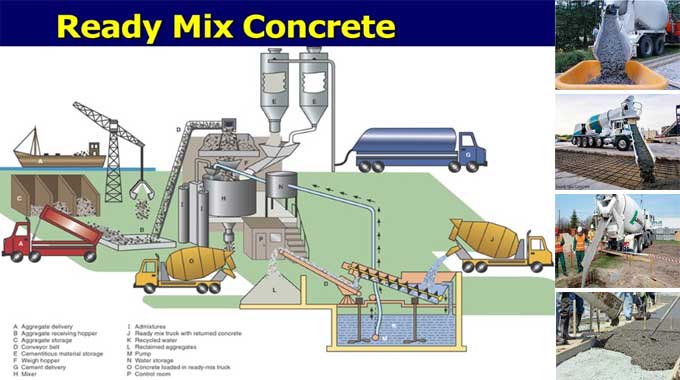

The global ready mix concrete market is experiencing robust growth, driven by rising urbanization, infrastructure development, and increased construction activity across both emerging and developed economies. According to a report by Mordor Intelligence, the ready mix concrete market was valued at USD 735.67 billion in 2023 and is projected to reach USD 1,045.23 billion by 2029, growing at a CAGR of 6.1% during the forecast period. Similarly, Grand View Research estimates significant expansion, citing advancements in sustainable construction materials and the shift from on-site mixing to factory-controlled production as key drivers. This growth trajectory has intensified competition among manufacturers, leading to increased innovation, scalability, and regional consolidation. As demand surges, identifying the leading players in the ready mix concrete space becomes critical for stakeholders across construction, engineering, and procurement. The following list highlights the top 10 ready mix concrete manufacturers shaping the industry through production capacity, geographic reach, technological leadership, and strategic partnerships.

Top 10 Ready Mix Company Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 National Ready Mixed Concrete Association

Domain Est. 1996

Website: nrmca.org

Key Highlights: Concrete InFocus covers a comprehensive range of topics of importance to ready mixed producers and suppliers including success stories, best practies, equipment ……

#2 Redimix Companies, Inc.

Domain Est. 2000

Website: redimixcompanies.com

Key Highlights: Redimix Companies has evolved into the leading ready-mixed concrete supplier in New Hampshire. Headquartered in Manchester, NH and with 7 different facilities ……

#3 Terminal Ready

Domain Est. 2004

Website: terminalreadymix.com

Key Highlights: We’re a family-operated concrete company with nearly 70 years of experience as a ready-mix producer and contractor. We pride ourselves on quality and the ……

#4 Leading Supplier of Concrete & Building Materials

Domain Est. 1996

Website: cemexusa.com

Key Highlights: Trusted building materials supplier and concrete supplier, Cemex US delivers ready-mix concrete, aggregates, and sustainable solutions nationwide for ……

#5 Thomas Concrete

Domain Est. 1997

Website: thomasconcrete.com

Key Highlights: After 40 years of serving customers, we are one of the leading suppliers of high quality ready-mixed concrete in the Southeast….

#6 GCC

Domain Est. 1997

Website: gcc.com

Key Highlights: GCC produces cement, concrete, aggregates and innovative products for the construction industries in Mexico, the United States, Latin America and Canada….

#7 Cement Concrete Delivery Company Los Angeles

Domain Est. 1998 | Founded: 1949

Website: aareadymix.com

Key Highlights: Since 1949, At A & A Ready Mixed Concrete Inc, we are concrete experts with the passion, the expertise and the guts to take on any job….

#8 Chaney Enterprises

Domain Est. 2003

Website: chaneyenterprises.com

Key Highlights: We provide ready-mix concrete, sand, stone, gravel, and hardscapes throughout the Mid-Atlantic and Southeastern regions….

#9 Ready Mix USA

Domain Est. 2005

Website: readymixusa.com

Key Highlights: We are your local ready-mix concrete supplier, ready to help you meet your project goals, backed by superior customer service. Learn More….

#10 SRM Concrete

Domain Est. 2006

Website: smyrnareadymix.com

Key Highlights: SRM owns and operates ready-mix plants, quarries, cement terminals, harbors, and other construction products and services. SEARCH LOCATIONS. Our Experience….

