The global blind rivet market, which includes Rivnuts (also known as threaded inserts or blind nuts), is experiencing steady growth driven by rising demand in aerospace, automotive, and construction industries. According to Mordor Intelligence, the global blind rivet market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2029. This expansion is fueled by the increasing need for lightweight, durable fastening solutions in manufacturing processes, particularly in regions with robust industrial activity such as North America, Europe, and Asia-Pacific. Rivnuts, valued for their ability to provide strong, threaded attachments in thin or blind-side materials, are becoming a go-to solution in assembly applications where access is limited to one side. As demand rises, several manufacturers have emerged as leaders in innovation, quality, and product range. Based on market presence, product diversity, and technical capabilities, the following seven companies stand out as the top Rivnut size manufacturers shaping the industry’s future.

Top 7 Rivnut Sizes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Blind Rivet Nuts

Domain Est. 1996

Website: sherex.com

Key Highlights: Sherex is the leading manufacturer of blind rivet nuts in North America and has a wide array of rivet nut lines for all kinds applications….

#2 Rivet Nuts

Domain Est. 2009

Website: rivetsonline.com

Key Highlights: Our rivet nuts kits and blind rivet kits include an assortment of fasteners (from 50 to 200 pieces in various sizes, depending on the kit), along with ……

#3 Standard Rivnut

Domain Est. 1997

Website: libertyeng.com

Key Highlights: Rivnuts® are available in aluminum, steel or stainless steel. Unified thread sizes of 4-40, 6-32, 8-32, 10-32, 10-24,1/4-20, ……

#4 Rivet Nuts

Domain Est. 1997

Website: lawsonproducts.com

Key Highlights: 90-day returnsDiscover Lawson rivet nuts designed for strength and long-lasting performance. Create strong threaded connections easily—order Lawson rivet nuts ……

#5 R

Domain Est. 1999

Website: avkfasteners.com

Key Highlights: The R-N Series® is ideal for applications requiring heavy push out loads such as for the attachment of leg leveling screws to the bottom of equipment….

#6 RIVNUT® blind rivet nuts and RIVSTUD® blind rivet studs

Domain Est. 2000

Website: boellhoff.com

Key Highlights: This is where you can use RIVNUT® load-bearing nut or RIVSTUD® stud threads. Various versions and sizes provide the perfect solution for every application….

#7 Rivet Nuts

Domain Est. 2003

Website: imperialsupplies.com

Key Highlights: Free delivery over $400 365-day returns…

Expert Sourcing Insights for Rivnut Sizes

2026 Market Trends for Rivnut Sizes

As industries continue to evolve toward lightweight construction, modular design, and automation, the demand for reliable blind fastening solutions like rivnuts is expected to grow significantly by 2026. Rivnut sizes—a critical factor in performance, compatibility, and application suitability—are poised to reflect broader market dynamics in manufacturing, aerospace, automotive, and construction sectors. The following analysis outlines key trends expected to influence rivnut size demand and innovation through 2026.

