The global market for industrial vacuum equipment has experienced steady expansion in recent years, driven by rising demand across sectors such as manufacturing, food & beverage, pharmaceuticals, and pulp & paper. According to a 2023 report by Mordor Intelligence, the global vacuum pumps market was valued at USD 3.8 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028. This growth is fueled by technological advancements, increasing automation, and the need for energy-efficient vacuum solutions in industrial applications. Press vacuum systems—critical in processes requiring precise control of suction, compaction, and filtration—are witnessing heightened adoption, particularly in papermaking and dewatering operations. With manufacturers focusing on innovation, reliability, and compliance with sustainability standards, competition among key players has intensified. Based on market presence, performance metrics, and technological capabilities, the following list highlights the top 10 press vacuum manufacturers shaping the industry today.

Top 10 Press Vacuum Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Vacuum Laminating Technology Inc.

Domain Est. 2001

Website: vacuum-press.com

Key Highlights: We manufacture Vacuum Bag Presses and Vacuum Frame Presses for veneering,laminating and clamping,using the finest materials to provide years of heavy-duty ……

#2 Vacuum Press Brands & Manufacturers

Domain Est. 2015

Website: vacuum-presses.com

Key Highlights: Overview of leading vacuum press manufacturers for veneering, laminating and thermoforming. Compatible membranes and components supplied across Europe….

#3 Global Vacuum Presses

Domain Est. 2005

Website: globalvacuumpresses.com

Key Highlights: Global Vacuum Presses offers specially designed vacuum presses, thermoforming stations and hydraulic presses for any applications….

#4 Vacuum Membrane Presses

Website: vacuum-presses.eu

Key Highlights: Manufacturer of VACUUM PRESSES. VACUUM MEMBRANE PRESSES for woodworking and for processing of solid surface materials….

#5 Vacuum Presses

Domain Est. 1997

Website: wabashmpi.com

Key Highlights: Increase quality and productions with the Side Slab and Vacuum Shroud presses from Wabash MPI. Request a quote today!…

#6 Hydraulic and Servo Vacuum Presses

Domain Est. 1998

Website: macrodynepress.com

Key Highlights: Custom Heat Vacuum Presses Made to Order Our heat vacuum presses are available in a wide variety of configurations and capacities from 50 tons to 2,000 tons….

#7 VacuPress® Fliptop Table Press (Frame System)

Domain Est. 1998

Website: vacupress.com

Key Highlights: VacuPress® Fliptop Table Press kits are heavy duty top loading vacuum presses for flat & low profile curved wood work. Offered in: base or base & frame….

#8 Vac

Domain Est. 1998

Website: vac-u-clamp.com

Key Highlights: We manufacture custom vacuum presses for the forming, laminating and thermofoil industries. We also manufacture vacuum bags, pumps and woordworking ……

#9 GVPNA

Domain Est. 2016

Website: gvpna.com

Key Highlights: Global Vacuum Presses engineers, manufactures and markets high-quality vacuum membrane presses, preheating ovens, hydraulic presses, tools and customized ……

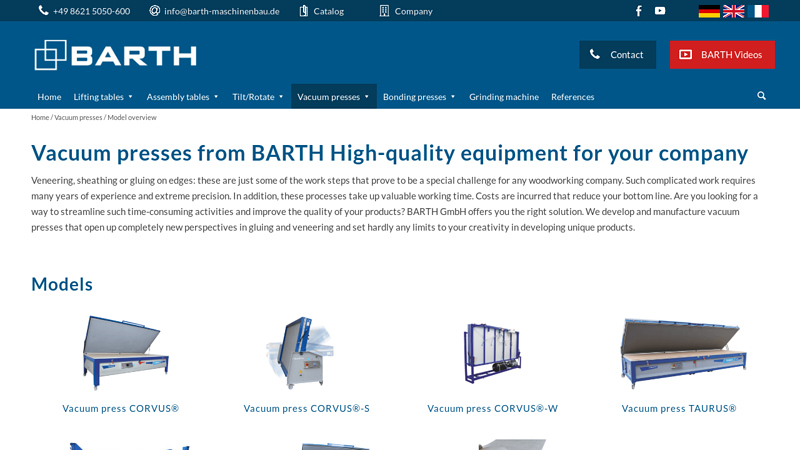

#10 Vacuum presses from BARTH High

Website: barth-maschinenbau.de

Key Highlights: We develop and manufacture vacuum presses that open up completely new perspectives in gluing and veneering and set hardly any limits to your creativity….

