The global restaurant ventilation fans market is experiencing robust growth, driven by increasing demand for energy-efficient kitchen exhaust systems in commercial foodservice operations. According to a 2023 report by Mordor Intelligence, the global commercial kitchen ventilation market was valued at USD 3.8 billion and is projected to grow at a CAGR of 5.2% from 2023 to 2028. This expansion is fueled by stringent health and safety regulations, rising restaurant construction, and the growing emphasis on indoor air quality and sustainability. Additionally, Grand View Research highlights that advancements in fan technology—such as variable speed drives and low-noise operation—are reshaping purchasing decisions among restaurant operators. As the foodservice industry evolves, the need for high-performance, code-compliant ventilation solutions has made selecting the right manufacturer a critical component of kitchen design. In this context, the following list highlights the top 10 restaurant ventilation fan manufacturers leading innovation, reliability, and market share in this dynamic sector.

Top 10 Restaurant Ventilation Fans Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Twin City Fan & Blower

Domain Est. 1997

Website: tcf.com

Key Highlights: Twin City Fan & Blower is an industry-leading designer and manufacturer of high-quality custom, semi-custom and standard fans ranging from heavy-duty industrial ……

#2 AcmeFan

Domain Est. 1997

Website: acmefan.com

Key Highlights: Our Company: Commercial & Industrial Ventilation, Agricultural Ventilation, Horticulture Ventilation, OEM Wheels, Props, & Fans….

#3 Industrial Ceiling Fans, Ventilation and Specialty Cooling Equipment.

Domain Est. 2008

Website: airdistributor.net

Key Highlights: 9-day delivery 30-day returnsWe offer one of the largest selection of specialty air related products at factory direct pricing. On these pages, you will discover air handling and h…

#4 CaptiveAire

Domain Est. 1997

Website: captiveaire.com

Key Highlights: CaptiveAire is the nation’s leading manufacturer of commercial kitchen ventilation systems, and now provides a complete solution of fans, heaters, ductwork, ……

#5 Industrial Fans Direct

Domain Est. 2005

Website: industrialfansdirect.com

Key Highlights: Patterson fans stand up to the rigors of industrial use while retaining low maintenance. Whether you’re managing a large warehouse, a manufacturing facility, ……

#6 Kitchen Exhaust Fans

Domain Est. 1995

Website: greenheck.com

Key Highlights: Providing a complete ventilation solution for commercial kitchens and restaurants. Greenheck is the leading supplier of air movement, control and conditioning ……

#7 Loren Cook Company: Air Moving Experts

Domain Est. 1996

Website: lorencook.com

Key Highlights: Product Categories ; General Ventilation ; Kitchen Ventilation ; Gravity Ventilation ; Laboratory Ventilation ; Smoke Control….

#8 Accurex

Domain Est. 1997

Website: accurex.com

Key Highlights: We engineer commercial kitchen ventilation systems including hoods, fans, and controls – efficient, safe, and compliant solutions from Accurex….

#9 S&P USA Ventilation Systems

Domain Est. 2005

Website: solerpalau-usa.com

Key Highlights: At S&P USA Ventilation Systems, we specialize in solving ventilation and indoor air quality (IAQ) challenges for commercial and residential applications….

#10 High

Domain Est. 2022

Website: garvee.com

Key Highlights: In stock Rating 4.9 (50) Discover the GARVEE 1400 CFM Roof Exhaust Fan, perfect for restaurants and warehouses. Its versatile design ensures efficient ventilation and noise ……

Expert Sourcing Insights for Restaurant Ventilation Fans

2026 Market Trends for Restaurant Ventilation Fans

The restaurant ventilation fan market is poised for significant transformation by 2026, driven by advancements in technology, evolving health and safety regulations, and growing sustainability concerns. As the foodservice industry rebounds and adapts post-pandemic, demand for efficient, intelligent, and eco-friendly ventilation solutions is accelerating. Below are the key trends shaping the restaurant ventilation fan market in 2026.

Increasing Demand for Energy-Efficient Systems

Energy efficiency remains a top priority for commercial kitchens aiming to reduce operational costs and carbon footprints. In 2026, ventilation fans with high-efficiency motors (such as EC or brushless DC motors), variable speed drives, and smart controls dominate the market. These systems dynamically adjust fan speed based on cooking load, significantly cutting energy consumption by up to 50% compared to traditional constant-speed models. Government incentives and green building certifications like LEED and ENERGY STAR are further accelerating adoption.

