The global demand for rice-based ingredients continues to surge, driven by increasing consumer interest in natural, sustainable, and functional food and cosmetic products. According to Grand View Research, the global rice processing market size was valued at USD 145.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. A key segment within this expansion is rice bran and rice polish—byproducts of rice milling rich in oils, proteins, and antioxidants, widely used in nutraceuticals, skincare, animal feed, and health foods. As sustainability and circular economy models gain traction in agribusiness, manufacturers are innovating to extract higher value from rice polishing, turning waste streams into premium ingredients. With Asia Pacific dominating both rice production and processing, and growing demand in North America and Europe for clean-label products, rice polish manufacturers are strategically scaling production, enhancing extraction technologies, and expanding their global footprint. In this evolving landscape, the following nine companies stand out for their technological capabilities, product quality, and market reach.

Top 9 Rice Polish Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

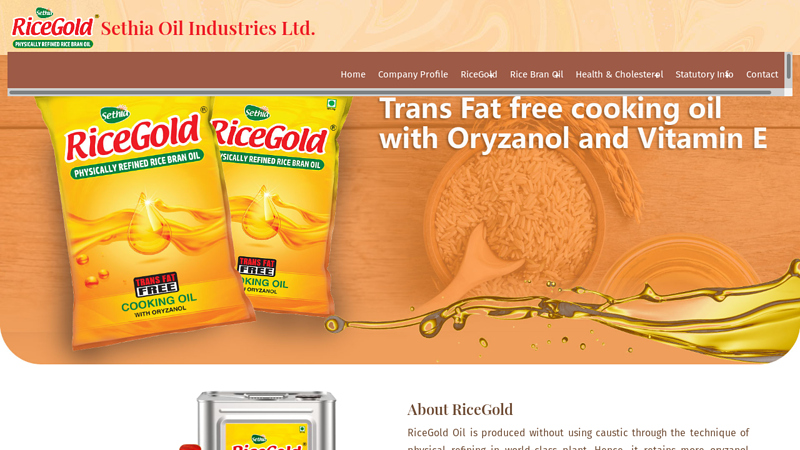

#1 Sethia Oil Industries Ltd.

Domain Est. 2001

Website: sethiaoils.com

Key Highlights: About RiceGold. RiceGold Oil is produced without using caustic through the technique of physical refining in world-class plant….

#2 Cattle Feed

Domain Est. 2023

Website: rdplfeeds.com

Key Highlights: Manufacturer of Cattle Feed – 50 Kg Rice Polish, Rice Gluten Powder, Soybean Meal Doc offered by Rdpl Feeds Private Limited, Aligarh, Uttar Pradesh….

#3 Pragati Agri Products Pvt Ltd

Website: pragati.ltd

Key Highlights: Pragati Agri Products Pvt Ltd. is a leading manufacturer of high-quality Crude Rice Bran Oil, De Oiled Rice Bran & Lose Crude Rice Bran Oil….

#4 Riceland

Domain Est. 1996

Website: riceland.com

Key Highlights: For over a century, Riceland has been proudly farmer-owned, with every grain of rice rooted in dedication, care, and tradition. Our farmer-owners are the heart ……

#5 Ricela – Rice Bran Oil

Domain Est. 2002

Website: ricela.com

Key Highlights: Rice bran oil is nutritious edible oil produced from the oily layer of brown rice which is separated as rice bran while polishing white rice….

#6 Kohinoor Foods Limited

Domain Est. 2006

Website: kohinoorfoods.in

Key Highlights: The Taste Of Indian Spices. We believe that healthy eating, clean air, and gentle character is the best start to genuine wellbeing….

#7 Rice Bran

Domain Est. 2017

Website: flamingoofoods.com

Key Highlights: What is Rice Bran? Rice bran, also known as rice polish, is the nutrient-rich outer layer of the rice kernel removed during the milling process….

#8 Rice Polish

Domain Est. 2020

Website: royalflourmills.com

Key Highlights: Rice polish is a by-product of rice obtained in the milling operation of brushing the grain to polish the kernel, after the hull and bran have been removed….

