The global hydroponics market is experiencing robust expansion, driven by rising demand for sustainable agriculture, controlled environment farming, and increased urbanization. According to Grand View Research, the global hydroponics market size was valued at USD 33.4 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 12.1% from 2024 to 2030. This surge is further supported by advancements in material science and irrigation technologies, with PVC emerging as a preferred material due to its durability, cost-efficiency, and resistance to corrosion in nutrient-rich environments. As commercial and hobbyist growers increasingly adopt PVC-based hydroponic systems for scalability and ease of customization, a new wave of manufacturers has emerged to meet the demand. Based on market presence, production capacity, innovation, and global reach, the following are the top 10 PVC hydroponic system manufacturers shaping the future of soilless farming.

Top 10 Pvc Hydroponic System Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Pvc Hydroponic System Factories, Manufacturer

Domain Est. 2023

Website: m.sinabeacon.com

Key Highlights: Explore our PVC Hydroponic System options at Shandong Hualiang Greenhouse Engineering Co., Ltd. for efficient and high-quality solutions. Contact us today!…

#2 CropKing Inc

Domain Est. 1998

Website: cropking.com

Key Highlights: Cropking Inc. has over 30 years of experience in commercial greenhouse and hydroponic manufacturing, sales, and customer support……

#3 Hydroponics Growing System Manufacturer

Domain Est. 2021

Website: hydroponicschina.com

Key Highlights: Hydroponics Growing System Sale | Customized Design Free | Local Support | Automated & Remote Management | Reasonable Price | Complete System….

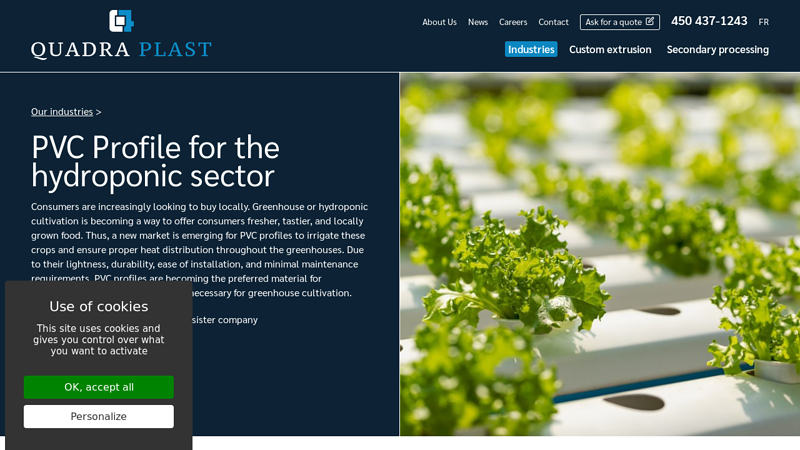

#4 PVC Profile for the hydroponic sector

Domain Est. 1997

Website: quadraplast.com

Key Highlights: PVC profiles are becoming the preferred material for transporting and treating the water necessary for greenhouse cultivation….

#5 ZipGrow™ Towers

Domain Est. 2008

Website: zipgrow.com

Key Highlights: The best vertical hydroponic farming systems in the world start with ZipGrow™ Towers. Learn more about our flagship product today!…

#6 FloraFlex

Domain Est. 2010

Website: floraflex.com

Key Highlights: 30-day returnsFloraFlex offers an extensive selection of hydroponic growing supplies, such as nutrients, drip irrigation kits, coconut coir, light shields, and more….

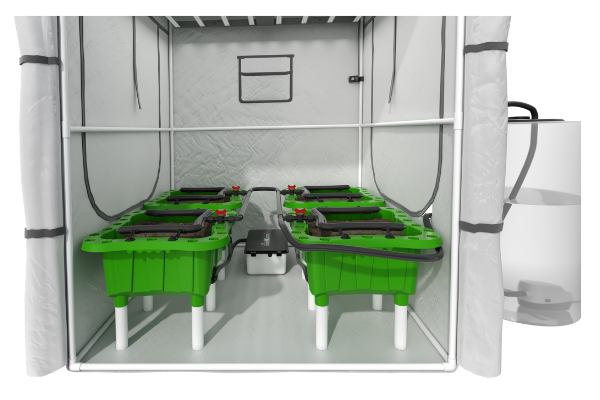

#7 Hydroponic Growing Systems

Domain Est. 2016

Website: growrillahydroponics.com

Key Highlights: 14-day returnsGrowrilla Hydroponics is a 100% Italian brand of hydroponic growing systems, designed and manufactured in Italy by growers for growers….

