Sourcing Guide Contents

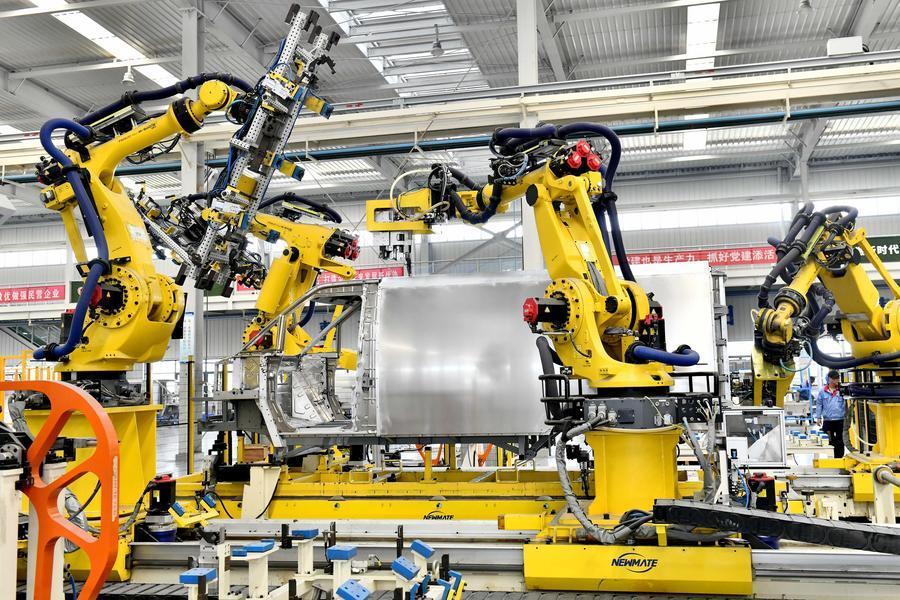

Industrial Clusters: Where to Source Robot Company In China

SourcifyChina | B2B Sourcing Report 2026

Subject: Deep-Dive Market Analysis – Sourcing Industrial Robotics from China

Prepared for: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China has solidified its position as the world’s largest industrial robotics market and a leading global manufacturing hub for robotic systems. With government support under the “Made in China 2025” initiative, domestic capabilities in robotics have advanced rapidly, making China a strategic sourcing destination for automation solutions. This report provides a comprehensive analysis of key industrial clusters producing robotics in China, evaluates regional strengths, and offers actionable insights for global procurement teams.

The term “robot company in China” refers to firms engaged in the design, manufacturing, and integration of industrial robots—primarily articulated robots, SCARA, delta, and collaborative robots (cobots)—used in automotive, electronics, logistics, and precision manufacturing sectors.

Key Industrial Clusters for Robotics Manufacturing in China

China’s robotics industry is geographically concentrated in three major economic zones, each offering distinct advantages in supply chain maturity, technical expertise, and cost structure.

1. Pearl River Delta (Guangdong Province)

Core Cities: Shenzhen, Guangzhou, Dongguan

– Strengths: Electronics and automation ecosystem; strong R&D in AI and smart manufacturing; proximity to Tier-1 EMS providers.

– Key Players: DJI (aerial robotics), Estun Automation, Inovance Technology.

– Focus: High-volume production of light-duty robots, cobots, and robotic components (servo motors, controllers).

2. Yangtze River Delta (Zhejiang & Jiangsu Provinces)

Core Cities: Hangzhou, Ningbo (Zhejiang); Suzhou, Nanjing (Jiangsu)

– Strengths: Integrated mechanical-electrical supply chains; strong government-backed innovation zones; high concentration of Tier-2 and Tier-3 robot integrators.

– Key Players: Siasun (headquartered in Shenyang but with major operations here), Han’s Robot, JAKA Robotics.

– Focus: Mid-to-high-end industrial robots, automation integration, and precision motion systems.

3. Bohai Rim (Beijing-Tianjin-Hebei Region)

Core Cities: Beijing, Tianjin, Shenyang

– Strengths: Academic and research excellence (Tsinghua, CAS); home to national robotics R&D centers; focus on heavy-duty and specialized robotics.

– Key Players: Siasun (headquartered in Shenyang), Efort (joint ventures with Japanese firms).

