The global PVC panel wall market is experiencing robust growth, driven by rising demand for cost-effective, durable, and low-maintenance interior finishing solutions across residential, commercial, and industrial sectors. According to a 2023 report by Grand View Research, the global PVC wall panel market size was valued at USD 37.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. This growth is fueled by rapid urbanization, increasing renovation activities, and a shift toward sustainable building materials with longer lifespans. Additionally, PVC panels offer advantages such as moisture resistance, ease of installation, and design versatility, making them a preferred alternative to traditional wall coverings like paint, tiles, and wood. As construction activities surge across emerging economies and environmental regulations push for energy-efficient materials, manufacturers are investing in innovation and scalable production. In this evolving landscape, a select group of companies are leading the charge in product development, market reach, and sustainability. Based on market presence, production capacity, product range, and innovation, here are the top 10 PVC panel wall manufacturers shaping the industry today.

Top 10 Pvc Panel Wall Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Palram Americas

Domain Est. 1999

Website: palram.com

Key Highlights: Palram is the leading polycarbonate manufacturer and PVC supplier. Explore our wide range of thermoplastic technology solutions….

#2 Custom Decorative Wood Wall Panels Manufacturers, Factory

Domain Est. 2020

Website: ltpvcfactory.com

Key Highlights: Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other ……

#3 Manufacturer of PVC Plastic Wall & Ceiling Panels

Domain Est. 2000

Website: epiplastics.com

Key Highlights: Our web site offers a wide selection of panel designs, suited for different applications that require sanitation, moisture and corrosion resistant….

#4 Dumaplast: Sustainable PVC wall cladding

Domain Est. 2012

Website: dumaplast.com

Key Highlights: Dumaplast is a leading manufacturer of PVC wall cladding, ceiling cladding, waterproof flooring, outside wall cladding and much more….

#5 PVC Panel Suppliers

Domain Est. 2017

Website: duramaxpvcpanels.com

Key Highlights: Duramax PVC Wall Panels is the premier manufacturer of Plastic Panels and Vinyl Wall Paneling. Vinyl panels are a perfect replacement for FRP Wall Panels….

#6 PVC Wall Panel Manufacturer in India

Website: pvcwallpanelmanufacturer.com

Key Highlights: Manufacturer of PVC wall panels for interiors, ceilings & commercial spaces. Decorative, waterproof & durable panels. Bulk supply across India….

#7 Wetwall

Domain Est. 1999

Website: wetwall.com

Key Highlights: Discover a wide range of waterproof wall solutions at Wetwall. Enhance your spaces with our premium collection of stylish and durable wet wall panels….

#8 Trusscore

Domain Est. 2002

Website: trusscore.com

Key Highlights: … . Our PVC-based wall and ceiling panels are easy-to-install and high-performance replacements for traditional drywall and fiber-reinforced plastic panels….

#9 Wall Paneling

Domain Est. 2002

Website: imeca.com

Key Highlights: From adding warmth and texture to creating a focal point or accent wall, our wall paneling products provide endless design possibilities….

#10 PVC Panels For Walls & Ceilings

Domain Est. 2012

Website: delbypvcpanels.com

Key Highlights: Delby provides different types and colors of laminate flooring pvc wall panels for home, offices, bathroom which are environment friendly and best in price….

Expert Sourcing Insights for Pvc Panel Wall

2026 Market Trends for PVC Panel Wall

The global market for PVC panel walls is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and increasing demand in both residential and commercial construction. As sustainability, cost-efficiency, and design flexibility become central to interior solutions, PVC panel walls are emerging as a preferred alternative to traditional materials like drywall, wood, and ceramic tiles. This analysis explores key market trends expected to shape the PVC panel wall industry in 2026.

Rising Demand in Residential and Commercial Sectors

By 2026, the demand for PVC panel walls is projected to grow substantially in both residential and commercial applications. In residential spaces, homeowners are increasingly opting for PVC panels due to their ease of installation, moisture resistance, and low maintenance—especially in kitchens, bathrooms, and basements. The modular design allows for quick renovation with minimal disruption, appealing to urban dwellers and property renovators.

In the commercial sector, hotels, hospitals, offices, and retail spaces are adopting PVC panels for their durability and hygienic properties. The non-porous surface resists mold and bacteria, making it ideal for healthcare environments. Additionally, the ability to customize textures and finishes supports branding and aesthetic goals in retail and hospitality.