#8 The Bucket Company

Domain Est. 2016

Website: thebucketcompany.com

Key Highlights: The Bucket Company offers a wide selection of hydroponic supplies for all growing applications. From home gardens to commercial facilities, our range of ……

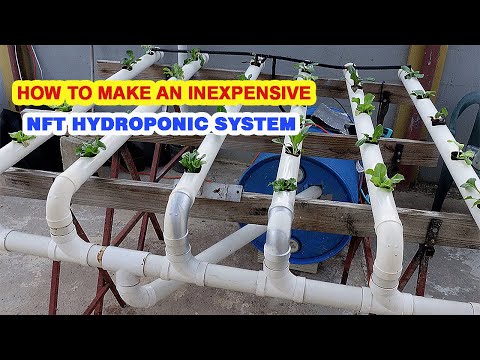

#9 NFT PVC hydroponic system Company

Domain Est. 2018

Website: wellgaingreenhouse.com

Key Highlights: Wellgain has been dedicated to providing quality Commercial hydroponic farming lettuce for domestic and overseas markets. Inquiry now!…

#10 Best Pvc Hydroponic System Design Manufacturer

Domain Est. 2024

Website: miilkiiagrow.com

Key Highlights: MIILKIIA AGRICULTURE is a leading PVC hydroponic system design manufacturer. Find high-quality and efficient solutions for your agricultural needs….

Expert Sourcing Insights for Pvc Hydroponic System

H2: 2026 Market Trends for PVC Hydroponic Systems

The global market for PVC hydroponic systems is poised for significant transformation by 2026, driven by advancements in urban agriculture, cost-effective materials, and growing demand for sustainable food production. The use of polyvinyl chloride (PVC) in hydroponic setups remains popular due to its durability, affordability, and ease of assembly, making it a preferred choice for both commercial growers and hobbyists. Several key trends are expected to shape the PVC hydroponic system market in 2026.

1. Rising Adoption in Urban and Vertical Farming

Urbanization and land scarcity are accelerating the shift toward vertical and indoor farming, particularly in densely populated regions. PVC hydroponic systems, with their modular and space-efficient design, are increasingly being integrated into urban farms, rooftop gardens, and community agriculture projects. Their lightweight structure and adaptability make them ideal for multi-tiered setups, supporting the expansion of urban food production.

2. Cost-Effectiveness Driving DIY and Small-Scale Use

PVC remains one of the most economical materials for constructing hydroponic systems. In 2026, the trend toward do-it-yourself (DIY) agriculture is expected to grow, especially in developing economies and among home gardeners. Online tutorials, pre-cut PVC kits, and open-source designs are empowering individuals to build low-cost hydroponic systems, further boosting market demand.

3. Sustainability and Environmental Concerns

While PVC is cost-efficient, environmental concerns related to its production and recyclability may influence future innovations. By 2026, manufacturers are likely to respond with eco-friendly alternatives or recycled PVC options to meet sustainability standards. Regulatory pressures and consumer preferences for greener materials could drive R&D into bio-based or recyclable piping solutions compatible with hydroponics.

4. Integration with Smart Agriculture Technologies

The convergence of hydroponics and smart farming technologies is a key trend. In 2026, PVC hydroponic systems are increasingly being paired with IoT sensors, automated nutrient dosing, and climate control systems. While PVC itself is passive, its use in sensor-equipped frameworks allows for real-time monitoring of pH, water levels, and nutrient delivery—enhancing yield efficiency and reducing labor costs.

5. Expansion in Emerging Markets

Regions such as Southeast Asia, Africa, and Latin America are witnessing growing interest in hydroponics due to water scarcity and food security challenges. PVC’s affordability and ease of transport make it a practical solution for off-grid and rural applications. Government initiatives and NGO-led agricultural programs are expected to promote PVC-based systems as part of broader food resilience strategies.

6. Competitive Pressure from Alternative Materials

Though PVC dominates, competition from materials like HDPE, PEX, and food-grade polymers is increasing. These alternatives offer improved UV resistance and lower leaching risks, appealing to organic and high-end commercial operations. By 2026, PVC system manufacturers may need to enhance product quality—such as UV-stabilized or lead-free PVC—to maintain market share.

In conclusion, the 2026 market for PVC hydroponic systems will be shaped by urban farming growth, cost sensitivity, technological integration, and sustainability demands. While PVC remains a cornerstone material due to its practicality, continued innovation and adaptation will be essential to meet evolving environmental and performance standards.

