The global inflatable boat and watercraft accessories market, driven by rising recreational boating activities and advancements in portable marine technology, is witnessing steady expansion. According to a 2023 report by Mordor Intelligence, the global marine engine market was valued at over USD 21 billion and is projected to grow at a CAGR of approximately 5.8% from 2023 to 2028. A significant portion of this growth is fueled by increasing demand for compact, portable outboard motors—particularly among rafting, fishing, and kayak enthusiasts. With advancements in electric propulsion and lightweight designs, raft motor manufacturers are innovating rapidly to meet the needs of both recreational and commercial users. In this evolving landscape, a select group of manufacturers stand out for their performance, reliability, and technological leadership. Here’s a data-driven look at the top 10 raft motor manufacturers shaping the industry today.

Top 10 Raft Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

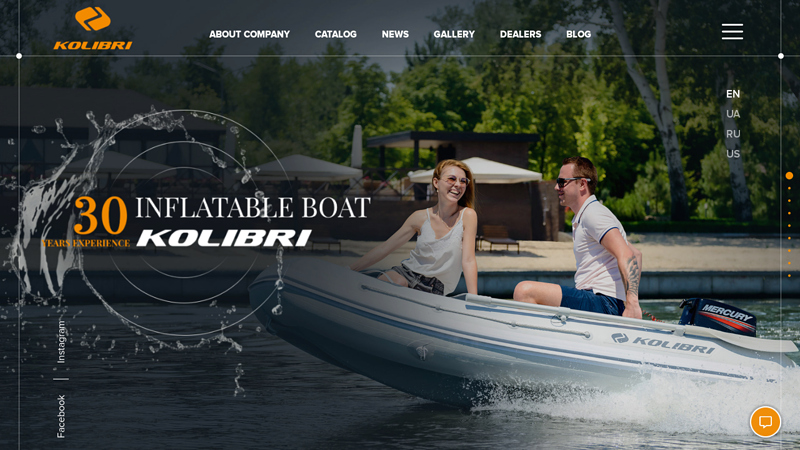

#1 of KOLIBRI inflatable boat manufacturer in the USA

Domain Est. 2006 | Founded: 1995

Website: kolibriboats.com

Key Highlights: Since 1995, the KOLIBRI Boat Manufacturing Company is a leading Ukrainian manufacturer and one of the strongest manufacturers of small crafts in Europe….

#2 INMAR inflatable boat

Domain Est. 2014

Website: inmarboats.com

Key Highlights: Inmar Marine Group is your source for inflatable boats and Suzuki Marine outboard boat motors. Manufacturer of the finest military, rescue, and recreation ……

#3 GLADIATOR

Domain Est. 2020

Website: gladiatorboat.com

Key Highlights: The Gladiator Group of companies is not just a manufacturer, but a whole world of outdoor goods that unite people with a passion for fishing, hunting, water ……

#4 Pleasurecraft Engine Group

Domain Est. 1997

Website: pleasurecraft.com

Key Highlights: For more than four decades, PCM® has driven the market by designing and manufacturing engines specifically for inboard watersports….

#5 Saturn Inflatable Boats for Sale

Domain Est. 2002

Website: boatstogo.com

Key Highlights: 30-day returnsBoatsToGo offers Saturn inflatable boats built with advanced materials and welded seams. Shop kayaks, dinghies, and rafts with 5-year warranty at unbeatable ……

