The global pressure relief valve market, a critical component in boiler systems and industrial safety infrastructure, is experiencing steady growth driven by increasing demand across power generation, oil & gas, chemical processing, and HVAC sectors. According to Grand View Research, the global pressure relief valve market was valued at USD 4.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This growth is fueled by stringent safety regulations, rising industrial automation, and the growing emphasis on operational safety in high-pressure environments—highlighting the pivotal role of reliable valve manufacturers. As boiler systems become more advanced and regulatory standards more rigorous, the need for precision-engineered pressure release valves has never been greater. In this landscape, a select group of manufacturers have emerged as industry leaders, combining innovation, compliance, and global reach to meet the evolving demands of modern industrial applications. This list highlights the top nine pressure release valve boiler manufacturers shaping the future of safe and efficient thermal systems.

Top 9 Pressure Release Valve Boiler Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 United Brass Works, Inc.

Domain Est. 1996

Website: ubw.com

Key Highlights: United Brass Works is a leading industrial valve manufacturer offering a range of high-quality products, including boiler, ball, globe, angle, and blowdown ……

#2 Kunkle Valve, Safety and Relief Valves

Website: kunklevalve.company

Key Highlights: Kunkle Valve is a leading manufacturer of quality safety and relief valve products for industrial and commercial applications, including steam, air, ……

#3 Thermon

Domain Est. 1994

Website: thermon.com

Key Highlights: New Electric Boiler Solution. Thermon’s Minke™ Electric Hot Water Boiler from the Precision Boiler family delivers power, precision, and reliability in a ……

#4 Smart Relief Valve

Domain Est. 1995

Website: watts.com

Key Highlights: This small piece of technology, when connected, will provide you with advance warnings of boiler discharge, letting you address potential problems before they ……

#5 WARE

Domain Est. 2000

Website: wareinc.com

Key Highlights: WARE is an industrial and commercial boiler service provider, offering rental equipment, boiler sales, service and maintenance, and boiler parts….

#6 Amtrol

Domain Est. 1994

Website: amtrol.com

Key Highlights: Company · History · Internal Stories · Careers · Products · Residential Products · Well Water · Plumbing & Hot Water · Heating Systems · Commercial Products….

#7 Sid Harvey Boiler Part Finder Boiler Relief Valve

Domain Est. 1997

Website: sidharvey.com

Key Highlights: Pressure Relief Valve 3/4 x 1″ FPT 50 psi Watts Regulators series 740 boiler pressure relief valves are used in hot water space heating boiler applications to ……

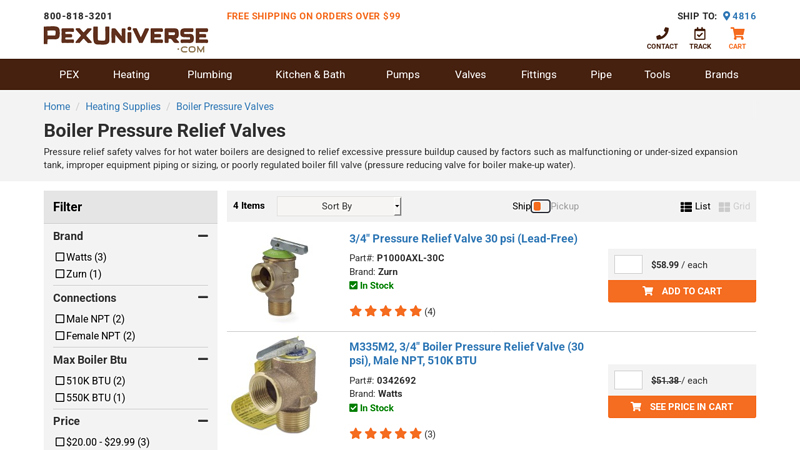

#8 Boiler Pressure Relief Valves

Domain Est. 2009

Website: pexuniverse.com

Key Highlights: Free delivery over $99High-quality relief & safety pressure valves for hot water (hydronic) residential and commercial boiler applications….