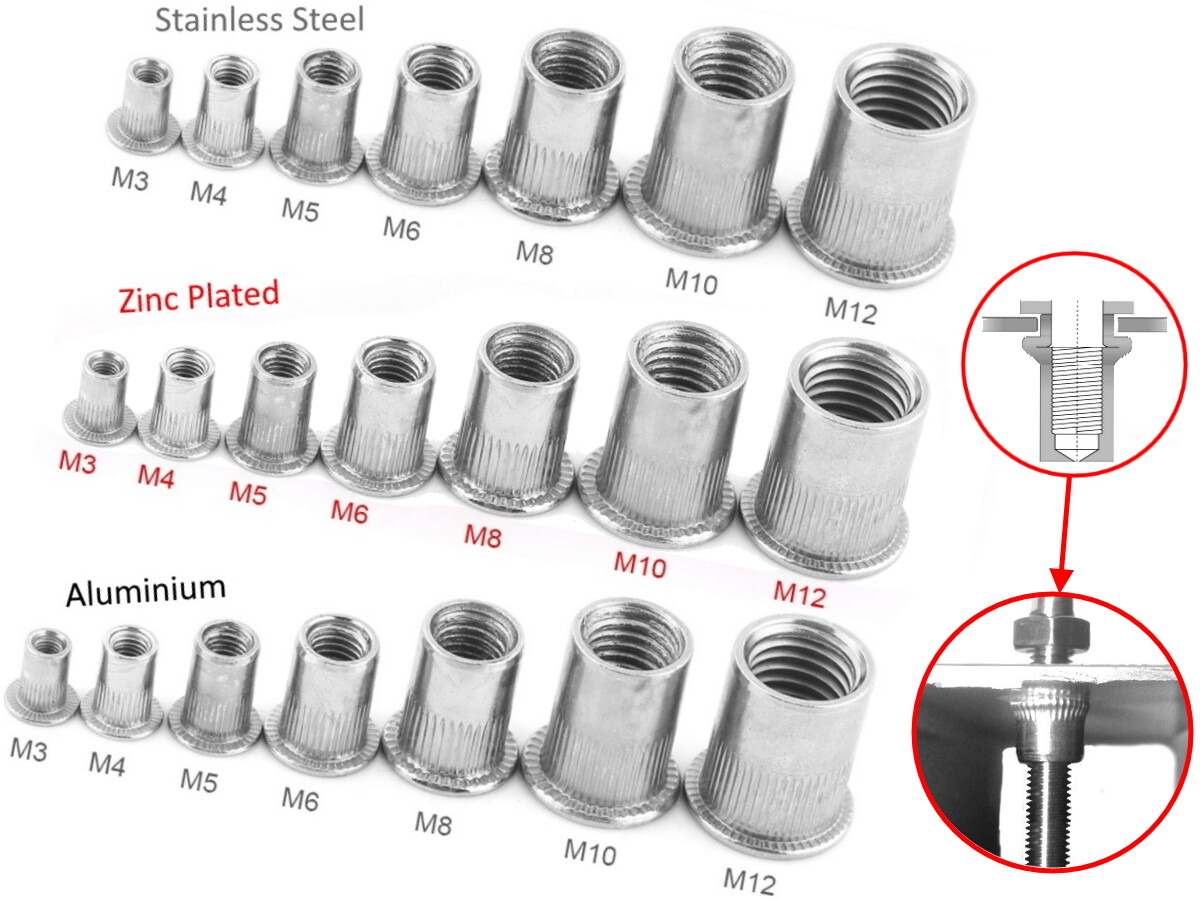

Growing Demand for Miniaturized Rivnut Sizes

One of the most prominent trends shaping the rivnut market is the increasing need for smaller, precision-engineered fasteners. As electronics, drones, medical devices, and compact consumer products become more advanced, manufacturers are adopting thinner materials and tighter assembly spaces. This shift is driving demand for miniaturized rivnut sizes, such as #2, #4, and M3 variants. By 2026, these smaller sizes are expected to see above-average growth, particularly in high-tech manufacturing and robotics.

Standardization and Global Compatibility

With globalization driving supply chain integration, there is a rising emphasis on standardization. Rivnut sizes adhering to international standards (e.g., ASME B18.6.9, DIN 7175) will be favored to ensure interchangeability and reduce inventory complexity. Manufacturers are likely to consolidate product lines around popular sizes—such as #6, #8, #10, M4, M5, and M6—offering high compatibility across regions. By 2026, companies that support dual imperial and metric sizing with clear cross-reference guides will gain a competitive edge.