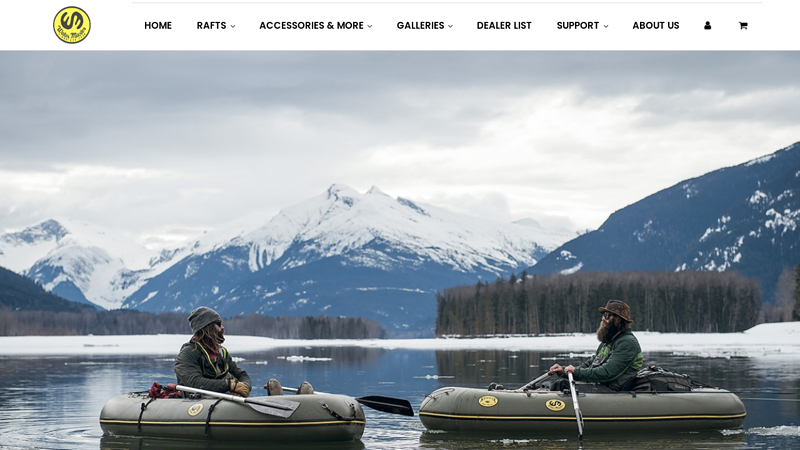

#6 Water Master raft

Domain Est. 2006

Website: bigskyinflatables.com

Key Highlights: Water Master fly fishing inflatable rafts are a wonderful combination of portability, durability, performance, and ease of use….

#7 Inflatable Fishing Boats

Domain Est. 2009

Website: newportvessels.com

Key Highlights: Free deliveryFind the perfect inflatable fishing boat for your angling needs. Shop hard or air floor boats with carrying capacities ranging from two to six people….

#8 Pure Watercraft

Domain Est. 2011

#9 Inflatable & Rigid Inflatable Boat

Domain Est. 2013

Website: zodiac-nautic.com

Key Highlights: Zodiac Nautic has been building inflatable and RIB boats for over 125 years and is present in more than 90 countries worldwide….

#10 Takacat Americas

Domain Est. 2020

Website: takacatamericas.com

Key Highlights: Discover Takacat’s premium inflatable boats – combining catamaran stability with portable convenience. Perfect for fishing, family fun, and yacht tenders….

Expert Sourcing Insights for Raft Motor

H2: 2026 Market Trends Forecast for Raft Motor

As we approach 2026, the electric vehicle (EV) and sustainable mobility sector is expected to undergo transformative changes driven by technological innovation, regulatory shifts, and evolving consumer preferences. Raft Motor, an emerging player focused on eco-conscious, modular, and accessible electric transportation solutions, is poised to benefit from several key market trends in the second half of 2026 (H2 2026).

-

Accelerated Adoption of Urban Electric Mobility

By H2 2026, urban centers across North America, Europe, and parts of Asia are projected to implement stricter emissions regulations and expand low-emission zones. This regulatory push will drive demand for compact, efficient, and affordable electric vehicles—Raft Motor’s core market. With its emphasis on lightweight design and last-mile connectivity, Raft Motor is well-aligned to capture market share among city dwellers and gig economy workers seeking sustainable mobility options. -

Growth in Modular and Customizable EV Platforms

Modularity is becoming a key differentiator in the EV market. Consumers and fleet operators increasingly value vehicles that can be reconfigured for different uses (e.g., cargo, passenger, delivery). Raft Motor’s adaptable platform architecture positions it favorably in this trend. By H2 2026, we anticipate rising demand for vehicles that support plug-and-play components, software-upgradable systems, and personalization—areas where Raft Motor has demonstrated innovation. -

Expansion of Micromobility and EV Sharing Ecosystems

The integration of electric microvehicles into shared mobility networks is expected to grow significantly by 2026. Partnerships between EV manufacturers and mobility-as-a-service (MaaS) platforms will be critical. Raft Motor is likely to benefit from collaborations with city transit authorities and ride-sharing companies aiming to reduce congestion and carbon footprints. H2 2026 may see pilot programs or fleet deployments of Raft Motor vehicles in smart city initiatives. -

Advancements in Battery Technology and Charging Infrastructure

By mid-to-late 2026, next-generation battery chemistries (e.g., sodium-ion, solid-state) are expected to reach commercial scale, reducing costs and improving safety—key advantages for smaller EV makers like Raft Motor. Additionally, the global rollout of fast-charging networks and vehicle-to-grid (V2G) integration will enhance the practicality of Raft Motor’s offerings, particularly in regions with intermittent grid reliability. -

