The global PVC pipe irrigation systems market is experiencing robust growth, driven by rising demand for water-efficient agricultural practices, expanding farmland in developing regions, and supportive government initiatives promoting micro-irrigation. According to a report by Mordor Intelligence, the global agricultural irrigation systems market is projected to grow at a CAGR of over 7.5% from 2024 to 2029, with PVC piping remaining a dominant material due to its affordability, durability, and ease of installation. Similarly, Grand View Research estimates that the global plastic pipes and fittings market, which includes PVC, will expand at a CAGR of 5.8% from 2023 to 2030, fueled by increased infrastructure investments and the push for sustainable water management. As the demand for reliable and cost-effective irrigation solutions continues to rise, manufacturers specializing in PVC pipe systems are at the forefront of innovation and scalability. Below, we spotlight the top 10 PVC pipe irrigation system manufacturers shaping the future of modern agriculture.

Top 10 Pvc Pipe Irrigation System Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 JM Eagle™

Domain Est. 2007

Website: jmeagle.com

Key Highlights: JM Eagle is the innovative leader that combines advanced technology with superior customer service to create the industry’s most sophisticated and diverse ……

#2 Cresline Plastic Pipe Co.

Domain Est. 1998

Website: cresline.com

Key Highlights: As one of the largest full-line pipe manufacturers, Cresline’s family of companies offers industry leading coast-to-coast service….

#3 Drip Irrigation System & Technology

Domain Est. 2000

Website: netafimusa.com

Key Highlights: Netafim is the world’s leading drip irrigation technology company supplying multiple industries with smart drip irrigation systems that help to fight food ……

#4 Spears Manufacturing, PVC & CPVC Plastic Pipe Fittings & Valves

Domain Est. 1996

Website: spearsmfg.com

Key Highlights: ISO9001 Certified – PVC & CPVC Sch 40 and 80 fittings molded from 1/8 – 14 inch….

#5 Netafim

Domain Est. 1996

Website: netafim.com

Key Highlights: Netafim is the global leader in drip irrigation solutions. Since introducing the world’s first drip irrigation system, we continuously develop innovative ……

#6 Irrigation Piping Offerings

Domain Est. 1997

Website: charlottepipe.com

Key Highlights: We manufacture a complete line of irrigation piping, including standard and specialty irrigation, DWV, and pressure products. Explore more resources here….

#7 Jain Irrigation Systems Ltd.

Domain Est. 1997

Website: jains.com

Key Highlights: Products We Offer · Drip Irrigation Systems · Micro & Mini Sprinklers · Sprinkler Irrigation · Filters, Dosing Pump & Injectors · PVC Pipes & Fittings · PE Pipes & ……

#8 DBC Irrigation Supply

Domain Est. 2000

Website: dbcirrigation.com

Key Highlights: 30-day returnsDBC Irrigation Supply is a locally owned wholesale and retail supplier of irrigation and outdoor living products….

#9 PVC Irrigation Pipe

Domain Est. 2009

Website: ipexna.com

Key Highlights: We manufacture a full range of PVC Irrigation pipe and fittings, offering an end-to-end solution for any customer need….

#10 Agriculture & Irrigation PVC Systems

Domain Est. 2021

Website: westlakepipe.com

Key Highlights: Westlake Pipe & Fittings is a leading provider of corrosion- and chemical-resistant PVC irrigation pipe and fittings for the agriculture and irrigation ……

Expert Sourcing Insights for Pvc Pipe Irrigation System

2026 Market Trends for PVC Pipe Irrigation Systems

The global market for PVC pipe irrigation systems is poised for significant transformation by 2026, driven by technological advancements, environmental considerations, and evolving agricultural demands. This analysis explores key trends shaping the industry, including growth drivers, regional developments, sustainability concerns, and competitive dynamics.

Increasing Adoption in Precision Agriculture

A major trend influencing the PVC pipe irrigation market is the rising integration of PVC systems into precision agriculture frameworks. Farmers are increasingly adopting drip and sprinkler irrigation systems that rely heavily on PVC piping due to their durability, cost-efficiency, and ease of installation. By 2026, the demand for smart irrigation solutions—compatible with IoT sensors and automated water management systems—is expected to boost PVC pipe usage, especially in emerging economies with expanding agricultural sectors.

Sustainability and Environmental Regulations

Environmental concerns are reshaping material preferences in irrigation infrastructure. While PVC is cost-effective and long-lasting, it faces scrutiny over its environmental footprint, particularly regarding recyclability and plastic waste. By 2026, regulatory pressures in Europe and North America may push manufacturers to develop eco-friendly PVC formulations or promote recyclable variants. Additionally, the push for circular economy models could lead to greater investment in PVC recycling technologies tailored for agricultural reuse.

Regional Market Expansion

Asia-Pacific is expected to dominate the PVC pipe irrigation market by 2026, led by countries such as India, China, and Indonesia, where government initiatives support modernized irrigation to enhance food security. In Africa, growing investments in agricultural infrastructure—backed by international development agencies—will increase demand for affordable and reliable PVC-based systems. Meanwhile, in the Americas, drought-prone regions like the U.S. Southwest and parts of Latin America will continue to rely on efficient PVC irrigation networks to conserve water.