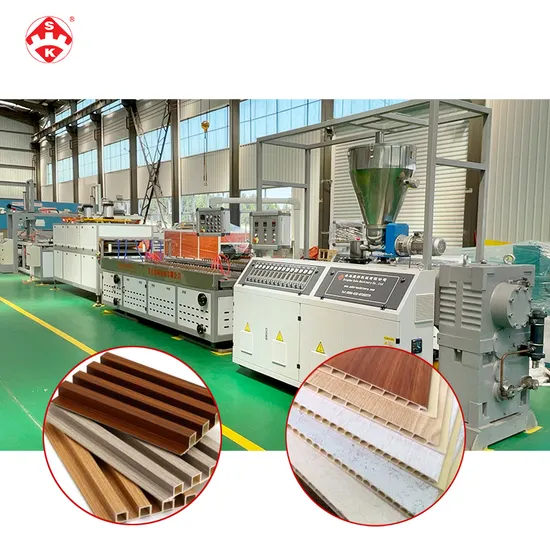

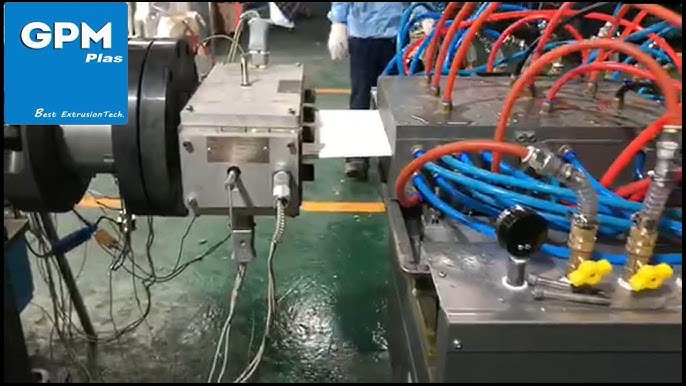

Advancements in Design and Material Innovation

One of the most influential trends shaping the 2026 market is the rapid innovation in PVC panel design and manufacturing. Manufacturers are introducing panels that mimic natural materials such as wood, marble, and stone with high-definition printing and embossing techniques. These realistic finishes enhance visual appeal without the high cost or maintenance of authentic materials.

Moreover, the development of fire-retardant, anti-microbial, and UV-resistant PVC formulations is expanding the application scope. Smart-integrated panels featuring embedded lighting, sound insulation, or IoT connectivity are beginning to enter premium segments, particularly in smart homes and high-end offices.

Sustainability and Eco-Friendly Production

Environmental concerns are reshaping the PVC panel market. While traditional PVC has faced criticism for its environmental impact, especially regarding disposal and chlorine content, the industry is responding with greener alternatives. By 2026, an increasing number of manufacturers are expected to use recycled PVC content and adopt closed-loop production systems to reduce waste.

Bio-based plasticizers and chlorine-free formulations are being explored to improve the eco-profile of PVC panels. Certifications such as Greenguard and Cradle to Cradle are becoming more common, helping environmentally conscious consumers and businesses make informed choices. Regulatory pressures in Europe and North America are expected to accelerate the shift toward sustainable PVC solutions.

Growth in Emerging Markets

Emerging economies in Asia-Pacific, Latin America, and Africa are expected to be major growth drivers for the PVC panel wall market by 2026. Rapid urbanization, expanding middle-class populations, and government initiatives for affordable housing are increasing demand for cost-effective and durable interior finishing materials.

Countries like India, Indonesia, and Vietnam are witnessing a construction boom, with PVC panels gaining favor due to their quick installation and resilience in humid climates. Local manufacturing is on the rise, reducing import dependency and lowering prices, further stimulating market penetration.

E-Commerce and Direct-to-Consumer Distribution

The distribution landscape for PVC panel walls is evolving, with e-commerce platforms playing a larger role by 2026. Online marketplaces and manufacturer websites now offer detailed product catalogs, 3D visualization tools, and DIY installation guides, empowering consumers to make informed purchases without relying on traditional retailers.

Direct-to-consumer (DTC) models are reducing costs and enabling faster delivery. Subscription-based or modular panel systems are being introduced for rental properties and temporary spaces, catering to the growing trend of flexible living and working environments.

