The global PTFE washers market is experiencing steady growth, driven by rising demand across industries such as automotive, aerospace, chemical processing, and semiconductor manufacturing, where high-performance sealing solutions are critical. According to Grand View Research, the global PTFE market was valued at USD 6.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030, fueled by PTFE’s exceptional chemical resistance, low friction coefficient, and thermal stability. As industrial applications increasingly require reliable, non-reactive components, PTFE washers have become essential in minimizing leaks, reducing wear, and ensuring system integrity under extreme conditions. This growing demand has spurred innovation and competition among manufacturers worldwide. Based on production capacity, technical expertise, quality certifications, and global reach, the following are the top 10 PTFE washers manufacturers shaping the industry today.

Top 10 Ptfe Washers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

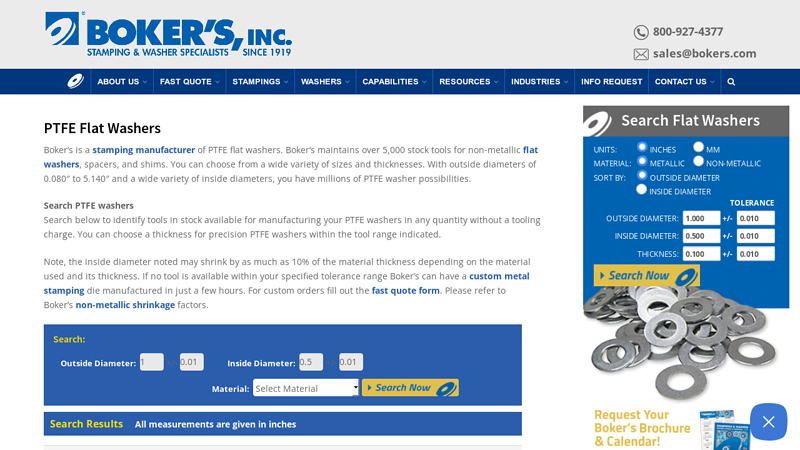

#1 PTFE Flat Washers

Domain Est. 1996

Website: bokers.com

Key Highlights: Boker’s is a stamping manufacturer of PTFE flat washers. Boker’s maintains over 5,000 stock tools for non-metallic flat washers, spacers, and shims. You can ……

#2 Teflon™ PTFE Washer Manufacturer

Domain Est. 1996

Website: newprocess.com

Key Highlights: New Process Fibre offers high-performance Teflon™ PTFE washers to fulfill the needs of diverse industries. Learn more about the material’s capabilities….

#3 PTFE Plastic Washers

Domain Est. 2002

Website: cannongasket.com

Key Highlights: Our Teflon Washers, PTFE Washers have superior electrical insulating properties, high dielectric strength/stability and is used in a variety of industries ……

#4 Lamons

Domain Est. 2002

Website: lamons.com

Key Highlights: Lamons is one of the largest custom gasket, bolt, & seal manufacturers globally, committed to providing industry leading sealing solutions. Call us today!…

#5 PTFE Washer Manufacturer and Supplier

Domain Est. 2004

Website: mcpengineering.co.uk

Key Highlights: MCP Engineering Plastics Limited are a UK PTFE Washer manufacturer and supplier, with in-house machining and tooling capabilities….

#6 Engineered PTFE Components

Domain Est. 1996

Website: trelleborg.com

Key Highlights: A wide range of filled and unfilled engineered PTFE components are made available to all types of industry. They include valve seats, pump….

#7 PTFE Washers ISO 7093 / DIN 9021 Bülte

Domain Est. 1997

Website: bulte.com

Key Highlights: PTFE washer ISO 7093, DIN 9021 ➤ M2-M20 ✓ corrosion-resistant Teflon ✓ insulating, non-adhesive ✓ large outer diameter ➤ Request a quote now!…