Cost-Effectiveness and Infrastructure Development

PVC remains the preferred material for irrigation due to its low cost, corrosion resistance, and lightweight nature. As governments and private sectors invest in rural electrification and irrigation infrastructure, PVC pipes offer a scalable solution. By 2026, ongoing rural development projects, particularly in South Asia and Sub-Saharan Africa, will sustain strong demand for PVC irrigation systems, outpacing alternatives like HDPE or metal pipes in many cost-sensitive markets.

Technological Innovations and Product Enhancements

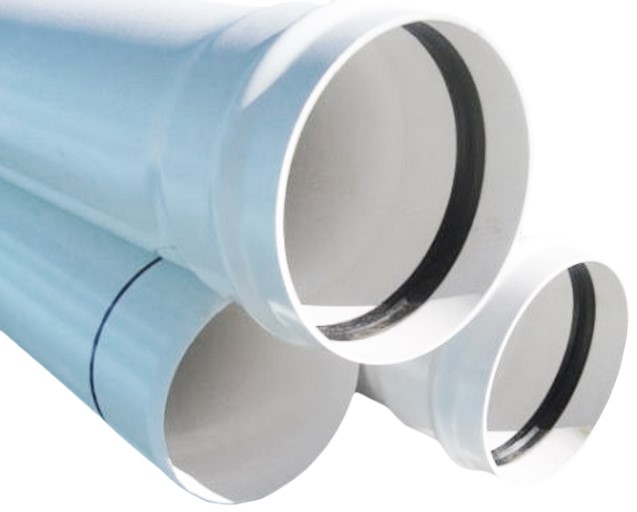

Manufacturers are responding to market demands by introducing UV-stabilized, high-pressure-rated, and antimicrobial PVC pipes designed specifically for irrigation. Innovations such as co-extruded PVC pipes with enhanced durability and reduced biofilm formation are gaining traction. By 2026, these value-added products are expected to capture a growing share of the market, particularly in commercial farming and greenhouse applications.

Competitive Landscape and Market Consolidation

The PVC irrigation pipe market is becoming increasingly competitive, with key players expanding production capacities and entering strategic partnerships. Companies are focusing on vertical integration—controlling raw material supply to finished product delivery—to improve margins and ensure quality. By 2026, market consolidation is likely, with larger manufacturers acquiring regional suppliers to strengthen distribution networks and increase global reach.

Conclusion

By 2026, the PVC pipe irrigation system market will be shaped by a convergence of agricultural modernization, environmental responsibility, and regional infrastructure growth. While challenges around sustainability persist, ongoing innovation and strong demand in developing regions position PVC as a resilient and adaptive solution in global irrigation. Stakeholders who invest in eco-conscious manufacturing and smart integration capabilities will be best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing PVC Pipe Irrigation Systems (Quality & Intellectual Property)

Sourcing PVC pipe irrigation systems involves more than just selecting the right diameter and length. Overlooking key quality and intellectual property (IP) aspects can lead to system failures, financial losses, and legal risks. Below are common pitfalls to avoid:

Poor Material Quality and Non-Compliance

One of the most frequent issues is sourcing PVC pipes made from substandard or recycled materials that do not meet industry standards (e.g., ASTM D1785 or ISO 4422). Low-quality PVC may degrade quickly under UV exposure, crack in fluctuating temperatures, or fail under pressure, leading to leaks and costly repairs. Always verify material certifications and ensure pipes are rated for irrigation use and local environmental conditions.

Inconsistent Wall Thickness and Dimensional Tolerances

Inferior PVC pipes often have inconsistent wall thickness, which compromises pressure ratings and structural integrity. Pipes that fall outside acceptable dimensional tolerances may not fit properly with fittings, causing leaks or system inefficiencies. Request samples and conduct dimensional inspections before bulk ordering to confirm compliance with specifications.

Lack of UV and Chemical Resistance

Many low-cost PVC pipes are not adequately stabilized against UV radiation, leading to embrittlement and premature failure when exposed to sunlight. Similarly, some pipes may degrade when in contact with certain fertilizers or water treatments. Ensure the PVC formulation includes proper UV inhibitors and chemical resistance additives suitable for agricultural applications.

Counterfeit or Unbranded Products

Some suppliers offer generic or counterfeit versions of branded irrigation systems at lower prices. These may mimic reputable brands but fail to meet performance standards. Always source from authorized distributors or directly from manufacturers with verifiable supply chains. Check for authentic branding, batch numbers, and traceability documentation.

Ignoring Intellectual Property Rights

Using or distributing PVC irrigation components that infringe on patented designs, trademarks, or proprietary technologies can result in legal action, product seizures, or financial penalties. For example, using a patented coupling design or copying a branded valve mechanism without authorization violates IP laws. Conduct due diligence on suppliers and request IP compliance statements to mitigate risk.