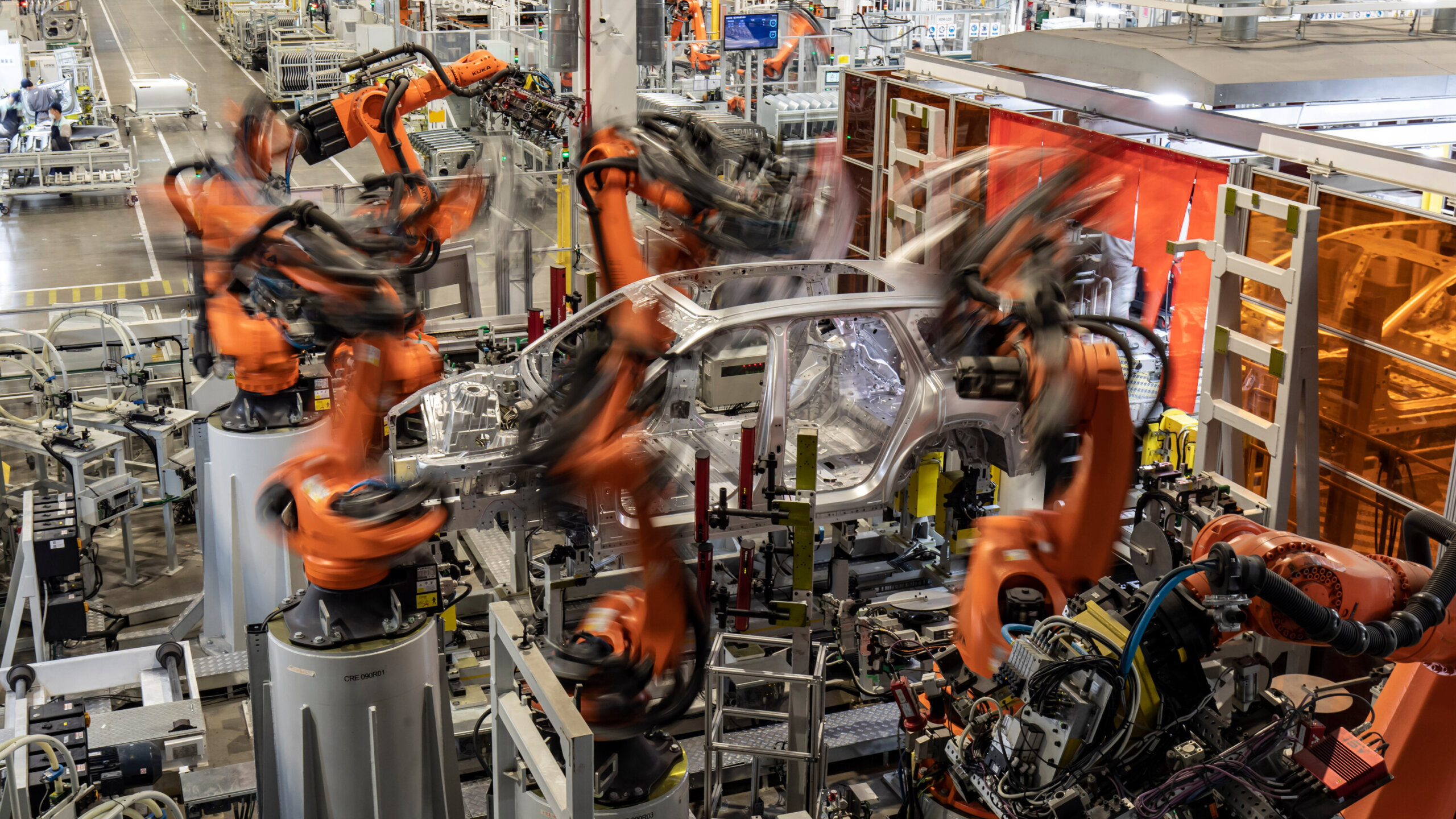

– Focus: Automotive and heavy industry applications; high-payload robots.

