The global rebar coupler market is experiencing robust growth, driven by rising demand for reinforced concrete structures in infrastructure, commercial, and residential construction. According to Mordor Intelligence, the Rebar Couplers Market was valued at nearly USD 2.1 billion in 2023 and is projected to grow at a CAGR of over 7.5% through 2029. This expansion is fueled by increasing urbanization, the adoption of sustainable construction practices, and the need for seismic resilience in modern buildings. With advancements in mechanical splicing technologies and stricter regulatory standards for structural integrity, rebar couplers are becoming essential components in high-rise buildings, bridges, and tunnels. As demand intensifies across North America, Asia-Pacific, and the Middle East, a select group of manufacturers are leading innovation, quality, and global market penetration. Below, we highlight the top 10 rebar coupler manufacturers shaping the future of construction engineering.

Top 10 Rebar Coupler Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

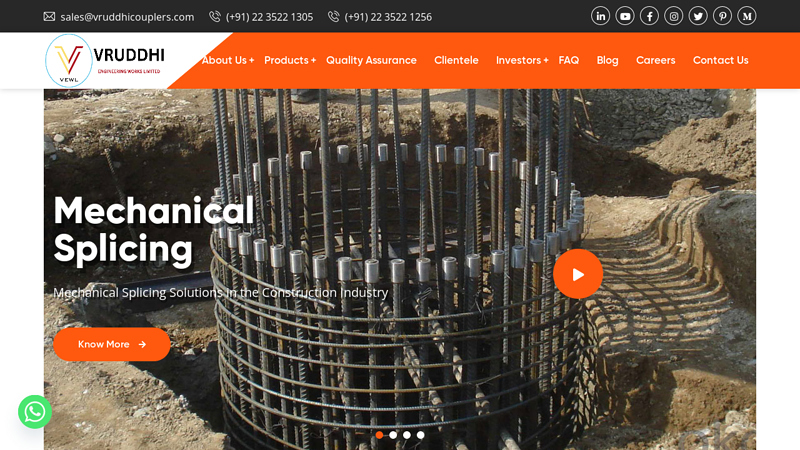

#1 Rebar Couplers, Rebar Coupler Manufacturers, Rebar couplers …

Domain Est. 2020

Website: vruddhicouplers.com

Key Highlights: Leading manufacturer, supplier and exporter of Rebar Couplers backed by vast experience and expertise. An ISO-9001:2015 accredited company providing ……

