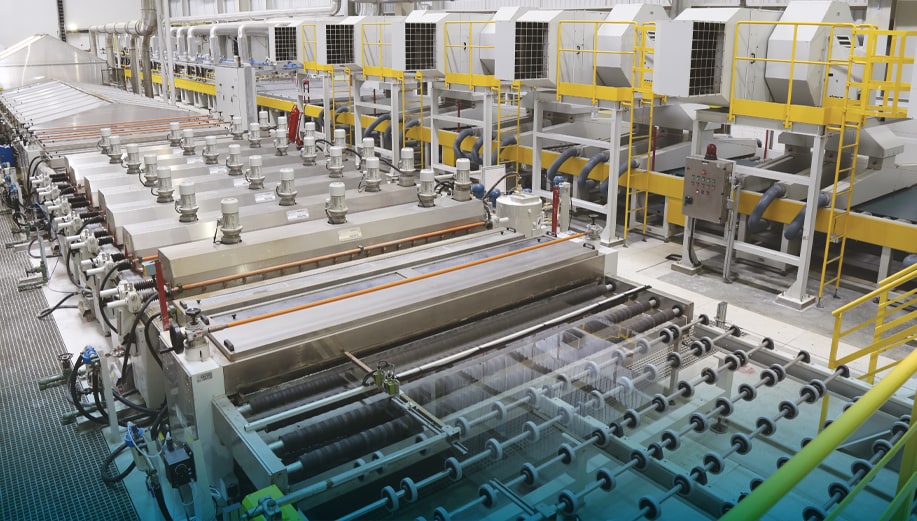

The global glass and mirror manufacturing industry is experiencing steady growth, driven by rising demand in construction, automotive, and architectural sectors. According to Mordor Intelligence, the global flat glass market was valued at USD 137.8 billion in 2023 and is projected to reach USD 178.2 billion by 2029, growing at a CAGR of 4.4% during the forecast period. This expansion is fueled by increasing urbanization, infrastructure development, and the surge in energy-efficient building designs that incorporate advanced glass solutions. Additionally, innovations in smart mirrors and reflective technologies are expanding applications in residential, commercial, and automotive end-use sectors. As demand for high-performance, sustainable, and aesthetically refined glass products rises, selecting manufacturers that combine quality, scalability, and technological innovation becomes critical. Based on production capacity, geographic reach, product diversity, and industry reputation, the following six companies stand out as leading quality glass and mirror manufacturers shaping the future of the industry.

Top 6 Quality Glass & Mirror Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Quality Glass & Mirror

Domain Est. 2004

Website: qualityglassomaha.com

Key Highlights: Quality Glass & Mirror Service, Inc. is your single source custom glass and aluminum, manufacturer, retailer and installer….

#2 Glass Repair

Domain Est. 2007

Website: akronqualityglass.com

Key Highlights: We offer a wide range of services to meet your needs. From glass replacement for windows to custom glass shower enclosures, custom mirrors, custom table tops….

#3 Quality Glass and Mirror Quality Glass and Mirror

Domain Est. 1998

Website: qualityglassandmirror.com

Key Highlights: We will give you a free estimate on shower doors, vanity mirrors, beveled mirrors, glass table tops, glass shelves or any other custom glass work that you could ……

#4 Glass & Aluminum Products

Domain Est. 2002 | Founded: 1985

Website: qualglass.com

Key Highlights: Since 1985, Quality Glass and Mirror Service, LLC has been providing quality glass and aluminum products and services to customers throughout the Midwest….

#5 Quality Glass & Mirror

Domain Est. 2015

Website: qualityglassqc.com

Key Highlights: Specializing in crafting flat glass for vintage vehicles, residential windows, and custom glass and mirror work, we have all your glass supply and service needs ……

#6 Contractor

Domain Est. 2021

Website: qualityglassnmirror.com

Key Highlights: Quality Glass & Mirror Inc – Custom Frameless Glass Shower Enclosures, Mirror, Tabletops, Sneeze Guards, Glass Shields. Easy quick installation located in ……

Expert Sourcing Insights for Quality Glass & Mirror

2026 Market Trends for Quality Glass & Mirror

The glass and mirror industry is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and increasing emphasis on sustainability. For a company like Quality Glass & Mirror, understanding these key trends is critical for strategic planning and maintaining a competitive edge.

Sustainability and Eco-Friendly Materials

Environmental responsibility will be a dominant force in 2026. Consumers and commercial clients alike are demanding greener building materials. This trend favors companies that prioritize recycled glass content, energy-efficient manufacturing processes, and low-emission coatings. Quality Glass & Mirror can capitalize by highlighting its use of sustainable practices, offering products with environmental certifications, and investing in closed-loop recycling systems for production waste.

