The global pressure switch market is experiencing steady growth, driven by increasing demand across industrial, HVAC, and water management applications. According to Mordor Intelligence, the pressure switch market was valued at USD 692.8 million in 2023 and is projected to reach USD 915.7 million by 2029, growing at a CAGR of 4.7% during the forecast period. This expansion is fueled by rising automation in manufacturing processes, stricter safety regulations, and the growing adoption of smart control systems in residential and commercial infrastructure. As pumps remain a critical component in fluid handling systems, the need for reliable pump pressure switches—used to monitor and control pump operations—has surged. To help industry stakeholders make informed decisions, we’ve compiled a data-driven profile of the top 9 pump pressure switch manufacturers shaping the market, based on product innovation, global reach, and technological advancement.

Top 9 Pump Pressure Switch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pressure switches for industrial automation

Domain Est. 1995

Website: danfoss.com

Key Highlights: Danfoss industrial automation pressure switches are accurate, robust, and perform flawlessly everyday, even under the harshest conditions….

#2 Pressure Switch Manufacturers

Domain Est. 2002

Website: pressure-switches.net

Key Highlights: We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application….

#3 Pressure Switches & Sensors

Domain Est. 1995

Website: norgren.com

Key Highlights: Pressure switches and sensors can be used to automatically monitor pressure levels in a pneumatic system, or be used for more complex monitoring functions….

#4 Pressure switch

Domain Est. 1996

Website: wika.com

Key Highlights: WIKA pressure switches are fitted with high-quality microswitches. They feature high long-term stability and precision….

#5 Pressure Switch

Domain Est. 2000

Website: aymcdonald.com

Key Highlights: You can find pressure switches at AY McDonald Mfg. Co. Rely on knowledge and experience that stems all the way back to 1856 to help you fulfill your pump needs….

#6 Pressure sensors

Domain Est. 2014

Website: telemecaniquesensors.com

Key Highlights: Consistently recognized as the #1 switch on the market, the century-old Pumptrol brand water pressure switch has expanded to an entire line of industry-leading ……

#7 Pressure Switches

Domain Est. 2022

#8 Series DA/DS Bourdon Tube Pressure Switches

Domain Est. 2022

Website: dwyeromega.com

Key Highlights: In stock Rating 5.0 (1) Aug 21, 2025 · The Mercoid DA/DS Series is one of the world’s broadest lines of pressure switches. The DA/DS Series has extremely high sensitivity and gre…

#9 Pressure switches

Website: condor-werke.de

Key Highlights: The MDR-R control pressure switch is a compact pressure switch with high precision. It is universally applicable, meets the high requirements of the……

Expert Sourcing Insights for Pump Pressure Switch

2026 Market Trends for Pump Pressure Switches

Increasing Demand in Water Management Infrastructure

By 2026, the global pump pressure switch market is expected to experience significant growth, primarily driven by rising investments in water management infrastructure. Urbanization and population growth, especially in emerging economies across Asia-Pacific and Africa, are fueling the need for reliable water supply and wastewater treatment systems. Pump pressure switches play a critical role in these systems by automatically controlling pump operation based on system pressure, ensuring energy efficiency and equipment longevity. Governments and municipalities are increasingly modernizing aging water infrastructure, leading to higher demand for automated control components like pressure switches in booster pumps, well pumps, and irrigation systems.

Technological Advancements and Smart Integration

A major trend shaping the 2026 landscape is the integration of digital and smart technologies into traditional pump controls. Manufacturers are developing intelligent pressure switches with IoT (Internet of Things) connectivity, enabling remote monitoring, predictive maintenance, and real-time diagnostics. These smart switches can communicate with building management systems (BMS) or industrial automation platforms, providing data on pressure fluctuations, pump cycles, and potential faults. This shift toward Industry 4.0 and smart home ecosystems is pushing demand for pressure switches with digital displays, adjustable setpoints via mobile apps, and compatibility with communication protocols like Modbus or BACnet.

