The global air compressor market is experiencing robust growth, driven by increasing demand across manufacturing, automotive, and construction industries. According to Mordor Intelligence, the market was valued at USD 38.5 billion in 2023 and is projected to grow at a CAGR of over 5.5% from 2024 to 2029. A critical component enabling the efficient and safe operation of air compressors is the pressure switch, which controls compressor cycles by monitoring system pressure. As automation and energy efficiency become priorities, demand for reliable and precision-engineered pressure switches is rising in parallel. With key players focusing on enhanced durability, digital integration, and compliance with international standards, the competitive landscape among pressure switch manufacturers is rapidly evolving. This report highlights the top 9 manufacturers leading innovation and market share in pressure switches for air compressor applications.

Top 9 Pressure Switch In Air Compressor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Air Compressor Pressure Switches

Domain Est. 1999

Website: portlandcompressor.com

Key Highlights: Free delivery over $199Air compressor pressure switches and conversion kits for Ingersoll-Rand, Campbell Hausfeld, Chicago Pneumatic, RolAir, Emglo. OEM, Furnas, Condor….

#2 Pressure Switch For Reciprocating Compressors

Domain Est. 2001

Website: ingersollrand.com

Key Highlights: This air compressor pressure switch is an OEM replacement for all Ingersoll Rand reciprocating air compressors….

#3 Fire Protection Pressure Switches For Air Compressors

Domain Est. 1998

Website: generalairproducts.com

Key Highlights: Upgrade any mechanical pressure switch on your fire protection air compressor with one of our state of the art digital pressure switches….

#4 Air Compressor Industry

Domain Est. 2000

Website: lefoo.com

Key Highlights: LEFOO offers full-range components for the compressor industry, including LF15/LF1X air compressor pressure switches, LF7X oil pressure switches & LFSV ……

#5 Pressure Switches

Domain Est. 2003

Website: aircompressorservices.com

Key Highlights: 2-day delivery 90-day returnsThis tool senses when the pressure in the tank changes and will trigger the adding or decreasing of air accordingly. This helps to keep ……

#6 Air Compressor Pressure Switch, Easy Replacement

Domain Est. 2004

Website: miltonindustries.com

Key Highlights: This universal pressure switch is designed to seamlessly replace pressure switches on compressors with up to 2 HP at 120V 1 phase, 3 HP at 240V 1 phase, or 5 HP ……

#7 LF10-L – AIR COMPRESSOR PRESSURE SWITCH

Domain Est. 2006

#8 Pressure Switches

Domain Est. 2010

Website: compressor-source.com

Key Highlights: Free delivery over $19 60-day returns…

#9 Air Compressor Pressure Switch LFDS61 Supplier …

Domain Est. 2020

Website: lefoogroup.com

Key Highlights: Out of stock Rating 4.8 (50) Lefoo designs and manufactures high-quality air compressor regulator switch. Featured with simple operation, clear display, anti-vibration, high cont…

Expert Sourcing Insights for Pressure Switch In Air Compressor

H2: 2026 Market Trends for Pressure Switches in Air Compressors

The global market for pressure switches in air compressors is poised for significant transformation by 2026, driven by technological innovation, industrial automation trends, and increasing demand for energy-efficient systems. Here are the key market trends expected to shape the industry landscape:

1. Rising Demand from Industrial Automation and Manufacturing

As industries across manufacturing, automotive, and aerospace continue to adopt automated processes, the need for reliable and precise control components like pressure switches is growing. Air compressors are integral to powering pneumatic tools and systems in automated production lines. By 2026, the integration of smart pressure switches with programmable logic controllers (PLCs) and industrial IoT platforms is expected to enhance operational efficiency and predictive maintenance capabilities.

2. Growth in Energy-Efficient and Smart Compressor Systems

Energy efficiency remains a top priority for industrial operators due to rising energy costs and environmental regulations. Modern air compressors are increasingly equipped with intelligent pressure switches that optimize on/off cycles, reduce energy waste, and extend equipment lifespan. The trend toward variable speed drive (VSD) compressors—paired with digital pressure switches—will further accelerate market growth, with demand concentrated in regions enforcing strict energy standards such as the EU and North America.

3. Advancements in Digital and Smart Pressure Switch Technology

Traditional mechanical pressure switches are gradually being replaced by electronic and digital variants offering higher accuracy, remote monitoring, and diagnostics. By 2026, smart pressure switches with built-in sensors, wireless connectivity (e.g., Bluetooth, Wi-Fi), and compatibility with Industry 4.0 systems will gain substantial market share. These devices enable real-time pressure tracking, alarm notifications, and data logging—crucial for preventive maintenance and system optimization.