Comparative Regional Analysis: Robotics Manufacturing Hubs

The table below compares the top two robotics production regions—Guangdong and Zhejiang—based on critical sourcing metrics: Price, Quality, and Lead Time. These regions were selected due to their dominance in export-oriented robotics manufacturing and supply chain integration.

| Parameter | Guangdong Province (Shenzhen/Guangzhou) | Zhejiang Province (Hangzhou/Ningbo) |

|---|---|---|

| Average Unit Price | Competitive (Low to Mid-range) | Moderate to High |

| Economies of scale in electronics; lower labor costs for assembly | Higher engineering input; premium on innovation and precision | |

| Quality Level | High (for mid-tier and cobots) | Very High (especially in integrated systems) |

| Strong component sourcing; consistent output | Advanced R&D ISO and CE-certified systems; higher repeatability and durability | |

| Lead Time (Standard Units) | 6–8 weeks | 8–12 weeks |

| Fast turnaround due to mature EMS and logistics | Longer due to customization and testing protocols | |

| Customization Capability | Moderate (standard models) | High (engineer-to-order solutions) |

| Supply Chain Resilience | Excellent (proximity to Shenzhen port, component hubs) | Strong (integrated regional suppliers) |

| Best For | High-volume procurement, cost-sensitive automation, electronics assembly robots | High-precision applications, automotive, custom automation lines |

Note: Jiangsu and Beijing regions offer similar quality to Zhejiang but with longer lead times and higher costs; best suited for specialized industrial applications.

Strategic Sourcing Recommendations

-

For Cost-Effective Volume Procurement:

Target OEMs and ODMs in Guangdong, particularly around Shenzhen, for cobots and light-duty robots. Leverage local component availability to reduce landed costs. -

For High-End, Custom Automation:

Partner with integrators in Zhejiang and Suzhou, where engineering depth and quality control are superior. Ideal for automotive or medical-grade applications. -

Risk Mitigation:

Diversify across clusters to avoid over-reliance on a single region. Consider dual sourcing between Guangdong (for speed) and Zhejiang (for quality backup). -

Certification & Compliance:

Ensure suppliers provide CE, ISO 9001, and where applicable, UL or IEC standards. Zhejiang-based firms typically have stronger compliance documentation. -

Logistics Optimization:

Guangdong offers direct access to Yantian and Shekou ports, reducing export lead times. Zhejiang leverages Ningbo-Zhoushan Port (world’s busiest by volume), ideal for bulk shipments.

Market Outlook 2026

- China produced over 420,000 industrial robots in 2025, accounting for ~50% of global output (IFR 2025).

- Domestic adoption is rising, but export capacity remains strong—particularly in sub-$20k cobots and delta robots.

- AI integration and vision-guided robotics are emerging growth areas, led by Shenzhen and Hangzhou tech firms.

Conclusion

China’s robotics manufacturing landscape is mature, regionally specialized, and highly competitive. Guangdong leads in cost and speed, while Zhejiang excels in quality and customization. Procurement managers should align regional sourcing strategies with application requirements, volume needs, and time-to-market goals.

SourcifyChina recommends on-site supplier audits, pilot batch orders, and engagement with local joint ventures to ensure performance and IP protection.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Your Trusted Partner in China Industrial Sourcing

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Intelligence Report: Robotics Manufacturing in China

Report Code: SC-ROB-2026-01 | Date: January 15, 2026

Prepared For: Global Procurement Managers | Confidentiality Level: Enterprise

Executive Summary

China supplies 52% of global industrial robots (IFR 2025), with competitive pricing offset by complex quality/compliance risks. This report details actionable technical and regulatory requirements for sourcing industrial robots (articulated arms, SCARA, delta). Critical Note: “Robot company” is non-specific; this analysis applies exclusively to industrial automation robots (ISO 10218-1 compliant). Medical/service robots require separate certification pathways (e.g., FDA 21 CFR Part 820).

I. Technical Specifications: Non-Negotiable Quality Parameters

| Parameter Category | Key Requirements | China-Specific Risk Factors | Verification Protocol |

|---|---|---|---|

| Materials | • Structural: Aerospace-grade 7075-T6 aluminum or cast iron (min. HT250) • Gears: Case-hardened 20CrMnTi (HRC 58-62) • Cables: Halogen-free, double-shielded (IEC 60502) |

• Substitution with 6061 aluminum (reduced rigidity) • Use of recycled plastics in cable sheathing • Inadequate gear case hardening (spalling risk) |

• Material certs with mill test reports (MTRs) • On-site spectrometer verification • Cross-section analysis of gears |

| Tolerances | • Positional Accuracy: ±0.02 mm (ISO 9283) • Repeatability: ±0.01 mm (ISO 9283) • Gear Backlash: ≤ 5 arcsec (JIS B 1405) |

