The global rubber mulch market is experiencing steady growth, driven by increasing demand for sustainable landscaping solutions and rising awareness about environmental conservation. According to Grand View Research, the global rubber mulch market size was valued at USD 281.5 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by expanding applications in playgrounds, athletic fields, and residential landscaping, where recycled rubber mulch offers a durable, eco-friendly alternative to traditional wood mulch. With mounting regulations on tire disposal and growing emphasis on circular economy practices, manufacturers are increasingly investing in advanced processing technologies to meet quality and safety standards. As the demand for recycled rubber products continues to rise, a select group of manufacturers has emerged as leaders in innovation, scalability, and product performance. Below, we highlight the top 9 recycled rubber tire mulch manufacturers shaping the industry’s future.

Top 9 Recycled Rubber Tire Mulch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 From Tire To Rubber Mulch

Domain Est. 1998

Website: rubberecycle.com

Key Highlights: Turning them into rubber mulch is a pretty new technology. Any tire, from big vehicles to bicycles, can be used to make rubber mulch….

#2 Eco-Flex®

Domain Est. 1999

Website: eco-flex.com

Key Highlights: Eco-Flex is an industry pioneer in the recycling of rubber tires. We use these tires to manufacture high value, end use, recycled rubber products….

#3 Rubber Mulch In Chicagoland

Domain Est. 2002

Website: recycledrubber.com

Key Highlights: We specialize in high-quality rubber mulch made from 100% recycled tires. Located in Joliet, IL, we proudly serve the entire Chicagoland area….

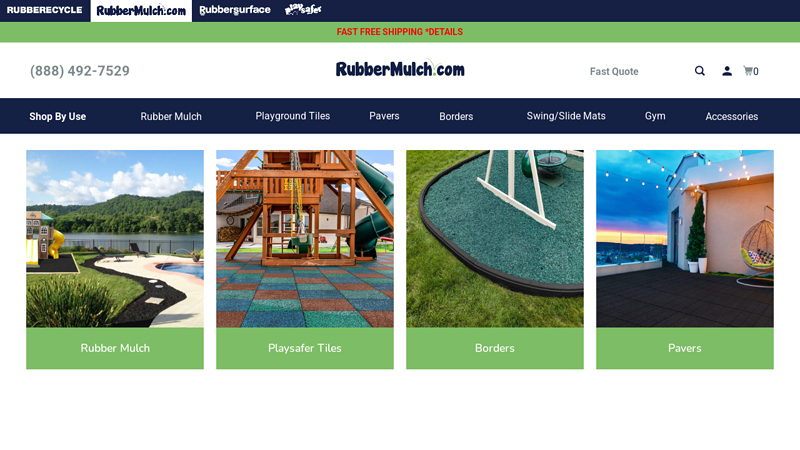

#4 Rubber Mulch

Domain Est. 2002 | Founded: 1997

Website: rubbermulch.com

Key Highlights: Rubber Mulch has been producing superior quality rubber products since 1997. Best prices on commercial, residential, playground, landscaping, bulk, ……

#5 rubber mulch

Domain Est. 2003

Website: americanparkscompany.com

Key Highlights: Rubber mulch is made from 100% clean recycled car tire material, and offer the highest impact absorbing ratings of all loose fill surfacing options….

#6 Liberty Tire Recycling

Domain Est. 2004

Website: libertytire.com

Key Highlights: Welcome to Liberty Tire Recycling. Discover how we turn end-of-life tires into safe, eco-friendly products through our tire recycling processing and ……

#7 Recycled Rubber Mulch

Domain Est. 2009

Website: rubberdesigns.com

Key Highlights: Our rubber mulch is made from used tires that are cleaned, shredded, and processed into small pieces. The result is a durable, eco-friendly mulch option ……

#8 Rubber Mulch

Domain Est. 2013

Website: imcoutdoorliving.com

Key Highlights: IMC Outdoor Living is the only company to produce a full line of 100% recycled rubber products for both residential and commercial landscaping applications….

#9 Rubber Mulch

Website: ecoshred.green

Key Highlights: EcoShred uses only quality rubber made from 100% recycled tires for our rubber mulch. AVAILABLE IN A VARIETY OF COLORS. EcoShred mulch comes in many ……

Expert Sourcing Insights for Recycled Rubber Tire Mulch

H2: Market Trends for Recycled Rubber Tire Mulch in 2026

By 2026, the recycled rubber tire mulch market is poised for substantial growth, driven by increasing environmental awareness, regulatory support, and expanding applications across multiple industries. Key trends shaping the market include:

-

Sustainability and Circular Economy Initiatives

Governments and private sectors are placing greater emphasis on circular economy models, promoting the recycling of end-of-life tires into valuable products like rubber mulch. The push to reduce landfill waste and lower carbon footprints is accelerating investments in tire recycling infrastructure, directly benefiting the recycled rubber mulch segment. -

Stringent Environmental Regulations

Regulatory bodies in North America, Europe, and parts of Asia-Pacific are enforcing stricter waste tire management policies. These regulations are incentivizing the conversion of scrap tires into safe, reusable materials. For example, the U.S. Environmental Protection Agency (EPA) and the European Tyre and Rubber Manufacturers’ Association (ETRMA) continue to support tire-derived products, including mulch, under green procurement programs. -

