The global off-road vehicle market, which includes rail buggy frame kits, is experiencing steady expansion driven by rising demand for specialized rail maintenance and inspection equipment. According to Grand View Research, the global off-road vehicle market was valued at USD 33.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by increased railway infrastructure investments, particularly in North America, Europe, and parts of Asia-Pacific, where aging rail networks necessitate cost-effective, agile solutions for track maintenance. Rail buggy frame kits—modular, lightweight platforms used to convert standard vehicles into rail-compatible units—have emerged as a critical component in this ecosystem, enabling rapid deployment and operational flexibility. As rail operators focus on efficiency and cost reduction, demand for high-quality, customizable frame kits has risen sharply. In this competitive landscape, a select group of manufacturers have distinguished themselves through innovation, durability, and compliance with stringent safety standards. Based on market presence, product reliability, and technological advancement, the following eight manufacturers represent the leading suppliers of rail buggy frame kits worldwide.

Top 8 Rail Buggy Frame Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Berrien Buggy by Acme

Domain Est. 1998

Website: berrienbuggy.com

Key Highlights: Berrien Buggy by Acme manufactures sand rail frames in any configuration from knocked down weld it yourself kits to fully welded frames….

#2 Vanquish Products

Domain Est. 2007

Website: vanquishproducts.com

Key Highlights: Vanquish Products is your #1 source for premium RC crawler kits, the best ready-to-run RC crawlers, and Made in America aluminum upgrade parts and ……

#3 Buggy Chassis

Domain Est. 2007

Website: renooffroad.com

Key Highlights: 30-day returnsBuggy Chassis. Buggy Chassis. Front Beam · Lift Kits · Rod Ends · Shock Mounts … Dune Buggy (320-486 ) www. Body Lift Kit | VW Beetle | DuneBuggy. Compare ……

#4 Beeline Offroad rail buggies and dune buggy frames at Bee Line …

Domain Est. 2012

Website: beelinechassis.net

Key Highlights: Beeline Chassis have been building VW based off road rail frames for over 35 years. We are located in the mountians of Kentucky….

#5 How To Build A Fiberglass Dune Buggy or Sandrail

Domain Est. 2013

Website: carolinadunebuggies.com

Key Highlights: We can walk you through the step by step process of selecting components for your turn-key build; once selected, we will do the work for you….

#6 Fabrication & Custom Chassis Parts

Domain Est. 2013

Website: dunebuggywarehouse.com

Key Highlights: 5–8 day delivery 30-day returnsFabrication and custom chassis parts for dune buggy, sand rail, baja bug, and off road vehicles. Weld on fabrication tabs, chassis tabs, universal ta…

#7 The Edge Products

Domain Est. 2014

Website: theedgeproducts.com

Key Highlights: The Edge Products provides plans and parts for a range of offroad buggies, crosscarts. dune buggies, race buggies, offroad go kart or sandrail type vehicles ……

