The global portable air compressor market is experiencing steady expansion, driven by rising demand across automotive, construction, and outdoor recreation sectors. According to Grand View Research, the global air compressor market was valued at USD 38.3 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.2% from 2024 to 2030. A key trend shaping this growth is the increasing consumer preference for quiet, energy-efficient, and portable models—particularly in personal and small-scale commercial applications. Noise reduction technologies, lightweight designs, and advancements in oil-free pump systems have become differentiating factors among manufacturers. As urban living spaces grow denser and home-based projects rise, the demand for low-decibel portable compressors has surged. In response, a select group of manufacturers have emerged as leaders in balancing performance, portability, and sound efficiency—setting new benchmarks in a competitive and evolving landscape.

Top 8 Quiet Portable Air Compressor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Our Family of Brands

Domain Est. 1996 | Founded: 2006

Website: gastmfg.com

Key Highlights: Jun-Air. Experience the power of silence with Jun-Air, a Gast company since 2006 and the global leader in quiet air compressor technology….

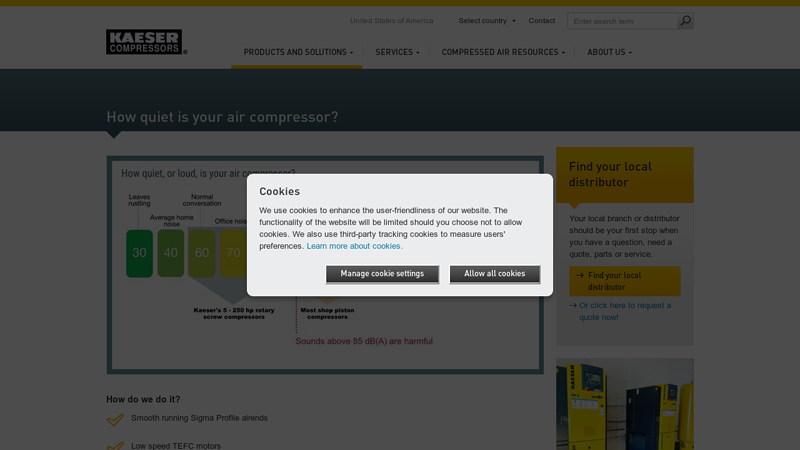

#2 Quiet Air Compressors

Domain Est. 1996

Website: us.kaeser.com

Key Highlights: Noisy air compressors are a thing of the past for Kaeser customers. Learn about how we create the best quiet air compressors and the benefits of having one!…

#3 Global Industrial Portable Quiet Air Electric Compressor, 1.8 HP, 20 …

Domain Est. 1997

Website: globalindustrial.com

Key Highlights: In stock Rating 5.0 (1) This silent air compressor is not only 80% quieter than most, but it’s proven to last up to three times as long as it’s competitors….

#4 Compressors

Domain Est. 1995

Website: ridgid.com

Key Highlights: Shop RIDGID purpose-built, durable air compressors here….

#5 Silentaire: Portable Air Compressors

Domain Est. 1997

Website: silentaire.com

Key Highlights: We offer a wide variety of quiet compressors in both oil lubricated and oil free applications. Our product lines include the Scorpion Compressors, Super Silent ……

#6 Silent Air Compressor

Domain Est. 1997

Website: werther.com

Key Highlights: Exceptionally Quiet Air Compressor. When operating under full load this line of ultra-quiet and low noise air compressors offers low decibel levels as low as 30 ……

#7 M18 FUEL 2 Gallon Compact Quiet Compressor

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: The MILWAUKEE® M18 FUEL™ 2 Gallon Compact Quiet Compressor is only 68dB(A), making it the quietest cordless compressor & quieter than most corded options….