Growing Demand in Landscaping and Playground Safety

Recycled rubber tire mulch is increasingly favored over traditional wood mulch due to its durability, resistance to decomposition, and superior shock-absorbing properties. By 2026, demand is expected to surge in residential landscaping, municipal parks, and playgrounds—especially in schools and recreational areas where safety standards require impact-absorbing surfacing. -

Innovation in Product Quality and Safety

Concerns over potential leaching of heavy metals or volatile organic compounds (VOCs) have prompted manufacturers to enhance purification processes. Advanced washing, decontamination, and quality certification (e.g., ASTM F1292, IPEMA) are becoming standard, boosting consumer confidence and expanding market acceptance. -

Urbanization and Green Infrastructure Development

Rapid urbanization, particularly in emerging economies, is driving the need for sustainable urban landscaping. Cities are incorporating green spaces, rooftop gardens, and eco-parks—applications where recycled rubber mulch offers long-term cost savings and low maintenance, further fueling adoption. -

Cost Competitiveness and Supply Chain Improvements

As tire collection networks and recycling technologies become more efficient, production costs for rubber mulch are declining. This cost advantage, combined with longer lifespan compared to organic mulches, improves the total cost of ownership, making it an attractive option for commercial and municipal buyers. -

Rising Adoption in Agriculture and Sports Fields

Beyond landscaping, new applications are emerging. Rubber mulch is being used in equestrian arenas, synthetic turf infill, and agricultural ground cover due to its moisture retention and weed suppression capabilities. These niche markets are expected to grow steadily through 2026. -

North America and Europe Leading Market Expansion

These regions dominate the recycled rubber mulch market due to mature recycling ecosystems and strong environmental regulations. However, Asia-Pacific is anticipated to witness the highest growth rate, driven by increasing urban projects and rising awareness in countries like China, India, and South Korea.

In conclusion, the 2026 market for recycled rubber tire mulch reflects a confluence of environmental responsibility, technological advancement, and diversified application demand. As sustainability becomes a cornerstone of global policy and consumer choice, recycled rubber mulch is positioned to become a mainstream material in eco-friendly construction and landscaping.

Common Pitfalls When Sourcing Recycled Rubber Tire Mulch (Quality and Intellectual Property)

Inconsistent Material Quality and Contaminants

One of the most frequent challenges in sourcing recycled rubber tire mulch is variability in material quality. Since the mulch is derived from post-consumer tires, differences in tire composition, age, and origin can lead to inconsistent color, texture, and particle size. Poor processing may leave behind contaminants such as metal fragments, fiber, or residual adhesives. These impurities not only affect the aesthetic and functional performance of the mulch but can also pose safety risks, especially in playground or landscaping applications. Buyers must verify suppliers’ screening and purification processes to ensure compliance with industry standards like ASTM F3012.

Lack of Standardized Testing and Certifications

Many suppliers do not consistently adhere to or provide documentation for recognized safety and environmental standards. Without proper certifications (e.g., ASTM, EN, or CPSC compliance), there is increased risk of elevated levels of heavy metals (like lead or zinc), polycyclic aromatic hydrocarbons (PAHs), or volatile organic compounds (VOCs). Sourcing without verified test reports can expose buyers to liability, especially in public or child-safe installations. It’s essential to demand up-to-date, third-party lab testing data before procurement.

Intellectual Property (IP) and Branding Infringement

Some suppliers may misrepresent their products by using proprietary names or branding associated with established, high-quality rubber mulch brands without authorization. This includes copying patented product formulations, color blends, or performance claims. Using such counterfeit or misrepresented materials can expose the buyer to legal risks, particularly in commercial projects where specifications require certified products. Always verify the supplier’s right to use specific brand names or technology and confirm original manufacturer documentation.

Inadequate Traceability and Supply Chain Transparency

Recycled rubber mulch often passes through multiple processors and distributors, making it difficult to trace the original source of the tires or processing methods used. This lack of transparency increases the risk of unintentionally sourcing material from unethical or non-compliant facilities. Without a clear chain of custody, it’s challenging to ensure environmental claims (e.g., “100% post-consumer”) are accurate or that the product meets sustainability goals.

Misleading Environmental and Safety Claims

Some suppliers make unsubstantiated claims about the eco-friendliness or non-toxic nature of their rubber mulch. Terms like “non-toxic,” “organic,” or “green” may be used deceptively, despite the material originating from synthetic rubber and chemical additives. Buyers should scrutinize marketing language and require evidence to support environmental claims, avoiding greenwashing that could impact project credibility or regulatory compliance.

Logistics & Compliance Guide for Recycled Rubber Tire Mulch

Overview and Definitions

Recycled rubber tire mulch is a product made from processed scrap tires, commonly used in landscaping, playgrounds, athletic fields, and erosion control. It is created by shredding and processing used tires into uniform rubber granules or nuggets. Due to its durable, shock-absorbent, and long-lasting properties, it’s a popular alternative to organic mulches. However, its production, transportation, and use are subject to environmental, health, and safety regulations across jurisdictions.