Focus on Energy Efficiency and Sustainability

Regulatory pressures and the global push toward energy conservation are compelling industries and consumers to adopt energy-efficient pumping solutions. Pressure switches contribute to this goal by preventing pump short-cycling and ensuring pumps only operate when necessary. By 2026, energy efficiency standards such as MEPS (Minimum Energy Performance Standards) will likely influence design requirements, favoring pressure switches with precise control, low differential settings, and minimal power consumption. Demand is rising for switches designed to work seamlessly with variable frequency drives (VFDs), enhancing overall system efficiency in HVAC, industrial processing, and commercial plumbing applications.

Growth in Industrial and Commercial Applications

Beyond residential water systems, industrial and commercial sectors are key growth areas for pump pressure switches. In manufacturing, food and beverage processing, and chemical industries, precise pressure control is essential for process reliability and safety. Similarly, the expansion of commercial real estate and smart buildings is increasing the deployment of advanced pumping systems for heating, cooling, and fire protection—each requiring reliable pressure switching. The trend toward modular and pre-fabricated pump skids also favors integrated pressure control solutions, driving innovation in compact, durable, and customizable pressure switch designs.

Regional Market Dynamics and Supply Chain Adjustments

The Asia-Pacific region is projected to dominate the pump pressure switch market by 2026, led by rapid industrialization in countries like China, India, and Southeast Asian nations. North America and Europe will maintain strong demand due to infrastructure upgrades and stringent environmental regulations. However, supply chain resilience and localization of manufacturing are becoming strategic priorities post-pandemic. Companies are increasingly sourcing components regionally and investing in automation to mitigate disruptions, which may influence pricing and availability of pressure switches in the coming years.

Competitive Landscape and Product Differentiation

As the market matures, competition among manufacturers is intensifying. Leading players are focusing on product differentiation through enhanced durability (e.g., corrosion-resistant materials), wider pressure ranges, and compliance with international standards (e.g., CE, UL, RoHS). There is also a growing emphasis on user-friendly designs, such as push-button calibration and visual indicators, to reduce installation time and service costs. Mergers and partnerships between switch manufacturers and pump OEMs are expected to increase, aiming to offer fully integrated pumping solutions that improve performance and reliability.

Common Pitfalls Sourcing Pump Pressure Switches (Quality & IP)

Sourcing pump pressure switches involves more than just matching specifications on paper. Overlooking critical quality and Ingress Protection (IP) factors can lead to premature failures, safety hazards, and costly downtime. Here are the most common pitfalls to avoid:

1. Overlooking Real-World IP Rating Suitability

- Assuming IP65 is Sufficient for All Wet Environments: While IP65 (dust-tight, protected against water jets) is common, it may not be adequate for:

- High-Pressure Washdowns (IP67/IP69K): Food & beverage, pharmaceutical, or harsh industrial cleaning requires IP67 (immersion up to 1m) or IP69K (high-pressure, high-temperature washdown).

- Submersion or Constant Splashing: Applications near pumps in pits or fountains might need IP68 (continuous immersion).

- Consequence: Water ingress leads to corrosion, electrical shorts, and switch failure.

- Ignoring Environmental Compatibility: The IP rating assumes standard conditions. Consider:

- Chemical Exposure: Harsh cleaners, oils, or process chemicals can degrade seals and gaskets rated for water only. Verify chemical resistance.

- Temperature Extremes: High ambient temperatures can compromise seal integrity, reducing effective IP protection. Low temperatures can embrittle seals.

- UV Exposure: Outdoor applications require UV-resistant housings; standard plastics can crack, compromising the IP seal.

- Neglecting Installation Impact: Poor installation practices (damaged seals, overtightened terminals, kinked conduits) can instantly void the IP rating, regardless of the switch’s inherent rating.

2. Compromising on Build Quality & Materials

- Choosing Based Solely on Lowest Price: Ultra-low-cost switches often use inferior materials:

- Housings: Cheap plastics prone to cracking, warping, or UV degradation instead of robust thermoplastics (e.g., PBT, PA) or metal.

- Diaphragms: Low-grade elastomers (e.g., NBR) that harden, crack, or swell when exposed to water, oils, or temperature cycles, instead of durable materials like EPDM, Viton (FKM), or stainless steel.

- Electrical Contacts: Tin-plated contacts prone to oxidation and welding; high-quality switches use silver or silver alloy contacts for reliability and longevity.

- Springs: Poor-quality springs fatigue quickly, leading to loss of setpoint accuracy.

