The global prefab studio manufacturing market is experiencing robust growth, driven by rising demand for modular, cost-effective, and sustainable living and workspaces. According to Grand View Research, the global modular construction market size was valued at USD 132.1 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2024 to 2030. This surge is fueled by accelerated project timelines, reduced construction waste, and increasing urbanization, particularly in North America and Europe. As remote work and accessory dwelling units (ADUs) gain traction, prefab studio solutions have become a go-to option for homeowners, developers, and enterprises alike. With innovation in design, energy efficiency, and smart technology integration, leading manufacturers are setting new benchmarks in quality and scalability. Based on market presence, production capacity, customer reviews, and technological advancement, here are the top 9 prefab studio manufacturers shaping the future of modular spaces.

Top 9 Prefab Studio Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Construction Services

Domain Est. 2015

Website: plantprefab.com

Key Highlights: We work with your architect to build to your exact specifications. Our factory and processes were designed specifically for custom projects….

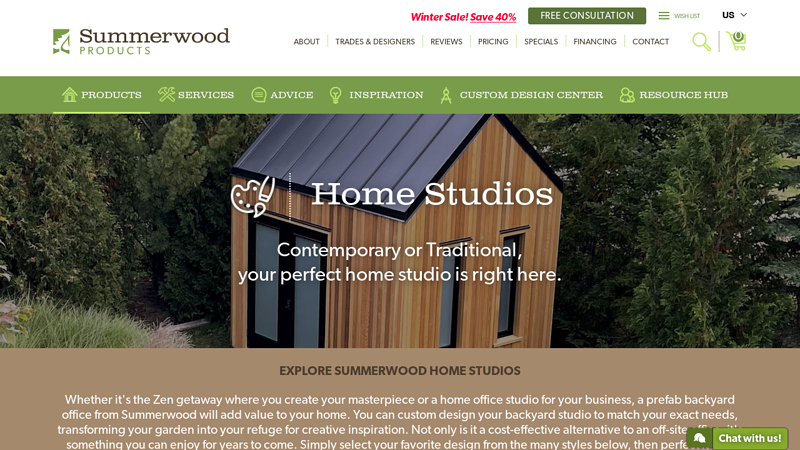

#2 Backyard Office & Studios

Domain Est. 1996

Website: summerwood.com

Key Highlights: A prefab backyard office from Summerwood will add value to your home. You can custom design your backyard studio to match your exact needs….

#3 ideabox

Domain Est. 2005

Website: ideabox.us

Key Highlights: Discover customizable, energy-efficient prefab homes designed for modern, sustainable living with smart design, elegant finishes, and flexible floorplans….

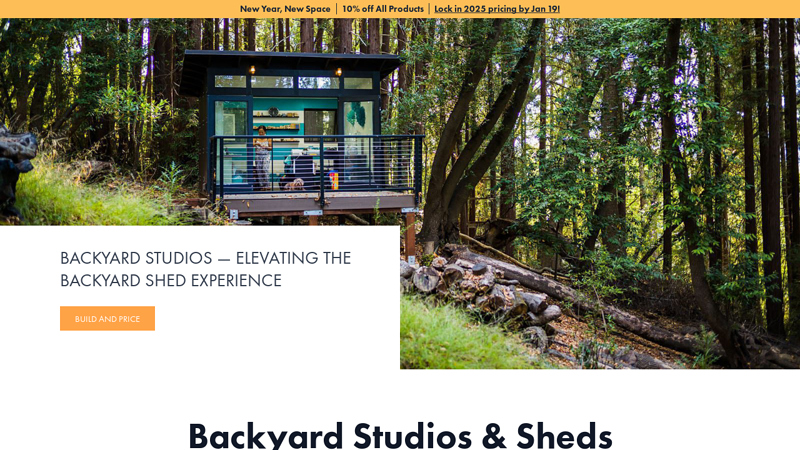

#4 Custom, Prefab Backyard Studios

Domain Est. 2008

Website: studio-shed.com

Key Highlights: Affordable luxury for your backyard. Learn about Studio Shed’s cost-effective solutions and financing options to create your ideal space without breaking ……

#5 Cerca Homes

Domain Est. 2018

Website: cercahomes.com

Key Highlights: Looking for a high-quality, affordable prefabricated home? CERCA offers a wide range of prefabricated houses, from small cottages to spacious family homes….

#6 Dextall

Domain Est. 2019

Website: dextall.com

Key Highlights: Dextall Studio is a cutting-edge software that translates visionary architectural concepts into visible cost, precise, fabrication-ready models….

#7 Modular DIY Backyard Studio Sheds

Domain Est. 2020

Website: mod-shed.com

Key Highlights: Our elegant studio kits are customizable and are designed to be easy to assemble quickly using just a few common tools….