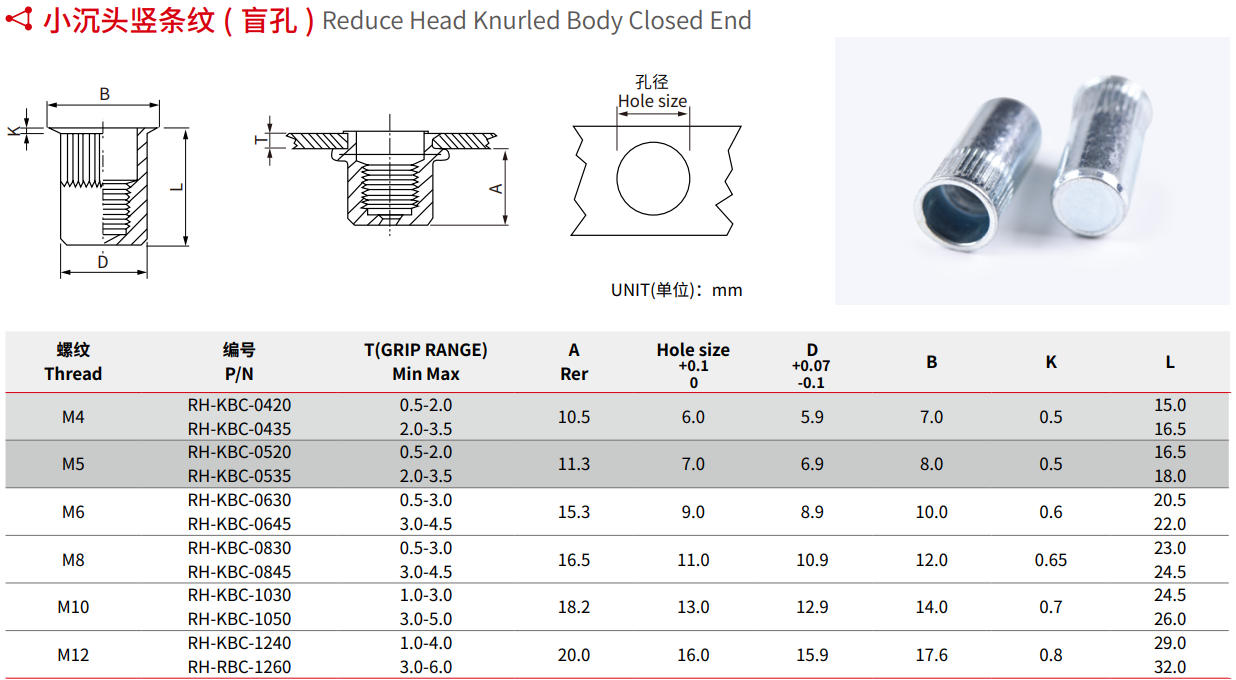

Shift Toward Larger Rivnut Sizes in Heavy Industries

While miniaturization dominates certain sectors, heavy industries like aerospace, transportation, and industrial machinery are increasing their use of larger rivnut sizes (e.g., #12, 1/4″-20, M8, and M10) due to demands for higher torque resistance and structural integrity. These applications require robust fastening in composites and lightweight alloys, where larger rivnuts provide superior load distribution. The push for fuel-efficient aircraft and electric vehicles (EVs) using aluminum and carbon fiber will amplify demand for high-strength, larger-sized rivnuts through 2026.

Material-Specific Sizing Innovations

As new materials such as advanced composites, high-strength steels, and magnesium alloys enter mainstream production, rivnut sizing is adapting to accommodate different material thicknesses and hardness. Custom sizing—particularly in mid-range diameters (e.g., M5–M8)—is expected to rise as engineers seek optimized grip ranges and insertion forces. By 2026, expect increased availability of specialized rivnut sizes tailored for specific material stacks, including longer grip lengths and flange variations.

Automation and Precision Installation Driving Size Consistency

The expansion of automated assembly lines necessitates highly consistent fastener dimensions. Rivnut sizes used in robotic installation must meet tight tolerances to ensure reliable feeding, placement, and setting. This trend reinforces demand for precision-manufactured, tightly controlled rivnut sizes—especially in high-volume sectors like automotive and EV manufacturing. Standardized sizing with minimal variance will be critical, pushing suppliers toward tighter quality control and digital traceability by 2026.

Sustainability and Lightweighting Influencing Size Selection

Sustainability initiatives are pushing manufacturers to reduce component weight without sacrificing strength. This dual objective is influencing rivnut size selection—favoring optimized, application-specific sizes that offer maximum holding power with minimal added mass. For instance, M5 and #8 sizes are increasingly preferred over bulkier alternatives in electric vehicle battery trays and chassis assemblies. By 2026, lifecycle assessments may include fastener weight and recyclability, further shaping size preferences.

