The global construction materials market is experiencing steady expansion, driven by rising infrastructure development and urbanization, particularly across emerging economies. According to Mordor Intelligence, the global joint filler market is projected to grow at a CAGR of approximately 5.2% from 2023 to 2028. This growth is fueled by increasing demand for durable, weather-resistant materials in roadways, bridges, and commercial buildings—applications where premolded joint fillers play a critical role in preventing structural damage due to thermal expansion and moisture ingress. With stringent building codes and a growing focus on long-term structural integrity, contractors and engineers are increasingly specifying high-performance premolded options over traditional alternatives. As a result, innovation and reliability among manufacturers have become key differentiators. Below, we spotlight the top eight premolded joint filler manufacturers leading the market through product quality, technical expertise, and global reach.

Top 8 Premolded Joint Filler Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Expansion Joints

Domain Est. 1999

Website: lymtal.com

Key Highlights: A cost effective system utilizing a factory cured, premolded urethane seal which is installed in the field by adhering in place with a polymeric nosing compound ……

#2 Preformed Joint Fillers

Domain Est. 2003

Website: dot.state.mn.us

Key Highlights: Preformed Joint Fillers · W.R. Meadows, Inc. · Nomaco · Global Wholesale Supply · ProFlex · JD Russel Company · Guidance · Contact….

#3 Concrete Expansion Joints

Domain Est. 1995

Website: wrmeadows.com

Key Highlights: X-FOAM expansion joint filler is a flexible, lightweight, non-staining, polypropylene, closed-cell expansion joint filler….

#4 Joint Sealants

Domain Est. 1995

Website: usa.sika.com

Key Highlights: … joint sealant solutions that will suit all of your construction needs, browse our product lines to find which joint sealant is the solution for your next…

#5 Movement & Expansion Joints

Domain Est. 1995

Website: laticrete.com

Key Highlights: 30-day returnsProtect your floor from cracks and movement with LATICRETE’s full line of expansion joint profiles. Learn more and protect your floors today!…

#6 Expansion Joint Filler Boards

Domain Est. 2001

Website: madar.com

Key Highlights: Conquer expansion in buildings, bridges, roads, and more with these durable, versatile boards made from recycled bitumen fibers….

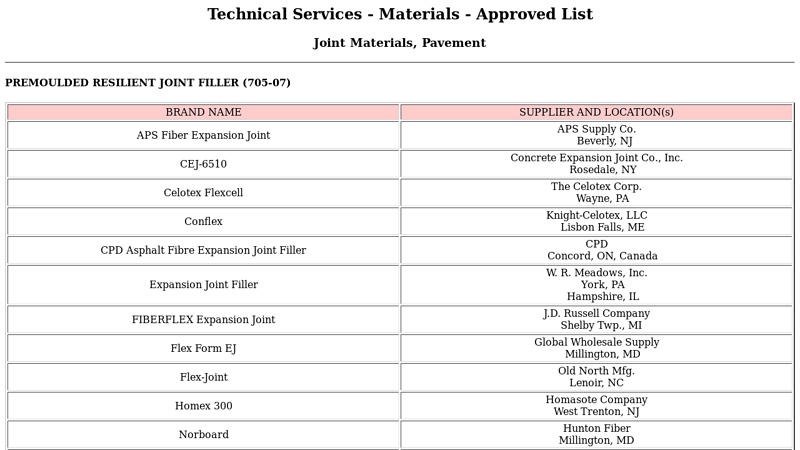

#7 Premoulded Resilient Joint Filler (705

Domain Est. 2002

Website: dot.ny.gov

Key Highlights: PREMOULDED RESILIENT JOINT FILLER (705-07) ; BRAND NAME, SUPPLIER AND LOCATION(s) ; APS Fiber Expansion Joint. APS Supply Co. Beverly, NJ ; CEJ- ……

#8 Concrete Expansion Joint Fillers & Surface Repair

Domain Est. 2009

Website: xtremepolishingsystems.com

Key Highlights: 3-day delivery 15-day returns…

Expert Sourcing Insights for Premolded Joint Filler

H2: 2026 Market Trends for Premolded Joint Filler

The global premolded joint filler market is expected to experience steady growth through 2026, driven by rising infrastructure development, urbanization, and increasing demand for durable construction materials. These elastomeric or foam-based products are essential in concrete construction—used in bridges, highways, buildings, and dams—to accommodate movement, prevent debris intrusion, and enhance structural longevity.

