The global PVC roof tiles market is experiencing steady momentum, driven by increasing demand for lightweight, corrosion-resistant, and cost-effective roofing solutions in both residential and commercial construction. According to a report by Mordor Intelligence, the global plastic roofing market—of which PVC roof tiles are a key segment—is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This growth is fueled by rapid urbanization, infrastructure development in emerging economies, and a rising preference for sustainable and long-life building materials. PVC roof tiles, known for their durability, low maintenance, and energy efficiency, are increasingly replacing traditional materials like concrete and metal. With expanding applications in tropical and coastal regions due to their resistance to UV exposure and harsh weather, the demand for high-performance PVC roofing has spurred innovation and competition among manufacturers. As the market evolves, several key players are emerging as leaders in technology, production scale, and product quality—shaping the future of modern roofing solutions.

Top 10 Pvc Roof Tiles Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

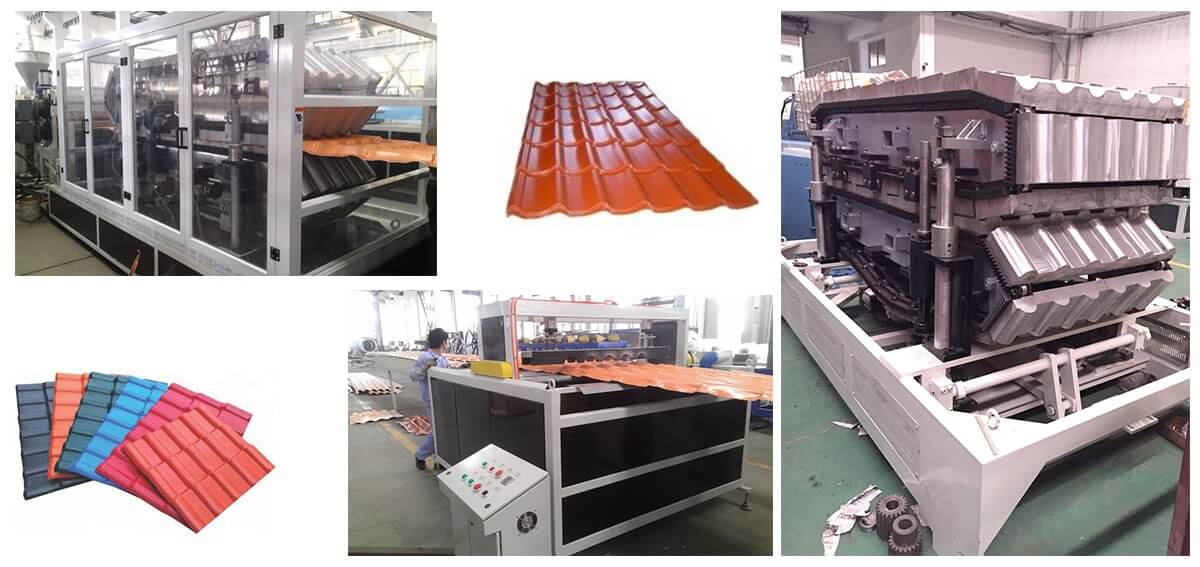

#1 Guangdong Yangming Photovoltaic Technology Co., Ltd.

Website: lessoroofingsheet.com

Key Highlights: Professional roofing materials manufacturer with 40000㎡ facility & 15 production lines. Offering innovative UPVC & resin roofing solutions with advanced R&D ……

#2 PVC Roofing Tile Manufacturers and Suppliers

Domain Est. 2018

Website: pingyunrooftile.com

Key Highlights: Find professional PVC roofing tile manufacturers and suppliers in China here. Our factory also provides high quality PVC roofing tile with cheap price, ……

#3 GAF Roofing

Domain Est. 1996

Website: gaf.com

Key Highlights: As North America’s largest roofing manufacturer, GAF is an industry leader that produces quality, innovative roofing materials….

#4 Sangobuild

Domain Est. 2014

Website: sangobuild.com

Key Highlights: SANGOBUILD is the roof tile manufacturer among the stone coated roofing tile field who pass the ISO9001:2008 Quality Management System….

