The global prefabricated patio covers market is experiencing robust growth, driven by rising demand for low-maintenance outdoor living solutions and faster installation times compared to custom-built structures. According to Grand View Research, the global market for outdoor furniture and structures—encompassing prefabricated patio covers—was valued at approximately USD 21.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further amplified by increasing residential renovation activities and a growing preference for modular, weather-resistant outdoor shading systems. Mordor Intelligence also projects steady expansion in the architectural and structural metal products market—key components of prefab patio systems—citing urbanization and infrastructure spending as key drivers. As consumer demand shifts toward customizable, cost-effective, and quickly deployable outdoor solutions, manufacturers specializing in prefabricated patio covers are scaling production and innovation. Based on market presence, product range, customer reviews, and technological advancement, the following are the top 10 prefabricated patio covers manufacturers leading this expanding industry.

Top 10 Prefabricated Patio Covers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

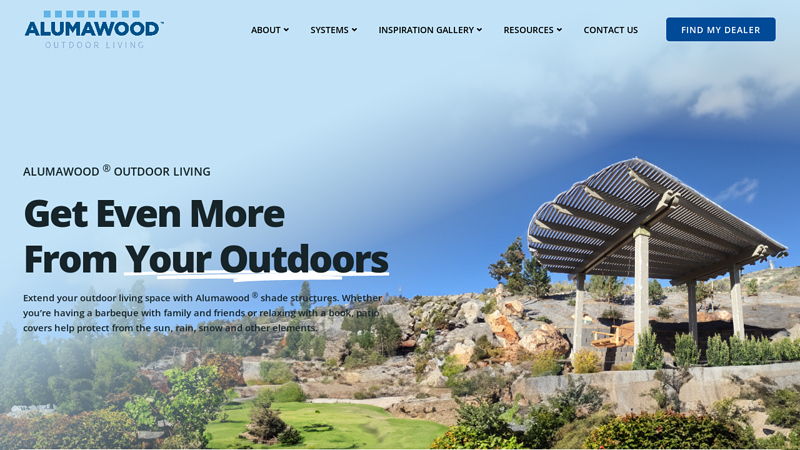

#1 Alumawood

Domain Est. 2010

Website: alumawoodfactorydirect.net

Key Highlights: Our custom designed Maxxwood®, Alumawood® and Equinox® patio covers and pergolas offer the perfect blend of style, durability and protection….

#2 Wrisco’s Enclosure Installation Services

Domain Est. 1996

Website: wrisco.com

Key Highlights: Our pre-engineered patio covers can complement a variety of sites, roofs, and resident conditions. And our dealers are qualified to assist you in planning a ……

#3 Patio Covers

Domain Est. 1998

Website: temosunrooms.com

Key Highlights: Patio covers from TEMO are ideal for homeowners who want a beautiful, easy-to-install shade structure. Our covers come in two styles: solid roof and carport….

#4 Aluminum Patio Covers Installers

Domain Est. 1999 | Founded: 2006

Website: eliteexteriors.com

Key Highlights: We have been installing custom, high quality, durable patio covers, sunrooms & louvered roofs since 2006. Request a Free In Home Estimate Today!…

#5 American Patio Covers

Domain Est. 2004

Website: americanpatiocovers.com

Key Highlights: We provide fully customizable patio covering systems to protect and beautify your outdoor space. Produced from the most weatherable polymer on the market, ……

#6 Aluminum Patio Covers That Look Like Wood

Domain Est. 2008

Website: alumawoodpatio.com

Key Highlights: Transform your outdoor space with Alumawood’s premium aluminum shade structures. Upgrade your outdoor space with lattice, solid and insulated panel systems….