#9 Boiler Pressure Relief Valve, 3/4

Domain Est. 2020

Website: rapiroy.com

Key Highlights: Rating 4.0 (15) Jan 1, 2026 · 3/4″, Boiler Water Pressure Relief Valve, On Hydronic Boilers Up To 550,000 BTU, Standard Pressure Relief Setting Is 30 PSI, Iron Body With ……

Expert Sourcing Insights for Pressure Release Valve Boiler

H2: 2026 Market Trends for Pressure Release Valve Boilers

As the global industrial and residential infrastructure continues to evolve, the market for pressure release valve boilers is anticipated to undergo significant transformation by 2026. Driven by regulatory changes, technological advancements, and increasing emphasis on safety and energy efficiency, several key trends are expected to shape the landscape of pressure release valve boiler systems.

Rising Demand for Safety and Compliance

One of the most influential trends in the 2026 market is the tightening of international safety standards for boiler operations. Governments and regulatory bodies—such as ASME (American Society of Mechanical Engineers), the European Pressure Equipment Directive (PED), and local safety codes—are enforcing stricter compliance requirements. This regulatory push is driving demand for advanced pressure release valves (PRVs) that offer higher reliability, fail-safe mechanisms, and real-time monitoring capabilities. Manufacturers are responding by integrating smart sensors and predictive maintenance features into their boiler PRV systems, ensuring early detection of pressure anomalies and reducing the risk of catastrophic failures.

Integration of Smart Technology and IoT

By 2026, the adoption of Internet of Things (IoT)-enabled pressure release valves in boiler systems is expected to accelerate. Smart PRVs equipped with wireless communication, remote diagnostics, and cloud-based analytics allow facility managers to monitor boiler health in real time. This trend is particularly strong in industrial sectors such as power generation, chemical processing, and district heating, where operational continuity and safety are paramount. Predictive analytics powered by AI algorithms will enable proactive maintenance, minimizing downtime and extending equipment lifespan. The convergence of industrial automation and boiler safety systems is expected to increase the market value of smart PRV boilers significantly over the next few years.

Growth in Energy Efficiency and Green Technologies

Sustainability is a major driver in the boiler market. In alignment with global decarbonization goals, the development of high-efficiency condensing boilers with optimized PRV systems is gaining momentum. These systems not only improve safety but also enhance thermal efficiency by maintaining optimal pressure levels and reducing energy waste. The integration of PRVs with renewable energy systems, such as solar thermal and biomass boilers, is projected to grow, especially in Europe and North America. By 2026, pressure release valve technologies will increasingly be designed to support hybrid and low-carbon heating solutions, meeting the demands of environmentally conscious consumers and corporate ESG (Environmental, Social, and Governance) standards.

Regional Market Dynamics

Asia-Pacific is expected to lead market growth in pressure release valve boilers by 2026, fueled by rapid urbanization, industrial expansion, and infrastructure development in countries like India, China, and Southeast Asian nations. Increased construction of commercial and residential buildings with centralized heating systems is boosting demand for reliable boiler safety components. In contrast, mature markets in North America and Europe will focus more on retrofitting existing boiler systems with advanced PRVs to meet new energy codes and safety regulations. Government incentives for upgrading aging infrastructure will further stimulate demand in these regions.

Supply Chain and Material Innovations

Material science advancements are also influencing the 2026 market. The use of corrosion-resistant alloys, such as stainless steel and duplex materials, is becoming standard in PRV construction to ensure durability in high-temperature and high-pressure environments. Additionally, additive manufacturing (3D printing) is beginning to play a role in producing complex valve geometries with improved performance characteristics. These innovations are expected to reduce manufacturing costs and lead times, while enhancing product reliability.

Conclusion

By 2026, the pressure release valve boiler market will be characterized by smarter, safer, and more sustainable systems. The convergence of digital technology, regulatory compliance, and environmental goals will drive innovation and market expansion across both developed and emerging economies. Companies that invest in intelligent safety solutions and align with global sustainability trends are likely to gain a competitive edge in this evolving landscape.