- Ignoring Pressure Media Compatibility: Using a switch with materials incompatible with the pumped fluid (e.g., water, oil, chemicals) causes:

- Diaphragm Degradation: Swelling, cracking, or embrittlement.

- Corrosion: Of wetted parts (diaphragm, pressure chamber, fittings).

- Consequence: Leaks, inaccurate switching, complete failure. Always verify material compatibility charts.

- Overlooking Mechanical Durability: Switches in high-vibration environments (e.g., on pumps) need robust construction. Flimsy housings or internal components loosen or fail prematurely.

3. Misunderstanding Switch Specifications & Performance

- Focusing Only on Pressure Range, Ignoring Switching Differentials: An inadequate or non-adjustable differential (the gap between cut-in and cut-out pressure) can cause:

- Short Cycling: The pump turns on/off too frequently, damaging the pump motor and switch contacts.

- Water Hammer: Rapid pressure changes stress pipes and fittings.

- Assuming All “Adjustable” Switches are Equal: Low-quality switches may have:

- Poor Adjustment Mechanisms: Knobs that strip easily or lack precision.

- Drift: Setpoints shift significantly over time or with temperature changes.

- Limited Adjustment Range: May not cover the required operating pressures effectively.

- Underestimating Electrical Load Requirements: Selecting a switch with insufficient contact rating (Amps/Volts) for the pump motor leads to:

- Contact Welding: Contacts fuse together, preventing the pump from turning off.

- Premature Contact Failure: Pitting and erosion from arcing.

- Consequence: Pump run-on, motor burnout, fire hazard. Always derate for motor loads (use switch rated for motor HP at system voltage).

4. Neglecting Certification & Safety Standards

- Omitting Essential Certifications: Using uncertified switches in critical applications risks safety and compliance:

- Electrical Safety: Lack of certifications like UL, CSA, TÜV, or CE (with relevant directives like LVD, EMC) means unsafe construction or shock/fire risk.

- Hazardous Areas: Using non-certified switches (e.g., ATEX, IECEx) in explosive atmospheres is extremely dangerous.

- Potable Water: Switches for drinking water systems must have NSF/ANSI 61 or equivalent certification to prevent contamination.

- Assuming “CE Mark” Guarantees Quality: CE marking is a self-declaration by the manufacturer. Verify the specific standards applied (e.g., EN 60947-5-1 for safety) and consider reputable brands with proven compliance history.

5. Underestimating Total Cost of Ownership (TCO)

- Prioritizing Initial Cost Over Long-Term Reliability: A slightly more expensive, high-quality switch from a reputable manufacturer often:

- Lasts Significantly Longer: Reducing replacement frequency and associated labor costs.

- Prevents Downtime: Avoids costly production stops or system failures.

- Protects Downstream Equipment: Reliable switching prevents pump damage from dry running or overpressure.

- Reduces Maintenance: Higher quality means fewer adjustments and checks needed.

- Ignoring Warranty & Support: Reputable suppliers offer better warranties and technical support, crucial if issues arise.

Conclusion: Avoiding these pitfalls requires diligence beyond the basic specs. Prioritize verified IP ratings suitable for the specific environment, invest in proven build quality and material compatibility, understand the full performance requirements (differential, load), demand relevant certifications, and evaluate the true TCO. Sourcing from reputable suppliers with strong technical support and documentation is key to ensuring reliable, safe, and long-lasting pump pressure switch performance.

