

Table: Rocker chair parts vs. recliner replacement parts vs. patio universal hardware

| Attribute | Rocker chair parts (bearings, runners, fasteners, brackets) | Recliner replacement parts (handle/cable sets, recliner kits) | Patio/yard universal hardware (spring plates, crossbar brackets, glides) |

|---|---|---|---|

| Primary use case | Classic/traditional rocking chairs; OEM replacement and repairs; mixed indoor/outdoor | Recliner sofas and chairs; field service of actuation/release systems | Outdoor patio, lawn, and deck chairs; ad hoc field repairs; retrofit compatibility |

| Typical cost range | Bearing kits: low; runners: medium–high | Handle/cable kits: low–medium; recliner mechanisms: medium–high | Spring plates/accessories: low–medium |

| Materials | Zinc-plated/galvanized alloy or carbon steel; occasional stainless | Zinc-plated steel alloys and die-cast alloys | Zinc-plated or powder-coated steel/stainless for outdoor use |

| Finish options | Zinc, zinc-nickel, black oxide, optional stainless | Zinc, black; rust-inhibiting coatings | Zinc or powder-coated; outdoor-grade finishes common |

| Strength/durability | Good for low–medium duty rocking loads; proper bearing and runner geometry critical | Strong actuation under cyclic loads; performance depends on mechanism fit/quality | Adequate for outdoor, medium loads; depends on crossbar diameter and spring capacity |

| Installation complexity | Moderate; alignment and pilot holes crucial; may need specific runner radii/bearings | Moderate; cable routing, tensioning, and cable end geometry sensitive | Low–moderate; hardware often “universal,” but fit is variable and may require custom fabrication |

| Serviceability | Field-replaceable bearings and fasteners; runners may need re-mortise | Replaceable handles/cables/mechanisms; quick service | Field-replaceable hardware; corrosion exposure higher outdoors |

| Availability (USA/EU) | Broad availability via retail and specialized suppliers; multiple finishes and M8/55mm variants | Strong USA presence; EU availability depends on local importers and brand-specific parts | Broad retail availability in USA; EU availability via general furniture hardware suppliers |

| Lead times | Short for standard SKUs; longer for custom runners/finishes | Short for common SKUs; longer for brand-specific kits | Short; standard items commonly in stock |

| Minimum order | Typically retail-oriented; OEM/bulk available | Retail and bulk available | Retail and bulk available |

| Standards/compliance | General hardware compliance; EU buyers should source RoHS/REACH-compliant finishes | General hardware compliance; EU buyers should source RoHS/REACH-compliant finishes | General hardware compliance; EU buyers should source RoHS/REACH-compliant finishes |

| Logistics footprint | Small, dense packages; heavy runners add weight | Compact; moderate weight | Medium volume; bulk packaging for plates/brackets |

Analysis

- Rocker chair parts

- Strengths: Purpose-built for rocking loads and kinematics; predictable alignment with bearings/runners; broad finish and sizing options (e.g., M8x55mm zinc alloy kits).

- Considerations: Fit depends on runner radius/bearing envelope; runner mass/size increases shipping costs; OEM-style finishes may have longer lead times.

-

Best for: OEM or professional refurbishment of rocking chairs requiring accurate geometry, repeatable motion, and consistent finish.

-

Recliner replacement parts

- Strengths: Established, cost-effective kits designed for fast field service; high demand ensures wide availability.

- Considerations: Design is specific to recliner mechanisms; not interchangeable with rocker chair runners/bearings; performance relies on correct geometry and cable routing.

-

Best for: Recliners requiring handle/cable/mechanism replacement; not a substitute for rocker chair runners or bearings.

-

Patio/yard universal hardware

- Strengths: Low cost and fast availability; works for outdoor decks, lawn, and patio chairs; corrosion-resistant finishes are common.

- Considerations: “Universal” fit often requires modification; may lack the geometry precision needed for smooth rocking; long-term durability varies by hardware grade.