Integration of Smart Ventilation Technologies

Smart ventilation systems are becoming standard in modern restaurant designs. By 2026, most new installations include IoT-enabled fans that connect to building management systems (BMS) and cloud platforms. These systems use real-time data from sensors—monitoring temperature, humidity, smoke, and particulate levels—to optimize airflow and improve indoor air quality (IAQ). Remote monitoring, predictive maintenance alerts, and energy usage analytics offer operators greater control and reduced downtime.

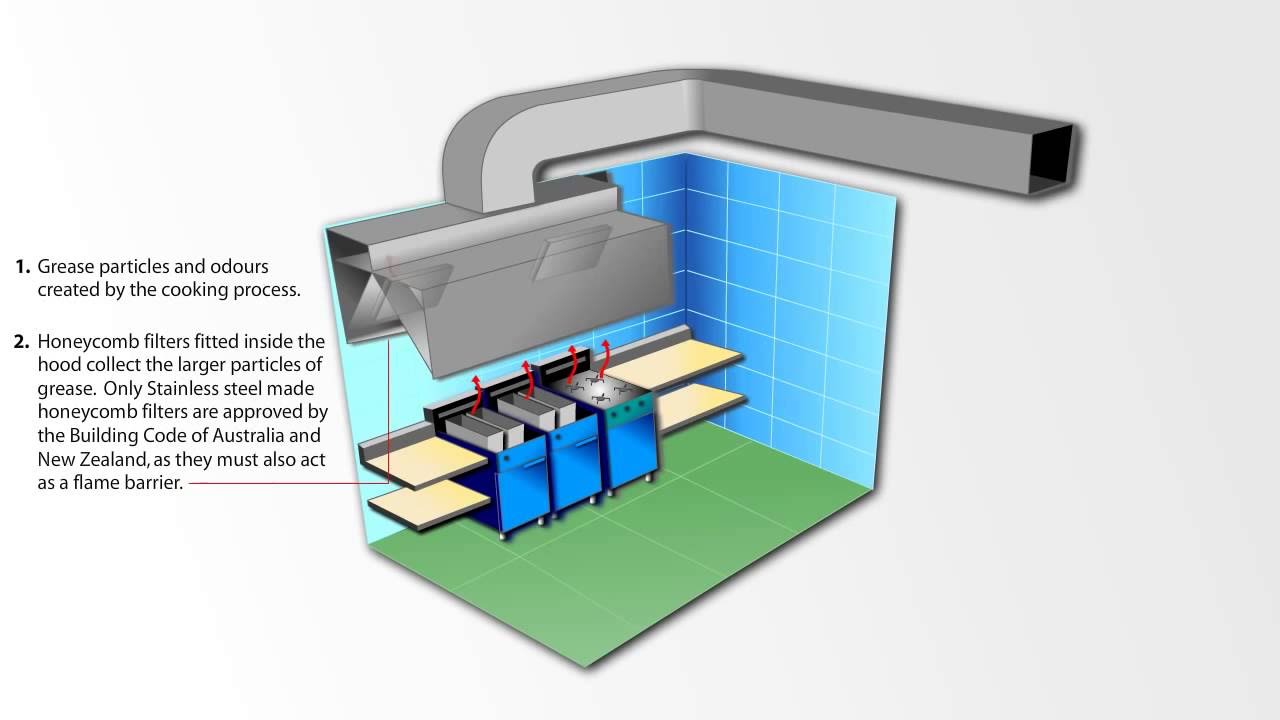

Emphasis on Indoor Air Quality and Health Compliance

Heightened awareness of indoor air quality following global health concerns has led to stricter ventilation standards. In 2026, restaurants are investing in advanced filtration systems—such as ULPA and activated carbon filters—integrated into ventilation hoods and exhaust fans to remove grease, odors, and airborne contaminants. Regulatory bodies in North America, Europe, and parts of Asia are updating codes to mandate higher air exchange rates and improved kitchen air management, directly influencing fan design and performance requirements.

Growth in Modular and Compact Designs

With the rise of cloud kitchens, food halls, and urban eateries operating in limited spaces, there is increasing demand for compact, modular ventilation solutions. By 2026, manufacturers are offering space-saving, high-performance fans designed for retrofit installations and non-traditional kitchen layouts. These units feature quieter operation, easy maintenance access, and flexible ducting options, making them ideal for fast-casual chains and delivery-focused concepts.