H2: Common Pitfalls When Sourcing a Pressure Release Valve for Boilers (Quality and IP Considerations)

Sourcing a Pressure Relief Valve (PRV) for boiler applications requires careful attention to quality standards and Ingress Protection (IP) ratings to ensure safety, reliability, and compliance. Below are common pitfalls to avoid:

-

Neglecting Certified Quality Standards

One of the most frequent mistakes is selecting valves without proper certification (e.g., ASME, PED, ISO 4126). Using uncertified or substandard valves can lead to catastrophic failures under high pressure and temperature. Always verify compliance with industry-specific standards relevant to your region and application. -

Overlooking Material Compatibility

Choosing a valve made from materials incompatible with boiler conditions (e.g., steam, high temperatures, or corrosive media) reduces lifespan and increases failure risk. Ensure the valve body, spring, and seals are constructed from suitable materials like stainless steel or brass rated for boiler use. -

Incorrect Sizing and Set Pressure

Undersized or incorrectly calibrated valves may not relieve pressure effectively, risking boiler overpressure. Always match the valve capacity (Kv value) and set pressure precisely to the boiler’s operating parameters and safety requirements. -

Ignoring Ingress Protection (IP) Ratings

The IP rating indicates protection against dust and moisture. In boiler rooms, which may be humid or exposed to water splashes, using a valve with insufficient IP protection (e.g., IP54 or lower) can lead to internal corrosion or mechanical failure. Opt for valves with appropriate ratings (e.g., IP65 or higher) when installed in harsh environments. -

Purchasing from Unverified Suppliers

Sourcing from non-reputable vendors increases the risk of counterfeit or poorly manufactured valves. Always procure from certified suppliers with verifiable track records and documentation, including test reports and material certifications. -

Failure to Consider Environmental Conditions

Ambient temperature, vibration, and exposure to chemicals can degrade valve performance. Ensure the selected PRV is designed for the specific environmental conditions of the boiler installation site. -

Lack of Maintenance and Testing Provisions

Some valves are not designed for easy inspection or manual testing. Choose models that allow routine testing (e.g., lift lever) and maintenance to comply with safety regulations and ensure long-term reliability. -

Disregarding Local Regulatory Requirements

Different regions have specific codes (e.g., ASME Section I for power boilers in the US, TRD in Germany). Failing to adhere to local rules can result in non-compliance, fines, or invalidated insurance.

By addressing these pitfalls—particularly ensuring high-quality, certified components and appropriate IP protection—you enhance system safety and avoid costly downtime or hazards.

H2: Logistics & Compliance Guide for Pressure Release Valves (PRVs) for Boilers

This guide outlines essential logistics and compliance considerations for the safe and legal handling, transportation, installation, and maintenance of Pressure Relief Valves (PRVs) used on boilers. Adherence is critical for safety, regulatory approval, and system integrity.

H2: Key Regulatory Standards & Certifications

- ASME Boiler and Pressure Vessel Code (BPVC):

- Section I: Mandatory for Power Boilers (e.g., utility, industrial process). PRVs must be ASME “S” or “HV” stamped (depending on location/application).

- Section VIII, Division 1: Mandatory for Pressure Vessels (including many heating boilers). PRVs must be ASME “U” stamped for the vessel, but the PRV itself requires ASME “UV” stamping.

- Certification: The PRV manufacturer must be an ASME Certificate Holder. The valve must bear the official ASME “UV” (or “S”/”HV”) symbol and National Board “VR” symbol.

- National Board of Boiler and Pressure Vessel Inspectors (NBBI):

- “VR” Stamp: Mandatory on the PRV. Issued by the National Board upon certification of the valve design and manufacturer’s quality system. Required for use on code-stamped boilers/vessels in the US and Canada.

- National Board “R” Stamp: For repair/alteration organizations (if applicable).