4. Expansion in Emerging Markets

Emerging economies in Asia-Pacific (especially China, India, and Southeast Asia), Latin America, and parts of Africa are witnessing rapid industrialization and infrastructure development. This expansion is fueling demand for air compressors in construction, mining, and manufacturing sectors—directly boosting the need for pressure switches. Local manufacturing initiatives and government investments in industrial parks are expected to create new opportunities for both domestic and international pressure switch suppliers.

5. Focus on Durability and Safety Compliance

With increasing emphasis on workplace safety and equipment reliability, pressure switches must meet stringent international standards such as CE, UL, and ISO certifications. Manufacturers are investing in robust materials (e.g., corrosion-resistant housings) and fail-safe designs to ensure performance in harsh environments. By 2026, compliance with safety regulations will be a key differentiator in competitive bidding for industrial contracts.

6. Competitive Landscape and Market Consolidation

The pressure switch market is witnessing consolidation as larger players acquire niche technology firms to enhance their digital offerings. Companies such as Honeywell, SMC Corporation, Schneider Electric, and Parker Hannifin are leading innovation with integrated smart solutions. At the same time, regional manufacturers are focusing on cost-effective, high-quality alternatives to capture price-sensitive markets.

7. Sustainability and Eco-Design Initiatives

Environmental concerns are influencing product design. By 2026, pressure switch manufacturers are expected to adopt eco-design principles—reducing hazardous materials, improving recyclability, and minimizing energy consumption during production. This aligns with broader trends in green manufacturing and corporate sustainability goals.

Conclusion

By 2026, the pressure switch market for air compressors will be characterized by a shift toward digitalization, energy efficiency, and integration with smart industrial ecosystems. Growth will be sustained by industrial automation, emerging market expansion, and technological advancements. Companies that invest in intelligent, reliable, and compliant pressure switch solutions will be best positioned to capitalize on these evolving market dynamics.

Common Pitfalls Sourcing Pressure Switches for Air Compressors: Quality and IP Rating Concerns

Sourcing the right pressure switch for an air compressor is critical for safety, performance, and longevity. However, several common pitfalls related to quality and Ingress Protection (IP) ratings can lead to premature failure, safety hazards, or system downtime. Here are the key issues to watch out for:

1. Poor Build Quality and Substandard Materials

One of the most frequent issues is selecting pressure switches made from low-quality materials or with poor manufacturing standards. Cheap switches often feature:

- Thin or brittle plastic housings that crack under vibration or temperature fluctuations.

- Low-grade internal components (e.g., brass instead of stainless steel diaphragms) prone to corrosion or fatigue.

- Inconsistent spring tension or calibration, leading to inaccurate pressure cut-in/cut-out settings.

Impact: These defects can result in erratic compressor cycling, inaccurate pressure control, or complete switch failure, increasing maintenance costs and downtime.

Mitigation Tip: Source from reputable manufacturers or suppliers with certifications (e.g., ISO 9001) and verify material specifications. Look for switches with robust metal housings and corrosion-resistant internals.

2. Incorrect or Misrepresented IP Rating

The Ingress Protection (IP) rating defines a switch’s resistance to dust and moisture. A common pitfall is assuming all switches are suitable for industrial environments without verifying the IP rating.

- Using IP44-rated switches outdoors or in washdown areas, where higher protection like IP65 or IP67 is required.

- Purchasing counterfeit or falsely labeled switches claiming high IP ratings without proper testing or certification.

Impact: Moisture or dust ingress can short-circuit electrical components, cause corrosion, or create safety hazards such as electric shock or fire.

Mitigation Tip: Always confirm the IP rating matches the operating environment. For harsh or outdoor conditions, use IP65 (dust-tight and protected against water jets) or higher. Request test reports or certification documentation from the supplier.

3. Lack of Compliance with Regional Safety Standards

Pressure switches must comply with regional electrical and safety standards (e.g., UL in North America, CE in Europe, CCC in China). Sourcing non-compliant switches—especially from unverified suppliers—can lead to:

- Legal and regulatory issues.

- Voided equipment warranties.

- Increased risk of fire or electric shock.

Impact: Non-compliant switches may lack essential safety features like overload protection or proper insulation.

Mitigation Tip: Ensure the switch carries relevant certifications for your region and application. Verify authenticity through official certification databases when possible.

4. Inadequate Pressure Range or Hysteresis Settings

Even high-quality switches can be unsuitable if their pressure range or differential (hysteresis) doesn’t match the compressor’s requirements.

- Selecting a switch with too narrow a pressure band, causing frequent cycling.