Sustainability and Noise Reduction Innovations

Sustainability extends beyond energy use to include material sourcing, recyclability, and noise pollution. In 2026, leading ventilation fan producers are adopting eco-friendly materials and quieter blade designs to meet both environmental and community noise regulations—especially in mixed-use urban developments. Low-noise fans (under 55 dBA) are becoming a competitive differentiator, particularly for rooftop and outdoor installations near residential zones.

Regional Market Dynamics

Growth in the Asia-Pacific region—especially in China, India, and Southeast Asia—is outpacing other markets due to rapid urbanization and a booming foodservice sector. Meanwhile, North America and Europe maintain strong demand driven by renovation cycles and compliance upgrades. Latin America and the Middle East are emerging markets, with increasing investment in commercial kitchen infrastructure supporting ventilation equipment sales.

Conclusion

By 2026, the restaurant ventilation fan market will be defined by intelligence, efficiency, and sustainability. Operators and developers are prioritizing systems that not only meet regulatory standards but also enhance operational performance and environmental responsibility. As technology continues to evolve, the integration of AI-driven controls, renewable energy compatibility, and circular design principles will likely shape the next wave of innovation in this critical segment of commercial kitchen infrastructure.

Common Pitfalls Sourcing Restaurant Ventilation Fans (Quality, IP)

Sourcing restaurant ventilation fans involves more than just selecting a model based on airflow. Overlooking key quality and Ingress Protection (IP) factors can lead to system failures, safety hazards, and costly downtime. Here are common pitfalls to avoid:

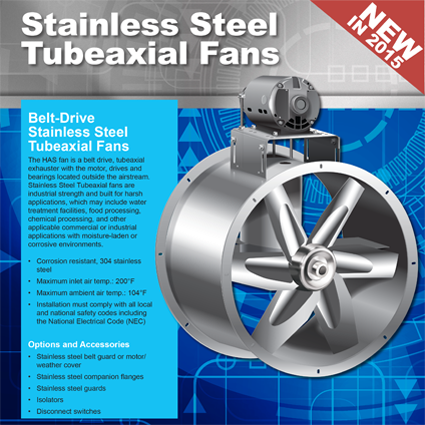

Overlooking Build Quality and Material Durability

Many suppliers offer fans made from low-grade materials that degrade quickly in high-heat, high-humidity, and grease-laden environments typical in commercial kitchens. Thin-gauge steel or plastic housings may corrode or warp, reducing efficiency and lifespan. Always verify the use of stainless steel (especially AISI 304 or 316) or corrosion-resistant coated metals designed for foodservice environments.

Ignoring Ingress Protection (IP) Ratings

The IP rating indicates protection against solid particles and liquids—critical in kitchens exposed to grease, steam, and frequent cleaning. A common mistake is selecting fans with low IP ratings (e.g., IP44) that are insufficient for harsh kitchen hoods. For exhaust fans above cooking lines, IP55 or higher is recommended to prevent grease and moisture ingress that can damage motors and electrical components.

Assuming All Motors Are Suitable for High Temperatures

Standard motors may fail under continuous exposure to high ambient temperatures from cooking equipment. Some fans use non-thermal protected or non-continuous duty motors, which overheat and burn out. Ensure the fan includes a thermally protected, continuous-duty motor rated for elevated temperatures (typically up to 140°C/284°F for kitchen exhaust).

Failing to Verify Third-Party Certifications

Lack of recognized certifications (e.g., UL, CE, AMCA, or HVI) is a red flag for substandard quality. These certifications validate performance claims, safety, and energy efficiency. Sourcing untested or uncertified fans can result in non-compliance with local health and fire codes.

Prioritizing Low Cost Over Long-Term Value

Cheaper fans often cut corners on components like bearings, motor insulation, and fan blade balance. These compromises lead to increased noise, vibration, and premature failure. Investing in a higher-quality fan reduces maintenance costs, energy consumption, and operational disruptions over time.

Neglecting Compatibility with Kitchen Ventilation Standards

Fans must meet local codes and industry standards (e.g., International Mechanical Code, NFPA 96). Selecting a fan without verifying compliance—especially regarding airflow capacity (CFM), fire suppression integration, and duct sealing—can result in failed inspections or insurance issues.

By addressing these pitfalls early, operators and procurement teams can ensure reliable, safe, and code-compliant ventilation systems that support kitchen performance and longevity.