Common Pitfalls Sourcing PVC Hydroponic Systems (Quality & IP)

When sourcing PVC hydroponic systems, especially from third-party manufacturers or generic suppliers, several critical pitfalls related to quality and intellectual property (IP) can significantly impact your project’s success, cost, and legal standing. Being aware of these risks is essential for informed decision-making.

Quality Concerns

1. Substandard PVC Material Composition

Many low-cost PVC systems use recycled or off-spec PVC that may contain harmful additives like lead, phthalates, or BPA. These substances can leach into the nutrient solution, contaminating crops and posing health risks. Ensure the PVC is food-grade (NSF/ANSI 61 certified) and UV-stabilized if used outdoors.

2. Inconsistent Manufacturing Tolerances

Poorly manufactured fittings and pipes often have inconsistent inner diameters, misaligned holes, or warped components. This leads to leaks, poor water flow, and difficulty in assembly—resulting in system inefficiencies and increased maintenance.

3. Inadequate Structural Integrity

Thin-walled PVC or poorly designed structures may not support the weight of water, plants, and growing media over time. This can cause sagging, cracking, or system collapse, especially in larger installations.

4. Poor UV and Heat Resistance

Standard PVC degrades under prolonged sunlight, becoming brittle and discolored. Suppliers may not specify UV resistance, leading to premature system failure in greenhouse or outdoor applications.

5. Lack of System Integration Testing

Generic PVC systems are often sold as components without full system validation. This increases the risk of incompatibility between pumps, tubing, and emitters, reducing overall hydroponic efficiency.

Intellectual Property (IP) Risks

1. Infringement of Patented Designs

Many innovative hydroponic configurations (e.g., NFT channels, drip manifolds, tower systems) are protected by utility or design patents. Sourcing generic copies of patented systems—especially from regions with lax IP enforcement—can expose your business to legal action, injunctions, or costly litigation.

2. Unauthorized Use of Trademarks

Some suppliers may replicate branding or use names closely resembling established hydroponic brands (e.g., “AquaGarden” vs. “AeroGarden”). Using such products can lead to trademark infringement claims, even if you are unaware.

3. Copying Proprietary System Architecture

Custom hydroponic layouts or integrated control systems may be protected by trade secrets or design rights. Replicating these without authorization—even using PVC components—can violate IP laws, particularly if the design is novel and non-obvious.

4. Limited Recourse for IP Violations

When sourcing from overseas suppliers, enforcing IP agreements or seeking remedies for infringement is often difficult and costly. Contracts may lack enforceable IP clauses, leaving buyers vulnerable.

5. Risk to Your Own Innovation

If you design a custom PVC hydroponic system and fail to protect it with patents or design registrations, suppliers or competitors may copy and commercialize it, undermining your competitive advantage.

Best Practices to Avoid Pitfalls

- Specify food-grade, UV-stabilized PVC (e.g., NSF-certified).

- Request material test reports and compliance documentation.

- Conduct prototype testing before large-scale sourcing.

- Perform IP clearance searches before adopting or selling a design.

- Work with reputable suppliers who respect IP and offer indemnification.

- Consider patenting or trademarking your unique system designs.

By proactively addressing quality and IP concerns, you can ensure a reliable, safe, and legally compliant hydroponic solution.

Logistics & Compliance Guide for PVC Hydroponic Systems

Introduction

PVC (polyvinyl chloride) hydroponic systems are widely used due to their durability, cost-effectiveness, and ease of assembly. However, shipping, handling, and regulatory compliance require careful planning to ensure safe delivery, environmental safety, and adherence to applicable standards. This guide outlines key logistics considerations and compliance requirements for businesses manufacturing, importing, exporting, or distributing PVC hydroponic systems.

Material Safety & Regulatory Compliance

REACH and RoHS Compliance

Ensure that all PVC components comply with international chemical regulations:

– REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): Confirm that PVC materials do not contain restricted substances such as phthalates (e.g., DEHP, DBP, BBP) above permissible limits.

– RoHS (Restriction of Hazardous Substances): Although primarily for electronics, if your system includes electronic components (e.g., pumps, timers), ensure compliance with RoHS 3, which restricts substances like lead, cadmium, and mercury.

Documentation such as Safety Data Sheets (SDS) and compliance certificates must be available for customs and customer requests.

Food-Grade PVC Requirements

Since hydroponic systems come into contact with water and plants intended for consumption:

– Use food-grade PVC certified to meet NSF/ANSI Standard 51 (Food Equipment Materials) or equivalent (e.g., FDA 21 CFR §177.2500).

