Introduction: Navigating the Global Market for Red Synthetic Leather

Global demand for red synthetic leather spans automotive interiors, marine seating, furniture, and fashion accessories. Yet inconsistent color matching, variable thickness and backing, and fragmented lead times make procurement risky.

Before you commit, anchor your decisions to standard specifications. The table below summarizes the signals that repeatedly separate reliable stock from misaligned SKUs across common red product types.

| Category | Key Specs to Verify | Signals to Watch | Typical Ranges Observed |

|—|—|—|—|

| Roll goods (faux leather, marine-grade) | Thickness, backing, grain, width, roll length, Martindale/average rubs | “Vinyl,” “outdoor/marine,” abrasion claims, fabric count | 0.8–1.0 mm; 54–56 in width; 1-yard cuts commonly sold |

| Sheets/rolls (craft/consumer) | Size, thickness, adhesion or sewability | Roll vs sheet, maroon vs scarlet distinction | 12×53 in sheets, ~0.8–0.9 mm |

| Repair/patch | Adhesive type, substrate compatibility, size | Self-adhesive claim, vinyl/leather repair label | ~15.7×40 in patches |

This guide equips you to:

– Identify the right composition (PU, PVC, split-leather-backed, or marine vinyl) for your application.

– Navigate MOQs, lead times, and logistics across global suppliers.

– Validate claims on color fastness, abrasion, and flame resistance using independent test data.

– Implement quality gates—lab dips, roll inspections, and supplier audits—before mass production.

– Manage compliance (e.g., REACH, Prop 65), sustainability documentation, and traceability.

Build your sourcing strategy with clarity, reduce downstream rework, and deliver consistently rich reds that meet your buyers’ expectations.

Illustrative Image (Source: Google Search)

Article Navigation

- Top 10 Red Synthetic Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for red synthetic leather

- Understanding red synthetic leather Types and Variations

- Key Industrial Applications of red synthetic leather

- 3 Common User Pain Points for ‘red synthetic leather’ & Their Solutions

- Strategic Material Selection Guide for red synthetic leather

- In-depth Look: Manufacturing Processes and Quality Assurance for red synthetic leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘red synthetic leather’

- Comprehensive Cost and Pricing Analysis for red synthetic leather Sourcing

- Alternatives Analysis: Comparing red synthetic leather With Other Solutions

- Essential Technical Properties and Trade Terminology for red synthetic leather

- Navigating Market Dynamics and Sourcing Trends in the red synthetic leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of red synthetic leather

- Strategic Sourcing Conclusion and Outlook for red synthetic leather

- Important Disclaimer & Terms of Use

Top 10 Red Synthetic Leather Manufacturers & Suppliers List

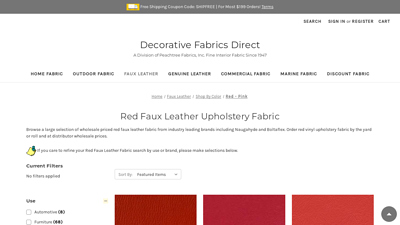

1. Red Faux Leather Upholstery Vinyl – Decorative Fabrics Direct

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Free delivery over $199 14-day returnsBrowse a large selection of wholesale priced red faux leather fabric from industry leading brands including Naugahyde and Boltaflex….

2. Faux Leather – Sallie Tomato

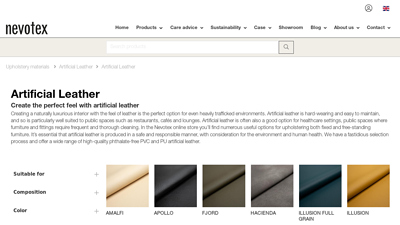

3. Artificial & synthetic leather for public environment, furniture – Nevotex

Domain: nevotex.com

Registered: 1999 (26 years)

Introduction: We have a fastidious selection process and offer a wide range of high-quality phthalate-free PVC and PU artificial leather….

4. Garrett Leather Homepage

Domain: garrettleather.com

Registered: 1996 (29 years)

Introduction: Shop Leather by Color. White & Cream · Beige & Taupe · Gray · Brown · Black · Blue, Teal, & Purple · Green & Yellow · Red, Pink & Orange. Shop More Products….

Illustrative Image (Source: Google Search)

5. Best Faux Synthetic Leather Manufacturer & Supplier in India

Domain: rockuniquoters.com

Registered: 2023 (2 years)

Introduction: Arton is your go-to supplier for premium PVC synthetic leather in India. Ideal for upholstery, automotive, fashion, footwear and various industries….

6. Banofi Leather | Plant-based Leather

Domain: banofileather.com

Registered: 2022 (3 years)

Introduction: Banofi is a material innovation company, developing plant-based leather made from banana crop waste. Banofi’s vegan leather is the best leather alternative….