Logistics & Compliance Guide for Pump Pressure Switch

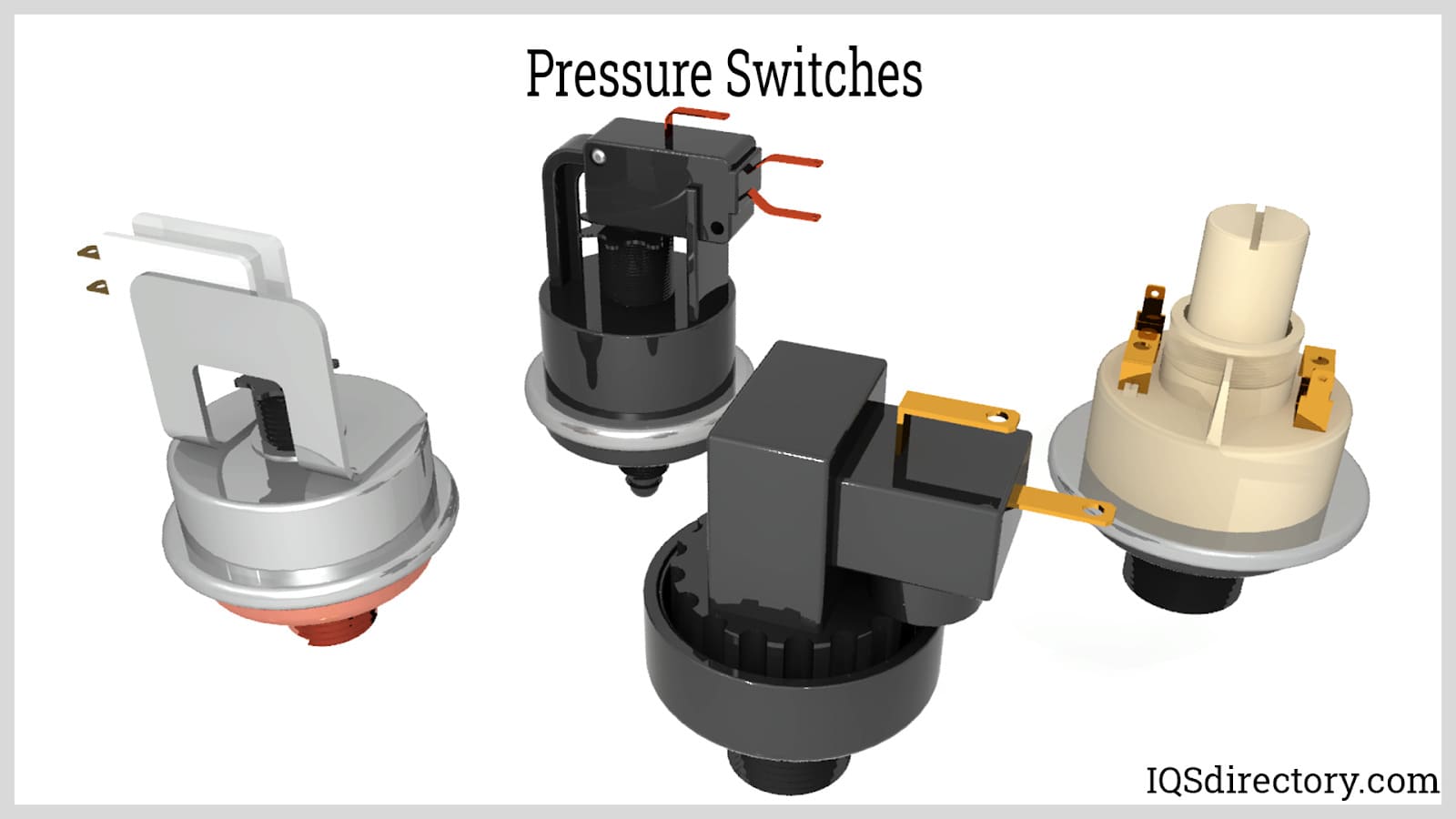

Product Overview

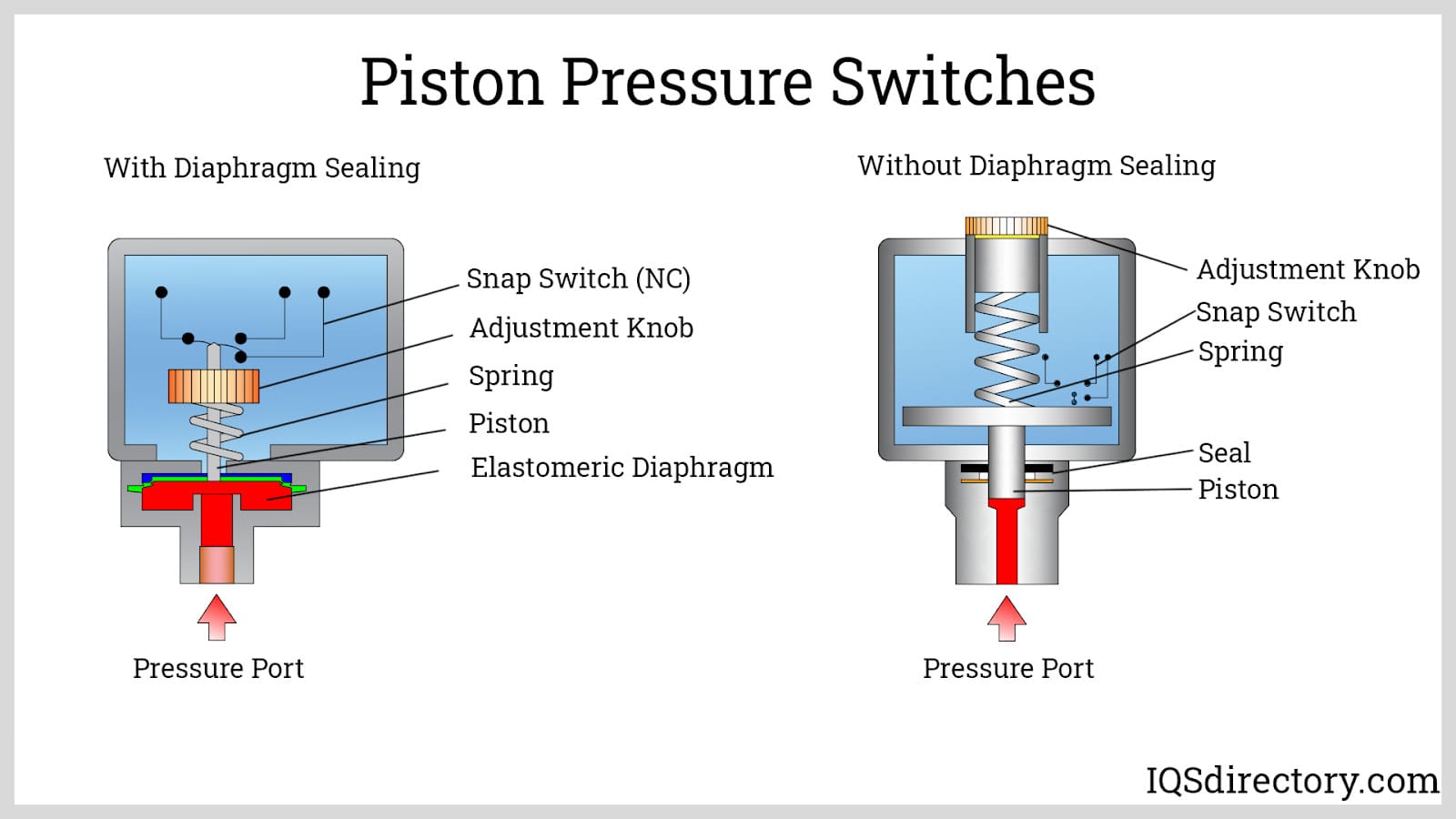

A pump pressure switch is an electromechanical device used to monitor and control the pressure in pumping systems. It automatically turns a pump on or off based on preset pressure thresholds, ensuring efficient operation and protecting equipment from damage due to overpressure or dry running. These switches are commonly used in water supply systems, HVAC, industrial machinery, and irrigation.

Classification & HS Code

The correct Harmonized System (HS) code is essential for international shipping and customs clearance.

Recommended HS Code: 9032.89.00

Rationale: This code generally covers automatic regulating or controlling instruments and apparatus, not elsewhere specified or included. Pressure switches may fall under this category depending on design and application. However, local customs authorities may classify them under 8536.50 (electrical switches) if primarily electrical in function.

Action: Confirm the appropriate code with your destination country’s customs authority or a licensed customs broker.

Packaging & Labeling Requirements

Proper packaging and labeling ensure product integrity and regulatory compliance during transit.

- Packaging:

- Use anti-static, cushioned packaging to protect sensitive components.

- Seal units in moisture-resistant bags if shipping to humid regions.

- Individual units should be boxed; bulk shipments must be palletized and stretch-wrapped.

-

Include desiccant packs for long-distance or marine shipments.

-

Labeling:

- Include product name, model number, manufacturer details, and batch/lot number.

- Affix CE, UKCA, or other regional conformity marks as applicable.