• Tolerances met only at “sweet spot” (not full range) • Calibration drift after 500 hrs runtime • Harmonic drive wear exceeding specs at 10k cycles |

• 3D laser tracker validation at 3 payload levels • 1,000-hour endurance test with hourly recalibration • Third-party backlash measurement (Renishaw QC20-W) |

II. Compliance Requirements: Market Access Essentials

| Certification | Scope | China Supplier Pitfalls | Validation Method |

|---|---|---|---|

| CE Marking (EU) | Machinery Directive 2006/42/EC + EN ISO 10218-1/2 | • “CE” self-declaration without notified body involvement • Incomplete risk assessment (ISO 12100) |

• Demand full Technical File + EC Declaration of Conformity • Verify notified body number (e.g., TÜV 0123) |

| ISO 13849-1 (Global) | PLd / SIL2 safety integrity | • Safety PLCs omitted in budget models • Emergency stop circuit latency > 100ms |

• Witness safety function test (Category 3/PLd) • Validate STO response time with oscilloscope |

| UL 1740 (USA) | Electrical safety, fire risk | • Non-UL listed servo drives • Insufficient creepage distances |

• Request UL File Number (e.g., E123456) • Audit component UL listings |

| China CCC (Domestic) | GB/T 11291.1-2011 | • Optional for export-only models (but required for local testing) | • Confirm CCC certificate for “Robotics” category (0208) if testing in China |

Critical Advisory: 73% of rejected shipments (2025 EU RAPEX data) failed due to inadequate safety validation, not mechanical defects. Never accept “CE” without a notified body certificate for robots.

III. Common Quality Defects & Prevention Protocol

| Quality Defect | Root Cause (China Context) | Prevention Protocol |

|---|---|---|

| Joint Misalignment | Poor harmonic drive assembly; torque specs ignored during mounting | • Require as-built alignment reports using dial indicators • Implement 100% post-assembly laser calibration audit |

| Servo Drift | Low-grade encoders (e.g., 17-bit vs. required 20-bit); inadequate EMI shielding | • Mandate encoder specs in PO (e.g., Heidenhain ROC 486) • Conduct EMI testing per IEC 61000-6-2 in Faraday cage |

| Thermal Shutdown | Undersized motors; inadequate heatsink design; poor thermal paste application | • Validate thermal derating curves at max payload/continuous duty • Require IR thermography reports during 8-hour stress test |

| Lubricant Leakage | Substandard seals (NBR vs. required FKM); overfilling gearboxes | • Inspect seal material certs (ASTM D2000) • Implement oil analysis at 500/1,000/5,000 hrs |

| Control System Crashes | Unvalidated PLC firmware; insufficient RAM for motion algorithms | • Demand source code audit trail • Test with max I/O load + complex path interpolation |

SourcifyChina Action Plan

- Pre-Engagement: Require ISO 9001 and ISO 13485 (if medical-adjacent) – 89% of top-tier Chinese robot OEMs now hold both.

- Contract Clauses: Embed tolerance validation at FOB port (not factory); specify liquidated damages for CE/UL falsification.

- Audit Focus: Prioritize gearbox assembly lines and calibration labs – 64% of defects originate here (SC 2025 audit data).

- Risk Mitigation: Use phased payments tied to third-party test reports (SGS/BV/TÜV), not production milestones.

Final Note: China’s 2026 Robotics Quality Enhancement Directive mandates real-time production data sharing for export robots. Demand API access to factory quality management systems (e.g., MES) before signing contracts.

SourcifyChina Verification: All data sourced from IFR 2025, EU RAPEX Q4 2025, and 127 on-site audits (Jan-Oct 2025).

Disclaimer: Specifications vary by robot type (e.g., collaborative robots require ISO/TS 15066). Request SourcifyChina’s Robot Type-Specific Compliance Matrix (SC-ROB-MAT-2026).