- API 576: Inspection of Pressure Relieving Devices. Provides industry best practices for inspection and testing frequency (typically annually for boiler service).

- Local Jurisdictional Requirements: State, Provincial, or Municipal authorities having jurisdiction (AHJ) may have additional rules, inspection requirements, or registration processes. Always verify with the local boiler inspector.

- International Standards (If Applicable):

- PED (Pressure Equipment Directive 2014/68/EU): Required for PRVs placed on the market in the European Economic Area. Requires CE marking and involvement of a Notified Body.

- CRN (Canadian Registration Number): Required for boilers and pressure vessels in Canada. The boiler/vessel design requires CRN registration with the provincial authority; the PRV must be suitable for the registered design.

H2: Logistics: Transportation & Handling

- Packaging & Protection:

- PRVs must be shipped in original manufacturer packaging or equivalent protective packaging.

- Critical: Protect the inlet and outlet openings with robust, sealed caps (usually plastic or metal) to prevent contamination (dirt, moisture, debris) and physical damage to the seat/sealing surfaces.

- Protect the lifting lever (if present) from bending or damage.

- Documentation:

- Bill of Lading (BOL): Accurately describe the shipment (e.g., “Pressure Relief Valves, ASME UV Certified”).

- Material Safety Data Sheet (MSDS/SDS): Generally not required for the valve itself, but required for any lubricants or cleaning agents shipped with it. The valve material (e.g., brass, stainless steel) may have associated SDS.

- Certification Documents: Ship with or ensure immediate access to:

- Manufacturer’s Data Report (MDR) or Certificate of Conformity (CoC).

- ASME “UV” Certificate (or “S”/”HV”).

- National Board “VR” Certificate.

- Test Report (Proof Pressure, Seat Tightness).

- CRN documentation (if required for Canada).

- PED Declaration of Conformity (if applicable).

- Storage:

- Store in a clean, dry, temperature-controlled environment.

- Keep protective caps ON until installation.

- Avoid exposure to corrosive atmospheres, excessive vibration, or physical impact.

- Store upright if possible.

- Handling:

- Never drag, drop, or subject valves to impact.

- Handle by the body, not the cap, lever, or bonnet.

- Use appropriate lifting equipment for large/heavy valves.

H2: Logistics: Installation Requirements

- Pre-Installation Checks:

- Verify the PRV specifications (Set Pressure, Capacity, Connection Size/Type, Material, Temperature Rating) match the boiler/vessel requirements and design documentation.

- Crucial: Confirm ASME “UV” and National Board “VR” stamps are present and legible.

- Inspect for shipping damage. Check protective caps are intact.

- Verify the valve is the correct type (e.g., safety valve, safety relief valve) for the boiler service (steam, hot water, etc.).

- Installation Best Practices:

- Cleanliness: Thoroughly clean boiler outlet piping. Ensure NO debris (scale, weld slag, dirt) enters the valve.

- Orientation: Install strictly per manufacturer’s instructions (usually vertical, discharge up). Never install upside-down.

- Piping: Use full-bore, short, straight discharge piping with minimal bends. Avoid reducing the pipe size downstream of the valve. Ensure discharge piping is adequately supported and vents safely (to atmosphere, away from personnel, considering temperature/steam). Piping must allow free discharge without restriction.

- Connections: Use correct gaskets and proper torque on flange bolts or pipe thread sealant (if applicable, avoid contaminating the valve interior). Ensure alignment to prevent strain.

- Isolation Valves: NEVER install an isolation valve between the boiler and the PRV. Isolation valves are only permitted on inlet piping under very specific, code-allowed conditions (e.g., multiple valves with specific procedures) and require AHJ approval. They are prohibited on the discharge piping.

- Lifting Lever: Ensure the lever operates freely. Do not obstruct it. It must be accessible for manual testing.

- Tagging: Attach a permanent tag indicating Set Pressure, Date of Last Test, and Next Test Due Date.