Expert Sourcing Insights for Press Vacuum

H2: Market Trends for Press Vacuum Technology in 2026

As of 2026, the press vacuum technology market is experiencing transformative growth driven by advancements in industrial automation, rising demand for energy-efficient manufacturing processes, and increased focus on precision in high-value sectors such as automotive, aerospace, and electronics. Press vacuum systems—used to combine mechanical pressing with vacuum environments to eliminate voids, improve material bonding, and enhance product quality—are becoming increasingly integral in advanced manufacturing workflows. Below are the key market trends shaping the press vacuum industry in 2026:

-

Growing Adoption in Composites Manufacturing

The aerospace and automotive industries are increasingly utilizing composite materials (e.g., carbon fiber-reinforced polymers) to reduce weight and improve fuel efficiency. Press vacuum systems are critical in autoclave and vacuum-assisted resin transfer molding (VARTM) processes. With OEMs pushing for lightweight vehicle designs and next-generation aircraft, demand for high-performance press vacuum solutions is surging. -

Integration with Industry 4.0 and Smart Manufacturing

Press vacuum systems are being enhanced with IoT-enabled sensors, real-time monitoring, and predictive maintenance capabilities. In 2026, smart press vacuum machines can automatically adjust pressure, temperature, and vacuum levels based on live feedback, improving process consistency and reducing scrap rates. This integration supports digital twin technologies and data-driven quality assurance. -

Expansion in Renewable Energy Applications

The wind energy sector is a major driver, where press vacuum technology is used in the production of wind turbine blades. As global investments in renewable energy continue to rise, manufacturers are scaling up blade production using vacuum-assisted pressing to ensure structural integrity and durability under extreme conditions. -

Focus on Sustainability and Energy Efficiency

Regulatory pressures and corporate sustainability goals are pushing manufacturers to adopt energy-efficient equipment. Modern press vacuum systems in 2026 feature optimized vacuum pumps, heat recovery mechanisms, and reduced cycle times—lowering overall energy consumption and operational costs. -

Regional Market Shifts and Supply Chain Localization

Asia-Pacific, particularly China and India, is emerging as a key growth region due to expanding manufacturing bases and government support for high-tech industries. Meanwhile, North America and Europe are focusing on reshoring critical production, boosting demand for advanced press vacuum systems in localized factories. -

Advancements in Materials Science

New materials such as thermoplastic composites and multifunctional laminates require precise control of pressure and vacuum during forming. Innovations in press vacuum technology—such as multi-zone vacuum control and rapid cycling—are enabling the processing of these next-generation materials. -

Increased Customization and Modular Designs

End-users are demanding modular and scalable press vacuum systems that can be reconfigured for different applications. Equipment suppliers are responding with customizable platforms that support quick changeovers, reducing downtime and increasing operational flexibility.

Conclusion

By 2026, the press vacuum market is poised for sustained growth, underpinned by technological innovation and expanding applications across high-growth industries. Companies investing in intelligent, energy-efficient, and adaptable press vacuum solutions are well-positioned to lead in this evolving landscape.

Common Pitfalls in Sourcing Press and Vacuum Systems (Quality, IP)

When sourcing press and vacuum systems—especially in industries like semiconductor, pharmaceutical, or advanced manufacturing—overlooking critical quality and intellectual property (IP) considerations can lead to significant operational, financial, and legal risks. Below are common pitfalls to avoid:

1. Underestimating Quality Requirements for Critical Applications

Press and vacuum systems often operate in high-precision environments where even minor deviations can cause product defects or process failures. A common mistake is selecting suppliers based solely on cost or lead time, without verifying compliance with industry-specific quality standards (e.g., ISO 9001, SEMI F47, or GMP). Inadequate quality controls can result in inconsistent performance, increased downtime, and contamination risks.

2. Inadequate Validation and Documentation

Many sourcing teams fail to demand complete quality documentation such as Material Test Reports (MTRs), calibration certificates, or Factory Acceptance Test (FAT) records. Without these, it becomes difficult to validate system performance or meet regulatory audits. Lack of traceability can also complicate root cause analysis during failures.

3. Overlooking Supplier Qualification and Audit Rights

Relying on unqualified or second-tier vendors without conducting on-site audits increases the risk of subpar workmanship. Ensure suppliers have a proven track record and allow for periodic quality audits. Contractual terms should include audit rights and non-conformance reporting procedures.

4. Ignoring Intellectual Property (IP) Ownership and Licensing

A major pitfall is assuming that purchasing equipment transfers full IP rights. Custom-designed press or vacuum systems may include proprietary control algorithms, mechanical designs, or software. Without clear contractual agreements, buyers may face limitations on maintenance, modification, or resale. Always define IP ownership upfront—preferably assigning all custom-developed IP to the buyer.

5. Using Proprietary Components Without Licensing Clarity

Suppliers may integrate third-party components with restricted licenses. If the end-user doesn’t have proper access or redistribution rights, future upgrades or repairs could be blocked. Ensure that all embedded software and firmware are either open-licensed or come with perpetual, royalty-free usage rights.

6. Inadequate Protection of Internal Specifications and Designs

When providing detailed technical specifications to potential suppliers, companies risk exposing sensitive process know-how. Without robust Non-Disclosure Agreements (NDAs) and data handling clauses, there’s a risk of IP leakage or reverse engineering by the supplier or its subcontractors.