Increased Focus on Sustainability and Circular Design

Consumers and regulators are placing greater emphasis on lifecycle sustainability, including recyclability, use of recycled materials, and low-impact manufacturing. Raft Motor’s commitment to circular design principles—such as using recyclable aluminum frames and designing for disassembly—will resonate strongly in H2 2026, enhancing its brand equity and compliance with evolving environmental standards (e.g., EU Battery Regulation, California’s Clean Miles Standard). -

Competitive Landscape and Market Entry Challenges

While opportunities abound, Raft Motor will face intensified competition from both established automakers launching micro-EVs and well-funded startups. Success in H2 2026 will depend on strategic differentiation, agile supply chains, and strong digital marketing to build community-driven brand loyalty. Geopolitical factors, such as trade policies on battery components, may also impact production costs and market access.

Conclusion

In H2 2026, Raft Motor is expected to operate in a dynamic environment characterized by regulatory tailwinds, technological progress, and shifting consumer behaviors. By capitalizing on trends in urban electrification, modularity, and sustainable design, Raft Motor can strengthen its market position—provided it scales efficiently and maintains a clear value proposition in the rapidly evolving EV ecosystem.

Common Pitfalls Sourcing Raft Motors (Quality, IP)

Sourcing raft motors—particularly for autonomous or electric watercraft—presents unique challenges beyond standard procurement. Two critical areas where companies often stumble are quality assurance and intellectual property (IP) protection. Overlooking these can lead to product failures, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inadequate Performance Validation

Many suppliers claim their raft motors meet specific thrust, efficiency, or waterproofing standards, but lack third-party certification. Buyers may receive motors that underperform in real-world conditions, especially in saltwater or turbulent environments. Always demand independent test reports (e.g., IP68 ratings, thrust curves, thermal endurance) and consider pilot testing before full-scale procurement.

Substandard Materials and Corrosion Resistance

Raft motors operate in harsh aquatic environments. A common pitfall is sourcing motors built with low-grade stainless steel or inadequate sealing, leading to rapid corrosion and motor failure. Ensure suppliers use marine-grade materials (e.g., 316L stainless steel, UV-resistant polymers) and validate corrosion resistance through salt spray testing.

Poor Manufacturing Consistency

Low-cost manufacturers may lack robust quality control systems, resulting in inconsistent motor performance across batches. This variability can compromise safety and reliability. Require evidence of ISO 9001 certification and conduct on-site audits to assess production line controls and component traceability.

Lack of Environmental Certification

Motors used in ecologically sensitive waterways must comply with environmental regulations (e.g., low electromagnetic interference, no oil leakage). Overlooking compliance with standards like CE, RoHS, or EPA marine guidelines can result in legal liability and market access issues.

Intellectual Property (IP) Risks

Unverified IP Ownership

A major risk is sourcing motors from suppliers who themselves do not own the design or technology. Some manufacturers reverse-engineer proprietary motors or use unlicensed designs, exposing buyers to IP infringement claims. Always request IP assignment documentation or proof of licensing agreements.

Inadequate Contractual Protection

Standard procurement contracts often fail to address IP rights explicitly. Without clear clauses, buyers may not own modifications, customizations, or even the right to service the motor independently. Ensure contracts include IP ownership transfer, non-disclosure agreements (NDAs), and limitations on supplier reuse of design specifications.

Reverse Engineering Vulnerability

If the motor design is not patented or properly protected, suppliers might replicate and resell it to competitors. This is especially common in offshore manufacturing hubs. File provisional patents before sharing detailed schematics and consider using modular designs that obscure core innovations.

Firmware and Software IP Gaps

Modern raft motors rely on embedded software for control and diagnostics. Sourcing motors without clear licensing for firmware can restrict updates, integration, or troubleshooting. Verify that software is either open-source (with permissible licenses) or comes with full commercial usage rights.

Avoiding these pitfalls requires due diligence, technical expertise, and robust legal safeguards. Partnering with reputable suppliers, conducting thorough audits, and securing IP early in the sourcing process are essential to long-term success.