- Best for: Ad hoc outdoor repairs and non-critical applications; acceptable when exact rocking geometry is not critical.

Selection guidance

– Choose rocker chair parts when you need smooth, durable rocking motion and repeatable assembly. Verify runner radius, bearing size (e.g., M8 x 55mm), and finish (zinc vs. stainless) per application and environment.

– Use recliner replacement parts for recliners—these kits are engineered for actuation forces and release geometry that rocking chair parts do not address.

– Select patio/yard universal hardware for quick, cost-effective outdoor fixes where exact motion profiles and alignment tolerances are flexible.

Essential Technical Properties and Trade Terminology for rocker chair parts

Essential Technical Properties and Trade Terminology for Rocker Chair Parts

This section consolidates the critical technical properties and trade terminology used to source and evaluate rocker chair parts for B2B buyers in the USA and Europe. It aligns to common product types found in the market and the specifications that drive fit, durability, and compliance.

Illustrative Image (Source: Google Search)

Key Technical Properties by Component

Bearing connecting piece kits (fasteners + sleeves/housings)

| Property | Typical requirements | Notes |

|—|—|—|

| Thread | M8 x 1.25 (metric), also M8 x 55 mm overall length seen on-market | Verify lead and pitch (M8 fine also exists). If sold in the USA, confirm compatibility with imperial hardware to avoid cross-threading. |

| Hardware class | Coarse thread (M8 x 1.25) recommended for vibration resistance | Zinc alloy or steel components commonly offered. |

| Materials | Housing/sleeve in zinc alloy or steel; steel Grade 8.8 or 10.9 for bolts/screws | Steel for higher load; zinc alloy for lighter loads and corrosion resistance. |

| Finish/coating | Zinc plating (clear/yellow), E-coat, or black oxide for steel; passivation for stainless | 72–96 h salt spray is a practical performance target for plated steel in indoor/outdoor furniture. |

| Rated load/strength | Target working load ≥ 250 kg per assembly (static), higher for premium lines | Confirm with actual test data. Hardware grade and thread engagement drive capacity. |

| Torque | Typical clamp load achievable with M8, Grade 10.9 in the 20–30 Nm range | Use lubricated threads if needed; document torque to avoid crushing wood. |

| Assembly | Includes screws/bolts, washers, bearing/sleeve, optional decorative caps | “4 pcs kit” and “8 pcs kit” variants are market-common. |

| Testing | Salt spray; proof load; thread shear; Rockwell hardness; torque-tension test | Provide certificates on request. |

| Packaging | Small polybag, labeled part number, barcode/QR; inner carton for assortments | Optional: hardware-only export box configurations. |

| Compliance | REACH (EU), RoHS (EU), Prop 65 (CA) if plated/chem-treated | Declare coating type; provide SDS if coatings change. |

Wood runners (steam-bent solid wood)

| Property | Typical requirements | Notes |

|—|—|—|

| Species | White oak, red oak, beech (primary choices in market) | Oak offers good bending and toughness; beech has high strength but lower rot resistance. |

| Moisture content | 6–8% EMC before finishing | Critical for dimension stability post assembly. |

| Dimensions | 1-1/16″ wide runners; typical rockers with 24″–30″ radius | Confirm seat height, radius, and bearing seat geometry. |

| Tolerance | ±1.0 mm for profiles after bend; bearing seats within 0.3 mm | Pre-mill seats if CNC capacity is limited at assembly. |

| Adhesive | D3/D4 water-resistant adhesives for joints | D4 for exterior-exposed joints. |

| Finish options | Hardwax oil, lacquer, waterborne UV-cure; optional UV inhibitor | Clarify VOC and REACH for EU exports. |

| Tests | Moisture check; glue line shear (EN 204 or equivalent); dimensional stability | Provide glue line test certificates. |

| Grading | FAS/1COM or equivalent (visual), clear on bearing seats | Specify “skip-planed” or “hand-selected” near bond area if needed. |

| Compliance | Formaldehyde limits: TSCA Title VI (US) and CARB Phase 2; E1/E05 for EU (EN 717-1) | Declare emissions class for exports. |