7. Failure to Address IP in Service and Maintenance Contracts

Post-purchase service agreements may involve remote diagnostics or firmware updates that expose system logic. Ensure maintenance contracts include clauses that restrict the supplier’s use of operational data and prohibit reverse engineering of system behavior.

Avoiding these pitfalls requires a proactive sourcing strategy that prioritizes quality assurance, thorough supplier vetting, and ironclad IP protections in all contractual agreements.

Logistics & Compliance Guide for Press Vacuum

This guide outlines key logistics and compliance considerations for the safe, efficient, and legally compliant handling, storage, transportation, and use of press vacuum equipment (e.g., vacuum presses, vacuum bags, pumps, and related systems).

Regulatory Compliance

Ensure all operations adhere to relevant local, national, and international regulations. Key areas include:

– Occupational Health and Safety (OHS): Comply with OSHA (or equivalent) standards for workplace safety, including machine guarding, electrical safety, and hazard communication.

– Electrical Standards: Verify equipment meets applicable electrical codes (e.g., NEC in the U.S., IEC internationally) and carries required certifications (e.g., UL, CE, CSA).

– Environmental Regulations: Follow EPA (or equivalent) guidelines for the disposal of vacuum bagging materials, resins, and other consumables used in vacuum press processes.

– Import/Export Controls: For international shipments, comply with customs regulations, export control laws (e.g., EAR), and proper documentation (commercial invoices, packing lists, certificates of origin).

Equipment Handling and Storage

Proper handling and storage prevent damage and extend equipment life.

– Lifting and Moving: Use appropriate lifting equipment (forklifts, pallet jacks) for heavy components like vacuum platens or pumps. Never lift by hoses or control panels.

– Storage Conditions: Store equipment in a clean, dry, temperature-controlled environment. Protect vacuum bags and seals from UV exposure, sharp objects, and extreme temperatures.

– Positioning: Keep vacuum presses on level, stable surfaces with adequate clearance for operation and maintenance.

Transportation Requirements

Safely transport press vacuum systems to avoid damage or safety hazards.

– Packaging: Secure all components in robust packaging with cushioning. Use original crates when possible. Label fragile or heavy items clearly.

– Securement: During transit, ensure equipment is anchored to prevent shifting. Cover exposed connectors and hoses.

– Documentation: Include safety data sheets (SDS) for any hazardous materials (e.g., release agents, resins) and equipment manuals in the shipment.

Installation and Site Preparation

Prepare the installation site to meet operational and safety standards.

– Space Requirements: Allow sufficient space for press operation, material loading/unloading, and emergency access.

– Power Supply: Confirm voltage, phase, and amperage requirements match site power. Use dedicated circuits if recommended.

– Ventilation: Ensure adequate ventilation if using solvent-based resins or adhesives in conjunction with the vacuum process.

Operational Safety and Training

Ensure personnel are trained and procedures are in place for safe operation.

– Operator Certification: Only trained and authorized personnel should operate press vacuum equipment.

– Personal Protective Equipment (PPE): Require appropriate PPE, including safety glasses, gloves, and hearing protection where applicable.

– Lockout/Tagout (LOTO): Implement LOTO procedures during maintenance or servicing to prevent accidental startup.

Maintenance and Inspection

Regular maintenance ensures reliability and compliance.

– Scheduled Servicing: Follow manufacturer-recommended maintenance intervals for pumps, seals, heating elements, and control systems.

– Inspection Logs: Maintain records of inspections, repairs, and component replacements.

– Calibration: Periodically calibrate pressure and temperature sensors to ensure process accuracy and repeatability.

Waste Management and Disposal

Handle waste materials responsibly and in accordance with environmental laws.

– Segregation: Separate hazardous waste (e.g., resin-contaminated vacuum bags) from general waste.

– Disposal Vendors: Use licensed waste disposal contractors for hazardous materials.

– Recordkeeping: Maintain waste manifests and disposal records for audit purposes.

Documentation and Recordkeeping

Maintain accurate records to support compliance and traceability.

– Equipment Logs: Track usage, maintenance, and incidents for each press unit.

– Compliance Certificates: Keep copies of CE, UL, or other certification documents on file.

– Training Records: Document employee training and certifications related to equipment operation and safety.

Adherence to this guide ensures safe, efficient, and legally compliant operations involving press vacuum systems. Regular reviews and updates are recommended to reflect changes in regulations or equipment.

Conclusion on Sourcing Press Vacuum Systems

In conclusion, sourcing a press vacuum system requires a comprehensive evaluation of technical specifications, operational requirements, supplier reliability, and lifecycle costs. Selecting the appropriate vacuum technology—whether mechanical, pneumatic, or hybrid—must align with the specific demands of the press application, including cycle speed, vacuum level, energy efficiency, and integration capabilities. A thorough supplier assessment ensures not only product quality and after-sales support but also long-term performance and minimal downtime. By prioritizing durability, efficiency, and compatibility with existing systems, organizations can optimize productivity and reduce operational costs. Ultimately, a well-informed sourcing decision enhances press performance, supports consistent production output, and contributes to overall manufacturing excellence.