#5 Gongli PVC Roof Manufacturers and Building Materials

Domain Est. 2018

Website: glroofsheet.com

Key Highlights: High-quality PVC roof sheet products from GONGLI pvc roofing , one of the leading PVC roof manufacturers in China, providing durable building materials for ……

#6 Your Trusted Pvc Roof Tiles Manufacturers

Website: duolongtrade.com

Key Highlights: At Duolong Trade, we specialize in manufacturing high-performance PVC roof tiles designed for building material wholesalers, regional trading companies, ……

#7 Eagle Roofing

Domain Est. 1995

Website: eagleroofing.com

Key Highlights: For 30 years, Eagle Roofing Products has manufactured high quality roofing solutions that are durable, long-lasting and environmentally friendly….

#8 PVC Roofing Systems

Domain Est. 1997

Website: jm.com

Key Highlights: Built to withstand the test of time, our PVC roofing membranes are made to resist the toughest weather conditions and chemicals….

#9 IB Roof Systems

Domain Est. 1997

Website: ibroof.com

Key Highlights: IB Roof Systems is the leader in roof membrane, manufacturing durable pre-fab single-ply pvc roofs for commercial systems. Easy installation, saves money….

#10 BRAVA Roof Tile

Domain Est. 2016

Website: bravarooftile.com

Key Highlights: Brava Roof Tile manufactures the best synthetic slate, cedar shake, & Spanish roofing tiles with a 50-year warranty. See why composite roof tile is better!…

Expert Sourcing Insights for Pvc Roof Tiles

2026 Market Trends for PVC Roof Tiles

The global market for PVC roof tiles is poised for significant transformation by 2026, driven by evolving construction practices, sustainability demands, and technological advancements. Several key trends are expected to shape the industry landscape:

H2: Rising Demand for Lightweight and Easy-Installation Roofing Solutions

As labor costs rise and construction timelines shorten globally, the demand for lightweight, DIY-friendly roofing materials continues to grow. PVC roof tiles offer a distinct advantage with their low weight, reducing structural load requirements and simplifying transportation and installation. By 2026, manufacturers will increasingly focus on modular designs and interlocking systems that enable faster, tool-free installation—appealing to both contractors and homeowners, especially in emerging markets and regions prone to rapid urbanization.

H2: Enhanced Focus on Sustainability and Recyclability

Environmental regulations and consumer preferences are pushing the construction industry toward greener materials. Although traditional PVC has faced criticism for environmental impact, the industry is responding with innovations in recycled-content PVC and improved end-of-life recyclability. By 2026, expect wider adoption of bio-based plasticizers and post-consumer recycled PVC in roof tile formulations. Certifications such as EPDs (Environmental Product Declarations) and compliance with green building standards (e.g., LEED, BREEAM) will become critical differentiators in competitive markets.

H2: Expansion in Emerging Economies

Fast-growing construction sectors in Asia-Pacific, Africa, and Latin America will be primary drivers of PVC roof tile demand by 2026. Countries like India, Indonesia, Nigeria, and Mexico are witnessing increased rural and urban housing initiatives where cost-effective, durable, and weather-resistant materials are essential. Government infrastructure programs and low-cost housing projects will accelerate the adoption of PVC tiles as an affordable alternative to concrete or clay tiles, particularly in tropical and high-rainfall regions.

H2: Technological Advancements in Durability and Aesthetics

Ongoing R&D efforts are enhancing the performance of PVC roof tiles, particularly in UV resistance, thermal stability, and impact strength. By 2026, next-generation tiles will feature advanced co-extrusion techniques that provide superior color retention and weatherability. Additionally, manufacturers are investing in realistic textures and colors to mimic traditional materials like slate, wood, or terracotta, making PVC tiles more appealing in residential and architectural applications where aesthetics matter.

H2: Competitive Pressure and Price Volatility

While PVC offers cost advantages, raw material price fluctuations—especially linked to oil markets—pose risks. By 2026, manufacturers may adopt hedging strategies or vertical integration to stabilize costs. Increased competition from alternative synthetic roofing materials (e.g., modified bitumen, composite polymers) will pressure PVC producers to innovate and offer value-added features such as solar reflectivity or integrated insulation layers to maintain market share.