Expert Sourcing Insights for Ready Mix Company

H2: Market Trends Shaping the Ready-Mix Concrete Industry in 2026

The global ready-mix concrete (RMC) market in 2026 is poised for significant transformation, driven by economic, technological, environmental, and regulatory forces. Understanding these key trends is critical for Ready Mix Companies to maintain competitiveness, ensure profitability, and capitalize on emerging opportunities.

1. Accelerated Focus on Sustainability and Low-Carbon Solutions (H3)

- Net-Zero Pressure Intensifies: Government regulations (e.g., EU Green Deal, US IRA), corporate ESG commitments, and investor demands will make reducing embodied carbon in concrete non-negotiable. Companies face mandates for Environmental Product Declarations (EPDs) and carbon footprint reporting.

- Alternative Binders Dominate Innovation: Significant R&D and commercial scaling of SCMs (Supplementary Cementitious Materials) like fly ash, slag, and silica fume will continue. Novel binders like calcined clays (LC3), geopolymers, and carbon-cured concrete will move from pilot projects to broader market adoption.

- Carbon Capture, Utilization, and Storage (CCUS): Investment in CCUS technologies at cement plants and potential integration points within the RMC supply chain will grow, driven by carbon pricing mechanisms and subsidies.

- Circular Economy Integration: Increased use of recycled concrete aggregate (RCA) and other industrial by-products will be standard practice, supported by improved processing and quality control standards.

2. Digitalization and Smart Operations (H3)

- AI & Predictive Analytics: Widespread adoption of AI for optimizing mix designs (balancing performance, cost, and carbon), predicting demand fluctuations, managing fleet logistics (route optimization, fuel efficiency), and forecasting maintenance needs for plants and trucks.

- IoT and Real-Time Monitoring: Embedded sensors in trucks and potentially in fresh concrete will provide real-time data on slump, temperature, and location, enabling proactive quality control, delivery verification, and enhanced customer service.

- Integrated Digital Platforms: Cloud-based platforms will seamlessly connect orders, dispatch, plant operations, delivery tracking, invoicing, and customer portals, improving efficiency and transparency across the value chain.

- Advanced BIM Integration: RMC suppliers will increasingly integrate with Building Information Modeling (BIM) systems used by contractors, allowing for precise volume estimation, scheduling, and project coordination.

3. Supply Chain Resilience and Vertical Integration (H3)

- Securing Raw Materials: Strategic partnerships and potential vertical integration (e.g., owning aggregates or SCM sources) will be crucial to mitigate volatility in cement, sand, gravel, and SCMs (especially fly ash from declining coal power).

- Geopolitical Risk Management: Diversification of supply sources and regionalization of production will be prioritized to reduce exposure to global disruptions (e.g., shipping, trade conflicts).

- On-Demand & Micro-Plants: Growth in small, mobile, or modular batching plants located closer to urban construction sites to reduce delivery times, fuel consumption, and improve responsiveness for small-batch orders.

4. Evolving Construction Demands and Urbanization (H3)

- Affordable & Sustainable Housing: Government initiatives and population growth, especially in developing regions, will drive demand for cost-effective, durable, and sustainable housing solutions – a core market for standardized RMC.

- Infrastructure Renewal & Investment: Major government spending programs (e.g., US Infrastructure Investment and Jobs Act, EU Recovery Funds) will boost demand for RMC in roads, bridges, transit systems, and utilities, often requiring high-performance or specialty mixes.

- Tall Buildings & Complex Structures: Urban density will increase demand for high-strength, self-consolidating, and rapid-setting concrete mixes for skyscrapers and complex architectural projects.

- Industrial & Data Centers: Booming demand for data centers, EV battery plants, and advanced manufacturing facilities will require vast amounts of concrete, often with specific performance criteria.

5. Workforce Challenges and Automation (H3)

- Labor Shortages: The persistent shortage of skilled drivers and plant operators will intensify, pushing investment in automation.

- Automation Advancements: Increased deployment of automated batching, robotic truck loading, and potentially autonomous or remote-operated concrete pumps. Driver-assist technologies in mixer trucks will become standard to improve safety and efficiency.

- Upskilling: Workforce training will shift focus towards managing digital systems, data analysis, and operating automated equipment.

6. Regulatory & Economic Landscape (H3)

- Carbon Pricing & Taxes: The expansion of carbon taxes and emissions trading schemes will directly impact the cost structure of cement (the primary carbon source), making low-carbon RMC more economically competitive.