A key trend shaping the 2026 outlook is the surge in public and private infrastructure investments, particularly in emerging economies across Asia-Pacific, Latin America, and Africa. Countries like India, Indonesia, and Brazil are launching large-scale transportation and urban development projects, directly boosting demand for high-performance joint fillers that ensure structural resilience.

Sustainability is another driving force. By 2026, manufacturers are increasingly focusing on eco-friendly materials, including recycled content and low-emission production processes, to meet tightening environmental regulations and green building certifications like LEED and BREEAM. This shift is encouraging innovation in bio-based and recyclable premolded joint filler solutions.

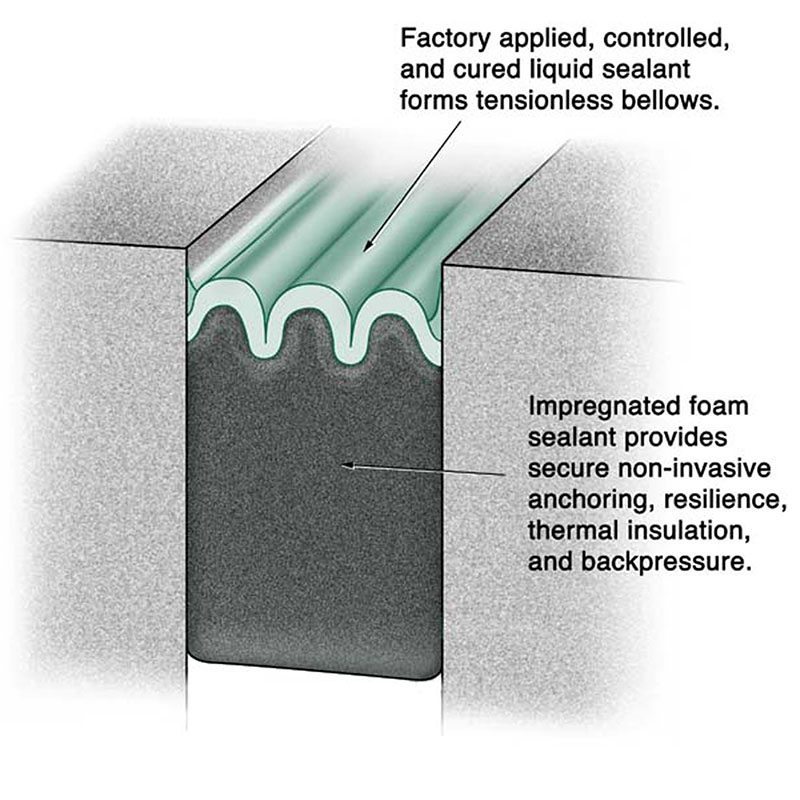

Technological advancements are also influencing market dynamics. The development of closed-cell foam fillers with enhanced compressibility, UV resistance, and moisture barrier properties is improving product performance and lifespan. Smart construction trends may further integrate sensors into joint systems, though this remains in early stages.

Regionally, North America and Europe maintain mature markets with steady demand due to infrastructure renovation and seismic retrofitting projects. Meanwhile, the Asia-Pacific region is projected to lead market growth, supported by rapid urbanization and government-backed infrastructure initiatives such as China’s Belt and Road and India’s National Infrastructure Pipeline.

Supply chain resilience has become a strategic focus post-pandemic. By 2026, leading suppliers are localizing production and diversifying raw material sources to mitigate disruptions, especially for petroleum-derived polymers used in many joint filler formulations.

In summary, the 2026 premolded joint filler market will be characterized by growth in emerging regions, a push toward sustainable and high-performance materials, and integration with modern construction practices—positioning the industry for innovation and expansion in both volume and application scope.

Common Pitfalls Sourcing Pre-molded Joint Filler (Quality and Intellectual Property)

Sourcing pre-molded joint filler requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to project delays, structural failures, costly rework, or legal disputes. Below are key pitfalls to avoid:

Poor Material Quality and Performance

One of the most significant risks when sourcing pre-molded joint filler is selecting a substandard product that fails to meet project specifications. Common quality-related pitfalls include:

- Inadequate Compression and Recovery Properties: Low-quality fillers may not compress sufficiently during concrete pouring or fail to recover adequately after load release, leading to joint leakage or cracking.