In conclusion, the 2026 outlook for PVC roof tiles is optimistic, underpinned by demand for efficient, sustainable, and aesthetically pleasing roofing solutions. Success will depend on the industry’s ability to innovate, respond to environmental concerns, and expand strategically in high-growth regions.

Common Pitfalls When Sourcing PVC Roof Tiles (Quality and Intellectual Property)

Sourcing PVC roof tiles can offer cost-effective and durable roofing solutions, but buyers often encounter significant challenges related to quality inconsistencies and intellectual property (IP) risks. Being aware of these pitfalls is crucial to ensuring long-term performance and legal compliance.

Poor Material Quality and Durability

One of the most frequent issues is receiving PVC roof tiles made from low-grade or recycled materials that degrade quickly under UV exposure, extreme temperatures, or physical stress. Inferior formulations may lead to discoloration, warping, brittleness, or cracking within a few years, undermining the expected lifespan of the product.

Lack of Standard Certification and Testing

Many suppliers, especially in less regulated markets, fail to provide tiles that meet international standards such as ISO, ASTM, or local building codes. Without proper certification, buyers risk installing non-compliant materials that may not withstand environmental loads, leading to safety hazards and costly replacements.

Inconsistent Product Dimensions and Fit

Poor manufacturing control can result in tiles with inconsistent thickness, length, or interlocking mechanisms. This leads to installation difficulties, gaps in coverage, water leakage, and an unprofessional appearance—increasing labor costs and reducing overall roof integrity.

Misrepresentation of Product Specifications

Some suppliers exaggerate technical claims, such as fire resistance, UV protection, or lifespan. For example, a tile may be advertised as “UV-stabilized for 20 years” but lacks verifiable test reports or independent lab validation, leading to premature failure in real-world conditions.

Intellectual Property Infringement Risks

Sourcing PVC roof tiles from certain manufacturers may expose buyers to IP violations. Some suppliers replicate patented tile designs, profiles, or branding without authorization. Purchasing such products—even unknowingly—can lead to legal liabilities, shipment seizures, or reputational damage, especially in regulated markets.

Counterfeit or Grey Market Products

Low-cost offers may involve counterfeit tiles or grey market goods that bypass official distribution channels. These products often lack warranty support, technical documentation, and traceability, making it difficult to address defects or performance issues after installation.

Inadequate Technical Support and Warranty

Reputable suppliers provide detailed installation guidelines, structural support data, and clear warranty terms. Many low-cost vendors offer little to no technical assistance or void warranties under vague conditions, leaving buyers without recourse when problems arise.

Unverified Manufacturing Practices

Suppliers may outsource production to unveted third-party factories with substandard quality control. Without on-site audits or transparent supply chains, buyers cannot ensure consistency or ethical manufacturing practices, increasing the risk of defective batches.

Mitigating these pitfalls requires due diligence: vetting suppliers thoroughly, requesting material test reports, verifying IP rights, and securing contractual quality assurances before placing orders.

Logistics & Compliance Guide for PVC Roof Tiles

Overview

PVC roof tiles offer a lightweight, durable, and weather-resistant roofing solution. However, their successful distribution and installation depend on proper logistics planning and adherence to regulatory compliance standards across different markets. This guide outlines key considerations for the safe transport, storage, and compliance of PVC roof tiles.

Packaging & Handling

- Protective Packaging: PVC roof tiles should be packed in robust, weather-resistant wrapping (typically plastic film or shrink-wrapped bundles) on wooden or composite pallets to prevent deformation and surface damage.

- Stacking & Weight Limits: Pallets must be stacked evenly and not exceed height or weight limits specified by the manufacturer to avoid collapse during transit.

- Manual Handling: Provide clear handling instructions to prevent cracking or warping. Avoid dragging or dropping tiles. Use mechanical aids (e.g., forklifts) where possible.

- Labeling: Pallets must be clearly labeled with product type, dimensions, batch number, handling instructions (e.g., “Fragile,” “This Side Up”), and safety warnings.

Transportation

- Vehicle Requirements: Use enclosed or covered trucks to protect tiles from UV exposure, rain, and debris. Secure loads with straps or nets to prevent shifting.