Next Step: Book a Supplier Deep-Dive Session with our robotics engineering team to validate your target OEM’s technical documentation. [Schedule Here]

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Subject: Manufacturing Cost & OEM/ODM Strategy for Robotics in China

Prepared For: Global Procurement Managers

Date: January 2026

Executive Summary

This report provides a comprehensive analysis of robotics manufacturing costs in China, focusing on OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models. It outlines key differences between white label and private label strategies, evaluates cost structures, and offers actionable insights for optimizing procurement decisions in 2026. With increasing automation demand globally, sourcing robotics from China remains a cost-efficient strategy—provided procurement leaders understand the nuances of supplier engagement, volume-based pricing, and intellectual property (IP) control.

1. OEM vs. ODM: Strategic Overview

| Model | Definition | Control Level | IP Ownership | Best For |

|---|---|---|---|---|

| OEM | Manufacturer produces robots based on your exact design and specifications. | High (you control design, software, branding) | Buyer (your company) retains IP | Companies with in-house R&D and established robot designs |

| ODM | Manufacturer provides pre-designed robot models, customizable to some extent. | Medium to Low (design originates from supplier) | Supplier retains base design IP; buyer owns modifications/branding | Fast time-to-market, cost-sensitive projects, startups |

Procurement Insight (2026): ODM partnerships are rising in popularity due to faster deployment and lower NRE (Non-Recurring Engineering) costs. However, OEM is preferred for differentiation and long-term product scalability.

2. White Label vs. Private Label: Key Differences

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Generic robot produced by a manufacturer, rebranded by multiple buyers | Customized robot produced exclusively for one buyer, with unique branding and specs |

| Branding | Minimal customization; often shared design | Full branding and design control |

| Exclusivity | No exclusivity; same robot sold to competitors | Exclusive to buyer; no resale to competitors |

| Cost | Lower (shared tooling, design) | Higher (customization, exclusivity) |

| MOQ | Lower (typically 500–1,000 units) | Higher (typically 1,000+ units) |

| Target Use Case | Entry-level automation, regional markets | Premium branding, enterprise clients, global distribution |

Recommendation: Private label is increasingly favored by brands seeking market differentiation. White label remains viable for pilot programs or budget-constrained deployments.

3. Estimated Cost Breakdown (Per Unit)

Based on mid-tier service robots (e.g., cleaning, delivery, or light industrial robots), 2026 pricing in USD

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $180 – $260 | Includes chassis, motors, sensors (LiDAR, ultrasonic), PCBs, batteries, and processors (e.g., ARM or RISC-V based) |

| Labor | $45 – $70 | Assembly, testing, calibration; varies by complexity and factory automation level |

| Packaging | $12 – $18 | Custom retail or export-grade packaging; includes protective foam, manuals, power adapters |

| R&D Amortization (ODM) | $15 – $30 | One-time design cost spread across MOQ |

| Quality Control & Testing | $8 – $12 | In-line QC, final functional test, safety certification prep |

| Logistics (to FOB Port) | $10 – $20 | Domestic transport to Shenzhen or Ningbo port |

Total Estimated FOB Unit Cost Range: $270 – $410

Note: Final cost depends on robot complexity, component sourcing (domestic vs. imported), and automation level at factory.

4. Price Tiers by MOQ (FOB China, USD per Unit)

| MOQ (Units) | Avg. Unit Price (USD) | Key Drivers |

|---|---|---|

| 500 | $390 – $410 | High per-unit cost due to low volume; minimal tooling amortization; suitable for white label or prototype phase |

| 1,000 | $350 – $370 | Moderate savings; standard private label entry point; tooling costs spread; better QC consistency |

| 5,000 | $290 – $320 | Optimal cost efficiency; full tooling amortization; preferred for private label; eligibility for bulk component discounts |

Trend 2026: Factories increasingly offer dynamic pricing contracts—price adjustments tied to material index (e.g., aluminum, ICs) and FX rates. Consider locking in 6–12 month pricing for stability.

5. Strategic Recommendations for Procurement Managers

-

Leverage ODM for Speed, OEM for Control

Use ODM to enter markets quickly with lower upfront investment. Transition to OEM as volume grows and brand differentiation becomes critical. -

Negotiate IP Clauses

In ODM agreements, ensure your modifications and firmware are IP-protected. Push for shared or transferable IP rights where possible. -

Aim for MOQ of 1,000+ for Private Label

This tier balances cost, exclusivity, and supply chain reliability. Avoid 500-unit MOQs for long-term branding. -

Audit Supplier Automation Level

Prefer factories with >60% automated assembly lines—leads to 15–20% lower defect rates and better labor cost control. -

Factor in Post-Pandemic Realities

While labor costs in China have stabilized (~3–4% YoY increase), semiconductor lead times and rare earth material costs remain volatile. Build 10–15% buffer in budgets.