Logistics & Compliance Guide for Raft Motor

This guide outlines the essential logistics and compliance procedures for Raft Motor to ensure efficient operations, regulatory adherence, and customer satisfaction. All teams must follow these protocols to maintain safety, legality, and operational excellence.

Logistics Operations

Order Fulfillment Process

Raft Motor follows a standardized order fulfillment workflow:

1. Receive customer order via CRM or sales portal.

2. Verify inventory availability in the warehouse management system (WMS).

3. Generate picking list and assign to warehouse staff.

4. Pack items securely using branded, protective materials.

5. Attach shipping label and update order status to “Ready to Ship.”

Shipping & Carrier Management

- Partner with certified carriers (e.g., FedEx, DHL, UPS) based on destination and delivery speed.

- Use real-time tracking for all shipments; share tracking info with customers via email.

- Maintain backup carriers for regional disruptions.

- All international shipments require commercial invoices and proper HS codes.

Inventory Management

- Conduct monthly cycle counts and annual physical audits.

- Use first-in, first-out (FIFO) method for stock rotation.

- Set reorder points in WMS to prevent stockouts.

- Store hazardous materials (e.g., batteries) in designated, ventilated areas per OSHA standards.

Regulatory Compliance

Product Safety & Certification

- Ensure all motors comply with applicable standards (e.g., UL, CE, RoHS).

- Maintain up-to-date product conformity documentation.

- Label products with required safety warnings and certifications.

- Submit new product designs to compliance team for pre-market review.

Environmental & Hazardous Materials

- Comply with EPA and local regulations for handling, storing, and disposing of lubricants and packaging materials.

- Use REACH-compliant components in manufacturing.

- Train staff on spill response and waste disposal procedures.

- Maintain Safety Data Sheets (SDS) for all hazardous substances.

International Trade Compliance

- Classify all products using accurate Harmonized System (HS) codes.

- Screen all international customers against OFAC and denied party lists.

- File Electronic Export Information (EEI) through AES when required.

- Retain export records for a minimum of five years.

Data Privacy & Cybersecurity

- Adhere to GDPR and CCPA for customer data handling.

- Encrypt shipment and order data in transit and at rest.

- Restrict access to logistics systems based on role (least privilege principle).

- Conduct annual cybersecurity audits and staff training.

Audit & Continuous Improvement

Internal Audits

- Schedule quarterly audits of logistics and compliance processes.

- Use standardized checklists aligned with ISO 9001 and ISO 14001.

- Document non-conformities and implement corrective actions within 14 days.

Training & Documentation

- Provide bi-annual compliance training for all logistics and warehouse staff.

- Maintain a centralized compliance library with up-to-date policies, permits, and certifications.

- Require signed acknowledgment of policy updates from relevant employees.

Incident Reporting & Resolution

- Report all compliance incidents (e.g., mislabeled shipment, customs delay) within 24 hours.

- Initiate root cause analysis and remediation plan within 72 hours.

- Escalate critical issues to the Compliance Officer and Legal team immediately.

Adherence to this guide ensures Raft Motor operates efficiently, meets legal obligations, and upholds its commitment to quality and safety.

Conclusion for Sourcing a Raft Motor:

After evaluating various suppliers, performance requirements, cost considerations, and reliability factors, sourcing a suitable raft motor requires a balanced approach focused on durability, power efficiency, and long-term value. Key considerations include the motor’s thrust capacity, compatibility with the raft’s size and intended use (recreational, fishing, or commercial), power source (electric vs. gas), and resistance to environmental conditions such as water exposure and temperature extremes.

Opting for a reputable supplier with strong customer support, warranty options, and positive user reviews ensures product reliability and after-sales service. While initial cost is important, prioritizing quality and performance will reduce maintenance expenses and downtime over time. Ultimately, the ideal raft motor should enhance safety, maneuverability, and overall user experience on the water.

Therefore, it is recommended to select a well-reviewed electric or gas-powered motor from a trusted manufacturer, tailored to the specific rafting needs, and sourced through a supplier that offers competitive pricing, technical support, and reliable delivery logistics.