#8 Homepage

Domain Est. 2016

Website: stealthcompressors.com

Key Highlights: Stealth Air Compressor are the perfect solution for taking on tough jobs. Portable enough to bring anywhere, and powerful enough to run most air tools ……

Expert Sourcing Insights for Quiet Portable Air Compressor

H2: 2026 Market Trends for Quiet Portable Air Compressors

The global market for quiet portable air compressors is poised for significant transformation by 2026, driven by advancements in technology, evolving consumer demands, and expanding applications across residential, industrial, and specialty sectors. These compact, low-noise air compressors are increasingly favored for their versatility, energy efficiency, and minimal environmental impact. Below are the key trends expected to shape the market in 2026:

-

Rising Demand for Noise Reduction Technology

As urbanization increases and living spaces become more compact, noise pollution concerns are pushing manufacturers to develop quieter models. By 2026, the integration of advanced sound-dampening materials, brushless motors, and vibration-reduction systems will be standard across mid-to-high-end models. Consumer preference for compressors operating below 60 decibels will accelerate innovation in acoustic engineering. -

Growth in DIY and Home Improvement Markets

The surge in do-it-yourself (DIY) culture, fueled by home renovation trends and online tutorial platforms, is boosting demand for user-friendly, quiet portable air compressors. Lightweight, oil-free, and maintenance-free models will dominate this segment, offering ease of use for tasks such as inflating tires, powering nail guns, and operating small pneumatic tools. -

Expansion in Automotive and Outdoor Applications

The automotive aftermarket and outdoor recreation sectors are emerging as key growth drivers. Quiet portable compressors are increasingly used for inflating off-road tires, camping gear, and inflatable boats. The integration of lithium-ion batteries and solar charging options will enhance portability and appeal to eco-conscious outdoor enthusiasts. -

Adoption of Cordless and Battery-Powered Models

By 2026, battery-powered air compressors will account for a growing share of the market. Improvements in lithium-ion battery capacity and charging speed will enable longer run times and greater power output. Cordless models offer unparalleled mobility, making them ideal for fieldwork, mobile repair services, and remote job sites. -

Focus on Energy Efficiency and Sustainability

Regulatory pressures and consumer awareness of energy consumption are pushing manufacturers toward energy-efficient designs. In 2026, quiet portable compressors will increasingly feature variable speed drives (VSD), smart pressure controls, and eco-modes to minimize power usage. Recyclable materials and lower carbon footprints in production will also become key selling points. -

Technological Integration and Smart Features

The integration of IoT and smart technology is on the rise. By 2026, leading models are expected to include Bluetooth connectivity, mobile app monitoring, automatic shut-off, pressure presets, and diagnostic alerts. These features enhance user experience, safety, and operational efficiency. -

Regional Market Growth and Competitive Landscape

North America and Europe will remain dominant markets due to high disposable income and stringent noise regulations. Meanwhile, Asia-Pacific—especially China, India, and Southeast Asia—will experience rapid growth, driven by industrialization and infrastructure development. Established players and new entrants alike will focus on product differentiation, affordability, and localized distribution networks. -

Increased Focus on Commercial and Light Industrial Use

Beyond consumer applications, quiet portable compressors are gaining traction in commercial settings such as photography studios, dental clinics, and small workshops where low noise and clean air output are essential. Oil-free compressors that deliver contaminant-free air will see increased adoption in sensitive environments.

In conclusion, the 2026 market for quiet portable air compressors will be defined by innovation in noise reduction, portability, energy efficiency, and smart functionality. As industries and consumers alike prioritize convenience, sustainability, and performance, manufacturers that adapt to these evolving trends will capture significant market share and drive future growth.

Common Pitfalls When Sourcing Quiet Portable Air Compressors (Quality & IP)

Sourcing a quiet portable air compressor requires careful attention to both performance and protection standards. Overlooking key aspects can lead to subpar equipment, safety risks, or premature failure. Here are the most frequent pitfalls to avoid:

Overlooking True Noise Ratings and Real-World Performance

Many suppliers advertise “quiet” compressors based on ideal lab conditions that don’t reflect actual use. Compressors may list noise levels measured at a distance under no load, ignoring vibration, motor whine, or pulsation noise. Always verify if the decibel (dB) rating is measured per ISO 3744 or similar standard, and check independent reviews for real-world performance. A unit claiming 40 dB but lacking certification may actually operate much louder.