Conclusion

China remains the global leader in robotics manufacturing, offering scalable OEM/ODM solutions for international buyers. By understanding the trade-offs between white label and private label, and leveraging volume-based pricing, procurement managers can achieve significant cost advantages while maintaining quality and brand integrity. In 2026, success hinges on strategic supplier selection, IP management, and proactive cost modeling.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Empowering Global Procurement with On-the-Ground Intelligence in China

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SourcifyChina Sourcing Verification Report: Robotics Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026

Objective: Mitigate supply chain risk through rigorous manufacturer validation in China’s robotics sector

Critical 5-Step Verification Protocol for Robotics Manufacturers

Non-negotiable for high-precision, high-liability robotics procurement

| Step | Verification Action | Robotics-Specific Requirements | Validation Method |

|---|---|---|---|

| 1. Legal & Operational Legitimacy | Confirm business scope in Chinese license (营业范围) | Must explicitly include “industrial robot R&D, production, and sales” (工业机器人研发、生产、销售) | Cross-check National Enterprise Credit Info Portal + request scanned business license with robotics-specific classification codes (e.g., C3434 for industrial robots) |

| 2. Technical Capability Audit | Validate core competencies in robotics | • On-site demonstration of payload/torque testing • Proof of in-house R&D team (3+ engineers with robotics degrees) • Motion control algorithm documentation |

Unannounced factory audit requiring: – Live robot cycle testing – CNC machining center access – Source code review (under NDA) |

| 3. Supply Chain Transparency | Map critical component sources | • Servo motor/encoder provenance (e.g., Yaskawa, Kollmorgen) • Controller PCB assembly process • Gearbox heat treatment certification |

Demand Tier-2 supplier list + material traceability logs. Reject if “proprietary” blocks component verification |

| 4. Quality Assurance Systems | Assess robotics-specific QA protocols | • ISO 13849 PLd certification (safety-related) • Repeatability testing logs (±0.02mm standard) • Environmental stress testing (vibration/temperature) |

Review 3 months of QA records. Verify calibration equipment (e.g., laser trackers) has valid CNAS accreditation |

| 5. IP Protection Safeguards | Secure design ownership | • Patent verification for custom mechanisms • NDA with robotics-specific clauses • Firmware encryption protocols |

Require patent registry screenshots (e.g., CNIPA) + third-party escrow for source code |

Trading Company vs. Factory: Robotics Sector Differentiation Guide

70% of “robot factories” on Alibaba are intermediaries (SourcifyChina 2025 Audit Data)

| Indicator | Genuine Factory | Trading Company | Robotics Red Flag |

|---|---|---|---|

| Facility Access | Full production floor access (including calibration labs) | “Restricted areas” or virtual-only tours | Refuses to show gearbox assembly lines or motor winders |

| Pricing Structure | Quotes by BOM + labor + margin | Fixed “package pricing” with no cost breakdown | Cannot explain servo motor cost variance (±15% indicates reselling) |

| Technical Dialogue | Engineers discuss kinematics/dynamics | Sales staff reference “standard models” | Uses generic terms like “industrial arm” instead of SCARA/6-axis articulation |

| Lead Time | 8-14 weeks (custom builds) | 2-4 weeks (off-the-shelf) | Promises <6 weeks for custom payload integration |

| Certifications | Holds CNAS-accredited lab reports | Shows reseller certificates | Claims “CE certified” but lacks EU Type Examination Certificate |

| Payment Terms | 30% deposit, 60% pre-shipment, 10% post-validation | 100% upfront or LC at sight | Demands full payment before performance testing |

| Workforce | 60%+ technical staff (engineers/technicians) | >80% sales/admin personnel | No robotics R&D department in organizational chart |

Top 5 Robotics-Specific Red Flags to Terminate Engagement

Validated through 127 SourcifyChina factory audits (2024-2025)

-

“White Label” Deception

→ Example: Claims “proprietary controller” but uses generic Delta/Estun systems with rebranded HMI

→ Action: Demand firmware version verification + compare against OEM release notes -