Inadequate Documentation and Traceability

Reputable suppliers provide technical data sheets, compliance certificates, and batch traceability. Sourcing from vendors who lack proper documentation increases the risk of receiving non-compliant or unsafe products. Ensure all materials come with clear labeling and documentation for quality audits and warranty claims.

Overlooking Long-Term Supplier Reliability

Choosing suppliers based solely on low prices can backfire if they lack consistent quality control or vanish after delivery. Establish long-term relationships with suppliers who offer warranties, technical support, and proven track records in agricultural irrigation projects. This ensures ongoing quality and support for system maintenance.

By addressing these pitfalls proactively, buyers can secure reliable, high-performing PVC irrigation systems while avoiding legal and operational risks associated with poor quality and IP violations.

Logistics & Compliance Guide for PVC Pipe Irrigation System

Overview

This guide outlines the essential logistics considerations and regulatory compliance requirements for the procurement, transportation, installation, and maintenance of PVC pipe irrigation systems. Adhering to these guidelines ensures project efficiency, safety, environmental responsibility, and legal compliance.

Procurement & Sourcing

Source PVC pipes and fittings from certified manufacturers that comply with recognized standards such as ASTM D1785 (for pressure-rated PVC pipe) or ISO 1452. Ensure all materials meet specifications for irrigation use, including UV resistance, pressure class (e.g., Class 125, 200), and temperature tolerance. Request product conformity certificates and material test reports (MTRs) to verify compliance.

Transportation & Handling

PVC pipes are sensitive to impact, heat, and prolonged UV exposure. Transport pipes horizontally on flatbed trucks using cradles or supports to prevent bending. Secure loads to avoid shifting. Avoid dragging pipes and protect end caps during unloading. Store materials in shaded, dry areas off the ground, and cover with UV-resistant tarpaulins if stored outdoors for extended periods.

Import & Customs Compliance (International Shipments)

For cross-border shipments, ensure PVC irrigation components comply with destination country regulations. Prepare accurate documentation including commercial invoices, packing lists, and certificates of origin. Confirm compliance with local standards (e.g., NSF/ANSI 61 for potable water contact in the U.S., WRAS in the UK). Declare goods under the correct HS code (typically 3917.32 for rigid PVC pipes). Check for import duties, anti-dumping regulations, or environmental restrictions.

Regulatory Standards & Certifications

Verify that the PVC irrigation system meets applicable national and regional standards:

– United States: ASTM D1785, NSF/ANSI 61 (for safe water contact), NSF/ANSI 14 (plastic piping system components).

– European Union: EN 1452 series, CE marking per Construction Products Regulation (CPR).

– Australia: AS/NZS 1477.

– Other Regions: Confirm compliance with local water authority or agricultural department requirements.

Retain all certification documents for audits and inspections.

Environmental & Safety Compliance

PVC production and disposal have environmental implications. Ensure compliance with REACH (EU), RoHS, or TSCA (U.S.) regarding restricted substances. Avoid open burning of PVC waste—dispose of scrap through approved recycling programs. On-site, follow OSHA or local safety regulations during installation, including trenching safety, use of PPE, and handling of solvents and adhesives.

Installation & Field Compliance

Install systems in accordance with manufacturer instructions and engineering designs. Use approved PVC cements and primers rated for irrigation use. Pressure-test completed sections per local codes (typically 1.5x working pressure for 2 hours). Document installation with as-built drawings and inspection reports. Comply with local plumbing, agricultural, and water rights regulations, including permits for water extraction or land modification.

Maintenance & Record Keeping

Establish a maintenance schedule to inspect for leaks, blockages, and UV degradation. Replace damaged sections promptly using compliant materials. Maintain records of product certifications, installation logs, pressure tests, and repairs for a minimum of five years, or as required by local authorities.

Disposal & End-of-Life Management

At system decommissioning, recycle PVC components through certified recyclers where available. Document disposal methods to ensure compliance with local waste management laws and reduce environmental impact.

Conclusion

Effective logistics and strict compliance with applicable standards are critical for the performance and sustainability of PVC pipe irrigation systems. Proactive planning, documentation, and adherence to regulations support project success and long-term operational reliability.

Conclusion for Sourcing PVC Pipe Irrigation System

Sourcing a PVC pipe irrigation system offers a cost-effective, durable, and efficient solution for agricultural and landscaping water distribution needs. PVC pipes are widely available, easy to install, and resistant to corrosion, making them an ideal choice for both small-scale and large-scale irrigation projects. When sourcing, it is essential to consider factors such as pipe quality, compliance with industry standards (e.g., ISO, ASTM), supplier reliability, and long-term maintenance requirements. By selecting reputable suppliers and high-grade materials, stakeholders can ensure system longevity, minimize water loss, and optimize irrigation performance. Ultimately, a well-sourced PVC irrigation system contributes to improved water management, enhanced crop yields, and sustainable agricultural practices.