– Avoid PVC formulations containing lead-based stabilizers. Opt for calcium-zinc or organotin stabilizers instead.

Label products clearly as “Food-Grade” where applicable and provide certification upon request.

Packaging & Shipping Logistics

Protective Packaging

- Use sturdy, recyclable corrugated cardboard boxes with internal dividers or foam inserts to prevent damage during transit.

- Wrap PVC pipes and fittings in bubble wrap or stretch film to protect against scratches and UV degradation.

- Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Sunlight” warnings.

Dimensional Weight & Freight Optimization

- Optimize packaging size to minimize dimensional weight, especially for air freight.

- Consider flat-pack designs to reduce volume and shipping costs.

- For bulk shipments, use pallets secured with stretch wrap; standard pallet dimensions (e.g., 48” x 40”) facilitate efficient loading.

International Shipping Considerations

- Check import regulations in destination countries regarding plastic materials and agricultural equipment.

- Provide accurate Harmonized System (HS) codes (e.g., 3917.33 for tubes/pipes of PVC) for customs clearance.

- Include commercial invoices, packing lists, and certificates of origin with shipments.

Environmental & Disposal Compliance

Waste Electrical and Electronic Equipment (WEEE)

If the hydroponic system includes electrical components (e.g., submersible pumps, LED grow lights):

– Comply with WEEE directives in the EU and similar regulations elsewhere.

– Provide take-back information or recycling instructions to end users.

End-of-Life Management

- Design for disassembly and recyclability. Label PVC components with resin identification code (♳3).

- Encourage customers to recycle PVC through local plastic recycling programs.

Labeling & Documentation Requirements

Product Labeling

Each unit or package must include:

– Product name and model number

– Manufacturer/importer name and contact information

– Material composition (e.g., “PVC – Food Grade, NSF 51 Certified”)

– Country of origin

– Compliance marks (e.g., CE, UKCA, or FCC if applicable)

User Manuals & Safety Information

Provide multilingual instructions covering:

– Assembly and installation guidelines

– Maintenance and cleaning procedures

– Safety warnings (e.g., avoid high heat exposure, do not incinerate PVC)

– Compliance statements and regulatory information

Import/Export Controls and Tariffs

Restricted Substances Monitoring

Some countries restrict certain plastic additives. Verify compliance with:

– Proposition 65 (California, USA): Warn consumers if products contain phthalates or lead.

– China RoHS: Applies to electrical components in the system.

Tariff Classifications

Work with customs brokers to assign correct tariff codes. Examples:

– HS 3917.33: Tubes, pipes, and hoses of PVC

– HS 8424.89: Agricultural spraying machinery (if including pump assemblies)

Accurate classification prevents delays and ensures correct duty payments.

Quality Assurance & Testing

Pre-Shipment Inspections

- Conduct quality checks for dimensional accuracy, weld integrity, and surface defects.

- Perform water-tightness tests on assembled systems where possible.

Third-Party Certification

Obtain independent verification from accredited labs for:

– Material compliance (e.g., NSF, FDA)

– Structural integrity under operational conditions

– UV resistance for outdoor-use systems

Summary

Successful logistics and compliance for PVC hydroponic systems require attention to material safety, proper packaging, regulatory standards, and accurate documentation. By prioritizing food-grade materials, international compliance, and sustainable practices, businesses can ensure safe, legal, and efficient distribution of their hydroponic products worldwide.

Conclusion: Sourcing a PVC Hydroponic System

Sourcing a PVC hydroponic system presents a cost-effective, customizable, and scalable solution for both hobbyists and commercial growers. The widespread availability of PVC materials, combined with their durability and ease of assembly, makes them an attractive option for constructing efficient hydroponic setups such as NFT (Nutrient Film Technique), drip systems, or vertical towers. While PVC is affordable and versatile, it is essential to consider potential environmental and health concerns associated with certain types of plastic, especially under prolonged UV exposure or high temperatures. Using food-safe, UV-stabilized, or alternative materials like food-grade HDPE where possible can mitigate these risks.

Sourcing decisions should balance cost, longevity, sustainability, and safety. Whether sourcing locally to reduce shipping costs and support regional suppliers or importing in bulk for large-scale operations, proper quality checks and supplier reliability are crucial. Additionally, integrating sustainable practices—such as recycling PVC components or exploring eco-friendly alternatives—can enhance the system’s long-term viability.

In conclusion, PVC remains a practical and accessible choice for hydroponic systems, especially when sourced responsibly and used thoughtfully. With proper planning and material selection, a PVC-based hydroponic system can provide an efficient and productive growing environment for sustainable agriculture.