Regional Market Variations in Size Preferences

Regional differences will continue to influence rivnut size demand. North America is expected to maintain strong demand for imperial sizes (#6–#10), while Europe and Asia favor metric equivalents (M4–M6). However, hybrid manufacturing environments will drive demand for multi-size compatibility tools and kits. By 2026, global suppliers will likely offer modular tooling and size-flexible installation systems to serve diverse regional needs efficiently.

Conclusion

By 2026, the rivnut size landscape will be shaped by opposing yet complementary forces: miniaturization in tech sectors and robust sizing in heavy industry, all underpinned by standardization, automation, and sustainability. Manufacturers and suppliers that offer a balanced portfolio—spanning miniature to heavy-duty sizes, compliant with global standards, and adaptable to automated processes—will be best positioned to capitalize on emerging opportunities. Strategic investment in R&D for material-specific and application-optimized sizes will differentiate market leaders in the evolving fastener industry.

Common Pitfalls When Sourcing Rivnut Sizes (Quality, IP)

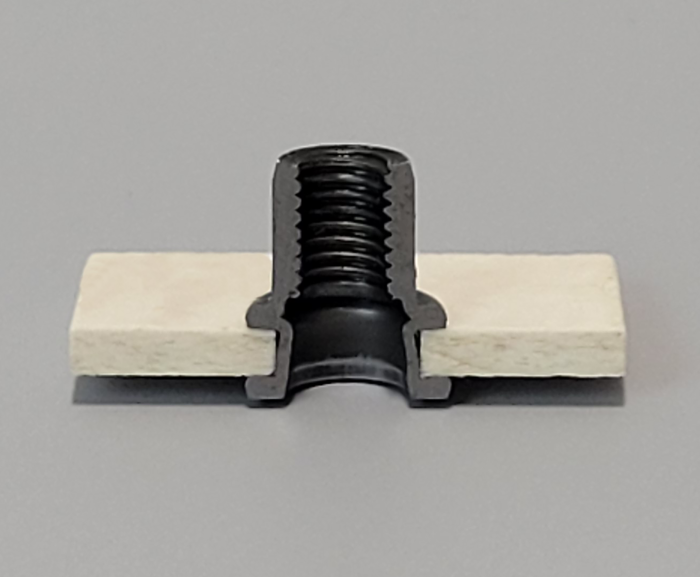

Sourcing the correct Rivnut (also known as blind rivet nuts) involves more than just matching size dimensions. Critical issues related to quality and Ingress Protection (IP) ratings can lead to product failure, safety hazards, or compliance issues if overlooked. Here are the most common pitfalls:

Inconsistent Quality Across Suppliers

Many suppliers, especially those from low-cost regions, may offer Rivnuts that appear dimensionally correct but use inferior materials or manufacturing processes. Poor-quality Rivnuts can have inconsistent thread integrity, reduced clamping force, or premature corrosion. Always verify certifications (e.g., ISO 9001), request material test reports (MTRs), and conduct sample testing before full-scale procurement.

Misunderstanding IP Rating Requirements

Rivnuts are sometimes used in enclosures where environmental sealing is critical. However, the Rivnut itself does not provide an IP rating—sealing depends on the installation method, gasketing, and mating components. A common mistake is assuming a metal Rivnut contributes directly to IP protection. Always assess the full assembly, not just the fastener, to ensure compliance with required IP standards (e.g., IP65, IP67).

Incorrect Material Selection for Environment

Choosing Rivnuts without considering environmental exposure can lead to corrosion and failure. For example, standard steel Rivnuts in a marine or high-humidity environment will rust, compromising both structural integrity and appearance. Always match the Rivnut material (e.g., stainless steel, aluminum, or plated variants) to the operating environment and ensure compatibility with the base material to avoid galvanic corrosion.

Overlooking Installation Tool Compatibility

Rivnuts require specific setting tools, and different brands or sizes may need unique mandrels or nosepieces. Sourcing Rivnuts without confirming tool compatibility can lead to improper installation, weak joints, or damage to the host material. Verify that the Rivnuts are compatible with your existing tooling or budget for new equipment.