#9 Rice Polish

Website: barrungroup.com

Key Highlights: We source rice polish from trusted rice mills, where it is carefully collected, cleaned, and processed to maintain its natural nutritional properties. Each ……

Expert Sourcing Insights for Rice Polish

H2 2026 Market Trends Analysis for Rice Polish

The global rice polish market is poised for significant evolution in the second half of 2026 (H2 2026), driven by shifting consumer preferences, technological advancements, and increasing focus on sustainability and wellness. Here’s a breakdown of the key trends expected to shape the market:

1. Heightened Demand Driven by Clean Beauty & Natural Ingredients

- Consumer Shift: The demand for “clean,” non-toxic, and naturally derived skincare ingredients will remain paramount. Rice polish, with its centuries-old heritage in Asian beauty rituals and its natural exfoliating (rice bran, rice powder) and brightening (ferulic acid, allantoin, vitamins) properties, perfectly aligns with this trend.

- Marketing Focus: Brands will heavily emphasize the natural origin, biodegradability, and traditional efficacy of rice polish in their formulations. Claims like “free-from harsh chemicals,” “plant-powered,” and “inspired by ancient rituals” will be prominent in H2 2026 campaigns.

- Transparency: Increased consumer scrutiny will push brands towards greater transparency in sourcing (e.g., non-GMO rice, specific regional origins) and processing methods.

2. Innovation in Formulation & Technology

- Beyond Basic Powder: While traditional powder-to-paste formats will persist, expect significant innovation:

- Encapsulation: Micro-encapsulation of rice-derived actives (like rice ferment filtrate) for controlled release and enhanced stability.

- Fermentation Focus: Fermented rice water and rice bran extracts (e.g., “sake” or “sake lees” derivatives) will gain traction due to their increased bioavailability, higher concentration of beneficial compounds (kojic acid, amino acids), and superior brightening/anti-aging effects.

- Multi-Functional Blends: Rice polish will be increasingly combined with other natural exfoliants (like enzymatic papaya/bromelain) or synergistic actives (hyaluronic acid, niacinamide, botanical oils) in pre-mixed creams, gels, or serums for added hydration and barrier support, moving beyond simple exfoliation.

- pH-Optimized & Enzyme-Enhanced: Formulations will be carefully pH-balanced and may incorporate gentle enzymes alongside physical exfoliation for a more sophisticated, less abrasive experience.

3. Sustainability & Ethical Sourcing as Core Pillars

- Waste Valorization: The “upcycled” narrative will strengthen. Brands will highlight sourcing rice polish from bran and germ removed during milling – materials often considered waste – positioning it as a sustainable, circular economy solution.

- Traceability & Regenerative Agriculture: Expect increased emphasis on traceable supply chains and partnerships with rice farmers practicing sustainable or regenerative agriculture. Certifications (e.g., Fair Trade, organic) will become more common and valued.

- Eco-Packaging: Sustainable packaging (refillables, biodegradable materials, recycled content) will be a major differentiator, especially for premium brands targeting eco-conscious consumers.

4. Expansion into New Product Categories & Personalization

- Beyond Face: While facial cleansers and masks remain core, expect rice polish to feature more prominently in body scrubs, scalp treatments (for gentle exfoliation), and even hair care products (leveraging rice water’s strengthening properties).

- Personalization: Growth in custom skincare will see rice polish offered as a key ingredient in customizable serums or bases, allowing consumers to tailor exfoliation level and benefits to their specific needs (e.g., sensitive skin, hyperpigmentation, dullness).

- “Skinimalism” Integration: Rice polish’s multi-benefit profile (exfoliation, brightening, mild nourishment) fits the “skinimalism” trend, appealing to consumers seeking effective, simplified routines with fewer, multi-tasking products.

5. Geographical Expansion & Premiumization

- Global Penetration: While deeply rooted in Asian markets (Japan, Korea, China), demand will grow significantly in North America, Europe, and emerging markets as global beauty consumers embrace K-Beauty and J-Beauty trends and natural ingredients.

- Premium & Niche Growth: The market will see strong growth in the premium and luxury segments. High-end brands will leverage unique rice varieties (e.g., black rice, red rice), advanced processing techniques (cold-pressed, specific fermentation strains), and scientific validation to command higher prices.

- Medical Aesthetic Adjacency: Clinics and dermatologists may increasingly recommend or incorporate rice polish-based treatments as a gentler alternative or complement to stronger chemical peels for maintenance and brightening.

6. Regulatory Scrutiny & Scientific Validation

- Increased Scrutiny: As claims around brightening (potentially linked to lightening) become more common, regulatory bodies in key markets may scrutinize marketing language more closely, requiring robust evidence.