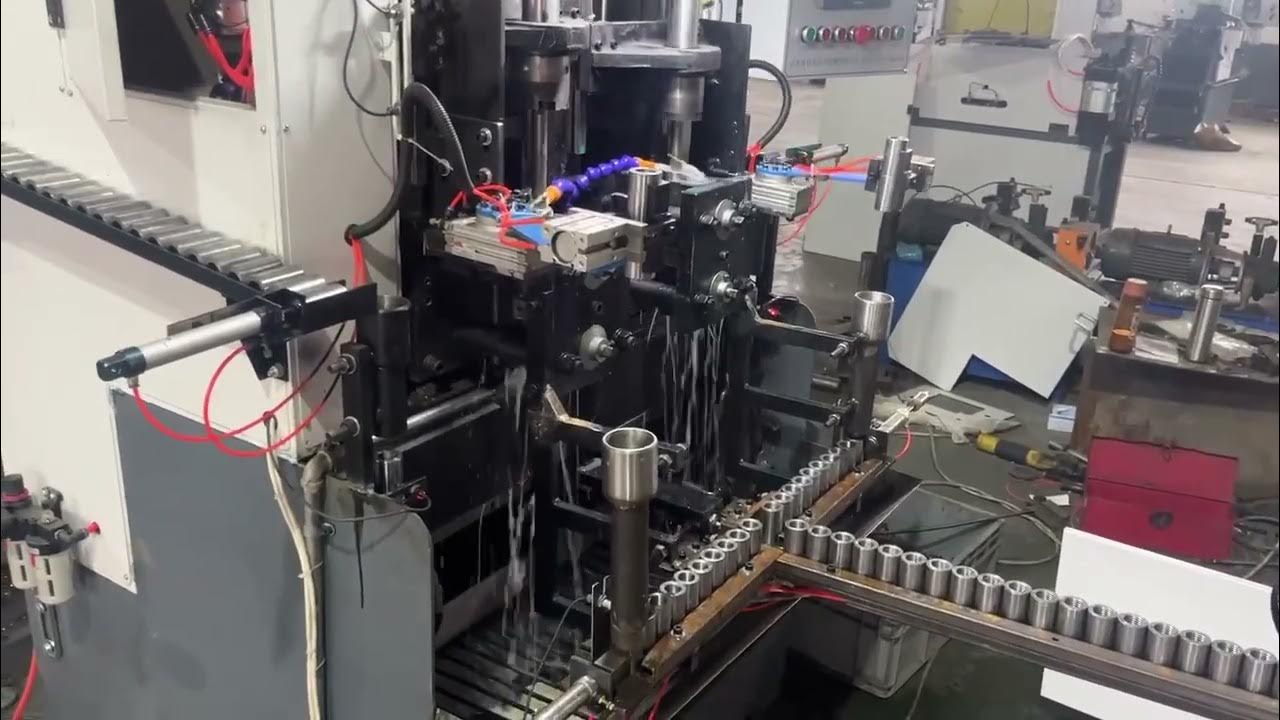

#2 Rebar Coupler and Coupler Making Machines Manufacturer

Website: rebarcouplerpro.com

Key Highlights: Rebar Coupler Pro is a leading manufacturer of high-quality rebar couplers and Coupler making Machines Manufacturer. We specialize in rebar threading ……

#3 Coupler systems

Domain Est. 1996

Website: halfen.com

Key Highlights: HALFEN Coupler systems from Leviat provide reliable and efficient solutions for all connections of reinforcement bars….

#4 Bar Lock® Couplers System

Domain Est. 1996

Website: daytonsuperior.com

Key Highlights: The Dayton Superior Bar Lock® Coupler System provides a simple, quick, cost effective method for splicing deformed rebar in tension and/or compression ……

#5 Nucor Rebar Fabrication & Installation Services and Projects

Domain Est. 1997

Website: nucor.com

Key Highlights: As the largest rebar fabricator in North America, Nucor has the capacity to fabricate and deliver over one million tons of rebar each year….

#6 Rebar Splices & Couplers

Domain Est. 1999

Website: dextragroup.com

Key Highlights: Rebar couplers are devices used to join lengths of rebar together, allowing the quick and safe creation of a high-performance splice on the construction site….

#7 nVent LENTON

Domain Est. 2001

Website: nvent.com

Key Highlights: nVent LENTON is a world leader in advanced mechanical rebar splicing systems. Our Rebar Splicing Specialists understand the reinforced concrete business and ……

#8 Regbar Construction

Domain Est. 2019

Website: regbar.com

Key Highlights: Regbar Reinforcing Rebar Couplers Using Rebar Couplers simplifies the design and construction of reinforced concrete and reduces the amount of required bars….

#9 Benefits of using rebar couplers

Domain Est. 2022

Website: angrebarcouplers.com

Key Highlights: Rebar couplers are parts that join two longitudinally moving reinforcing bars to create a mechanical splice. This method can easily be substituted with lap ……

#10 Rebar Coupler

Domain Est. 2024

Website: mitroindustries.com

Key Highlights: Rating 5.0 (2) Our Parallel Thread Couplers are highly durable and easy to install, providing a reliable connection for reinforcing steel bars….

Expert Sourcing Insights for Rebar Coupler

H2: 2026 Market Trends for Rebar Couplers

The global rebar coupler market is poised for significant evolution by 2026, driven by shifting construction dynamics, technological advancements, and growing emphasis on efficiency and sustainability. Key trends shaping the market include:

-

Accelerated Adoption in High-Rise & Infrastructure Projects: The continued global boom in high-rise buildings, bridges, tunnels, and large-scale infrastructure (driven by urbanization and government investment) will solidify rebar couplers as the preferred connection method. Their ability to ensure structural integrity under high stress, reduce congestion in dense reinforcement zones, and accelerate construction timelines makes them indispensable for complex projects, particularly in seismically active regions.