Assuming Size Standardization Across Brands

While Rivnut sizes follow general standards (e.g., MS, NAS, DIN), tolerances and thread forms can vary between manufacturers. Using a substitute brand without validating fit and performance can result in thread misalignment or reduced load capacity. Stick to reputable brands or conduct side-by-side testing when switching suppliers.

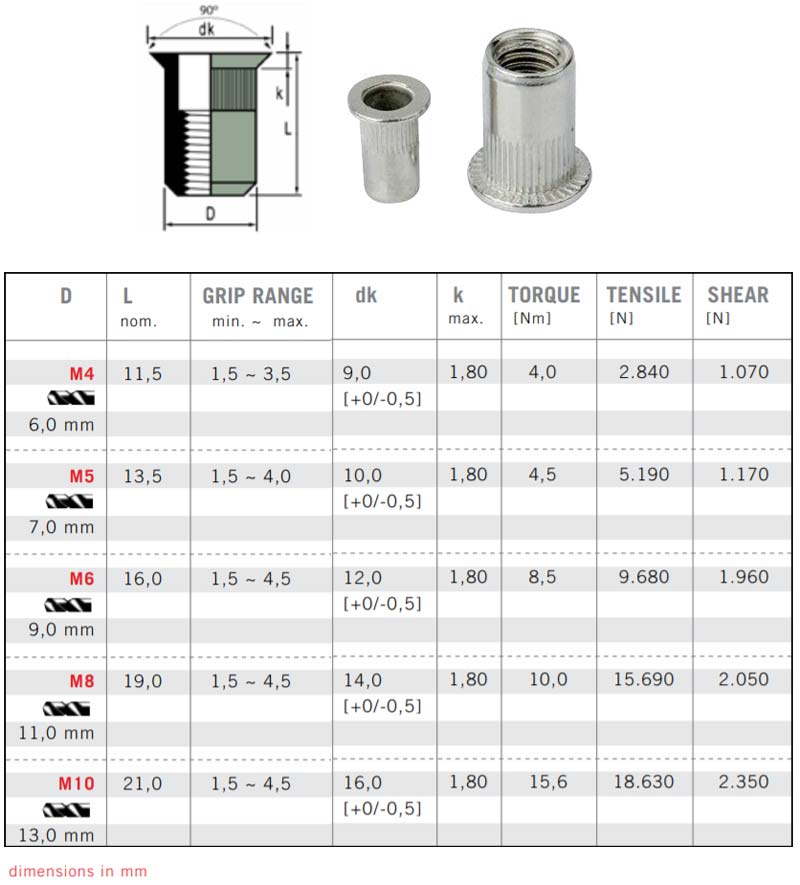

Neglecting Load and Torque Specifications

Smaller Rivnut sizes may not support high torque or shear loads. A frequent error is selecting a Rivnut based solely on hole size without verifying mechanical performance. Always cross-reference the application’s load requirements with manufacturer specifications to avoid joint failure.

By addressing these pitfalls proactively—focusing on quality verification, environmental suitability, and system-level performance—you can ensure reliable and compliant Rivnut installations.

Logistics & Compliance Guide for Rivnut Sizes

Understanding the logistics and compliance considerations for Rivnuts—also known as blind rivet nuts or threaded inserts—is essential for efficient supply chain management, quality assurance, and regulatory adherence. This guide outlines best practices for handling, storing, transporting, and ensuring compliance when working with various Rivnut sizes.

Size Classification and Standardization

Rivnuts are available in multiple sizes defined by thread type, diameter, grip range, and head style. Common standards include:

- ASNA (Aerospace Standard Nut Assembly) – Widely used in aerospace (e.g., ASNA 510, ASNA 520)

- MS (Military Standard) – Such as MS21051 and MS21052

- NAS (National Aerospace Standard) – Includes NAS1330, NAS1331, etc.