- Using a switch rated below the system’s maximum pressure, risking rupture or failure.

Impact: This leads to increased wear on the compressor motor and reduced lifespan of both the switch and compressor.

Mitigation Tip: Match the switch’s pressure rating (e.g., 100–175 psi) and adjustable differential to your compressor’s specifications. Always include a safety margin.

5. Poor Sealing and Gasket Degradation

Even with a high IP rating, poor sealing design or low-quality O-rings/gaskets can compromise protection over time.

- Gaskets made from incompatible materials that degrade when exposed to oil, moisture, or temperature extremes.

- Inadequate sealing around electrical conduits or pressure ports.

Impact: Gradual ingress of contaminants leads to internal corrosion and switch failure.

Mitigation Tip: Choose switches with high-quality, oil-resistant elastomer seals (e.g., NBR or Viton). Inspect seals during installation and maintenance.

By carefully evaluating quality, verifying IP ratings, and ensuring compliance and compatibility, you can avoid these common sourcing pitfalls and ensure reliable, safe operation of your air compressor system.

Logistics & Compliance Guide for Pressure Switch in Air Compressor

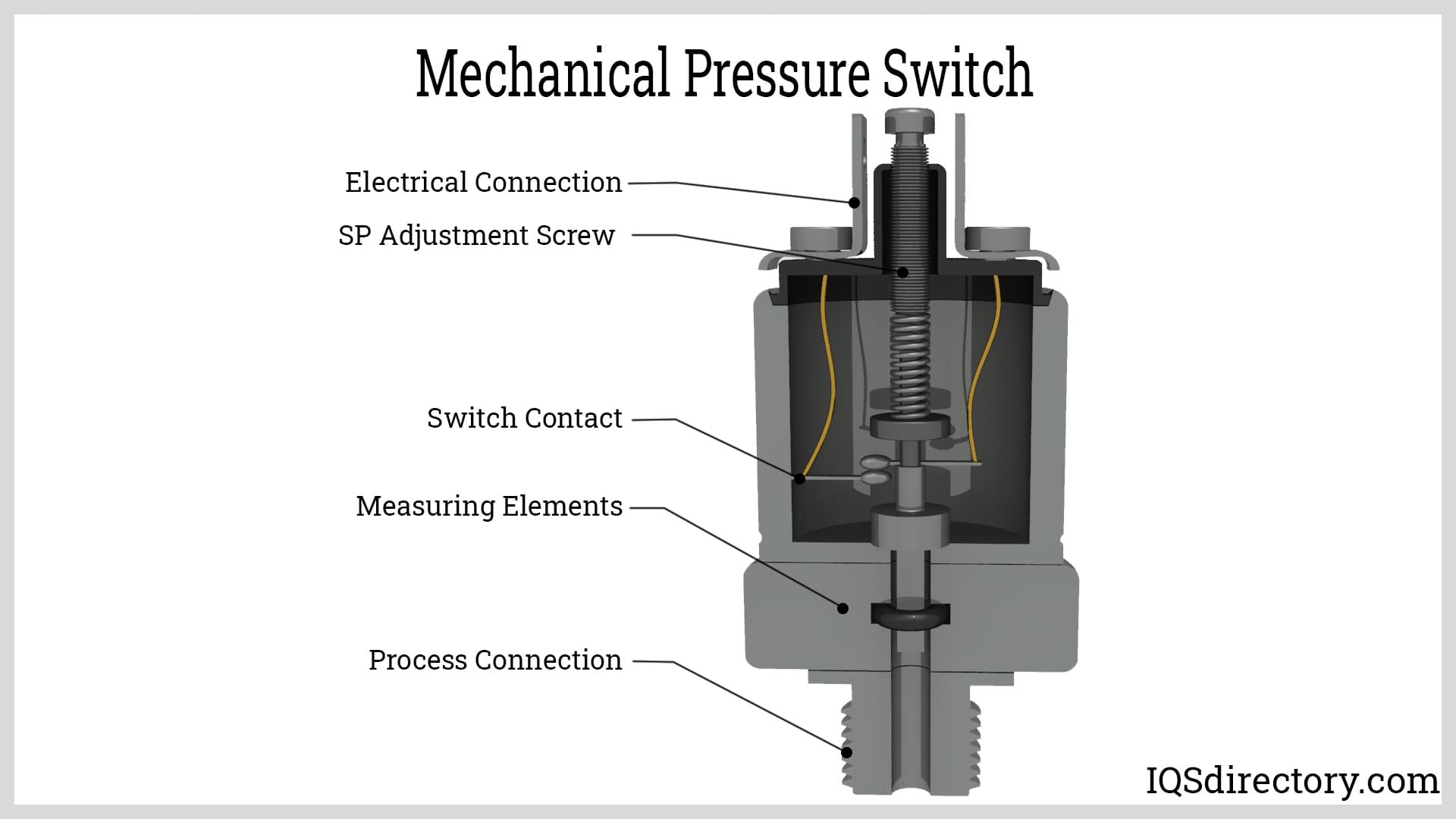

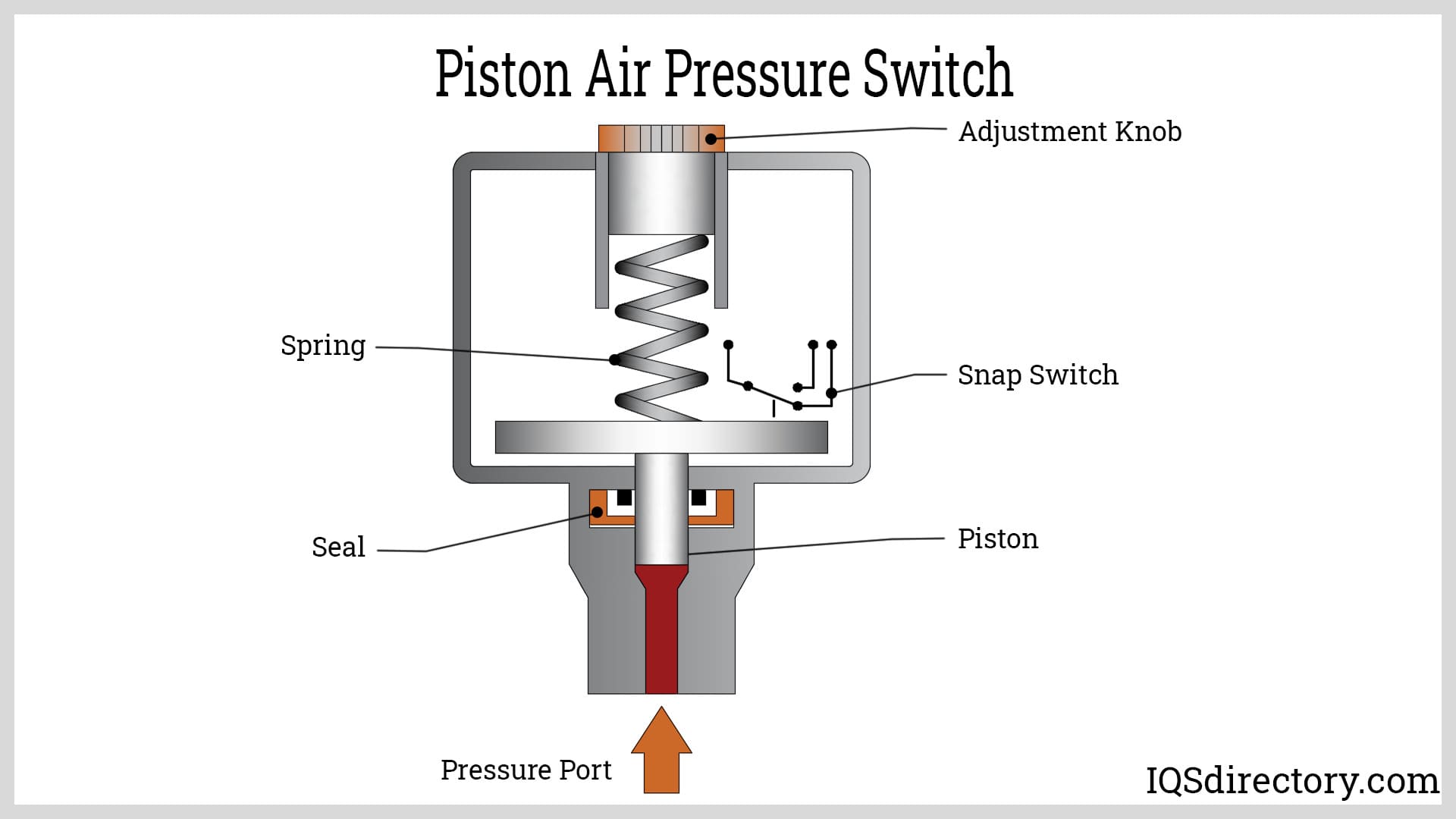

Understanding the Pressure Switch: Role and Importance

The pressure switch is a critical control component in air compressor systems. It automatically starts and stops the compressor motor based on system pressure, maintaining optimal pressure levels and preventing over-pressurization. Proper logistics and compliance handling ensures operational safety, regulatory adherence, and long-term equipment reliability.