- Temperature Control: Avoid prolonged exposure to extreme temperatures during transit, as high heat may cause warping or deformation of PVC materials.

- Transit Time & Route Planning: Minimize transit time and avoid routes with excessive vibration or rough terrain to reduce the risk of damage.

- International Shipping: For export, comply with International Maritime Dangerous Goods (IMDG) Code if applicable. PVC is generally non-hazardous, but documentation must confirm this. Use ISPM 15-compliant wooden pallets for international shipments.

Storage

- Indoor Storage Recommended: Store tiles indoors in a dry, well-ventilated area away from direct sunlight to prevent UV degradation and thermal expansion.

- Pallet Placement: Keep pallets on a level surface, elevated off the ground using pallets or racks to avoid moisture absorption.

- Stacking Height: Do not stack more than the manufacturer’s recommended number of layers to prevent bottom tiles from deforming.

- Fire Safety: Store away from open flames and high-heat sources. PVC is combustible and may emit toxic fumes when burned.

Regulatory Compliance

- Building Codes & Standards: Ensure tiles meet local building regulations (e.g., International Building Code – IBC, Eurocode, or country-specific standards). Confirm compliance with fire resistance, wind uplift, and load-bearing requirements.

- Fire Safety Regulations: PVC roof tiles must comply with fire performance standards such as ASTM E108 (U.S.) or EN 13501-1 (EU). Provide fire classification certificates (e.g., Class A, B, or C ratings).

- Environmental Regulations: Adhere to REACH (EU), RoHS, and other chemical restriction directives regarding phthalates, lead stabilizers, or other regulated substances in PVC formulations.

- Recycling & End-of-Life: Comply with local waste management laws. Provide information on recyclability and disposal methods, as PVC is recyclable but requires specialized processing.

Documentation

- Certificates of Conformity: Supply test reports and certifications (e.g., ISO 9001, CE Marking, or ANSI standards) to verify product quality and compliance.

- Safety Data Sheets (SDS): Provide SDS in accordance with GHS standards, particularly for occupational safety during handling and installation.

- Customs Documentation: For exports, include commercial invoices, packing lists, certificates of origin, and any required import permits or product-specific attestations.

Installation Guidelines (Compliance-Related)

- Manufacturer Instructions: Distribute approved installation manuals to ensure tiles are fixed according to structural and weatherproofing standards.

- Ventilation & Expansion Gaps: Emphasize the need for proper spacing to accommodate thermal expansion, preventing buckling.

- Fastener Compatibility: Recommend corrosion-resistant fasteners and correct spacing to meet wind load requirements.

Quality Assurance & Traceability

- Batch Tracking: Maintain batch traceability to support recalls or quality investigations.

- Pre-Shipment Inspection: Conduct quality checks before dispatch to ensure tiles meet dimensional, color, and performance specifications.

- Customer Support: Provide technical support and compliance documentation upon request to facilitate permitting and inspection processes.

Conclusion

Effective logistics and strict compliance are essential for the successful distribution of PVC roof tiles. Adhering to proper handling, storage, transportation, and regulatory standards ensures product integrity, safety, and market acceptance. Always consult local authorities and standards organizations to stay updated on evolving requirements.

Conclusion on Sourcing PVC Roof Tiles

Sourcing PVC roof tiles presents a viable, cost-effective, and sustainable solution for modern construction needs, particularly in regions requiring durable, lightweight, and weather-resistant roofing materials. These tiles offer advantages such as low maintenance, excellent insulation properties, resistance to corrosion and UV degradation, and ease of installation. Additionally, their long lifespan and recyclability contribute to environmentally responsible building practices.

When sourcing PVC roof tiles, it is essential to consider factors such as material quality, manufacturer reputation, compliance with local building standards, and long-term performance under specific climate conditions. Sourcing from reputable suppliers—either locally or internationally—ensures product reliability and access to technical support and warranties.

In conclusion, PVC roof tiles are a competitive alternative to traditional roofing materials, especially for budget-conscious and eco-friendly projects. With proper due diligence in supplier selection and adherence to quality standards, sourcing PVC roof tiles can deliver durable, aesthetically pleasing, and economically sound roofing solutions for residential, commercial, and industrial applications.