#8 Mini Office backyard pods, outdoor man caves and she sheds …

Domain Est. 2020

Website: minioffice.co

Key Highlights: Fix your focus with a turnkey backyard home office shed, studio or modern shed. Customize your outdoor man cave or she shed or turn it into a garden ADU, ……

#9 Customizable Prefab ADUs, Houses, Sheds, Saunas

Domain Est. 2022

Website: wllmd.com

Key Highlights: Modern, customizable, prefab Sheds and ADUs for an excellent backyard experience. 100% made in CA. 85% less waste. 200+ happy clients….

Expert Sourcing Insights for Prefab Studio

2026 Market Trends for Prefab Studio

Rising Demand for Sustainable and Fast-Track Construction

By 2026, environmental regulations and consumer preferences will drive significant demand for low-carbon building solutions. Prefab Studio is well-positioned to capitalize on this shift, as modular construction reduces material waste by up to 50% and cuts on-site emissions. With growing emphasis on ESG (Environmental, Social, and Governance) compliance, clients across residential, hospitality, and co-living sectors will increasingly favor prefabricated designs for their energy efficiency and faster carbon payback periods.

Technological Integration and Smart Building Adoption

The convergence of IoT, AI-driven design tools, and Building Information Modeling (BIM) will redefine off-site construction. In 2026, Prefab Studio can leverage AI to optimize module configurations for cost and performance, while integrating smart-home technologies directly into factory-built units. This enables clients to deploy turnkey, intelligent spaces—particularly in urban micro-housing and adaptive reuse projects—where time-to-market and tech readiness are critical differentiators.

Urbanization and Affordable Housing Pressures

With global urban populations expanding, cities will face intensified housing shortages. Governments and developers will turn to modular construction as a scalable solution for affordable and mid-density housing. Prefab Studio’s design-led, customizable approach allows it to stand out in a market often dominated by utilitarian prefab. By offering aesthetically refined, community-integrated modular units, the studio can capture public-private partnership (P3) projects and urban infill developments.

Supply Chain Resilience and Localization

Post-pandemic disruptions have led to a strategic shift toward regionalized manufacturing. In 2026, Prefab Studio can benefit from decentralized micro-factories and local material sourcing, reducing logistics costs and lead times. This trend supports “factory-to-site” models within metropolitan regions, aligning with circular economy principles and enhancing responsiveness to local design codes and climate conditions.

Customization at Scale Through Design Systems

Mass customization will become the norm in modular construction. Prefab Studio’s potential lies in developing proprietary design systems—modular kits of parts that allow for diverse configurations without sacrificing efficiency. By standardizing structural and service modules while enabling surface-level personalization (façades, interiors), the studio can deliver unique architectural expressions at scale, appealing to boutique developers and lifestyle brands.

Expansion into New Sectors

Beyond residential, demand will grow in education, healthcare, and disaster-resilient infrastructure. By 2026, modular classrooms, pop-up clinics, and emergency housing will require rapid deployment and high design quality. Prefab Studio’s focus on human-centered design and durability positions it to enter these mission-critical markets, especially in regions vulnerable to climate change and population displacement.

In summary, 2026 presents a robust growth trajectory for Prefab Studio, driven by sustainability mandates, technological innovation, urban housing needs, and sector diversification. Strategic investments in digital design, regional production, and cross-sector applications will be key to maintaining a competitive edge.

Common Pitfalls When Sourcing a Prefab Studio (Quality, IP)

Poor Quality Control and Inconsistent Standards

One of the most frequent challenges when sourcing from a prefab studio is inconsistent quality. Studios may lack standardized manufacturing processes or rigorous quality assurance protocols, leading to defects in materials, finishes, or assembly. Without clear performance benchmarks or on-site oversight, delivered modules may not meet design specifications, resulting in costly rework, delays, or compromised building integrity.

Weak or Unclear Intellectual Property (IP) Agreements

Engaging a prefab studio often involves sharing detailed architectural designs, technical drawings, and proprietary systems. A major pitfall is the absence of robust IP contracts that clearly define ownership, usage rights, and confidentiality. Without explicit agreements, clients risk losing control over their designs, or the studio may reuse project elements without permission—potentially leading to legal disputes or unauthorized replication.

Limited Transparency in Manufacturing Processes

Many prefab studios operate with limited visibility into their production workflows. Clients may struggle to verify material sources, construction methods, or compliance with building codes. This lack of transparency can mask substandard practices and increase the risk of receiving modules that fail inspections or underperform in real-world conditions.

Misaligned Design and Engineering Capabilities

Not all prefab studios possess the in-house expertise to handle complex architectural or engineering requirements. Sourcing from a studio with inadequate technical capacity can result in design compromises, structural inefficiencies, or non-compliance with local regulations—especially when projects demand custom solutions or integration with site-specific conditions.