Regulatory Compliance Requirements

Pressure switches used in air compressors must meet specific international and regional safety and performance standards. Key compliance certifications include:

- CE Marking (Europe): Must comply with the Pressure Equipment Directive (PED) 2014/68/EU and Electromagnetic Compatibility (EMC) Directive 2014/30/EU.

- UL/CSA (North America): Underwriters Laboratories (UL 508) and Canadian Standards Association (CSA C22.2 No. 14) for industrial control devices.

- ATEX/IECEx (Hazardous Areas): Required if the switch will be used in explosive atmospheres (e.g., industrial plants).

- RoHS and REACH (EU): Restriction of hazardous substances in electrical equipment and chemical compliance.

Ensure all pressure switches are supplied with valid certification documentation and test reports.

Packaging and Transportation Guidelines

Proper packaging is essential to prevent damage during shipping:

- Use anti-static, shock-absorbent packaging for electronic components.

- Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture.”

- Include desiccant packs if transporting through high-humidity environments.

- Secure switches in sturdy corrugated boxes with internal foam or molded inserts to prevent movement.

For international shipments, comply with IATA/IMDG regulations if batteries or hazardous components are present (rare for standard pressure switches).

Import/Export Documentation

Accurate documentation ensures smooth customs clearance:

- Commercial Invoice (with product description, value, and HS Code)

- Packing List (detailing quantity, weight, and dimensions)

- Certificate of Conformity (CoC) or Declaration of Conformity (DoC)

- Bill of Lading or Air Waybill

- Import permits (if required by destination country)

Common HS Code for pressure switches: 9032.89 (Automatic regulating or controlling instruments). Confirm with local customs authority.

Storage and Handling Procedures

Before installation, follow best practices for storage:

- Store in a dry, temperature-controlled environment (typically 5°C to 40°C).

- Avoid exposure to dust, corrosive gases, or direct sunlight.

- Keep in original packaging until ready for use.

- Handle with clean gloves to avoid contamination of electrical contacts.

Maximum recommended storage duration: 24 months from manufacture date.

Installation and Operational Compliance

Ensure correct installation to maintain compliance and safety:

- Follow manufacturer’s wiring and mounting instructions.

- Verify voltage and pressure rating compatibility with the compressor system.

- Ground the switch properly to avoid electrical hazards.

- Perform functional tests (cut-in/cut-out pressure settings) after installation.

Record installation details for compliance audits and maintenance tracking.

Maintenance and Recordkeeping

Regular maintenance supports continued compliance:

- Inspect for signs of wear, corrosion, or damage during routine compressor servicing.

- Test calibration annually or per manufacturer’s recommendations.

- Maintain a log of inspections, repairs, and replacements.

Retention of compliance and maintenance records is often required for 5–10 years, depending on jurisdiction.

End-of-Life and Disposal

Dispose of used pressure switches responsibly:

- Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU.

- Recycle components through certified e-waste handlers.

- Do not dispose of in regular landfill due to metal and electronic content.

Provide disposal guidelines to end users as part of product stewardship.

Adhering to this logistics and compliance guide ensures safe, legal, and efficient handling of pressure switches throughout their lifecycle in air compressor applications.

Conclusion on Sourcing a Pressure Switch for an Air Compressor:

Sourcing the correct pressure switch for an air compressor is a critical step in ensuring the safe, efficient, and reliable operation of the system. The pressure switch plays a vital role in automatically controlling the compressor’s motor by turning it on and off based on preset pressure limits, thereby maintaining optimal air pressure and preventing over-pressurization.

When sourcing a pressure switch, key factors must be carefully evaluated, including voltage and amperage ratings, pressure range (cut-in and cut-out settings), port size and thread type (e.g., NPT), and compatibility with the compressor’s motor and tank configuration. Additionally, environmental conditions such as dust, moisture, and thermal exposure should influence the choice of enclosure rating (e.g., IP protection) and switch durability.

Original Equipment Manufacturer (OEM) switches often guarantee perfect compatibility and performance but may come at a higher cost. Aftermarket or universal switches offer cost-effective alternatives, provided they meet the technical specifications and safety standards (e.g., UL, CE). It is essential to source components from reputable suppliers to avoid counterfeit or substandard products that could compromise safety and performance.

In summary, selecting the right pressure switch involves a balance of technical accuracy, safety compliance, and cost-efficiency. Proper research, verification of specifications, and attention to quality will ensure long-term reliability of the air compressor system and minimize downtime or maintenance issues.