Smart Glass and Advanced Technologies

Smart glass technologies—such as electrochromic, thermochromic, and switchable privacy glass—are transitioning from niche applications to mainstream adoption. By 2026, demand for dynamic windows that adjust tint based on sunlight, integrated mirror displays, and anti-fog or self-cleaning surfaces will grow in both residential and commercial sectors. Quality Glass & Mirror should consider expanding into high-margin smart glass solutions or partnering with technology providers to offer value-added products.

Customization and Design Innovation

Personalization remains a key driver in interior design. Homeowners and architects are seeking unique, tailor-made glass and mirror solutions—beveled edges, custom etching, colored tints, and oversized installations. Digital templating and CNC cutting technologies will enable greater precision and faster turnaround. Quality Glass & Mirror can differentiate itself by enhancing its custom design capabilities, showcasing a broader portfolio of artistic finishes, and leveraging digital tools for customer visualization.

Growth in Renovation and Remodeling

With housing markets stabilizing and many homeowners opting to renovate rather than relocate, the residential remodeling sector will remain strong through 2026. Kitchen and bathroom upgrades—where mirrors and glass showers are focal points—will drive demand. Quality Glass & Mirror can target this market with upgrade packages, energy-efficient glass options for windows and enclosures, and marketing campaigns focused on home value enhancement.

Commercial and Architectural Demand

The commercial real estate sector, particularly in healthcare, hospitality, and office spaces, will continue to invest in modern, light-filled environments. Large-format glass facades, interior glass partitions, and decorative mirror installations will be in demand for their aesthetic and functional benefits. Quality Glass & Mirror should strengthen relationships with architects, contractors, and design firms to secure project-based work and stay ahead of specification trends.

Supply Chain Resilience and Local Sourcing

Global supply chain disruptions have underscored the importance of reliability. By 2026, clients will increasingly favor suppliers with strong local sourcing, shorter lead times, and transparent logistics. Quality Glass & Mirror can gain a competitive advantage by optimizing its supply chain, investing in local inventory, and communicating reliability as a core service value.

Digital Integration and Customer Experience

Online quoting tools, augmented reality (AR) for visualizing installations, and seamless e-commerce platforms will become expected features. Customers want convenience and transparency. Enhancing the digital customer journey—from inquiry to installation scheduling—will be essential for attracting tech-savvy clients and streamlining operations.

In summary, 2026 presents both challenges and opportunities for Quality Glass & Mirror. Success will depend on embracing sustainability, adopting innovative technologies, delivering superior customization, and providing a seamless, digitally enhanced customer experience.

Common Pitfalls When Sourcing Quality Glass & Mirror (Quality, IP)

Sourcing high-quality glass and mirror products while protecting intellectual property (IP) involves navigating several potential pitfalls. Overlooking these can lead to substandard materials, production delays, legal issues, or compromised designs. Below are key challenges to avoid:

Inadequate Verification of Material Quality Standards

Many suppliers claim compliance with industry standards (e.g., ASTM, EN) but may not consistently meet them. Relying solely on certifications without third-party testing or factory audits can result in receiving glass with inconsistent clarity, thickness tolerances, or strength, leading to safety risks or product failure.

Poor Edge Work and Surface Finishing

Low-cost suppliers often cut corners on edge polishing, beveling, or surface coating processes. This leads to visible defects, chipping, or hazing, especially in high-end architectural or retail applications where aesthetics are critical.

Misrepresentation of Glass Type and Coatings

Suppliers may mislabel low-e, tempered, laminated, or insulated glass. For example, offering annealed glass as tempered or using inferior coatings that degrade under UV exposure. This compromises safety, energy efficiency, and longevity.

Inconsistent Mirror Quality and Backing Protection

Substandard mirrors often use poor silvering processes or inadequate protective backing, leading to tarnishing, spotting, or delamination over time—particularly in humid environments. Sourcing from unreliable manufacturers increases this risk.

Lack of Intellectual Property Safeguards

Custom glass designs, patterns, or mirror finishes may be reverse-engineered or replicated by suppliers and sold to competitors. Without strong contractual IP clauses, non-disclosure agreements (NDAs), and control over tooling/die ownership, your proprietary designs are vulnerable.

Insufficient Supply Chain Transparency

Opaqueness in the supply chain—such as subcontracting to unvetted third-party fabricators—can compromise both quality control and IP protection. You may not know where or how your products are actually being manufactured.

Inadequate Packaging and Handling Procedures

Glass and mirrors are fragile and prone to damage during shipping. Poor packaging—such as insufficient edge protection or improper bracing—can result in breakage, increasing costs and project delays.

Overlooking Compliance with Regional Regulations

Different markets have specific safety and environmental regulations (e.g., CE marking, CPSC, LEED). Sourcing without verifying regional compliance can lead to rejected shipments or legal liability.

Failure to Conduct On-Site Audits or Sample Testing

Relying only on digital catalogs or sample submissions without on-site production audits or independent lab testing increases the risk of quality deviations at scale.

Weak Contractual Protections for IP and Quality

Vague contracts that lack detailed quality specifications, IP ownership terms, or remedies for non-compliance leave buyers exposed. Ensure contracts clearly define tolerances, coating specs, and consequences for breaches.