Spring plates (fiberglass plates for patio/rocking chairs)

| Property | Typical requirements | Notes |

|—|—|—|

| Material | Fiberglass-reinforced polymer (FRP), white or translucent | Good outdoor stability; cost-effective replacement part. |

| Dimensions | 2.5″ x 5″ x 0.25″ common size | Verify hole pattern and spacing to existing hardware. |

| Surface | Smooth edges, UV-stabilized if used outdoors | Check chemical resistance to common patio cleaners. |

| Mechanical | Adequate flex and fatigue for cyclical rocking | Validate seat-to-floor loading against brand requirements. |

| Testing | 10k–50k cycle flex test; UV exposure | Provide cycle life and post-exposure ratings if outdoor use. |

| Packaging | Interleaved and cartonized; label size and SKU | Include mounting hardware if included. |

Recliner replacement parts (cables/handles)

| Property | Typical requirements | Notes |

|—|—|—|

| Compatibility | Designed for “most” recliner mechanisms; D-Ring handle, S-tip cable ends | Provide brand/line references and part mapping. |

| Materials | Stainless steel or galvanized cable; steel handle (zinc plated); UV-resistant handle cover | Specify minimum wire diameter and construction. |

| Exposed length | Market examples show 5″ | Document exact exposed length and total length. |

| Pull strength | Working load target ≥ 1.8 kN; 3:1 design factor | Provide test reports and fatigue data. |

| Handle finish | Zinc plated or powder-coated | Match existing décor and durability targets. |

| Cable coating | Nylon jacket optional | Specify friction coefficient if pre-lubed. |

| Testing | Tensile; cycle; corrosion (salt spray) | Certificates on request. |

| Compliance | REACH (EU), RoHS (EU), Prop 65 (CA) | Declare materials and plating type. |

Illustrative Image (Source: Google Search)

Adhesives for structural bonds

| Property | Typical requirements | Notes |

|—|—|—|

| Standard | EN 204 D3/D4 (EU) or equivalent water resistance | D4 recommended for exterior or high humidity. |

| Emission | US EPA TSCA Title VI; CARB Phase 2; EU E1/E05 | Provide emission certificates and SDS. |

| Open time | 5–15 minutes typical for assemblies | Match workshop conditions; offer alternative grades if needed. |

| Cure | Full cure in 24–72 h; hot-press schedules available | Provide press parameters if pre-assembled. |

| Viscosity | Application-specific | State pot life after mixing for 2K systems. |

| Certification | Declare EN 204 class and emission class; EN 1465 or equivalent for strength | Provide batch certificates and COA. |

Material, Finish, and Tolerances Quick Reference

| Category | Preferred materials | Common finishes/coatings | Tolerances (typical) | Notes |

|---|---|---|---|---|

| Steel hardware | Grade 8.8, 10.9; stainless A2/A4 where required | Zinc plated (72–96 h SST), E-coat, black oxide | ±0.2 mm on bore; H7 for bearing seats (hardware only) | Consider Loctite for threadlocking if vibration risk. |

| Zinc alloy | ZAMAK 3/5 | Clear/yellow chromate; powder coat | ±0.15 mm on bores | Lightweight; verify load rating vs steel. |

| Wood runners | White oak, red oak, beech | Oil, lacquer, waterborne UV | ±1.0 mm overall | Check glue line to EN 204; moisture 6–8%. |

| FRP spring plates | Fiberglass | UV-stabilized resin | Hole pattern within 0.3 mm | Good for outdoor patio furniture. |

| Cables/handles | Stainless or galvanized steel | Zinc plated, powder coat | Dimensions within ±1.0 mm | Provide pull strength and cycle test data. |

| Adhesives | PVAc, PUR, or urea-formaldehyde | — | — | Match grade to exposure; declare emissions. |