- Insufficient Durability: Inferior materials may degrade prematurely due to exposure to UV radiation, moisture, or chemical contaminants, compromising long-term joint performance.

- Non-Compliance with Standards: Some suppliers provide products that do not meet ASTM C1714, AASHTO M214, or other relevant standards, resulting in non-compliant installations.

- Inconsistent Dimensions and Tolerances: Poor manufacturing control can lead to variations in thickness, width, or density, making installation difficult and reducing effectiveness.

- Lack of Third-Party Testing: Suppliers may not provide verifiable test reports or certifications, making it difficult to confirm performance claims.

Intellectual Property (IP) Infringement Risks

Pre-molded joint filler formulations and designs can be protected by patents, trademarks, or trade secrets. Ignoring IP rights during sourcing can expose buyers and contractors to legal liability:

- Using Patented Technology Without Authorization: Some high-performance joint fillers incorporate proprietary materials or structural designs protected by active patents. Sourcing generic alternatives that mimic these features may constitute infringement.

- Reliance on “Copycat” Products: Suppliers may offer knock-offs of branded products with similar names or packaging, potentially violating trademarks or design patents.

- Insufficient Due Diligence: Buyers may fail to verify whether a supplier has the right to manufacture and sell the product, especially when sourcing from overseas or lesser-known manufacturers.

- Contractual Exposure: Contracts that require the use of “equal” products without proper validation may inadvertently specify infringing alternatives, leaving the specifier or contractor liable.

To mitigate these risks, always verify material certifications, request independent test data, conduct supplier audits, and consult legal or technical experts when evaluating non-original equipment manufacturer (OEM) products.