- “Green” Building Mandates: Stricter building codes and incentives for sustainable construction (e.g., LEED, BREEAM) will favor RMC suppliers offering verifiable low-carbon solutions.

- Interest Rates & Construction Cycles: Economic fluctuations will impact overall construction activity. RMC companies need agile financial models to navigate potential slowdowns in commercial real estate while capitalizing on resilient infrastructure and housing sectors.

Conclusion for Ready Mix Companies (H3):

Success in 2026 hinges on proactive adaptation. Leaders will be those who:

1. Embed Sustainability: Make low-carbon concrete the default offering through innovation and sourcing.

2. Embrace Digital Transformation: Leverage data and technology for operational excellence and customer value.

3. Fortify the Supply Chain: Ensure reliability and control over key inputs.

4. Invest in People & Tech: Address labor gaps with automation and upskilling.

5. Anticipate Regulation: Position themselves as compliance leaders, turning environmental requirements into a competitive advantage.

The 2026 RMC market will reward agility, innovation, and a deep commitment to sustainability and efficiency. Companies failing to adapt risk significant margin compression and market share loss.

Common Pitfalls When Sourcing a Ready Mix Concrete Company (Quality and Intellectual Property)

Sourcing a reliable ready mix concrete supplier is critical for construction project success, yet several pitfalls related to quality control and intellectual property (IP) considerations can lead to delays, cost overruns, and structural issues. Being aware of these common challenges helps mitigate risk.

Inadequate Quality Assurance Processes

One of the most significant risks is partnering with a supplier that lacks robust quality control systems. This includes inconsistent batching, poor raw material sourcing, or insufficient testing protocols. Without regular slump tests, compressive strength testing, and adherence to ASTM or local standards, the delivered concrete may not meet project specifications, leading to structural deficiencies or rework.

Lack of Traceability and Documentation

Proper documentation of mix designs, material sources, and test results is essential for quality assurance and regulatory compliance. Some ready mix companies fail to provide complete, auditable records. This lack of traceability can create disputes over responsibility if a concrete batch fails, and may also complicate warranty claims or legal accountability.

Misuse or Unauthorized Use of Proprietary Mix Designs

Ready mix suppliers often develop proprietary concrete formulations tailored to specific performance criteria (e.g., high early strength, durability in harsh environments). Sourcing from a company that uses or shares these formulations without proper licensing can expose your project or organization to intellectual property infringement claims, especially if the mix design was developed for a previous client under confidentiality agreements.

Insufficient Verification of Mix Design Credentials

Not all mix designs are created equal. A common pitfall is assuming that a supplier’s provided mix design is valid and tested. Failing to verify that the mix has been independently certified or tested by an accredited lab can result in non-compliant concrete. Always request third-party validation and ensure the design aligns with project requirements and local building codes.

Overlooking Supplier Subcontracting Practices

Some ready mix companies subcontract production or delivery without disclosing it. This can lead to inconsistent quality if the subcontractor does not follow the same standards. Additionally, subcontractors might use their own mix designs or materials, raising IP concerns if those designs are protected or if material substitutions affect performance.

Failure to Address IP Rights in Contracts

Many sourcing agreements neglect to clearly define ownership and usage rights related to custom mix designs. If your project requires a unique formulation, ensure the contract specifies whether your organization retains rights to the design, or if it becomes the supplier’s IP. Ambiguity here can limit future reuse or lead to additional licensing costs.

Geographic and Logistical Constraints Affecting Freshness

While not directly a quality control process, logistical issues such as long haul times or inadequate fleet management can degrade concrete quality before placement. Slump loss, premature setting, and temperature fluctuations are real concerns. Ensure the supplier has a proven logistics plan and uses admixtures appropriately to maintain workability.

By proactively addressing these pitfalls—focusing on documentation, verifying mix design legitimacy, clarifying IP rights, and enforcing quality standards—project managers can reduce risk and ensure the structural integrity and legal compliance of their construction projects.

Logistics & Compliance Guide for Ready Mix Concrete Company

Overview

This guide outlines the essential logistics and compliance procedures for a Ready Mix Concrete Company to ensure efficient operations, regulatory adherence, safety, and customer satisfaction. It covers transportation, scheduling, environmental regulations, safety protocols, and documentation.