- Demand for Proof: Consumers and retailers will demand more scientific backing for efficacy claims. Investment in clinical studies demonstrating the benefits of specific rice polish formulations (e.g., reduction in hyperpigmentation, improvement in skin texture) will be crucial for brand credibility and differentiation in H2 2026.

Conclusion for H2 2026:

The rice polish market in H2 2026 will be characterized by sophistication, sustainability, and science. Success will depend on brands that can innovate beyond basic exfoliation, leverage the powerful “natural” and “upcycled” narratives authentically, invest in sustainable and ethical practices, provide scientific validation for claims, and cater to the growing demand for personalized, multi-functional, and premium skincare experiences. The ingredient will solidify its position as a high-value, versatile component in the global beauty arsenal, moving firmly from niche traditional remedy to mainstream, scientifically-backed active.

Common Pitfalls Sourcing Rice Polish (Quality, IP)

Sourcing rice polish—also known as rice bran or rice oil polish—can present several challenges, particularly concerning quality consistency and intellectual property (IP) risks. Being aware of these pitfalls is essential for manufacturers in food, cosmetics, and nutraceutical industries.

Inconsistent Quality and Composition

Rice polish quality varies significantly based on rice variety, milling process, storage conditions, and geographical origin. Poorly processed or stored rice bran can suffer from high free fatty acid (FFA) levels due to lipase activity, leading to rancidity and reduced shelf life. Buyers may receive batches with inconsistent nutrient profiles (e.g., gamma-oryzanol, tocopherols, phytosterols), impacting product efficacy and formulation stability.

Lack of Standardized Specifications

Many suppliers do not adhere to industry-standard specifications for rice polish. Without clear parameters for moisture content, FFA levels, microbial load, and heavy metals, buyers risk receiving subpar material. This lack of standardization complicates quality control and can lead to batch rejections or inconsistent end-product performance.

Adulteration and Contamination Risks

Rice polish is sometimes adulterated with lower-cost fillers or by-products from other grains. Additionally, improper handling can introduce contaminants such as aflatoxins, pesticides, or heavy metals (e.g., arsenic, cadmium), especially if sourced from regions with poor agricultural controls. These pose serious health risks and regulatory compliance issues.

Intellectual Property (IP) Exposure

When sourcing rice polish for proprietary formulations—particularly in cosmetics or functional foods—there is a risk of inadvertently infringing on patented extraction methods, stabilization processes, or composition-of-matter claims. Some suppliers may use patented technologies to produce stabilized rice bran or enriched fractions (e.g., high-oryzanol extracts), and using such materials without proper due diligence can result in IP litigation.

Inadequate Documentation and Traceability

Suppliers may fail to provide full documentation, including certificates of analysis (CoA), process validation, or origin traceability. This opacity complicates regulatory compliance (e.g., FDA, EFSA, or organic certifications) and increases the risk of supply chain disruptions or recalls.

Insufficient Stabilization Process Disclosure

Rice polish is highly perishable due to endogenous enzymes. Effective stabilization (e.g., heat treatment, extrusion) is critical to preserve quality. However, some suppliers do not disclose stabilization methods or timelines, making it difficult to assess product stability and suitability for long-term use.

Geographic and Seasonal Supply Variability

Rice production is seasonal and region-dependent. Sourcing from a single origin increases vulnerability to supply shortages, price volatility, and quality fluctuations due to weather or crop disease. This can disrupt production planning and increase costs.

Conclusion

To mitigate these risks, buyers should:

– Establish stringent quality specifications and testing protocols.

– Conduct supplier audits and request full CoAs and IP disclosures.

– Prioritize suppliers with transparent, traceable, and sustainable sourcing practices.

– Consult legal experts when using rice polish in patented or innovative applications.

Proactive due diligence ensures both quality integrity and IP safety in rice polish sourcing.

Logistics & Compliance Guide for Rice Polish

Rice polish, also known as rice bran or rice oil cake (depending on processing), is a byproduct of rice milling with applications in animal feed, fertilizer, and biofuel production. Transporting and trading rice polish requires adherence to specific logistics protocols and compliance standards to ensure safety, quality, and regulatory conformity.

Regulatory Compliance

Rice polish is subject to agricultural, environmental, and international trade regulations. Compliance begins at the production stage and continues through transportation and final delivery.