-

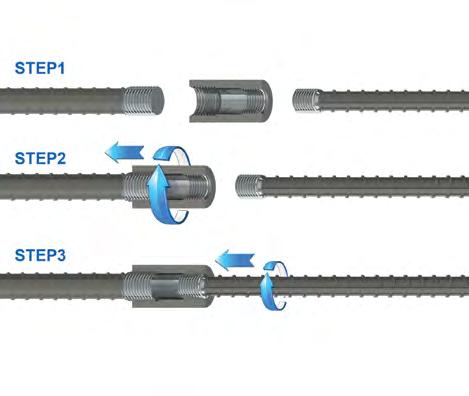

Dominance of Threaded (Mechanical) Couplers: Threaded couplers (including roll-threaded and cut-threaded types) will maintain and strengthen their market leadership. Advancements in thread rolling technology will enhance speed, consistency, and thread quality on-site. The focus will remain on reliability, ease of installation (often requiring only a wrench), and superior load transfer performance compared to lap splicing.

-

Strong Growth in Emerging Economies: Markets in Asia-Pacific (especially India, Southeast Asia, and parts of the Middle East) and Africa will experience the fastest growth. Rapid urbanization, significant government infrastructure spending (roads, railways, ports, housing), and the adoption of modern construction techniques will drive demand. Localized manufacturing and cost-competitive solutions will be key success factors.

-

Increased Focus on Quality, Standardization, and Certification: As projects become larger and safety standards rise, there will be heightened demand for couplers meeting stringent international standards (e.g., ISO 15835, ASTM A1044, BS 8666). Third-party certification (like ICC-ES, CE marking) will become non-negotiable for specifiers and contractors, pushing manufacturers towards higher quality control and transparency.

-

Sustainability and Labor Efficiency as Key Drivers: The push for sustainable construction will amplify the appeal of couplers. By drastically reducing rebar waste (compared to lap splices) and enabling faster construction (reducing energy consumption and site disruption), couplers contribute to greener projects. Furthermore, their ease of use reduces reliance on highly skilled labor for splicing, addressing labor shortages and lowering overall labor costs – a major selling point.

-

Technological Integration and Smart Solutions: While still emerging, the integration of digital technologies will gain traction. This includes:

- Digital Documentation: QR codes or RFID tags on couplers for traceability and quality assurance.

- Installation Monitoring: Potential for torque sensors or digital wrenches to ensure proper installation and provide verifiable records.

- BIM Integration: Enhanced compatibility with Building Information Modeling for precise planning and material optimization.

-

Competitive Landscape and Regional Dynamics: The market will remain competitive, with established global players (like Dextra, ThyssenKrupp, Macalloy) competing against strong regional manufacturers offering cost-effective solutions. Consolidation and strategic partnerships (e.g., with rebar suppliers or construction firms) are likely. Innovation in materials (e.g., high-strength, corrosion-resistant alloys) and specialized coupler designs (for specific applications like post-tensioning or seismic zones) will be key differentiators.

In summary, the 2026 rebar coupler market will be characterized by robust growth fueled by infrastructure demand, particularly in emerging economies, underpinned by the dominant position of reliable threaded couplers. Success will hinge on manufacturers’ ability to deliver certified, high-quality, sustainable, and increasingly smart solutions that address the core construction industry needs of speed, safety, cost-efficiency, and resilience.

Common Pitfalls When Sourcing Rebar Couplers (Quality and Intellectual Property)

Sourcing rebar couplers involves critical considerations beyond price and availability. Overlooking quality standards and intellectual property (IP) rights can lead to structural risks, legal liabilities, and project delays. Below are the most common pitfalls buyers encounter:

Poor Quality Control and Non-Compliance with Standards

Many suppliers offer rebar couplers that do not meet international or national standards (e.g., ASTM A1035, BS EN ISO 15630-1, or local building codes). Substandard materials, inadequate thread precision, or improper heat treatment can compromise joint strength and structural integrity. Buyers may receive products that look identical to certified couplers but fail under load, leading to safety hazards and costly rework.