Supply Chain and Material Sourcing Risks

Prefab studios often rely on third-party suppliers for critical components. If the studio lacks reliable supply chain management, delays or substitutions with inferior materials can occur. This not only impacts quality but may also violate sustainability goals or fire safety standards, particularly if material certifications are not properly documented.

Inadequate Post-Delivery Support and Warranties

After modules are delivered and assembled, issues may emerge that require technical support or repairs. Some prefab studios offer weak or poorly defined warranty terms, leaving clients responsible for troubleshooting and fixes. This lack of accountability can undermine long-term performance and increase lifecycle costs.

Overlooking Jurisdictional Compliance and Certification

Prefab buildings must meet local building codes, zoning laws, and certification requirements (e.g., ICC, LEED, energy codes). A common pitfall is assuming the studio is familiar with or will ensure compliance in the project’s jurisdiction. Failure to verify this upfront can result in rejected permits, failed inspections, or costly modifications post-fabrication.

Conclusion

To mitigate these risks, due diligence is essential: conduct site visits, review past projects, audit quality processes, and establish clear contractual terms—especially regarding IP ownership and performance standards—before finalizing any agreement with a prefab studio.

Logistics & Compliance Guide for Prefab Studio

Prefab Studio operates at the intersection of design, manufacturing, and construction, requiring streamlined logistics and strict adherence to compliance standards. This guide outlines best practices and essential requirements to ensure efficient operations, regulatory compliance, and customer satisfaction.

Supply Chain Management

Establish a reliable network of suppliers for raw materials (e.g., steel, timber, insulation, cladding). Prioritize suppliers with consistent quality, certifications (e.g., FSC for wood), and sustainable sourcing. Maintain safety stock levels for critical components and use just-in-time (JIT) delivery where feasible to reduce inventory costs. Implement vendor performance tracking to ensure accountability.

Manufacturing & Production Logistics

Coordinate modular component fabrication in controlled factory environments. Use digital workflows (BIM integration) to synchronize design with production schedules. Optimize factory layout for efficient material flow and minimize handling. Track work-in-progress (WIP) with real-time monitoring systems to maintain production timelines and quality control.

Transportation & Delivery

Plan transportation routes considering module dimensions, weight restrictions, and site access. Use specialized flatbed or low-loader trucks for oversized loads, ensuring compliance with local transport regulations (e.g., permits for oversize/overweight vehicles). Secure modules properly to prevent damage during transit. Coordinate delivery schedules with on-site construction teams to avoid delays and storage bottlenecks.

Site Installation & Coordination

Ensure on-site logistics plans include crane placement, staging areas, and temporary storage. Conduct pre-installation site audits to confirm foundation readiness and access conditions. Maintain clear communication between factory teams, transport crews, and site contractors. Follow standardized installation procedures to ensure structural integrity and safety.

Building Code Compliance

All prefab modules must meet or exceed local, state, and national building codes (e.g., International Building Code – IBC, NFPA standards). Design and fabricate units with jurisdiction-specific requirements in mind, including energy efficiency (e.g., IECC), seismic zones, and wind load ratings. Obtain necessary third-party inspections and certifications (e.g., ICC-ES, UL).

Environmental & Safety Regulations

Comply with environmental regulations such as EPA guidelines for emissions, waste management, and hazardous materials handling (e.g., VOC content in paints). Implement OSHA-compliant safety protocols in the factory and on-site. Maintain SDS (Safety Data Sheets) for all chemicals used and conduct regular safety training.

Quality Assurance & Documentation

Implement a quality management system (e.g., ISO 9001) covering design, manufacturing, and installation. Maintain detailed records of material certifications, inspection reports, and test results. Provide clients with comprehensive compliance documentation, including CO (Certificate of Occupancy) support files and operation/maintenance manuals.

International Considerations (If Applicable)

For cross-border projects, comply with import/export regulations, customs documentation, and international standards (e.g., CE marking in Europe, AS/NZS in Australia). Account for differences in voltage, plumbing, and fire safety requirements. Engage local compliance experts to navigate regional regulatory landscapes.

Continuous Improvement & Audits

Conduct regular internal audits of logistics and compliance processes. Solicit feedback from partners and clients to identify improvement areas. Stay updated on regulatory changes and emerging industry standards to maintain leadership in compliant, efficient prefab solutions.

In conclusion, sourcing a prefab studio offers a compelling combination of efficiency, cost-effectiveness, and design flexibility. With faster construction timelines, reduced waste, and high-quality factory-controlled manufacturing, prefabricated studios present a sustainable and scalable solution for a variety of needs—whether for home offices, creative workspaces, or rental income properties. By carefully selecting a reputable supplier, ensuring compliance with local building codes, and considering customization options, you can achieve a functional and aesthetically pleasing space that meets your specific requirements. Overall, investing in a prefab studio is a smart, forward-thinking choice that balances practicality with modern design.