Logistics & Compliance Guide for Restaurant Ventilation Fans

This guide outlines key logistics considerations and compliance requirements for the procurement, installation, and maintenance of ventilation fans in commercial restaurant settings. Adhering to these guidelines ensures operational efficiency, safety, and regulatory compliance.

Regulatory Standards and Certifications

Restaurant ventilation fans must comply with national and local building, fire, and health codes. Key standards include:

- NFPA 96 (National Fire Protection Association): Mandates requirements for ventilation control and fire protection in commercial cooking operations. Fans must be listed and labeled by a recognized testing laboratory (e.g., UL, ETL).

- UL 762 (Standard for Power-Operated Commercial Kitchen Ventilating Equipment): Ensures fans are constructed and tested for safe use in high-temperature, grease-laden environments.

- International Mechanical Code (IMC): Governs the design, installation, and inspection of mechanical systems, including ductwork, fan capacity, and airflow rates.

- Local Health Department Regulations: May impose additional requirements on grease extraction, odor control, and noise levels.

Always verify that fans carry appropriate certifications and meet jurisdiction-specific compliance mandates before purchase or installation.

Shipping, Handling, and Storage

Proper logistics practices are essential to prevent damage and ensure timely installation:

- Packaging: Fans should be shipped in manufacturer-approved, protective packaging to prevent deformation or component damage.

- Handling: Use appropriate lifting equipment (e.g., forklifts, pallet jacks) when moving heavy units. Avoid dragging or tilting fans excessively.

- Storage: Store fans in a dry, indoor environment away from dust, moisture, and extreme temperatures. Keep units on pallets and covered until installation.

- Lead Times: Account for potential delays due to custom configurations, high-demand periods, or supply chain constraints. Order in advance based on project timelines.

Installation Requirements and Permits

Installation must follow manufacturer specifications and code requirements:

- Permitting: Most jurisdictions require mechanical and electrical permits for fan and hood system installation. Submit plans for review prior to work commencement.

- Clearance and Access: Ensure adequate clearance around fans and ductwork for maintenance and fire suppression system operation.

- Ductwork Compatibility: Use rigid, UL-listed grease ducts with proper slope and access doors. Flexible connectors should be minimized and code-compliant.

- Electrical Compliance: Connect fans to dedicated circuits with proper overcurrent protection. All electrical work should be performed by licensed electricians per NEC (National Electrical Code).

Maintenance and Inspection Compliance

Regular maintenance is critical for fire safety and system efficiency:

- Cleaning Frequency: Per NFPA 96, fans, ducts, and grease filters must be cleaned at prescribed intervals (typically monthly for high-volume kitchens, quarterly for moderate use).

- Certified Service Providers: Use contractors certified in commercial kitchen exhaust system cleaning.

- Inspection Logs: Maintain detailed records of cleaning, inspections, and repairs. These may be requested during health or fire department audits.

- Fire Suppression System Integration: Ensure fan shutdown interlocks with fire suppression systems are tested regularly.

Environmental and Noise Regulations

Consider secondary compliance aspects:

- Exhaust Discharge: Fan exhaust must be directed away from air intakes, public walkways, and neighboring properties to avoid odor and grease nuisance.

- Noise Levels: Verify fan sound ratings (in sones or dBA) comply with local noise ordinances, especially in mixed-use or residential areas.

- Energy Efficiency: Where applicable, select ENERGY STAR®-rated or high-efficiency motors to meet sustainability goals and utility incentives.

Adhering to this logistics and compliance framework ensures your restaurant ventilation system operates safely, legally, and efficiently.

In conclusion, sourcing restaurant ventilation fans requires careful consideration of several key factors including airflow capacity (measured in CFM), energy efficiency, noise levels, ease of maintenance, and compliance with local health and safety regulations. Properly selected ventilation fans not only ensure a safe and comfortable kitchen environment by effectively removing heat, grease, smoke, and odors, but also contribute to improved indoor air quality and energy savings over time. It is essential to assess the specific needs of the kitchen layout, cooking volume, and equipment used when selecting the right system. Partnering with reputable suppliers and certified HVAC professionals can help ensure that the chosen ventilation solution meets industry standards and operates reliably. Ultimately, investing in high-quality, well-matched ventilation fans supports regulatory compliance, enhances employee comfort, extends the life of kitchen equipment, and contributes to the overall success and sustainability of the restaurant operation.