Lack of Third-Party Certification and Test Reports

A common issue is the absence of verifiable test reports or certifications from accredited laboratories. Some suppliers provide falsified or outdated documentation. Without current mill test certificates, tensile test results, or independent verification (e.g., from TÜV, SGS, or Intertek), it’s difficult to confirm performance claims, especially for mechanical splicing efficiency (e.g., meeting 125% of rebar yield strength).

Counterfeit or Imitation Products Infringing IP Rights

Reputable rebar coupler designs (such as grout-filled, taper-thread, or wedge-lock systems) are often protected by patents and trademarks. Sourcing from unauthorized manufacturers may result in counterfeit or knockoff products that infringe on intellectual property. Using such products exposes contractors and developers to legal action, supply chain disruptions, and reputational damage.

Inadequate Traceability and Batch Identification

Quality couplers should come with full traceability, including batch numbers, manufacturing dates, and material certifications. Many low-cost suppliers skip proper labeling, making it impossible to track defective batches or conduct root-cause analysis in case of failure. This lack of traceability also complicates compliance audits and quality assurance processes.

Misrepresentation of Material and Performance Claims

Some suppliers exaggerate performance capabilities—such as claiming ductile behavior or high fatigue resistance—without supporting data. Couplers made from subpar steel alloys or with incorrect thread geometry may not perform as expected under seismic loads or dynamic stress, risking structural failure in critical applications.

Ignoring Compatibility with Rebar Grades and Sizes

Not all couplers are universally compatible. Buyers may assume interchangeability across rebar grades (e.g., B500B, ASTM A615 Grade 60) or diameters, but mismatched couplers can lead to improper engagement, reduced load transfer, and splice failure. Confirming compatibility with project specifications is essential but often overlooked during procurement.

Failure to Audit Suppliers and Manufacturing Facilities

Relying solely on catalog specifications without conducting on-site supplier audits increases risk. Unannounced factory inspections help verify actual production processes, quality control systems, and adherence to IP agreements. Skipping due diligence may result in sourcing from subcontractors or gray-market producers with inconsistent quality.

Overlooking Long-Term Supplier Reliability and Support

Choosing vendors based only on upfront cost ignores after-sales support, technical assistance, and warranty terms. If issues arise during installation or inspection, unreliable suppliers may not provide timely replacements or engineering support, delaying project timelines and increasing liability.

Avoiding these pitfalls requires rigorous supplier vetting, insistence on certified products, and awareness of intellectual property implications. Engaging with reputable, licensed manufacturers ensures structural safety, legal compliance, and long-term project success.

Logistics & Compliance Guide for Rebar Couplers

Overview

Rebar couplers are mechanical devices used to join reinforcing steel bars (rebar) in concrete construction, providing structural continuity without the need for lap splicing. Proper logistics and compliance are critical to ensure product quality, structural integrity, and adherence to international, regional, and project-specific standards.

Product Classification & Documentation

- HS Code: Typically classified under HS 7326.90 (Other articles of iron or steel) or region-specific variants. Confirm with local customs authorities.

- Material Certification: Ensure mill test certificates (MTCs) or material test reports (MTRs) are provided for raw materials (e.g., alloy steel grade 45 or 40Cr).

- Product Certification: Couplers must be certified to relevant standards such as ASTM A1044, BS 8110, or ISO 15835. Include third-party test reports (e.g., from SGS, TÜV, or Intertek).

- Technical Dossiers: Maintain detailed technical specifications, installation instructions, and performance data.

International Standards & Compliance

- ASTM A1044: Standard specification for mechanical splices for reinforcing bars.

- BS 8110 / EN 1992-1-1 (Eurocode 2): Requirements for concrete structures and rebar splicing.

- ACI 318: Building code requirements for structural concrete (U.S.).

- ISO 15835: Specifies performance requirements for mechanical rebar couplers.

- Local Building Codes: Always verify compliance with country-specific regulations (e.g., UAE MOHRE, Saudi SASO, India BIS).