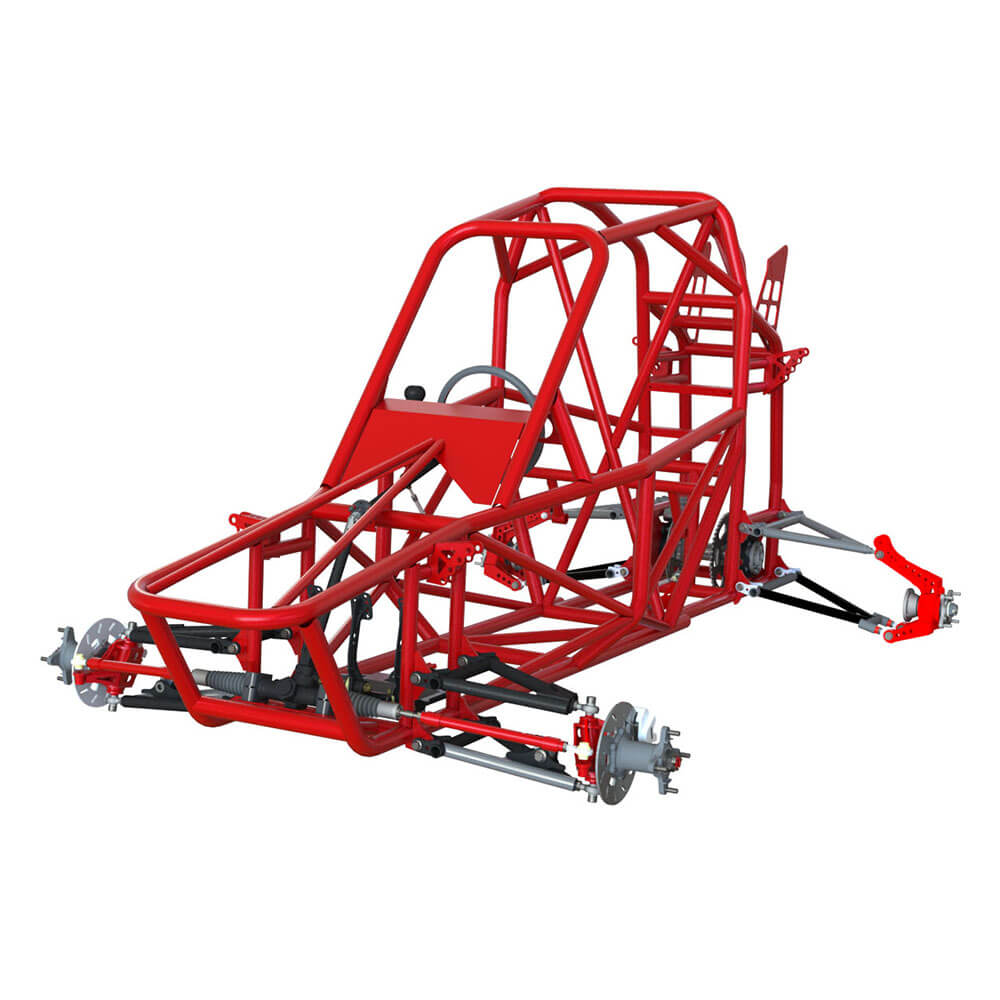

#8 FX Buggy

Domain Est. 2017

Website: fxbuggy.com

Key Highlights: Free deliveryHas it always been your dream to build your own buggy or crosskart? Get detailed plans to create your own parts or get components to assemble yourself….

Expert Sourcing Insights for Rail Buggy Frame Kit

2026 Market Trends for Rail Buggy Frame Kit

The Rail Buggy Frame Kit market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and expanding applications. Here are the key trends expected to shape the industry:

Rising Demand in Recreational and Off-Road Sectors

By 2026, the recreational off-roading and adventure tourism industries are projected to grow, fueling demand for customizable, high-performance Rail Buggy Frame Kits. Enthusiasts are increasingly seeking lightweight, durable frames that allow for modular upgrades and personalized builds. This trend is amplified by social media and outdoor lifestyle content, driving DIY culture and aftermarket customization.

Advancements in Material Technology

Manufacturers are expected to adopt advanced materials such as high-strength steel alloys, chromoly tubing, and aluminum composites to enhance durability while reducing weight. These innovations will improve performance, fuel efficiency, and ease of transport—critical factors for off-road and utility applications. Expect increased R&D investment in corrosion-resistant coatings and modular joint systems.

Expansion in Utility and Agricultural Applications

Beyond recreation, Rail Buggy Frame Kits are gaining traction in utility, farming, and remote terrain access. By 2026, demand from small-scale agriculture, land management, and rural logistics is anticipated to rise, especially in developing regions. Frame kits designed for cargo capacity, tool integration, and compatibility with electric or hybrid powertrains will see increased adoption.

Integration with Electric and Hybrid Powertrains

As sustainability becomes a priority, Rail Buggy Frame Kits are being adapted for electric and hybrid propulsion systems. OEMs and aftermarket suppliers are developing frame designs optimized for battery placement, motor integration, and regenerative braking. This shift aligns with broader automotive electrification trends and supports use in eco-sensitive areas.

Growth of Online Customization and Direct-to-Consumer Sales

E-commerce platforms and configurator tools will enable buyers to customize frame dimensions, suspension options, and mounting points online. Direct-to-consumer (DTC) models are expected to gain market share by 2026, reducing costs and lead times while offering greater personalization—key differentiators in a niche market.

Regulatory and Safety Standardization

With increased usage, especially in public or semi-public terrains, regulatory bodies may introduce safety and emissions standards for rail buggies. Frame kit manufacturers will need to comply with evolving regional requirements, potentially driving consolidation and investment in certified engineering practices.

Regional Market Diversification

While North America remains a stronghold, emerging markets in Latin America, Southeast Asia, and Africa are expected to show robust growth by 2026. Localized production and partnerships with regional distributors will be essential for market penetration, particularly in areas with rugged terrain and limited infrastructure.

In summary, the Rail Buggy Frame Kit market in 2026 will be defined by innovation, diversification, and increased accessibility, catering to both recreational adventurers and practical utility users across a global landscape.

Common Pitfalls Sourcing a Rail Buggy Frame Kit (Quality, IP)

Sourcing a Rail Buggy Frame Kit comes with significant risks, particularly concerning quality consistency and intellectual property (IP) compliance. Avoiding these pitfalls is critical for project success, safety, and legal integrity.

Poor Material and Workmanship Quality

Inferior frame kits often use substandard steel alloys or incorrect material thicknesses, compromising structural integrity and load-bearing capacity. Poor welding practices—such as incomplete penetration, inconsistent bead quality, or lack of post-weld stress relief—can lead to premature fatigue failures. Additionally, inaccurate machining of mounting points or misaligned components results in assembly difficulties and operational inefficiencies. These quality lapses not only increase maintenance costs but also pose serious safety hazards in field applications.