Confusing Portability with Practical Usability

“Portable” often means lightweight, but doesn’t guarantee ease of transport. Pitfalls include compressors with poor handle design, lack of wheels, or excessive vibration that makes carrying uncomfortable. Additionally, a compact unit may have a small tank, requiring frequent cycling—increasing noise and wear. Assess weight, ergonomics, and duty cycle to ensure true portability meets your operational needs.

Ignoring IP (Ingress Protection) Ratings for Intended Environment

The IP rating indicates protection against dust and moisture, but it’s often overlooked or misrepresented. A compressor with only IP20 offers minimal protection—fine for indoor workshops but risky in damp or dusty conditions. For outdoor or job-site use, aim for at least IP54 (dust-protected and splash-resistant). Beware of vague claims like “dust-resistant” without a certified IP code, as they offer no real assurance.

Prioritizing Low Cost Over Build Quality and Materials

Budget models often use lower-grade plastic components, undersized motors, or poorly sealed electronics, leading to reduced lifespan and reliability. Critical parts like the pump, motor bearings, and pressure switch must be durable. Skimping here increases downtime and replacement costs. Invest in compressors with aluminum or cast iron pumps, metal housings, and reputable component brands—even if the upfront cost is higher.

Assuming All “Oil-Free” Pumps Are Maintenance-Free and Silent

While oil-free compressors are cleaner and lighter, their pumps often generate more noise and heat due to higher friction. They also tend to wear faster in continuous use. Some suppliers overstate the longevity and quietness of oil-free designs. Verify duty cycle limits and sound profiles—oil-lubricated models, though heavier and requiring maintenance, may offer quieter and longer-lasting performance for frequent use.

Failing to Verify Certifications and Intellectual Property (IP) Authenticity

Counterfeit or uncertified products are common in the portable compressor market. Always check for genuine safety certifications (e.g., CE, UL, ETL) and ensure they’re traceable. Be cautious of listings that copy designs or branding from reputable brands without authorization—this raises intellectual property concerns and often indicates poor quality control. Sourcing from authorized distributors or manufacturers reduces IP and compliance risks.

Neglecting Thermal and Pressure Protection Features

Low-quality compressors may lack essential safety features like overheat protection, automatic shut-off, or pressure relief valves. These omissions increase fire and explosion risks, especially in enclosed or high-temperature environments. Ensure the unit includes thermal overload protection and meets pressure vessel safety standards to avoid hazardous failures.

By addressing these common pitfalls—particularly around misleading noise claims, inadequate IP ratings, and questionable build quality—you can source a quiet, portable air compressor that delivers reliable, safe, and long-term performance.

Logistics & Compliance Guide for Quiet Portable Air Compressor

Product Overview

The Quiet Portable Air Compressor is a compact, low-noise air compression solution designed for residential, automotive, and light industrial use. Its portability, energy efficiency, and reduced noise output make it ideal for indoor applications, mobile professionals, and noise-sensitive environments. This guide outlines key logistics and compliance considerations to ensure safe, efficient distribution and legal market access.

International Shipping & Handling

- Packaging Requirements: Units must be shipped in double-walled corrugated boxes with internal foam or molded inserts to prevent movement and protect sensitive components during transit. Include moisture-resistant wrapping in humid climates.

- Weight & Dimensions: Package dimensions must not exceed 24” x 12” x 18” with a gross weight under 50 lbs (22.7 kg) to qualify for standard parcel shipping. Heavier commercial models may require freight shipping (LTL/FTL).

- Labeling: External packaging must display:

- Product name and model number

- “Fragile – Handle with Care”

- “This Side Up” indicators

- UN number (if applicable for lithium components)

- HS Code: 8414.80 (for air pumps and compressors)

- Battery Considerations: If the unit includes a built-in lithium-ion battery, comply with IATA/IMDG regulations for lithium battery transport. Packages must bear the “Lithium Battery Mark” and include proper documentation.

Import/Export Compliance

- Tariff Classification: Classify under HS Code 8414.80. Confirm country-specific subheadings (e.g., 8414.80.60 in the U.S. for portable compressors).