Competitive Landscape and Market Consolidation

The PVC panel wall market is becoming increasingly competitive, with both established building material companies and new entrants vying for market share. Strategic partnerships, mergers, and acquisitions are expected to rise by 2026 as companies aim to expand their product portfolios and geographic reach.

Brands are differentiating themselves through design innovation, sustainability claims, and value-added services such as installation support and warranties. Regional players are also investing in R&D to match the quality of international brands while maintaining cost advantages.

Conclusion

By 2026, the PVC panel wall market will be shaped by innovation, sustainability, and shifting consumer demands across global regions. With enhanced aesthetics, improved environmental performance, and expanding applications, PVC panels are transitioning from a low-cost alternative to a premium interior solution. Stakeholders who embrace digital transformation, sustainable practices, and customer-centric design will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing PVC Panel Wall (Quality & IP)

Sourcing PVC panel walls can be cost-effective and efficient, but it comes with several risks—particularly concerning product quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure you receive durable, safe, and legally compliant products.

Poor Material Quality and Durability

Many low-cost PVC panels are made from recycled or substandard materials, leading to issues like warping, discoloration, and brittleness over time. Buyers may receive panels that lack UV resistance, are prone to cracking under temperature changes, or emit strong chemical odors due to poor stabilizers and additives.

Inaccurate Thickness and Dimensional Tolerances

Suppliers sometimes advertise PVC panels with specific thicknesses (e.g., 8mm or 10mm), but delivered products may fall short. Inconsistent panel widths or lengths can cause installation challenges, increased waste, and higher labor costs.

Misleading Fire-Retardant Claims

Some manufacturers claim their PVC panels are fire-resistant or self-extinguishing without proper certification. Without genuine testing and documentation (e.g., ASTM E84 or EN 13501), panels may pose safety hazards in commercial or residential spaces.

Lack of Compliance with Safety and Environmental Standards

PVC products may contain harmful substances like lead stabilizers or phthalates, especially when sourced from regions with lax regulations. Failing to verify compliance with REACH, RoHS, or local building codes can lead to rejected shipments or legal liabilities.

Inadequate Waterproof and Mold-Resistant Properties

While PVC is naturally moisture-resistant, low-quality panels may absorb water at the edges or backing due to poor lamination. This can result in swelling, mold growth, and delamination—especially in humid environments like bathrooms or kitchens.

Insufficient UV and Weather Resistance for Exterior Use

Exterior-grade PVC panels require UV stabilizers to prevent fading and degradation. Some suppliers market indoor panels as suitable for outdoor use, leading to premature deterioration when exposed to sunlight.

Intellectual Property (IP) Infringement Risks

When sourcing from overseas manufacturers, especially in high-volume production regions, there’s a risk of purchasing panels that copy patented designs, textures, or profiles. Using such products can expose your business to legal action, shipment seizures, or brand damage.

Counterfeit Certifications and Fake Test Reports

Unscrupulous suppliers may provide forged fire safety, environmental, or structural performance certifications. Always request verifiable test reports from accredited third-party labs and consider independent product testing before large-scale orders.

Inconsistent Surface Finish and Color Matching

Batch-to-batch color variations and uneven embossing are common with lower-tier manufacturers. This inconsistency can be highly visible in large installations, undermining the aesthetic quality of the finished space.

Limited Warranty and Poor After-Sales Support

Many budget suppliers offer little or no warranty, and customer service may be unresponsive after delivery. This becomes a major issue if defects are discovered post-installation, leaving buyers with costly remediation.

To avoid these pitfalls, conduct thorough supplier vetting, request physical samples, verify certifications, and include IP protection clauses in contracts. Third-party quality inspections and legal due diligence are essential for reliable, compliant sourcing.

Logistics & Compliance Guide for PVC Panel Wall

Product Overview

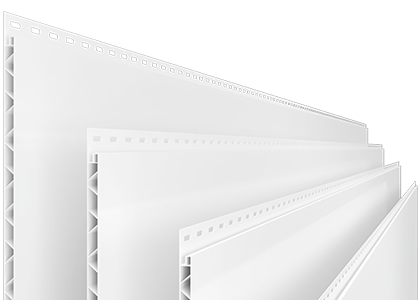

PVC panel walls are lightweight, durable interior cladding materials made from polyvinyl chloride (PVC). They are commonly used in residential, commercial, and industrial settings for walls and ceilings due to their moisture resistance, ease of installation, and low maintenance. This guide outlines the logistics handling, transportation, storage, and regulatory compliance considerations for PVC panel walls.