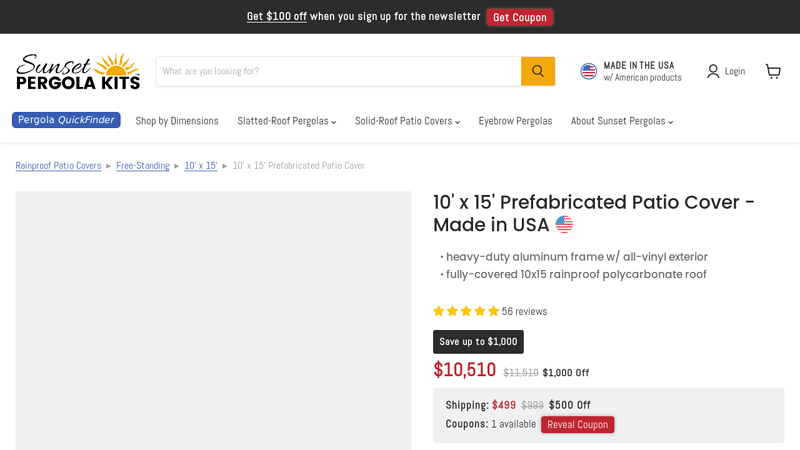

#7 10′ x 15′ Prefabricated Patio Cover

Domain Est. 2014

#8 Renaissance Patio

Domain Est. 2017

Website: renaissancepatio.com

Key Highlights: We design and manufacture the strongest and most beautiful line of decorative Patio Covers, Patio Roofing, Screen Rooms, Pergolas, Gazebos and Sunrooms….

#9 Azenco Outdoor

Domain Est. 2017

Website: azenco-outdoor.com

Key Highlights: Azenco Outdoor: The finest custom motorized pergolas, patio covers, and outdoor living solutions in the USA—a Hunter Douglas Outdoor brand….

#10 Patio Covers

Domain Est. 2020

Expert Sourcing Insights for Prefabricated Patio Covers

2026 Market Trends for Prefabricated Patio Covers

As consumer preferences shift toward outdoor living, cost-effective home improvements, and sustainable building solutions, the market for prefabricated patio covers is poised for significant growth and transformation by 2026. This analysis explores the key trends shaping the industry over the next few years, focusing on demand drivers, technological advancements, regional dynamics, and sustainability.

Rising Demand for Outdoor Living Spaces

The popularity of outdoor living continues to surge, fueled by changing lifestyles and increased time spent at home. Following the long-term impact of remote work and wellness-focused home environments, homeowners are investing in functional, aesthetically pleasing outdoor areas. Prefabricated patio covers offer an affordable and quick solution to enhance outdoor comfort by providing shade, protection from rain, and extended usability of patios and decks. By 2026, this demand is expected to remain strong, particularly among millennials and Gen Z homeowners who value both design and convenience.

Advancements in Material Technology

Innovation in materials is a critical trend influencing the prefabricated patio cover market. Manufacturers are increasingly utilizing lightweight, durable materials such as powder-coated aluminum, polycarbonate panels, and composite polymers. These materials offer greater resistance to weather, corrosion, and UV degradation, extending product lifespan and reducing maintenance. Additionally, integration with solar panels—where roof panels double as solar energy generators—is expected to gain traction, aligning with energy efficiency trends and government incentives for renewable energy adoption.

E-Commerce and Direct-to-Consumer Sales Growth

The distribution model for prefabricated patio covers is rapidly evolving. Online retailers and direct-to-consumer (DTC) brands are gaining market share by offering customizable kits, detailed installation guides, and augmented reality (AR) tools to visualize the product in a user’s space. By 2026, e-commerce is projected to dominate sales channels, especially as younger consumers prefer digital shopping experiences and value transparency in pricing and product specifications.

Emphasis on DIY Installation and Modular Design

Ease of installation remains a key selling point. Prefabricated patio covers are designed for DIY assembly, reducing labor costs and installation time. In 2026, expect to see even more modular and tool-free designs, with snap-together components and smart alignment systems. This trend lowers barriers to entry for homeowners and supports the growing do-it-yourself home improvement movement, which is further bolstered by instructional content on platforms like YouTube and TikTok.

Regional Market Expansion and Climate Adaptability

Regional demand varies based on climate and housing trends. In the Sun Belt regions of the U.S. (e.g., Texas, Florida, Arizona), high temperatures and strong outdoor culture drive demand for shade solutions. In contrast, northern states are seeing increased interest in all-season patio enclosures with insulation and weather-resistant features. Internationally, markets in Australia, Southern Europe, and the Middle East are also expanding due to urbanization and rising disposable incomes. Manufacturers are responding by offering climate-specific models with ventilation, snow load ratings, and hurricane-resistant designs.

Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing product development and consumer choices. By 2026, sustainability will be a major differentiator. Companies are adopting recycled materials, low-emission production processes, and recyclable packaging. Certifications such as Energy Star or Cradle to Cradle will become more common, appealing to environmentally conscious buyers. Additionally, the longevity and energy-saving potential of patio covers—by reducing indoor cooling needs through shade—will be emphasized in marketing.

Integration with Smart Home Ecosystems

Smart home technology is beginning to extend outdoors. In 2026, expect to see prefabricated patio covers integrated with features like automated retractable canopies, weather-responsive sensors, LED lighting, and app-controlled adjustments for sun exposure. These smart covers can sync with home automation systems (e.g., Alexa, Google Home), offering convenience and enhancing the overall outdoor living experience.

Competitive Landscape and Market Consolidation

The market is becoming increasingly competitive, with both established manufacturers and new entrants vying for market share. Larger home improvement companies may acquire niche patio cover brands to expand their outdoor product lines. At the same time, differentiation through design, customization options, and customer service will be critical. Brands that offer comprehensive warranties, installation support, and design software tools will have a competitive edge.

Conclusion

By 2026, the prefabricated patio cover market will be shaped by innovation, digital transformation, and evolving consumer expectations. As outdoor spaces become essential extensions of the home, demand for stylish, functional, and sustainable patio solutions will continue to rise. Companies that embrace technology, sustainability, and customer-centric design will lead the market into the next decade.

Common Pitfalls When Sourcing Prefabricated Patio Covers (Quality & Intellectual Property)

Sourcing prefabricated patio covers can streamline outdoor space improvements, but buyers often encounter significant challenges related to quality inconsistencies and intellectual property (IP) concerns. Being aware of these pitfalls helps ensure a reliable, legal, and durable investment.

Quality Inconsistencies and Substandard Materials

One of the most frequent issues is variable product quality, especially when sourcing from overseas or lesser-known manufacturers. Some suppliers may use inferior materials—such as thin-gauge aluminum, low-grade polycarbonate, or untreated steel—that compromise durability, weather resistance, and structural integrity. Without stringent quality control, products may arrive with poor welds, misaligned components, or inadequate finishes, leading to premature corrosion or failure. Buyers should verify material specifications, request third-party testing reports, and, if possible, inspect samples before bulk ordering.

Lack of Structural Certification and Compliance

Many prefabricated patio covers are marketed without proper engineering certifications or compliance with local building codes (e.g., wind load, snow load, or seismic requirements). Using uncertified structures can result in safety hazards, permit denials, or liability issues. Always confirm that the product meets regional standards (such as ICC-ES or ASTM) and is stamped by a licensed engineer when required—especially in areas prone to extreme weather.

Inadequate or Misleading Warranties

Some suppliers offer warranties that appear comprehensive but contain exclusions that limit real protection—such as voiding coverage for “normal wear,” installation by non-approved contractors, or environmental exposure. These terms may leave buyers responsible for costly repairs. Scrutinize warranty details, including duration, coverage scope, and claims processes, and prefer suppliers with transparent, transferable warranties.

Intellectual Property Infringement Risks

A growing concern in the prefab market is the unauthorized replication of patented designs, trademarks, or trade dress. Some manufacturers copy popular architectural styles, patented connection systems, or branded aesthetics without licensing. Sourcing such products exposes buyers to legal risk, including cease-and-desist orders or supply chain disruptions. Always vet suppliers for IP compliance, request proof of design ownership or licensing, and avoid unusually low-priced products that may be counterfeit or knock-offs.

Poor After-Sales Support and Spare Parts Availability

Many low-cost suppliers offer limited customer service, technical support, or access to replacement parts. If components are damaged during shipping or over time, long lead times or discontinued parts can render the entire system unusable. Prioritize suppliers with reliable support networks, detailed installation guides, and inventory of spare components.

By addressing these common pitfalls—prioritizing verified quality, regulatory compliance, robust warranties, IP legitimacy, and ongoing support—buyers can make informed decisions and secure durable, compliant, and legally sound patio cover solutions.