By proactively addressing these pitfalls through rigorous vetting, clear contracts, and ongoing quality oversight, businesses can secure reliable, high-performance glass and mirror products while safeguarding their intellectual property.

Logistics & Compliance Guide for Quality Glass & Mirror

This guide outlines essential logistics procedures and compliance requirements for Quality Glass & Mirror to ensure safe, efficient, and legally compliant operations throughout the supply chain—from procurement to delivery.

Order Processing & Documentation

All incoming orders must be verified for accuracy, including dimensions, glass type, finish, and delivery specifications. A standardized order form or digital entry system should be used company-wide. Required documentation for each order includes:

- Purchase Order (PO) confirmation

- Bill of Lading (BOL)

- Delivery schedule

- Safety Data Sheets (SDS), if applicable for coatings or adhesives

- Certificate of Compliance for glass standards (e.g., ANSI Z97.1, CPSC 16 CFR 1201)

Ensure all documents are stored electronically with backup and are accessible to logistics, production, and customer service teams.

Material Handling & Storage

Glass panels are fragile and require careful handling to prevent breakage, injury, and product loss. Follow these protocols:

- Use vacuum lifters or suction cup handles when moving large sheets.

- Store glass vertically in designated racks with protective padding between panels.

- Keep storage areas dry, clean, and free of foot traffic.

- Label all stored glass with project name, dimensions, and handling instructions.

- Restrict access to trained personnel only.

Mirror products require additional precautions due to reflective surface vulnerability—always handle using edge grips and avoid direct contact with the reflective side.

Packaging Standards

All glass and mirror products must be packaged to withstand transit and environmental conditions. Requirements include:

- Edge protection using corrugated fiberboard or foam inserts

- Shrink-wrapping or banding for stabilization

- Wooden crating or skids for large or custom orders

- Waterproof and puncture-resistant outer wrapping

- Clear labeling with “Fragile,” “This Side Up,” and handling icons

Custom packaging must be approved by the operations manager and documented for consistency.

Transportation & Delivery

Partner only with carriers experienced in handling fragile and oversized cargo. Key transportation guidelines:

- Confirm carrier insurance coverage meets company minimums ($1 million general liability).

- Require secure strapping and load blocking during transit.

- Use GPS-tracked vehicles for high-value or time-sensitive deliveries.

- Schedule deliveries during daylight hours with confirmed customer availability.

- Drivers must be trained in unloading procedures and use proper equipment (e.g., forklifts, dollies).

For in-house deliveries, ensure all company vehicles are maintained and drivers hold valid commercial licenses if required.

Safety & Regulatory Compliance

Adhere to OSHA, DOT, and local regulations at all times:

- Conduct monthly safety training for warehouse and delivery staff.

- Maintain up-to-date Material Safety Data Sheets (MSDS/SDS) for all chemicals used in production.

- Comply with Department of Transportation (DOT) regulations for hazardous materials (e.g., sealants, cleaners).

- Follow ANSI Z765 for measuring residential glass and glazing standards.

- Ensure compliance with building codes such as the International Building Code (IBC) and local ordinances.

All incidents (breakage, injuries, delivery errors) must be reported and logged within 24 hours.

Environmental & Sustainability Practices

Quality Glass & Mirror is committed to sustainable operations:

- Recycle all cardboard, wood, and metal scrap materials.

- Use low-VOC sealants and adhesives whenever possible.

- Optimize delivery routes to reduce fuel consumption.

- Partner with suppliers who demonstrate environmental responsibility.

Track and report sustainability metrics quarterly.

Customer Acceptance & Returns

Upon delivery:

- Obtain a signed delivery confirmation from the customer.

- Document product condition with photos if damage is suspected.

- Address claims within 48 hours; process replacements per warranty policy.

Returns are accepted only for manufacturing defects or delivery errors, with management approval. Refunds or credits must align with company policy and state regulations.

Audits & Continuous Improvement

Conduct internal logistics audits every quarter to assess:

- Compliance with safety and handling protocols

- Accuracy of documentation

- On-time delivery performance

- Customer satisfaction feedback

Use audit findings to refine processes, retrain staff, and improve supply chain efficiency.

By following this guide, Quality Glass & Mirror ensures consistent product quality, regulatory compliance, and customer trust across all logistics operations.

In conclusion, sourcing high-quality glass and mirrors requires a strategic approach that prioritizes material standards, supplier reliability, and specific application needs. By partnering with reputable manufacturers and suppliers who adhere to industry certifications and quality control processes, businesses can ensure durability, clarity, and safety in their products. Attention to factors such as thickness, finish, coatings, and customization options further enhances performance and aesthetic value. Ultimately, investing in premium glass and mirror materials not only improves end-user satisfaction but also supports long-term cost-efficiency and brand reputation. Conducting thorough research, requesting samples, and maintaining clear communication with suppliers are essential steps in achieving consistent quality and successful project outcomes.