-

Agricultural & Phytosanitary Regulations: Many countries require phytosanitary certificates for rice byproducts to prevent the spread of pests and diseases. Verify importing country requirements through national agricultural departments (e.g., USDA APHIS, EU Plant Health Authority).

-

Feed Safety Standards: When used in animal feed, rice polish must comply with feed safety regulations such as the EU Feed Hygiene Regulation (EC) No 183/2005 or the U.S. FDA’s Current Good Manufacturing Practice (cGMP) standards under the Food Safety Modernization Act (FSMA).

-

Labeling & Traceability: Proper labeling is essential. Include product name, batch number, date of production, net weight, origin, and any relevant hazard statements. Traceability systems should enable full supply chain tracking.

-

Customs & Import Documentation: Ensure accurate Harmonized System (HS) code classification (e.g., 2302.30 for rice bran in many jurisdictions), commercial invoices, packing lists, and certificates of origin are prepared. Some countries may impose import quotas or tariffs.

Packaging & Handling

Proper packaging and handling prevent contamination, spoilage, and safety hazards during storage and transport.

-

Packaging Types: Rice polish is commonly shipped in woven polypropylene bags (50–50 kg), jumbo bags (500–1000 kg), or in bulk for large-volume shipments. Moisture-resistant liners are recommended to prevent clumping and mold growth.

-

Storage Conditions: Store in a cool, dry, and well-ventilated area. Avoid direct contact with the ground and exposure to moisture. Ideal storage temperature: below 25°C with relative humidity under 70%.

-

Handling Precautions: Use protective equipment (gloves, masks) to avoid inhalation of fine dust. Implement dust control measures during loading/unloading due to combustible dust risks.

Transportation Requirements

Transport choice depends on volume, distance, destination, and customer specifications.

-

Containerized Shipping: For international trade, 20’ or 40’ dry containers are standard. Use container desiccants to control humidity. Fumigation may be required for certain destinations—ensure compliance with the International Standards for Phytosanitary Measures No. 15 (ISPM 15) for wooden pallets.

-

Bulk Transport: For domestic or regional shipments, bulk trucks or railcars may be used. Ensure vehicles are clean, dry, and dedicated to non-hazardous agricultural products.

-

Temperature & Moisture Monitoring: Use data loggers in long-haul shipments to monitor conditions. High moisture content (>12%) increases rancidity and microbial growth risk.

Safety & Environmental Considerations

Rice polish presents specific safety and environmental challenges that must be managed responsibly.

-

Combustible Dust Hazard: Rice polish dust can be explosive when suspended in air. Follow NFPA 652 (U.S.) or ATEX directives (EU) for dust control in processing and storage areas.

-

Spoilage & Rancidity: High oil content (in full-fat rice bran) makes it prone to oxidation. Use antioxidant treatments if necessary and limit storage duration. Monitor free fatty acid (FFA) levels.

-

Waste Management: Spills should be cleaned promptly using non-toxic methods. Unused or spoiled material must be disposed of according to local environmental regulations—composting or anaerobic digestion may be viable options.

Quality Assurance & Testing

Regular quality checks ensure product consistency and regulatory compliance.

- Key Parameters to Test:

- Moisture content (target: <12%)

- Oil content (varies by type: full-fat vs. defatted)

- Protein content

- Presence of aflatoxins and other mycotoxins

-

Microbial contamination (e.g., Salmonella, E. coli)

-

Third-Party Certification: Consider obtaining certifications such as ISO 22000, HACCP, or Organic (if applicable) to enhance marketability and compliance.

Conclusion

Successful logistics and compliance for rice polish involve a coordinated approach across production, packaging, transportation, and regulatory documentation. By adhering to international standards, maintaining quality control, and ensuring safety protocols, stakeholders can minimize risks and ensure efficient, lawful distribution of rice polish globally.

In conclusion, sourcing rice polish requires a strategic approach that balances quality, cost, sustainability, and supplier reliability. As a valuable byproduct of rice milling, rice polish is rich in nutrients and finds wide applications in animal feed, food supplements, and industrial uses. To ensure a consistent and high-quality supply, it is essential to partner with reputable suppliers who adhere to proper processing, storage, and handling practices to maintain product integrity. Additionally, considering factors such as geographical sourcing, seasonal availability, and market price fluctuations can significantly impact procurement efficiency. Ultimately, effective sourcing of rice polish not only supports operational needs but also contributes to sustainable agricultural value chains by utilizing milling byproducts efficiently.