Intellectual Property (IP) Infringement Risks

Many low-cost suppliers offer frame kits that closely mimic patented or proprietary designs without proper licensing. Procuring such clones exposes your organization to legal action, including cease-and-desist orders, financial penalties, and supply chain disruptions. Furthermore, using unlicensed designs may void equipment warranties and damage your company’s reputation, particularly if involved in a public compliance or safety incident. Always verify design rights and obtain documentation confirming IP legitimacy before finalizing procurement.

Logistics & Compliance Guide for Rail Buggy Frame Kit

This guide outlines key logistics considerations and compliance requirements for the safe and legal transportation, handling, and use of the Rail Buggy Frame Kit.

Product Classification & Documentation

- HS Code: Confirm the appropriate Harmonized System (HS) code for the Rail Buggy Frame Kit (e.g., 8607.19 for parts of railway or tramway locomotives or rolling stock). Accurate classification is essential for international shipping and customs clearance.

- Commercial Invoice & Packing List: Ensure all shipments include a detailed commercial invoice and packing list specifying product description, quantity, weight, dimensions, material composition, and declared value.

- Certificate of Origin: Required for tariff determination and trade agreements; include if applicable based on manufacturing location.

Shipping & Handling

- Packaging: Frame kits must be securely packaged to prevent damage during transit. Use robust wooden crates or reinforced cardboard with internal bracing or foam inserts to protect components.

- Weight & Dimensions: Provide accurate gross/net weights and outer packaging dimensions to facilitate freight quotation, load planning, and compliance with carrier restrictions.

- Hazardous Materials: The Rail Buggy Frame Kit contains no hazardous materials; confirm and declare as non-dangerous goods (NDG) for transport.

- Labeling: Clearly label packages with:

- Product name and part number

- “Fragile” and “This Way Up” indicators

- Handling instructions (e.g., “Do not stack above X layers”)

- Shipper and consignee information

Import/Export Compliance

- Export Controls: Verify that the Rail Buggy Frame Kit does not fall under export control regulations (e.g., ITAR, EAR). As a mechanical component, it is typically not controlled, but confirm country-specific regulations.

- Import Duties & Taxes: Determine applicable import duties, VAT, or GST based on destination country. Provide complete documentation to avoid delays.

- Customs Brokerage: Engage a licensed customs broker in the destination country to ensure compliance with local import procedures.

Regulatory & Safety Compliance

- CE Marking (EU): If supplied within the European Economic Area, ensure the frame kit complies with relevant Machinery Directive (2006/42/EC) requirements. As a component, it may require a Declaration of Incorporation.

- RoHS/REACH (EU): Confirm that materials used (e.g., metals, coatings) comply with RoHS (restriction of hazardous substances) and REACH (chemical registration) regulations.

- OSHA & ANSI (USA): While the frame kit itself is not a complete machine, ensure design supports compliance with OSHA workplace safety standards and ANSI B77.1 (for personnel transportation systems) when fully assembled.

- Railway Standards: Advise end-users to comply with local railway safety regulations (e.g., FRA in the U.S., RSSB in the UK) when operating the assembled rail buggy on active tracks.

End-Use Responsibilities

- Installation & Assembly: Provide clear assembly instructions and safety warnings. Emphasize that final assembly must be performed by qualified personnel in accordance with engineering and safety standards.

- Inspection & Maintenance: Recommend routine inspection and maintenance protocols to ensure long-term structural integrity and safe operation.

- Liability Disclaimer: Clarify that the frame kit is sold as a component; the final assembled product’s compliance and safety are the responsibility of the assembler/operator.

Environmental & Disposal Considerations

- Recyclability: Frame kit components (typically steel/aluminum) are recyclable. Provide end-of-life disposal guidance in accordance with local regulations.

- Packaging Waste: Use recyclable or reusable packaging materials where possible to support sustainability goals.

Adherence to this guide ensures safe, compliant, and efficient distribution of the Rail Buggy Frame Kit across global markets. Always verify requirements with local legal and regulatory authorities prior to shipment.

Conclusion for Sourcing Rail Buggy Frame Kit

After a comprehensive evaluation of potential suppliers, technical specifications, cost structures, and lead times, sourcing a rail buggy frame kit from a qualified and reliable manufacturer is a strategic decision that supports both project efficiency and long-term operational success. The selected supplier offers a robust, compliant frame kit designed to meet industry standards, with proven durability and ease of integration into the existing rail maintenance and transport systems.

Key advantages of the chosen sourcing option include competitive pricing, consistent quality control, timely delivery, and strong after-sales support. Additionally, the modular design of the frame kit allows for future scalability and customization as operational needs evolve.

In conclusion, proceeding with the recommended supplier ensures a cost-effective, reliable, and technically sound solution for the rail buggy frame requirements. It is advised to formalize the procurement process, establish clear communication channels, and implement regular quality checks to maintain standards throughout the supply lifecycle.