- ISO and DIN Standards – Used in industrial and automotive applications

Ensure all Rivnut sizes are clearly labeled per applicable standards. Documentation should include:

- Thread size (e.g., #4-40, M5, 1/4-20)

- Grip length (e.g., 0.063″, 1.6 mm)

- Material (e.g., steel, stainless steel, aluminum)

- Finish or plating (e.g., cadmium, zinc, passivated)

Packaging and Labeling Requirements

Proper packaging prevents damage and ensures traceability:

- Unit Packaging: Small Rivnuts should be packed in moisture-resistant bags or tubes, especially for corrosion-prone materials like carbon steel.

- Bulk Packaging: For larger orders, use anti-static or corrosion-inhibiting containers with internal dividers to avoid tangling.

- Labeling: Each package must display:

- Part number and size

- Quantity

- Material and finish

- Lot or batch number

- Date of manufacture

- Compliance markings (e.g., RoHS, REACH, DFARS)

Storage and Environmental Controls

Store Rivnuts in a clean, dry, temperature-controlled environment to prevent degradation:

- Humidity: Maintain relative humidity below 60% to prevent oxidation.

- Temperature: Store between 15°C and 25°C (59°F–77°F).

- Shelving: Keep off the floor and away from direct sunlight or chemical exposure.

- Segregation: Separate different sizes, materials, and finishes to prevent cross-contamination.

Transport and Handling

Follow these guidelines to maintain product integrity during shipping:

- Domestic & International Shipping: Use sturdy, sealed containers with protective cushioning.

- Hazardous Materials: Most Rivnuts are non-hazardous, but verify plating chemicals (e.g., cadmium) for IATA/IMDG compliance if applicable.

- Customs Documentation: Include detailed commercial invoices listing:

- HS Code (e.g., 7318.15 for threaded fasteners)

- Country of origin

- Material composition

- Value and quantity

Regulatory Compliance

Ensure adherence to regional and industry-specific regulations:

- RoHS (EU): Restricts hazardous substances; verify coatings and platings are compliant.

- REACH (EU): Requires declaration of Substances of Very High Concern (SVHC).

- DFARS (USA): Mandates traceability and country-of-origin reporting for defense contracts.

- ITAR (USA): Applies if Rivnuts are used in defense articles; control export and handling.

- Conflict Minerals (Dodd-Frank Act): Report use of tin, tantalum, tungsten, and gold if sourced from conflict regions.

Quality Assurance and Traceability

Maintain full traceability throughout the supply chain:

- Certificates of Conformance (CoC): Require suppliers to provide CoCs for each batch.

- Material Test Reports (MTRs): Essential for aerospace and defense applications.

- First Article Inspection (FAI): Conduct for new sizes or suppliers per AS9102.

- Lot Tracking: Use unique batch identifiers to support recalls or audits.

Supplier and Vendor Compliance

Audit and qualify suppliers based on:

- ISO 9001 or AS9100 certification

- Adherence to technical drawings and specifications

- Consistent packaging and labeling practices

- On-time delivery and defect rates

Disposal and Sustainability

Dispose of defective or excess Rivnuts responsibly:

- Recycle metal components through certified recyclers.

- Follow local regulations for disposing of chemically treated fasteners.

- Minimize waste via accurate inventory planning and just-in-time ordering.

Conclusion

Proper logistics and compliance management for Rivnut sizes ensures product reliability, regulatory adherence, and operational efficiency. By standardizing packaging, maintaining environmental controls, and validating supplier compliance, organizations can reduce risk and enhance supply chain performance across industries such as aerospace, automotive, and manufacturing.

In conclusion, selecting the appropriate rivnut (also known as a blind rivet nut) size is crucial for achieving a secure, reliable, and durable fastening in applications where access is limited to one side. Proper sourcing involves understanding the required thread size, material thickness, grip range, and load requirements. It is essential to match the rivnut diameter and length to the specific application to ensure optimal performance and structural integrity. Additionally, considering factors such as material compatibility, installation tools, and environmental conditions will further enhance reliability. By carefully evaluating engineering specifications and manufacturer guidelines, one can confidently source the correct rivnut size, ensuring efficient assembly and long-term performance across a wide range of industrial, automotive, and aerospace applications.