Understanding red synthetic leather Types and Variations

Understanding Red Synthetic Leather: Types and Variations

Red synthetic leather in B2B channels spans multiple constructions, thicknesses, and performance profiles. Selecting the right grade depends on the backing, polymer chemistry, finish, and intended use. The following synthesis covers five common red types that recur across USA and European catalogs, along with their typical features, applications, and practical pros/cons.

| Type (Backing + Polymer) | Typical Thickness | Key Features | Common Applications | Pros / Cons |

|---|---|---|---|---|

| Marine/Outdoor-Grade Vinyl (PVC on woven polyester/nylon) | ~1.0–1.2 mm | UV and salt/mist resistance; high abrasion; smooth, cohesive finish; good water resistance | Boat seating, outdoor cushions, automotive interiors, patio furniture | Pro: durable in harsh environments; Con: may stiffen in very cold climates; finish can be shiny/“plastic” for some aesthetics |

| Medium-Weight Faux Leather (PVC or PU on woven textile) | ~0.8–1.0 mm | Balanced hand (flex/drape); good tear and abrasion; cost-effective; matte to semi-gloss options | Sofas/chairs, automotive interiors, upholstery, mid-duty bags | Pro: versatile and value; Con: PU can delaminate if poorly formulated; PVC requires care with plasticizers |

| Thin Craft Sheet (microfiber/knit + PU/PVC) | ~0.4–0.6 mm | Supple hand; easy to cut/sew; wide color range including maroon/red | Fashion accessories, small leather goods, earrings, bows, craft projects | Pro: economical and easy to work; Con: limited durability; prone to tearing under load |

| Self-Adhesive Repair Vinyl/PVC Patch | ~0.5–0.8 mm (varies) | Pressure-sensitive adhesive backing; good initial tack; surface can be heat-activated; often grain-matched | Quick repairs for automotive interiors, furniture, bags, apparel | Pro: fast, tool-free application; Con: adhesive can creep under stress; limited long-term heat/UV resistance |

| Distressed/Antiqued “Crazy Horse” Look | ~1.0 mm | Pull-up effect; distressed surface; soft hand; casual aesthetic | Bags, small leather goods, upholstery accents | Pro: appealing vintage feel; Con: lower scuff resistance; finish may vary batch-to-batch |

1) Marine/Outdoor-Grade Vinyl (PVC on woven polyester/nylon)

- Performance profile

- High UV stability; resistant to salt mist and mildew; high abrasion resistance.

- Closed or cohesive PVC surface with woven backing; thickness ~1.0–1.2 mm.

- Good water resistance; maintains finish integrity under outdoor exposure.

- Applications

- Marine seating and cushions; automotive interior panels; outdoor furniture; patio/umbrella canopies.

- Pros/Cons

- Pro: Built for harsh environments; offers long service life outdoors.

- Con: Can stiffen at low temperatures; the smooth, glossy finish may not suit premium fashion aesthetics.

2) Medium-Weight Faux Leather (PVC or PU on woven textile)

- Performance profile

- Balanced flexibility and durability; thickness ~0.8–1.0 mm.

- PVC formulations offer cost efficiency and robust abrasion; PU variants provide a softer hand.

- Good tear resistance; suitable for upholstery seams and moderate stress loads.

- Applications

- Furniture upholstery (sofas, chairs); automotive interiors (dash skins, door panels); mid-duty bags and cases; general B2B upholstery projects.

- Pros/Cons

- Pro: Versatile across uses; strong value-to-performance ratio; wide color availability.

- Con: PVC requires attention to plasticizer content in some markets; PU can delaminate if coatings are thin or poor quality.

3) Thin Craft Sheet (microfiber/knit + PU/PVC)

- Performance profile

- Supple and easy to handle; thickness ~0.4–0.6 mm.

- Microfiber/knit backings support drape; typically soft-touch and matte to semi-gloss.

- Applications

- Fashion accessories (wallets, sleeves), small leather goods (key fobs), hair bows, earrings, craft projects.

- Pros/Cons

- Pro: Easy to cut and sew; economical for decorative items.

- Con: Not suited for high-stress applications; prone to tearing or stretching under load; limited UV/water resistance.

4) Self-Adhesive Repair Vinyl/PVC Patch

- Performance profile

- Pressure-sensitive adhesive layer; often grain-matched for visual continuity.

- Thickness varies widely; designed for immediate application without sewing.

- Some grades benefit from low heat activation for improved tack and finish.

- Applications

- Fast repairs of automotive upholstery and dashboards; seat bolster touch-ups; damaged furniture panels; bag and apparel repairs.

- Pros/Cons

- Pro: No tools required; quick turnaround; useful as a field fix.

- Con: Adhesive may creep over time; lower longevity in heat/UV environments; color matching must be verified before batch application.

5) Distressed/Antiqued “Crazy Horse” Look

- Performance profile

- Pull-up and distressed finish; soft hand; thickness ~1.0 mm.

- Designed to show patina and wear, with wax or oil treatments that create a casual aesthetic.

- Applications

- Bags, cases, laptop sleeves; accent panels in upholstery; small leather goods with vintage styling.

- Pros/Cons

- Pro: Attractive worn-in look; comfortable to handle.

- Con: Lower resistance to scuffs and abrasion; surface treatments can vary; batch-to-batch finish consistency may require QC checks.

Selection guidance

– Outdoor or wet environments: prioritize marine-grade PVC with woven backing for UV and abrasion performance.

– Upholstery and automotive interiors: medium-weight PVC/PU balances cost, durability, and hand.

– Small goods and craft applications: thin PU/PVC sheets maximize ease-of-use and cost.

– Repairs: self-adhesive vinyl patches for speed, with awareness of heat/UV constraints.

– Premium casual aesthetics: distressed “crazy horse” finishes for visual character, with care to manage scuff resistance.

Illustrative Image (Source: Google Search)

If durability and consistent quality across large runs are critical, favor products with defined backing specifications, documented abrasion scores, and verified polymer content. Always request test swatches for color, finish, and adhesive performance before bulk procurement.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.