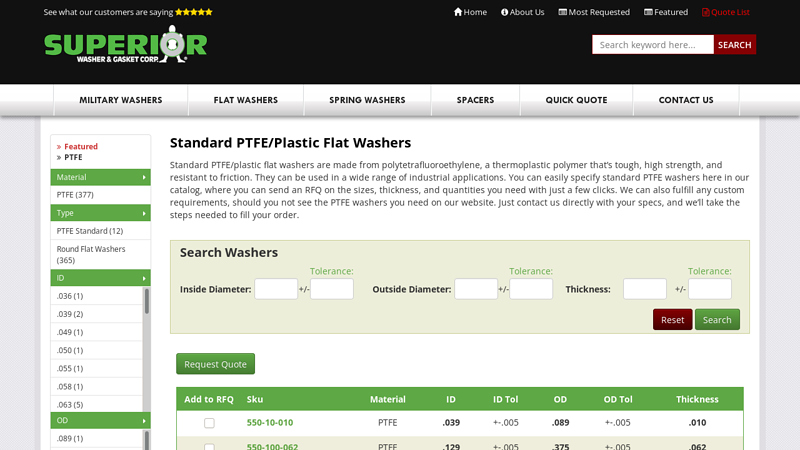

#8 PTFE Washers

Domain Est. 1997

Website: superiorwasher.com

Key Highlights: We can manufacture PTFE flat washers in just about any diameter and thickness you might need, and when you source them from us, you know you’ll get genuine ……

#9 PTFE Round Flat Washers

Domain Est. 1997

Website: seastrom-mfg.com

Key Highlights: A PTFE flat washer is a flat disc with a centrally located hole. PTFE flat washers have excellent anti –frictional properties, as well as excellent chemical and ……

#10 PTFE washers

Domain Est. 1997

Website: mcd-co.com

Key Highlights: McDowell & Company specializes in PTFE washers, manufacturing and distributing quality parts and components in the most efficient and economical methods ……

Expert Sourcing Insights for Ptfe Washers

H2: 2026 Market Trends for PTFE Washers

The global market for PTFE (Polytetrafluoroethylene) washers is poised for steady growth and transformation by 2026, driven by material advantages, technological advancements, and evolving end-user demands. Key trends shaping the market landscape include:

1. Rising Demand from High-Performance Industries:

The aerospace, automotive (particularly electric vehicles), semiconductor manufacturing, and chemical processing sectors are increasingly adopting PTFE washers due to their exceptional chemical inertness, thermal stability (-200°C to +260°C), and low coefficient of friction. The push for lighter, more efficient systems in EVs and advanced aircraft will amplify demand for reliable sealing solutions like PTFE washers.

2. Shift Towards Modified PTFE and Composite Materials:

While virgin PTFE remains popular, compounded grades (e.g., filled with glass fiber, carbon, graphite, or bronze) are gaining traction. These modified PTFEs offer enhanced mechanical strength, reduced cold flow, and improved wear resistance—addressing limitations of pure PTFE. By 2026, demand for filled PTFE washers is expected to outpace virgin grades in high-stress applications.

3. Increased Focus on Sustainability and Recycling:

Environmental regulations and corporate ESG goals are driving innovation in PTFE recycling technologies. Though challenging, advancements in reprocessing scrap and post-industrial PTFE are emerging. Suppliers investing in closed-loop systems or offering recycled-content PTFE washers will gain competitive advantage. Regulatory scrutiny on PFAS (per- and polyfluoroalkyl substances) may also influence formulation choices.

4. Regional Market Diversification and Supply Chain Resilience:

Asia-Pacific (especially China, India, and Southeast Asia) will remain the dominant market due to rapid industrialization and manufacturing expansion. However, geopolitical factors and supply chain disruptions are prompting companies to diversify sourcing and regionalize production. Nearshoring and onshoring trends in North America and Europe will support regional PTFE washer manufacturers.

5. Customization and Value-Added Services:

End-users are demanding more customized washers—specific dimensions, tolerances, and materials—to fit complex assemblies. Suppliers offering engineering support, rapid prototyping, and just-in-time delivery will differentiate themselves. Digital tools (e.g., 3D modeling, CAD integration) will enhance customization capabilities.

6. Digitalization and Smart Manufacturing:

PTFE washer producers are adopting Industry 4.0 technologies such as IoT-enabled monitoring, AI-driven quality control, and automated production lines. These improve consistency, reduce waste, and enable real-time traceability—critical for regulated industries like aerospace and pharmaceuticals.