Fleet Management & Vehicle Maintenance

All ready mix trucks must undergo scheduled maintenance to ensure safe and reliable operation.

– Conduct daily pre-trip inspections (brakes, tires, lights, drum functionality).

– Maintain detailed service logs and adhere to manufacturer-recommended maintenance intervals.

– Replace worn parts promptly to prevent on-site breakdowns.

– Ensure vehicles meet local emissions standards and are registered with appropriate authorities.

Dispatch & Scheduling

Efficient scheduling is critical to timely deliveries and optimal resource use.

– Use dispatch software to track truck locations, job sites, and load times.

– Coordinate closely with production batching plants to align mix preparation with delivery times.

– Account for traffic, weather, and site access conditions when planning routes.

– Communicate estimated time of arrival (ETA) to customers and site supervisors.

Load Documentation & Ticketing

Accurate documentation ensures billing accuracy and regulatory compliance.

– Generate a delivery ticket for each load, including:

– Customer name and job site address

– Order number and mix design

– Volume delivered (in cubic yards or meters)

– Time of batching, loading, and delivery

– Truck number and driver name

– Obtain customer or site supervisor signature upon delivery.

– Retain digital and physical copies of tickets for a minimum of 3 years.

Environmental Compliance

Ready mix operations must follow environmental protection regulations.

– Prevent washout water from entering storm drains; use designated washout areas with proper containment.

– Recycle returned concrete and process water where possible.

– Comply with local air quality standards (e.g., dust control at batch plants).

– Train drivers and plant staff on spill response procedures and proper disposal of materials.

Safety Protocols

Safety is paramount for drivers, plant workers, and job site personnel.

– Require all drivers to complete defensive driving and job site safety training.

– Enforce use of personal protective equipment (PPE), including high-visibility vests, hard hats, and steel-toed boots.

– Prohibit drum rotation during fueling or when personnel are near the chute.

– Implement a fatigue management policy to prevent driver overwork.

Regulatory Compliance

Stay current with all federal, state, and local regulations.

– Ensure drivers possess valid Commercial Driver’s License (CDL) with appropriate endorsements.

– Maintain compliance with Department of Transportation (DOT) Hours of Service (HOS) rules.

– Conduct random drug and alcohol testing per DOT requirements.

– Adhere to OSHA standards for workplace safety at plants and terminals.

Customer Site Procedures

Professional conduct and clear communication enhance customer relationships.

– Confirm site access and placement instructions before arrival.

– Follow site-specific safety rules (e.g., speed limits, PPE requirements).

– Avoid overloading chutes or placing concrete in unauthorized areas.

– Report any delays or issues to dispatch and customer immediately.

Recordkeeping & Audits

Maintain organized records for compliance and operational review.

– Store vehicle logs, training records, maintenance reports, and delivery tickets.

– Conduct internal audits quarterly to verify compliance with safety and environmental standards.

– Prepare for external inspections by regulatory agencies with up-to-date documentation.

Emergency Response

Be prepared for unexpected incidents.

– Equip all trucks with spill kits, fire extinguishers, and first aid supplies.

– Train drivers on emergency procedures, including spill reporting and accident response.

– Maintain a 24/7 emergency contact number for dispatch and management.

Continuous Improvement

Regularly review and refine logistics and compliance processes.

– Solicit feedback from drivers, customers, and site supervisors.

– Analyze delivery performance data to identify bottlenecks.

– Update training programs and procedures to reflect new regulations or technologies.

By adhering to this guide, your ready mix company can operate safely, efficiently, and in full compliance with all applicable rules and standards.

Conclusion for Sourcing a Ready-Mix Concrete Company

In conclusion, selecting the right ready-mix concrete supplier is a critical decision that directly impacts the quality, timeline, and cost-efficiency of a construction project. After thorough evaluation of potential suppliers, key factors such as product quality, consistency, delivery reliability, technical support, sustainability practices, and competitive pricing have proven essential in determining the best fit. A reliable ready-mix company should not only meet current project specifications but also demonstrate a commitment to safety, environmental responsibility, and long-term partnership. Based on comprehensive research and assessments, [insert chosen company name] has emerged as the most suitable supplier, offering a strong balance of performance, reliability, and value. Finalizing this partnership will support seamless project execution and contribute significantly to overall construction success.