Trade Terminology (B2B)

| Term | Definition/Notes |

|---|---|

| MOQ (Minimum Order Quantity) | Minimum lot size per SKU; hardware often packed by inner cartons; wood parts per layer/bundle. |

| OEM/ODM | OEM: supplied to brand specs with no branding; ODM: we design per your performance brief. |

| Customization | CNC cutting/boring, sand-to-size, custom profiles, logos, colors; lead time typically 2–6 weeks. |

| Lead time | Sample: 7–10 business days; mass production: 2–6 weeks depending on capacity and finishes. |

| Incoterms | EXW or FOB (US/EU buyers), CIF or DDP by request. |

| Payment terms | T/T or L/C; typical 30–50% deposit; 30–70% before shipment or on delivery (buyer preference). |

| QA | AQL per MIL-STD-105E; inspection levels II/III; critical defects 0.65–1.0. |

| Certificates | ISO 9001; TSCA/CARB for wood; REACH/RoHS for finishes/coatings; Prop 65 for California; EN 204 adhesives. |

| Packaging | Cartonized export packaging; hardware kit labeling/barcoding; wood bundle wrap and corner protection. |

| Logistics | Full container (FCL) or LCL; MOQ per container load; USA/EU customs brokers arranged by buyer unless DDP requested. |

| Returns/RMA | Specify within 30–60 days for manufacturing defects; provide photos and lot code. |

| Warranty | 1 year typical for hardware; 2 years for wood/adhesive (material/workmanship). |

| Compliance | Declared material/finish disclosure; SDS for coatings; test reports on request. |

| Thread size differences | M8 x 1.25 (metric) vs 5/16″-18 (imperial): do not intermix; specify clearly for USA shipments. |

Fasteners and Testing Quick Specs

| Fastener type | Standard | Markings | Proof load/strength | Salt spray | Torque reference |

|---|---|---|---|---|---|

| Metric socket cap screws, Grade 10.9 | ISO 4762 | 10.9 mark | Higher than Grade 8.8 | 72–96 h (plated) | Typical clamp loads achievable 20–30 Nm on M8, lubricated |

| Hex cap screws, Grade 8.8 | ISO 4017 | 8.8 mark | Grade 8.8 | 72–96 h | Provide torque-tension test data |

| Wood screws (general) | EN 14566 or equivalent | Per manufacturer | — | — | Match to wood density and pilot hole |

Note: If fasteners are sold to the US market alongside imperial parts, clearly indicate metric vs imperial to prevent cross-threading. Provide SDS for plating and coating processes upon request.

Navigating Market Dynamics and Sourcing Trends in the rocker chair parts Sector

Navigating Market Dynamics and Sourcing Trends in the Rocker Chair Parts Sector

Market snapshot: what the retail signal implies for B2B

Amazon listings act as a real-time barometer for demand, inventory depth, and price floors. The current assortment highlights the parts most sought and most easily replaced, and by extension the categories where B2B buyers should focus.

- Frequent SKUs and price floors

- Bearing assemblies/connectors: $9.99–$14.99 for 4–8 pcs (avg rating 4.3–4.6, review counts indicate consistent replenishment).

- Replacement spring plates (fiberglass/steel): ~$19.89 for 4 pcs (2.5″ x 5″ x 0.25″; rating 4.4).

- Steam-bent oak runners (1-1/16″ wide): $59.95 (rating 4.5; often low stock).

- Demand drivers

- Repair-first buying behavior: consumers replace wear items (bearings, spring plates) before replacing chairs.

- Furniture conversion: recliner repair parts (handles, cables) appear alongside rocker components, signaling cross-compatibility and DIY-friendly design.

- Wood restoration market: oak runners show selective availability and occasional scarcity, indicating artisanal or smaller-lot production.

These signals point to two sourcing imperatives for B2B: anchor your catalog on high-velocity wear items and secure dependable wood components through specialized woodpart suppliers.

Illustrative Image (Source: Google Search)

Demand drivers and segment dynamics

- Consumer repair and upgrades

- Bearings and connectors fail first; buyers prioritize quick-swap kits over rebuilds.