7. Competitive Landscape Intensification:

The market will see consolidation among mid-tier players, while leading material science companies expand their fluoropolymer portfolios. Price competition will persist, but innovation in material science and service offerings will be key differentiators.

In summary, the 2026 PTFE washer market will be characterized by material innovation, sustainability imperatives, regional diversification, and a growing emphasis on performance and service. Companies that adapt to these trends will be best positioned to capture growth in this niche but critical segment of the sealing industry.

Common Pitfalls Sourcing PTFE Washers (Quality, IP)

Sourcing PTFE (Polytetrafluoroethylene) washers requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance failures, supply chain disruptions, compliance issues, and legal risks. Below are key pitfalls to avoid:

Quality-Related Pitfalls

1. Inconsistent Material Purity and Grade

PTFE washers must meet specific industry standards (e.g., ASTM D1457, ISO 13000) depending on the application. A common pitfall is sourcing washers made from regrind or off-spec material, which can compromise chemical resistance, thermal stability, and mechanical strength. Always verify that the PTFE is virgin-grade and conforms to required specifications.

2. Poor Dimensional Accuracy and Tolerances

PTFE is a soft material prone to deformation during machining. Suppliers without precision machining capabilities may produce washers with inconsistent thickness, diameter, or flatness. This can result in leaks or uneven load distribution in sealing applications. Ensure suppliers use CNC machining and provide dimensional inspection reports.

3. Inadequate Surface Finish

A rough surface finish can lead to galling, leakage paths, or contamination in sensitive systems (e.g., semiconductor or pharmaceutical). Verify that surface roughness (Ra value) meets application requirements and that machining processes avoid tearing or smearing the PTFE surface.

4. Lack of Traceability and Certifications

Reputable suppliers should provide material certifications (e.g., CoA – Certificate of Analysis), lot traceability, and compliance with industry-specific standards (e.g., FDA, USP Class VI, EU 10/2011). Sourcing without documentation risks non-compliance in regulated industries.

5. Inconsistent Curing or Sintering Processes

Improper sintering (heat treatment) can leave residual stresses or incomplete crystallization in PTFE, reducing its performance at elevated temperatures. Ensure suppliers follow controlled thermal profiles and validate material properties post-processing.

Intellectual Property (IP)-Related Pitfalls

1. Unauthorized Use of Proprietary Designs

Many PTFE washer configurations (e.g., spiral-wound, jacketed, or custom profiles) are protected by patents or design rights. Sourcing generic copies of patented designs—even from offshore suppliers—can expose your company to infringement claims, especially if the washers are used in commercial products.

2. Reverse Engineering Without Licensing

While reverse engineering for analysis is often legal, manufacturing and selling replicas of patented washer designs without a license constitutes IP infringement. Avoid suppliers that advertise “exact replacements” for branded components unless proper licensing is confirmed.

3. Misuse of Trademarks and Branding

Some suppliers may falsely label washers as “equivalent to” or “compatible with” a branded product (e.g., “like Chemraz® or Kalrez®”), which can create trademark dilution or confusion. Ensure product descriptions are factual and avoid misleading branding.

4. Lack of IP Due Diligence in Supplier Contracts

Failing to include IP indemnification clauses in procurement agreements can leave your company liable for infringement claims arising from supplier-sourced components. Require suppliers to warrant that their products do not infringe third-party IP rights.

5. Sourcing from Regions with Weak IP Enforcement

Suppliers in jurisdictions with lax IP protection may knowingly produce counterfeit or copied designs. While pricing may be attractive, the long-term legal and reputational risks outweigh the short-term savings. Perform supplier audits and favor partners with transparent IP policies.

Best Practices to Mitigate Risks

- Specify material grade, tolerances, and certifications clearly in purchase orders.

- Audit suppliers for quality management systems (e.g., ISO 9001).

- Conduct first-article inspections and periodic batch testing.

- Consult legal counsel when sourcing near-patented designs.

- Use NDAs and IP clauses in supplier agreements.

By addressing both quality and IP concerns proactively, companies can ensure reliable performance and legal compliance when sourcing PTFE washers.