H2: Compliance: Inspection, Testing & Maintenance

- Initial Testing:

- The valve must be tested by the manufacturer at the specified set pressure and proof pressure. A test report is provided.

- Blowdown Test: The boiler must be raised to pressure under the supervision of the authorized inspector (e.g., ASME Authorized Inspector – AI) to verify the PRV lifts at the correct set pressure and reseats properly. This is often part of the boiler’s initial inspection.

- Routine Inspection & Testing (API 576 Guideline – Verify Local Rules):

- Frequency: Typically annual inspection and testing for boiler service. More frequent testing may be required by jurisdiction or for critical applications. Always follow the most stringent requirement.

- Visual Inspection: Check for corrosion, leakage, damaged discharge piping, tampering, blocked discharge, missing caps (on spare valves), and condition of the lifting lever.

- Functional Test (Manual Lift): Using the lifting lever, manually lift the valve disk slightly (approx. 1/4 of full lift) while the boiler is at NORMAL operating pressure (not safety valve set pressure). This verifies freedom of movement and checks for major seat leakage. Do not hold the lever open. Note: This does NOT verify set pressure accuracy.

- Set Pressure & Capacity Verification: Requires specialized equipment. Typically performed by a qualified valve repair organization (with National Board “R” Stamp) during overhaul or if malfunction is suspected. Involves removing the valve and testing on a calibrated test stand.

- Documentation & Records:

- Maintain detailed logs for each PRV:

- Manufacturer, Model, Serial Number, ASME/NB Stamps.

- Set Pressure, Capacity (lbs/hr or kg/hr steam).

- Date of installation.

- Date of each inspection and manual lift test.

- Name of inspector/technician.

- Results of tests (e.g., “Lifted at approx. 150 psi, reseated, minor seat leakage”).

- Date and details of any repair or overhaul.

- Next scheduled test date.

- Keep manufacturer’s documentation and test reports on file.

- Certification: Records must be available for review by the authorized inspector during boiler inspections.

- Maintain detailed logs for each PRV:

- Repairs & Overhaul:

- Only performed by organizations holding the appropriate National Board “R” Stamp (or equivalent jurisdictional approval).

- Requires complete disassembly, inspection, replacement of worn parts (disc, nozzle, spring, gaskets), reassembly, and retesting to set pressure and seat tightness.

- A new test report and “R” Stamp tag must be issued.

- Never attempt field repairs on the pressure-containing parts or spring.

H2: Critical Compliance Points Summary

- ASME “UV” and National Board “VR” Stamps are MANDATORY for code-stamped boilers/vessels in North America. No exceptions.

- Never install isolation valves on PRV inlet piping without explicit code allowance and AHJ approval. Prohibited on discharge piping.

- Annual inspection and manual lift test are standard (verify local rules).

- Protect openings during shipment, storage, and before installation.

- Maintain meticulous records.

- Use qualified “R” Stamp organizations for repairs.

- Always consult the local Authority Having Jurisdiction (AHJ) for specific requirements.

Disclaimer: This guide provides general information. Always adhere to the specific requirements of the applicable codes (ASME BPVC, NB-23), manufacturer’s instructions, and the regulations of the local Authority Having Jurisdiction (AHJ). Safety is paramount.

Conclusion:

Sourcing a pressure release valve for a boiler is a critical step in ensuring the safe and efficient operation of the heating system. As a key safety component, the pressure relief valve protects against excessive pressure buildup that could lead to equipment failure or hazardous situations. When sourcing this valve, it is essential to consider compatibility with the boiler’s specifications, including pressure rating, temperature range, connection size, and applicable codes and standards (such as ASME, CRN, or local regulations). Selecting a high-quality valve from a reputable supplier, ensuring proper certification, and verifying correct installation procedures are vital to maintaining system integrity and compliance. Ultimately, investing time and diligence in sourcing the right pressure release valve contributes significantly to the longevity of the boiler and, most importantly, the safety of the entire installation.