- Outdoor use expands corrosion risk, raising interest in plated (zinc, e-coat) hardware.

- Commercial/contract furnishing

- Hospitality, childcare, and healthcare favor replaceable parts to extend chair lifespan and minimize downtime.

- Specification convergence around standard fasteners and plate geometries reduces SKU complexity.

Sourcing trends shaping availability and pricing

- SKU concentration in bearing kits

- Many listings cluster around M8 x 45–55 mm zinc-alloy assemblies, suggesting a maturing product form factor.

- Buyers can leverage this standardization to achieve economies of scale and multi-sourcing, while watching for material variance between zamak and zinc die-cast.

- Wood components as bottlenecks

- Steam-bent runners are priced higher and stock fluctuates; lead times are more variable than for metal parts.

- Expect value in woodpart suppliers with FSC credentials and CNC bending capability.

- E-commerce’s role in price discovery

- Visible price floors and ratings enable quick benchmarking against B2B quotes.

- However, listings often show short lead times to Southeast Asia (e.g., “Fri, Dec 19 to Philippines”) whereas USA/Europe deliveries from the same factories typically take 15–35 days air or 30–60 days sea; plan inventory buffers accordingly.

Sustainability and compliance: what to require

- Materials and finishes

- Metals: prefer zinc die-cast with RoHS-compliant passivation; avoid unregulated zinc finishes. Zamak can suit lighter loads but requires performance validation.

- Wood: source FSC-certified rails and runners; specify moisture stability and curvature tolerances to reduce scrap.

- Coatings: require REACH and RoHS documentation; for outdoor items, specify salt spray/corrosion performance (e.g., ASTM B117 neutral salt spray hours).

- Recyclability and end-of-life

- Design kits for disassembly and metal recovery; minimize multi-material joins.

- Standards and testing

- Structural/performance testing: ASTM F1858 (outdoor furniture, including rocking chairs) for performance under cyclic loading and weather exposure.

- EN/EN ISO standards where applicable for furniture safety and durability in Europe.

- Supply chain sustainability

- Prefer suppliers with verifiable environmental practices; include material declarations and emissions reduction targets in RFQs.

Price/lead-time benchmarks (from public signals)

| Item category | Typical public price band | Notes for B2B negotiation |

|---|---|---|

| Bearing connector kits (M8 x 45–55 mm; 4–8 pcs) | $9.99–$14.99 | Often the same factories as B2B; negotiate pack counts, finishes, and MOQs. |

| Spring plates (fiberglass; ~2.5″ x 5″ x 0.25″; 4 pcs) | ~$19.89 | Validate thickness and glass content; test deflection. |

| Steam-bent oak runners (1-1/16″ wide; pair) | ~$59.95 | Low stock signals; secure woodpart suppliers and schedule bending capacity. |

For USA/Europe deliveries, add 15–35 days (air) or 30–60 days (sea) over online shipping estimates.

Sourcing strategy playbook

- Dual-track metals and wood

- Metals: multi-source from die-casters with REACH/RoHS and strong plating lines; standardize sizes to reduce inventory.

- Wood: partner with woodpart specialists capable of steam bending and CNC finishing; verify FSC supply and moisture stability.

- Performance guarantees, not just price

- Include salt spray tests, torque/wear thresholds, and deflection criteria in specifications; require first-article approval before production.

- SKU strategy

- Prioritize universal or near-universal bearings, spring plates, and fasteners; limit custom bent wood SKUs to validated top sellers.

- Lead-time planning

- Place Q1–Q2 orders for peak season to avoid holiday and Q4 congestion; negotiate faster shipping lanes where feasible.

Risk watchlist and mitigations

- Lead-time slippage on bent wood and finish steps

- Mitigation: dual-source woodpart suppliers; lock bending slots early; specify standard finishing options.

- Finish variability

- Mitigation: request plating QC data; require sample plates; define chromate variants and tolerances.

- Material substitution (zamak vs zinc; fiberglass vs steel content)