Logistics & Compliance Guide for PTFE Washers

Product Overview and Classification

PTFE (Polytetrafluoroethylene) washers are non-metallic sealing components widely used in industries such as aerospace, automotive, chemical processing, and pharmaceuticals due to their excellent chemical resistance, low friction, and high-temperature tolerance. From a logistics and compliance standpoint, proper classification, packaging, and documentation are critical to ensure safe and legal transport.

Regulatory and Compliance Requirements

PTFE washers are generally not classified as hazardous materials under major transport regulations (e.g., IATA, IMDG, ADR) when shipped in their solid, finished form. However, compliance with international standards such as REACH (EU), RoHS, and FDA (for food contact applications) may apply depending on end-use. Ensure that material certifications (e.g., FDA 21 CFR, ASTM D4894) are available and that products meet any customer-specific compliance needs.

Packaging and Handling Guidelines

To prevent contamination and physical damage, PTFE washers should be packaged in sealed, moisture-resistant materials such as polyethylene bags or vacuum-sealed containers. Use inner dividers or blister packs for delicate or precision washers. Outer packaging must be sturdy (e.g., corrugated cardboard or plastic totes) and labeled appropriately. Avoid exposure to dust, oils, or direct sunlight during storage and transit.

Shipping and Transportation Considerations

PTFE washers can be shipped via standard freight methods—air, sea, or ground—without special handling requirements. However, temperature extremes should be minimized during transit, especially in regions with severe climates. When shipping internationally, ensure Harmonized System (HS) code 3926.30 (other articles of plastics) is correctly applied for customs declarations. Include commercial invoices, packing lists, and any relevant compliance certificates.

Import/Export Documentation and Duties

For cross-border shipments, accurate export declarations are required. PTFE washers may be subject to import duties depending on the destination country. Verify free trade agreement eligibility (e.g., USMCA, EU-South Korea FTA) to potentially reduce tariffs. Maintain records of origin, material declarations, and end-use statements, particularly if supplying regulated industries.

Storage and Shelf Life Management

Store PTFE washers in a clean, dry, temperature-controlled environment (15–25°C recommended). Avoid long-term exposure to UV light or ozone sources. While PTFE has an indefinite shelf life under proper conditions, periodic inspections are advised for inventory older than five years, especially in critical applications.

Environmental, Health, and Safety (EHS) Notes

PTFE is chemically inert and safe under normal handling conditions. However, if exposed to high temperatures exceeding 260°C (500°F), it may degrade and release toxic fumes. Inform logistics partners of this risk to prevent accidental overheating during transport or storage. No special EHS labeling is required for finished PTFE parts under GHS when shipped at ambient temperatures.

Quality Assurance and Traceability

Maintain lot traceability for all PTFE washer batches. Include batch numbers, manufacturing dates, and material certifications with shipments where required. Adhere to ISO 9001 or AS9100 (if aerospace) standards to ensure consistent quality and regulatory alignment throughout the supply chain.

Conclusion for Sourcing PTFE Washers

Sourcing PTFE (Polytetrafluoroethylene) washers requires a strategic approach that balances material quality, supplier reliability, cost efficiency, and compliance with technical specifications. PTFE washers offer exceptional performance in demanding environments due to their outstanding chemical resistance, low friction, wide temperature tolerance, and electrical insulation properties. As such, selecting the right supplier is critical to ensuring consistent product quality and long-term reliability in applications across industries such as aerospace, automotive, pharmaceuticals, and chemical processing.

Key considerations in the sourcing process include verifying material certification (e.g., ASTM standards), assessing manufacturing capabilities (such as precision machining or molding), evaluating supplier lead times and scalability, and confirming adherence to quality management systems like ISO 9001. Additionally, exploring both domestic and international suppliers can optimize cost without compromising on quality, provided due diligence is conducted.

In conclusion, successful sourcing of PTFE washers hinges on a well-informed selection process that prioritizes material integrity, supplier credibility, and total cost of ownership. Establishing long-term partnerships with qualified suppliers not only ensures supply chain stability but also supports ongoing performance and compliance in critical applications.