- Country-Specific Regulations:

- United States: Comply with EPA noise emission standards and CPSC safety guidelines. FCC Part 15 for any electronic controls or wireless features.

- European Union: CE marking required under Machinery Directive (2006/42/EC), Low Voltage Directive (2014/35/EU), and RoHS (2011/65/EU). Noise levels must meet EN ISO 3744:2010.

- Canada: Meet CSA C22.2 No. 68 safety standards and comply with Health Canada’s noise emission regulations (SOR/2018-74).

- Australia/New Zealand: Comply with AS/NZS 60335.2.39 (safety) and AS/NZS 2161.1 (noise).

- Documentation: Provide commercial invoice, packing list, certificate of origin, and test reports (EMC, safety, noise) as required. For EU, issue an EU Declaration of Conformity.

Environmental & Safety Compliance

- Noise Emissions: The compressor must comply with local noise regulations. Maximum sound pressure levels should be ≤ 60 dB(A) at 1 meter for “quiet” classification. Testing per ISO 3744 or ANSI S12.15.

- Energy Efficiency: Where applicable, meet energy labeling requirements (e.g., EU Energy Label under Ecodesign Directive 2009/125/EC). Provide energy consumption data in product literature.

- Hazardous Substances: Ensure compliance with RoHS, REACH (EU), and Prop 65 (California). Declare restricted substances and provide SVHC information if requested.

- Waste Management: Adhere to WEEE (EU) or equivalent e-waste directives. Provide take-back information and recycling symbols on packaging and product.

Regulatory Certifications

- Mandatory Marks:

- CE Mark (EU)

- FCC ID (U.S., if applicable)

- CSA/UL (North America)

- RCM (Australia/NZ)

- Testing Requirements:

- Electrical safety: IEC 60335-1, IEC 60335-2-39

- Electromagnetic Compatibility (EMC): IEC 61000-6-3 (emissions), IEC 61000-6-1 (immunity)

- Noise: ISO 3744 or equivalent

- Vibration: ISO 20643 (if applicable)

- Third-Party Certification: Use accredited laboratories (e.g., TÜV, Intertek, UL) for testing and certification. Maintain technical files for audit readiness.

Storage & Distribution

- Warehouse Conditions: Store in dry, temperature-controlled environments (10°C–35°C). Avoid direct sunlight and humidity to prevent corrosion or seal degradation.

- Stacking Limits: Do not stack more than 5 layers high. Use pallets for bulk storage. Ensure forklift access paths are clear.

- Inventory Management: Implement FIFO (First In, First Out) to reduce shelf-life risks. Monitor for recalls or compliance updates.

End-of-Life & Sustainability

- Recycling Instructions: Include user guide inserts on proper disposal of electronic components and compressed air tanks.

- Take-Back Programs: Partner with local recyclers or establish return logistics for end-of-life units in regulated markets.

- Sustainability Claims: Avoid unsubstantiated “green” claims. Use only verified eco-labels (e.g., Energy Star if qualified).

Summary

Successful global distribution of the Quiet Portable Air Compressor requires strict adherence to transportation regulations, regional compliance standards, and environmental directives. Proactive certification, accurate documentation, and sustainable logistics practices ensure market access, reduce risk, and support brand integrity. Regular audits and updates to compliance protocols are recommended as regulations evolve.

In conclusion, sourcing a quiet portable air compressor requires careful consideration of several key factors including noise level (measured in decibels), portability, power source (electric or battery-operated), tank size, PSI and CFM ratings, and intended use (e.g., inflating tires, powering tools, or outdoor activities). Prioritizing models specifically designed for low noise output—typically under 60 dB—ensures minimal disturbance, making them ideal for indoor, residential, or recreational applications. Leading brands offer reliable, compact designs with features like oil-free pumps and built-in handles for ease of transport. By balancing performance, noise reduction, and portability, you can identify a compressor that meets both functional and environmental needs. Ultimately, investing in a high-quality quiet portable air compressor enhances convenience, efficiency, and user comfort across a wide range of applications.