Packaging and Handling

PVC panels are typically supplied in flat packs, shrink-wrapped or boxed, and stacked on wooden or plastic pallets. To ensure product integrity:

– Handle with care to avoid scratches, dents, or warping.

– Use mechanical aids (e.g., forklifts, pallet jacks) for moving full pallets.

– Avoid dragging panels across surfaces.

– Store panels flat to prevent bowing or deformation.

Transportation Guidelines

- Secure pallets firmly during transit using straps or load locks to prevent shifting.

- Protect from weather exposure; use covered trucks or waterproof tarps if open transport is necessary.

- Avoid extreme temperatures; prolonged exposure to heat above 60°C (140°F) may cause deformation.

- Stack no more than the recommended number of pallets high to prevent crushing lower layers.

Storage Conditions

- Store in a dry, well-ventilated, and covered area away from direct sunlight to prevent UV degradation.

- Maintain temperature between 5°C and 35°C (41°F to 95°F).

- Keep panels horizontal on flat, level surfaces; use spacers if stacked.

- Avoid storing near heat sources, chemicals, or flammable materials.

Import/Export Compliance

Ensure compliance with international trade regulations:

– Verify Harmonized System (HS) Code: Typically 3925.30 (other plates, sheets, film, foil, strip of plastics, unworked).

– Provide accurate product descriptions, material composition, and country of origin.

– Comply with destination country customs requirements, including import duties and documentation (commercial invoice, packing list, bill of lading).

– Confirm adherence to REACH, RoHS, or other chemical substance regulations in target markets.

Fire Safety and Building Codes

- PVC panels must meet local fire safety standards (e.g., ASTM E84 in the U.S., EN 13501-1 in the EU).

- Verify flame spread index (FSI) and smoke-developed index (SDI) ratings.

- Use fire-rated panels in high-risk areas such as commercial kitchens or public buildings.

- Ensure compliance with regional building codes for interior finish materials.

Environmental and Recycling Compliance

- PVC is recyclable (Resin Identification Code 3); provide disposal and recycling guidance to end users.

- Comply with local environmental regulations regarding plastic waste management.

- Avoid open burning of waste panels, as it may release harmful dioxins.

Certifications and Documentation

Maintain the following documentation for compliance:

– Material Safety Data Sheet (MSDS/SDS)

– Product conformity certificates (e.g., CE, UKCA, or UL)

– Test reports for fire performance, VOC emissions, and durability

– ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) if applicable

Labeling Requirements

Each package must include:

– Product name and specifications (size, thickness, color)

– Batch or lot number

– Manufacturer name and contact information

– Handling and storage instructions

– Compliance marks (e.g., CE, fire rating symbols)

End-User Compliance Support

Provide installers and contractors with:

– Installation guidelines compliant with local building practices

– Warranty information

– Maintenance instructions

– Guidance on proper disposal and recycling options

By following this logistics and compliance guide, stakeholders can ensure the safe, legal, and efficient distribution and use of PVC panel walls across global markets.

Conclusion for Sourcing PVC Panel Wall

Sourcing PVC panel walls offers a practical, cost-effective, and aesthetically versatile solution for both residential and commercial interior applications. Their lightweight nature, ease of installation, low maintenance, and resistance to moisture and mold make them particularly suitable for areas such as bathrooms, kitchens, and basements. Additionally, advancements in design and finishes now allow PVC panels to mimic high-end materials like wood, stone, or tile, providing an attractive finish without the associated costs and upkeep.

When sourcing PVC panels, it is essential to evaluate suppliers based on product quality, certifications (e.g., fire resistance, environmental standards), price competitiveness, lead times, and availability of customization options. Establishing relationships with reliable manufacturers or distributors—whether local or international—can ensure consistent supply and after-sales support.

In conclusion, PVC panel walls represent a smart investment for modern construction and renovation projects. With careful sourcing strategies focused on quality, sustainability, and long-term value, businesses and homeowners can benefit from a durable, visually appealing, and economical wall finishing solution.