- Include handling symbols (e.g., “Fragile,” “Do Not Stack,” “This Side Up”).

- Provide multilingual labels if shipping to non-English-speaking countries.

Regulatory Compliance

Ensure the pump pressure switch meets regional safety and performance standards.

- European Union (EU):

- Comply with the CE Marking Directive (e.g., Low Voltage Directive 2014/35/EU and EMC Directive 2014/30/EU).

- Provide an EU Declaration of Conformity (DoC).

-

RoHS 2 (2011/65/EU) compliance for restriction of hazardous substances.

-

United Kingdom (UK):

- Apply UKCA marking for products placed on the market in Great Britain.

-

Northern Ireland follows CE or UK(NI) marking under the Northern Ireland Protocol.

-

United States:

- Comply with UL 60947-5-1 or UL 508 standards for industrial control equipment.

-

FCC Part 15 compliance if the device emits electromagnetic radiation.

-

Canada:

- Requires CSA C22.2 No. 14 certification for control devices.

-

Must meet EMC requirements under ICES-003.

-

Other Regions:

- Australia/NZ: RCM mark per AS/NZS standards.

- China: CCC mark if applicable (check product category).

- South Korea: KC mark under KEMCO regulations.

Import/Export Documentation

Accurate documentation is critical for smooth customs processing.

- Commercial Invoice (with detailed product description, value, and HS code)

- Packing List (itemizing contents per package)

- Certificate of Origin (preferential or non-preferential, depending on trade agreements)

- Bill of Lading or Air Waybill

- Test Reports and Certifications (e.g., CE, UL, RoHS)

- Export Declaration (as required by exporting country)

- Import License (if required by destination country)

Transportation & Handling

- Mode of Transport: Suitable for air, sea, or ground freight. Use climate-controlled containers for sensitive electronics if traveling through extreme environments.

- Temperature & Humidity: Store and transport within -10°C to +50°C and relative humidity < 90% (non-condensing).

- Shock & Vibration: Avoid excessive impact; use shock-absorbing materials in packaging.

- Battery Considerations: If the switch includes a battery, comply with UN 3481 (lithium-ion) or UN 3091 (lithium-metal) shipping regulations.

Environmental & Disposal Compliance

- WEEE Directive (EU): Producers must register and provide take-back options for end-of-life equipment.

- RoHS: Ensure no restricted substances (e.g., lead, cadmium, hexavalent chromium) exceed limits.

- REACH (EU): Declare Substances of Very High Concern (SVHC) if present above threshold.

- Battery Directive (if applicable): Label with crossed-out wheeled bin symbol.

Record Keeping & Traceability

- Maintain records of compliance documentation, test reports, and shipping logs for at least 5 years.

- Implement a batch/lot traceability system to support recalls or field service actions.

- Update compliance status regularly to reflect changes in regulations.

Summary Checklist

- [ ] Confirm correct HS code with customs broker

- [ ] Package securely with environmental protection

- [ ] Apply required regional conformity marks

- [ ] Prepare complete export documentation

- [ ] Verify compliance with destination country standards

- [ ] Train logistics staff on hazardous material rules (if batteries included)

- [ ] Register for WEEE or equivalent recycling programs where applicable

Adhering to this guide ensures efficient global distribution and legal compliance for pump pressure switches.

Conclusion for Sourcing a Pump Pressure Switch

After evaluating technical specifications, performance requirements, and supplier capabilities, sourcing the appropriate pressure switch for pump applications is critical to ensuring system reliability, safety, and efficiency. The selection process must consider key factors such as pressure range, electrical ratings, durability, environmental conditions (e.g., exposure to moisture, vibration, or corrosive elements), and compatibility with the pump control system.

An optimal pressure switch should provide consistent operation under varying load conditions, support automation by accurately sensing pressure thresholds, and contribute to pump longevity by preventing dry running or overpressure situations. Additionally, sourcing from reputable manufacturers with proven quality standards (such as ISO certification) and responsive technical support ensures long-term performance and easier maintenance.

In conclusion, a well-sourced pressure switch not only enhances pump system performance but also reduces operational risks and maintenance costs. Prioritizing reliability, compatibility, and supplier reputation will lead to a successful integration within the pumping system, supporting efficient and uninterrupted operation across its lifecycle.