Logistics & Compliance Guide for Prefabricated Patio Covers

Product Classification and HS Code

Prefabricated patio covers typically fall under Harmonized System (HS) code 9406.00, which covers prefabricated buildings, including those of metal or aluminum. Confirm the exact classification based on primary material (e.g., aluminum, steel, polycarbonate) and construction type, as this affects import duties and customs clearance.

Import/Export Regulations

- Country-Specific Requirements: Verify import regulations in the destination country. For example, the U.S. enforces CBP (Customs and Border Protection) rules, while the EU requires CE marking for construction products.

- Tariffs and Duties: Research applicable tariffs based on the country of origin and destination. Free Trade Agreements (e.g., USMCA) may reduce or eliminate duties.

- Documentation: Prepare commercial invoices, packing lists, bill of lading/air waybill, and certificates of origin. Include technical specifications and material declarations.

Structural and Safety Compliance

- Building Codes: Ensure designs comply with local building codes (e.g., International Building Code – IBC in the U.S., Eurocodes in Europe). Key considerations include wind load, snow load, and seismic resistance.

- Engineering Certification: Provide stamped engineering drawings and structural calculations when required by local authorities. Many jurisdictions mandate professional engineer (PE) or equivalent certification.

- Permitting: Inform customers that installation may require permits. Supply necessary documentation (load specs, material certifications) to support permit applications.

Material Regulations

- Environmental Standards: Confirm materials meet REACH (EU), RoHS (for electrical components), and TSCA (U.S.) requirements if applicable.

- Sustainability and Recyclability: Provide information on material composition and recyclability, especially for metal components, to support green building certifications (e.g., LEED).

Packaging and Shipping Logistics

- Packaging Standards: Use durable, weather-resistant packaging with protective corner boards and waterproof wrapping. Clearly label crates with handling instructions (e.g., “Fragile,” “This Side Up”).

- Freight Options: Choose between FCL (Full Container Load) and LCL (Less than Container Load) based on volume. Use 20’ or 40’ containers for ocean freight; consider flat racks for oversized components.

- Labeling: Include product ID, serial numbers, handling symbols, and destination address. Use barcodes or QR codes for inventory tracking.

Installation and End-User Compliance

- Assembly Instructions: Provide clear, multilingual installation manuals with safety warnings and torque specifications. Include QR codes linking to video tutorials.

- Compliance Markings: Affix required compliance labels (e.g., load capacity, manufacturer info, CE mark, or ANSI Z223.1 sticker for the U.S.) directly on component parts.

- Warranty and Liability: Clearly state warranty terms and exclusions. Ensure disclaimers address proper installation and adherence to local codes.

Certifications and Testing

- Third-Party Testing: Conduct structural, wind, and load testing through accredited labs (e.g., ICC-ES, Intertek, TÜV).

- Product Certifications: Obtain necessary certifications such as:

- ICC-ES Evaluation Reports (for U.S. acceptance)

- CE Marking (for EU markets under Construction Products Regulation – CPR)

- CSA B149 (if including gas components in Canada)

Reverse Logistics and Returns

- Defective Product Handling: Establish a process for handling damaged or non-compliant shipments, including inspection, documentation, and replacement timelines.

- Warranty Claims: Define procedures for processing warranty claims, including return authorization (RMA) numbers and return shipping responsibilities.

Recordkeeping and Documentation Retention

Maintain records of compliance testing, engineering certifications, shipping documents, and customer communications for a minimum of 5–7 years to support audits and liability claims.

Summary

Successful logistics and compliance for prefabricated patio covers require careful attention to international trade rules, structural standards, and local regulations. Partnering with experienced freight forwarders and regulatory consultants ensures smooth transit and market access while minimizing legal and operational risks.

In conclusion, sourcing prefabricated patio covers offers a practical, cost-effective, and time-efficient solution for enhancing outdoor living spaces. With a variety of styles, materials, and sizes available, these pre-engineered structures provide convenience without compromising on durability or aesthetics. By carefully evaluating suppliers, comparing product quality, ensuring compliance with local building codes, and considering customization options, homeowners and contractors can make informed decisions that balance budget, functionality, and design. Overall, prefabricated patio covers represent a smart investment for those seeking a fast, reliable, and low-maintenance way to extend the usability of their outdoor areas year-round.