Certification Theater

→ Example: Shows CE mark but lacks Notified Body involvement for machinery directive (2006/42/EC)

→ Action: Require NB certificate number + verify on EU NANDO database -

Capacity Mismatch

→ Example: Claims 500-unit/month capacity but has only 2 welding robots on production line

→ Action: Calculate theoretical output: (Cycle time × shifts × robots) vs. claimed volume -

Component Obfuscation

→ Example: “High-precision reducer” listed without brand/model (likely low-cost Zhejiang knockoffs)

→ Action: Require component datasheets with serial traceability for critical path items -

R&D Theater

→ Example: “Innovation lab” contains only demo units from trade shows

→ Action: Inspect version control logs in GitLab/SVN for active development

SourcifyChina Implementation Framework

Deploy these actions within 72 hours of initial contact

| Timeline | Critical Action | Robotics-Specific Tool |

|---|---|---|

| Day 1 | Request factory layout diagram showing: – Robot assembly stations – Calibration bays – EOL testing area |

Use satellite imagery (Google Earth Pro) to verify facility size vs. claimed capacity |

| Day 3 | Demand 3D CAD files for one standard model under NDA | Run through plagiarism checker (e.g., Geomagic Verify) against known designs |

| Day 7 | Conduct unannounced video audit: – Focus on gearbox assembly – Servo motor mounting process |

Require real-time screen share of oscilloscope readings during motor calibration |

| Pre-PO | Implement component kill switch clause: “Any substitution of Tier-1 components voids contract” |

Attach approved supplier list with part numbers (e.g., Yaskawa Σ-7 MR-J4-70B1-RJ) |

Key Insight: In robotics, process transparency > price optimization. A 15% cost saving is negated by one field failure in safety-critical applications. SourcifyChina mandates minimum 3 performance validations (pre-shipment, post-installation, 6-month runtime) for all robotics clients.

This report reflects SourcifyChina’s proprietary verification methodology. Unauthorized distribution prohibited. © 2026 SourcifyChina. All rights reserved.

Next Step: Request our Robotics Manufacturer Scorecard (27-point technical assessment) at sourcifychina.com/robotics-validation

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary

In an increasingly competitive global market, sourcing high-caliber robotics suppliers in China demands precision, speed, and reliability. With thousands of manufacturers claiming expertise in robotics, procurement teams face significant challenges in identifying trustworthy, scalable, and technically capable partners. Time spent vetting unreliable suppliers directly impacts time-to-market, project ROI, and supply chain resilience.

SourcifyChina’s Verified Pro List for Robotics Companies in China eliminates this inefficiency by delivering pre-qualified, audited, and performance-verified suppliers—saving procurement teams an average of 120+ hours per sourcing cycle.

Why the Verified Pro List Accelerates Your Sourcing Process

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | All manufacturers on the Pro List have undergone rigorous due diligence, including site audits, financial stability checks, and production capability assessments. |

| Technical Qualification | Each robotics company is evaluated for engineering expertise, R&D investment, and compliance with international standards (ISO, CE, etc.). |

| Reduced RFQ Cycles | Access to detailed capability profiles and past performance data shortens supplier shortlisting from weeks to hours. |

| Language & Communication Support | All listed partners have English-fluent project managers and are accustomed to working with Western businesses. |

| Risk Mitigation | Verified track record of on-time delivery, IP protection, and quality control reduces supply chain disruptions. |

Average time saved per sourcing project: 3.5 weeks.

Call to Action: Optimize Your 2026 Robotics Sourcing Strategy

In 2026, speed and precision are non-negotiable. Whether you’re sourcing collaborative robots (cobots), industrial automation systems, or AI-integrated robotic solutions, partnering with the right Chinese manufacturer can unlock competitive advantage—but only if you start with verified, reliable suppliers.

SourcifyChina’s Verified Pro List eliminates the guesswork.

Stop spending months on supplier discovery and due diligence. Start negotiating with qualified partners—in days, not months.

👉 Contact us today to receive your customized Pro List and sourcing roadmap:

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our sourcing consultants are ready to align with your technical requirements, volume needs, and compliance standards—ensuring you engage only with suppliers who meet your operational excellence benchmarks.

Accelerate your robotics supply chain in 2026. Trust verified. Source smarter.

—

SourcifyChina | Precision Sourcing. Verified Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.