Packaging & Labeling Requirements

- Packaging: Use weather-resistant, labeled crates or shrink-wrapped bundles. Include desiccants in humid environments.

- Labeling: Each package must display:

- Product type (e.g., threaded, grout-filled, swaged)

- Size range (e.g., 16mm–40mm)

- Batch/lot number

- Manufacturer name and location

- Compliance marks (e.g., CE, ASTM, ISO)

- Handling symbols (e.g., “Do Not Stack,” “Protect from Moisture”)

Storage & Handling

- Storage Conditions: Store indoors in a dry, ventilated area off the ground. Prevent exposure to moisture, salt, or corrosive chemicals.

- Stacking: Limit stack height to avoid deformation. Use pallets and separate different sizes to prevent mix-ups.

- Handling: Use appropriate lifting equipment. Avoid dropping or dragging couplers to prevent thread damage.

Transportation Guidelines

- Mode of Transport: Suitable for road, sea, or air freight. For sea shipments, use moisture-barrier packaging and consider container desiccants.

- Temperature Control: Avoid extreme temperatures (>60°C or <–20°C) during transit.

- Documentation: Include commercial invoice, packing list, certificate of origin, and test reports with shipment.

- Incoterms: Clearly define responsibilities (e.g., FOB, CIF, DDP) in contracts to manage risk and compliance.

Quality Control & Inspection

- Pre-Shipment Inspection (PSI): Conduct dimensional checks, thread integrity tests, and visual inspection for defects.

- Third-Party Verification: Engage accredited labs for periodic performance testing (e.g., tensile strength, fatigue, seismic performance).

- Traceability: Maintain batch-level traceability from production to delivery using serialized records.

Import/Export Compliance

- Export Controls: Verify if rebar couplers require export licenses (rare, but check dual-use regulations).

- Import Duties & Taxes: Consult local customs for applicable tariffs and VAT.

- Conformity Assessment: Some countries require local approval (e.g., Dubai Civil Defense, Qatar MME).

Installation & Site Compliance

- Training: Provide certified training for installers on proper threading, torque application, and inspection.

- On-Site Testing: Conduct pull tests per project specifications (e.g., 1.25 x fy or full tensile strength).

- Documentation Handover: Deliver compliance certificates, test reports, and as-built records to the client.

Environmental & Safety Considerations

- RoHS/REACH: Confirm compliance if shipping to the EU. Couplers typically do not contain restricted substances but verify coatings.

- Waste Management: Recycle packaging materials (steel, wood, plastic).

- Safety Data Sheets (SDS): Required only if lubricants or coatings are supplied with couplers.

Record Retention & Audits

- Retain compliance documents, test results, and shipment records for a minimum of 10 years.

- Prepare for audits by certification bodies or clients at any stage of the supply chain.

Conclusion

Adhering to logistics and compliance protocols ensures rebar couplers meet structural, safety, and regulatory requirements. Consistent documentation, proper handling, and adherence to international standards are essential for project success and long-term liability protection.

Conclusion for Sourcing Rebar Couplers

In conclusion, sourcing rebar couplers is a critical aspect of ensuring structural integrity, construction efficiency, and long-term durability in reinforced concrete projects. The selection of high-quality couplers that meet international standards such as ISO, ASTM, or BS, along with compliance to project-specific engineering requirements, is essential for safe and reliable performance.

Key factors to consider when sourcing include material quality, manufacturing standards, ease of installation, corrosion resistance, and cost-effectiveness. Establishing relationships with reputable suppliers who provide proper certification, technical support, and consistent quality control further mitigates risks associated with on-site failures or delays.

Additionally, adopting threaded or grout-filled mechanical couplers can significantly reduce rebar congestion, accelerate construction timelines, and promote sustainability by minimizing steel waste. Ultimately, a strategic and informed approach to sourcing rebar couplers not only enhances structural safety but also contributes to overall project efficiency and cost optimization. Therefore, careful evaluation and due diligence in supplier selection and product specification are paramount for successful implementation in modern construction practices.