Regulatory Compliance

Recycled rubber tire mulch is regulated at federal, state, and local levels to ensure environmental safety and public health. Key compliance areas include:

Environmental Protection Agency (EPA) Guidelines

The U.S. EPA does not classify properly processed tire-derived mulch as hazardous waste when used in approved applications. However, the agency monitors chemical leaching and airborne particulate emissions. Facilities processing scrap tires must comply with EPA solid waste regulations under Subtitle D of the Resource Conservation and Recovery Act (RCRA).

Consumer Product Safety Commission (CPSC) Standards

For playground applications, the CPSC recommends that recycled rubber mulch meet impact attenuation standards (ASTM F1292) to reduce injury risk. The CPSC also supports ongoing research into potential chemical exposures but currently considers tire mulch safe when installed and maintained properly.

State and Local Regulations

Many states have specific rules governing the use of tire mulch:

– Some states restrict its use near waterways to prevent microplastic contamination.

– Others require third-party certification (e.g., SMART Certification or UL Environment validation) for use in public spaces.

– Local fire codes may impose limitations due to flammability concerns under extreme conditions.

Manufacturers and distributors must verify compliance with state-specific environmental and consumer safety regulations before distribution.

Material Safety and Testing

To ensure safety and compliance, recycled rubber tire mulch should undergo regular third-party testing for:

– Heavy metals (lead, cadmium, chromium, etc.) per EPA 3050B/6010D

– Polycyclic aromatic hydrocarbons (PAHs)

– Zinc and other leachable compounds

– Particle size and consistency (ASTM D422)

– Flammability and smoke density (ASTM E84)

Certification from accredited labs (e.g., UL, SGS, Intertek) helps demonstrate product safety and regulatory alignment.

Transportation and Handling

Transporting recycled rubber tire mulch requires adherence to Department of Transportation (DOT) and state-specific freight regulations.

Packaging and Labeling

- Bulk shipments are typically transported in open-top or covered dump trucks, bulk trailers, or super sacks.

- Bags must be labeled with product name, batch number, manufacturer information, and safety warnings (e.g., “Not for indoor use,” “Keep away from open flame”).

- Safety Data Sheets (SDS) must be provided per OSHA Hazard Communication Standard (29 CFR 1910.1200).

Transportation Requirements

- No special hazardous material placards are required for non-treated tire mulch under DOT 49 CFR, as it is generally not classified as hazardous.

- Carriers should prevent wind dispersion during transit by using tarps or sealed containers.

- Transport vehicles must comply with weight limits and state-specific road use regulations.

Storage and Site Management

Proper storage minimizes environmental risks and preserves product quality.

– Store in dry, well-ventilated areas away from direct sunlight to reduce UV degradation.

– Keep away from ignition sources due to low but present flammability risk.

– Use berms or containment areas if storing outdoors near storm drains to prevent runoff contamination.

– Rotate stock to ensure older inventory is used first (FIFO).

Installation and Usage Best Practices

To maintain compliance and performance:

– Install according to manufacturer specifications and ASTM guidelines (e.g., ASTM F1951 for accessibility, ASTM F1292 for impact attenuation).

– Use gloves and dust masks during installation to reduce skin contact and inhalation of fine particles.

– Avoid use in areas with high fire risk or near heat-generating equipment.

– Do not use indoors or in enclosed spaces due to potential off-gassing.

End-of-Life and Environmental Responsibility

Recycled rubber tire mulch has a long lifespan (8–10 years), but eventual disposal must be managed responsibly.

– Do not landfill unless permitted—some states classify it as solid waste and prohibit tire-derived materials in landfills.

– Explore take-back programs or reprocessing options through certified recyclers.

– Removal and replacement should follow local waste disposal regulations and include soil testing if contamination is suspected.

Recordkeeping and Documentation

Maintain comprehensive records for compliance audits, including:

– Certificates of Analysis (CoA) for each production batch

– SDS for all products

– Transportation logs and bills of lading

– Customer certifications and usage declarations (e.g., playground compliance)

– Annual environmental compliance reports where required

Conclusion

Recycled rubber tire mulch offers sustainable benefits but requires rigorous attention to logistics and regulatory compliance. Stakeholders—from producers to installers—must stay informed about evolving standards, conduct regular testing, and follow best practices in handling, transport, and disposal to ensure safety and legality across the supply chain.

In conclusion, sourcing recycled rubber tire mulch presents a sustainable, cost-effective, and durable solution for landscaping, playground safety, and erosion control. By repurposing waste tires, this practice supports environmental conservation by reducing landfill accumulation and lowering the demand for virgin materials. Recycled rubber mulch offers long-term benefits such as resistance to decomposition, reduced maintenance, and improved safety due to its shock-absorbing properties. However, careful consideration must be given to sourcing from reputable suppliers who adhere to quality and safety standards, ensuring the material is free from harmful contaminants and treated to minimize potential leaching. Overall, with responsible sourcing and proper installation, recycled rubber tire mulch is a viable and eco-friendly alternative to traditional mulching materials, aligning environmental goals with practical performance.