Logistics & Compliance Guide for Preformed Joint Filler

Overview of Preformed Joint Filler

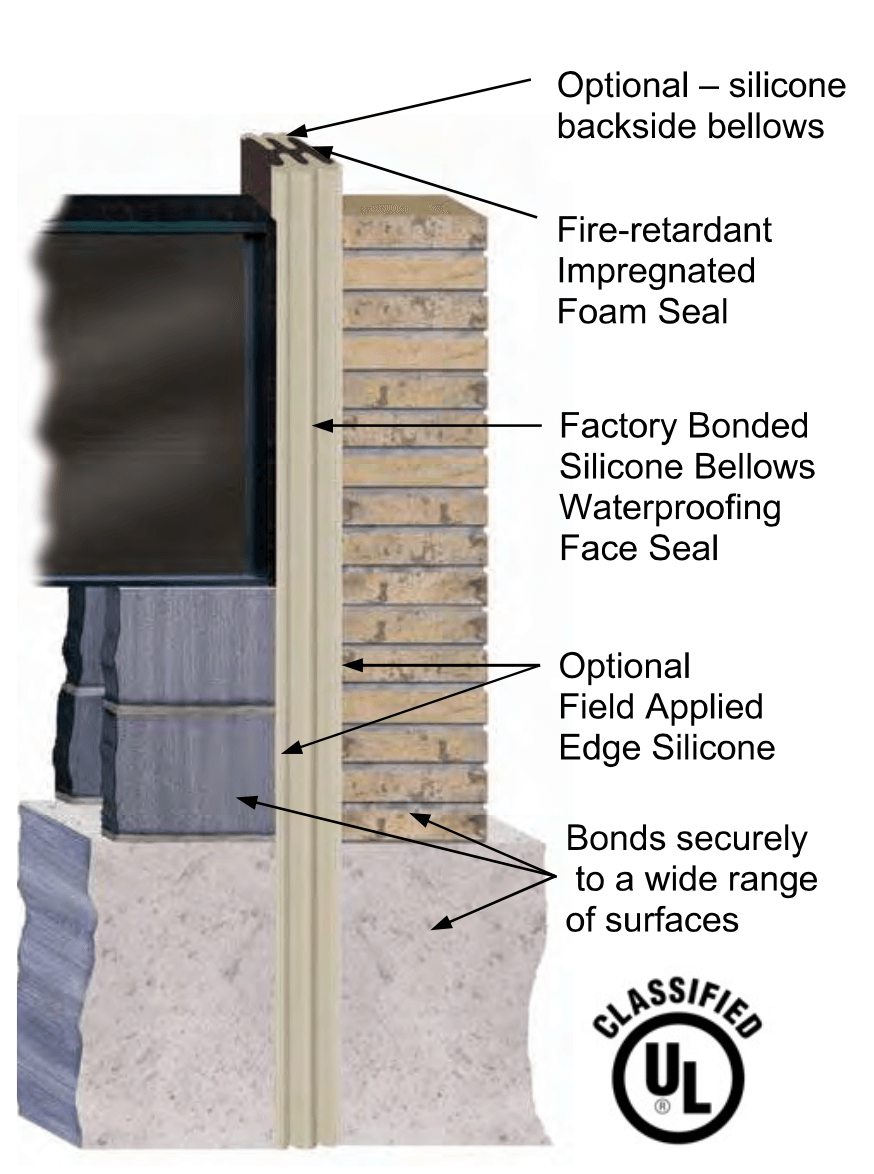

Preformed joint filler is a compressible material—commonly made from closed-cell foam, fiberboard, rubber, or polymer-based composites—designed to be installed in construction joints to prevent intrusion of debris and incompressibles. It accommodates movement in concrete, masonry, and pavement systems while preparing the joint for proper sealant application. Proper logistics and compliance management ensure product performance and regulatory adherence.

Storage & Handling Requirements

Store preformed joint filler in a dry, well-ventilated area, protected from direct sunlight, moisture, and extreme temperatures. Rolls or sheets should remain in original packaging until use to prevent deformation or contamination. Handle with care to avoid crushing or tearing, which may compromise performance. Avoid stacking heavy materials on filler rolls or panels, and store vertically when possible to maintain shape integrity.

Transportation Guidelines

During transport, secure packaging to prevent shifting, moisture exposure, or mechanical damage. Use covered vehicles to protect from rain, snow, and UV degradation. Temperature-sensitive materials (e.g., polymer-based fillers) should be transported within manufacturer-recommended temperature ranges. Ensure vehicles are clean and free of debris that could contaminate the product.

Regulatory Compliance

Preformed joint filler must comply with relevant industry standards such as ASTM C1780 (Standard Specification for Preformed Compression Seals) or ASTM D1751 (Standard Specification for Preformed Sponge Rubber and Cork Expansion Joint Fillers). Confirm product certification upon delivery. In some jurisdictions, volatile organic compound (VOC) emissions or material sourcing (e.g., recycled content) may be regulated—verify compliance with local environmental codes (e.g., EPA, EU REACH).

Safety & Environmental Considerations

While most preformed joint fillers are inert and non-hazardous, review the Safety Data Sheet (SDS) provided by the manufacturer. Some materials may generate dust during cutting; use appropriate personal protective equipment (PPE), including gloves and respiratory protection when necessary. Dispose of offcuts according to local waste management regulations—many materials are recyclable or landfill-safe depending on composition.

Installation & Field Compliance

Install only in clean, dry joints free of standing water or debris. Ensure filler depth and compression match project specifications to avoid over-compression or underfilling. Coordinate with sealant application schedules to prevent exposure to weather or traffic prior to sealing. Document compliance with project specifications and quality control procedures, including material batch numbers and inspection records.

Documentation & Traceability

Maintain records of material submittals, certificates of compliance, test reports, and delivery receipts. Track lot numbers and expiration dates (if applicable) to support warranty claims and facilitate recalls if needed. Provide as-built documentation showing installed product types and locations for long-term maintenance planning.

Conclusion:

Sourcing pre-molded joint filler requires a strategic approach that balances material quality, supplier reliability, cost-efficiency, and compliance with project specifications and industry standards. Selecting the right pre-molded joint filler—whether for concrete pavements, bridge decks, or other construction applications—ensures long-term durability, water resistance, and structural performance. It is essential to engage with reputable suppliers who offer certified products, consistent manufacturing quality, and technical support. Additionally, considering factors such as environmental conditions, installation methods, and lifecycle costs will contribute to optimal performance and reduced maintenance over time. Ultimately, informed sourcing decisions enhance project efficiency, reduce risks, and support the longevity and integrity of infrastructure systems.