Introduction: Navigating the Global Market for Powder Filling Machines

A single clogged auger or a ±2 % weight deviation on your fastest line can erase the margin on an entire shift. Yet Amazon alone lists 2,000+ “powder filling machines” from $229 bench-top units to six-figure monoblocks—spec sheets that read alike, lead-times that swing from 3 days to 16 weeks, and no clear map of which suppliers can pass an FDA or CE audit tomorrow.

This guide ends the guesswork. Written for North-American and European plant managers, sourcing directors and contract packers, it cuts through the noise to deliver:

| What you get | Why it matters |

|————–|—————-|

| Side-by-side comparison of 4 dominant technologies (auger, vacuum, net-weight, servo-cup) | Match powder flow behaviour to repeatable ±0.3 % accuracy |

| Verified supplier matrix: 28 OEMs, ISO 9001 + 21 CFR Part 11 or CE compliance, with 2024 FOB prices and real lead-times | Eliminate 6-week RFQ cycles |

| Risk checklist for ATEX, dust-classification, hygienic design and IIoT integration | Pass inspections without retrofits |

| Total-cost-of-ownership model line-by-line (changeover labour, consumables, energy, OEE loss) | Defend CAPEX to the CFO |

Use the clickable index to jump straight to your application—whether you are filling 5 g spice sachets at 120 ppm or 25 kg pharmaceutical drums under containment. Bookmark the editable Excel calculators; they are pre-loaded with the latest European energy and labour indices.

By the final page you will have a shortlist of vetted OEMs, a defendable ROI, and a specification pack you can drop straight into your capital request. Let’s start with the technology decision tree.

Article Navigation

- Top 10 Powder Filling Machine Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for powder filling machine

- Understanding powder filling machine Types and Variations

- Key Industrial Applications of powder filling machine

- 3 Common User Pain Points for ‘powder filling machine’ & Their Solutions

- Strategic Material Selection Guide for powder filling machine

- In-depth Look: Manufacturing Processes and Quality Assurance for powder filling machine

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘powder filling machine’

- Comprehensive Cost and Pricing Analysis for powder filling machine Sourcing

- Alternatives Analysis: Comparing powder filling machine With Other Solutions

- Essential Technical Properties and Trade Terminology for powder filling machine

- Navigating Market Dynamics and Sourcing Trends in the powder filling machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of powder filling machine

- Strategic Sourcing Conclusion and Outlook for powder filling machine

- Important Disclaimer & Terms of Use

Top 10 Powder Filling Machine Manufacturers & Suppliers List

1. Powder Filling Machinery Manufacturers and Suppliers in the USA …

Domain: thomasnet.com

Registered: 1996 (29 years)

Introduction: Powder Filling Machinery Manufacturers and Suppliers in the USA and Canada · Massman Automation · Massman Automation · DCI, Inc. · DCI, Inc. · Custom Equipment ……

2. 12 Powder Filling Machine Manufacturers in 2025 – Metoree

Domain: us.metoree.com

Registered: 2020 (5 years)

Introduction: Here are the top-ranked powder filling machine companies as of November, 2025: 1.Micmachinery.co.,Ltd, 2.Shree Bhagwati Machtech, 3.Adinath ……

3. Top 10 Global Powder Packaging Machine Manufacturers In 2025 –

Domain: allpackchina.com

Registered: 2021 (4 years)

Introduction: Top 10 Global Powder Packaging Machine Manufacturers In 2025 · 1.Syntegon · 2.Rovema · 3.Paxiom Group · 4.ALLPACK · 5.Viking Masek · 6.nVenia · 7.Concetti · 8.Matcon….

4. Powder Filling Machine – AMS Filling Systems

Domain: amsfilling.com

Registered: 1997 (28 years)

Introduction: AMS is a leading powder filling machine manufacturer that caters to various industries requiring precise powder-filling solutions….

Illustrative Image (Source: Google Search)

5. Powder & Liquid Filling Machine – Romaco

Domain: romaco.com

Registered: 1998 (27 years)

Introduction: Powder & Liquid Filling Machines by Macofar. Romaco Macofar is a global supplier of filling solutions for sterile and non-sterile powders and liquids….

6. Best 8 Industrial Filling Machine Manufacturers in 2025 – LIENM

Domain: lienm.com

Registered: 2012 (13 years)

Introduction: Overview of the Best Industrial Filling Machine Manufacturers in 2025 · 1. LIENM – Industrial Filling Machine Experts · 2. PACKO Filling Systems….

7. Auger Dry Powder Filling Machine-ZONESUN

Domain: zonesuntech.com

Registered: 2014 (11 years)

Introduction: 5–10 day delivery 7-day returnsZONESUN offer semi-automatic and automatic auger powder filling machine to dispenses dry powders into bottles or sachets.They are designed for small ……

8. China Dry Powder Filling Machine Manufacture and Factory | Tops

Domain: topspacking.com

Registered: 2016 (9 years)

Introduction: Shanghai Tops Group Company produced a number of different types of dry powder filling machine. Desktop table, semi-auto type, automated linear type, ……

Illustrative Image (Source: Google Search)

Understanding powder filling machine Types and Variations

Understanding Powder Filling Machine Types and Variations

| Type | Features | Applications | Pros / Cons |

|---|---|---|---|

| Auger (Net-Weight) Filler | Servo-driven auger, load-cell feedback, 0.1–1 % accuracy, 5–2 000 g range, stainless-closed hopper, dust-tight spindle | Pharma, nutraceuticals, spices, protein, chemical additives | + High accuracy, easy CIP/SIP, recipe memory – Sensitive to flowability, requires frequent auger change-over for different densities |

| Cup Filler (Volume) | Interchangeable volumetric cups, rotary turret, 30–120 fills/min, no electronics, compressed-air assist | Food (coffee creamer, flour), agro, detergent powders | + Low CAPEX, fast change-over, no power on mobile units – ±2–3 % tolerance, density drift affects weight |

| Vacuum / Level Fill (Net-Weight) | Vacuum suck-back, conical hopper, weigh cell under each container, 1–50 kg, low-dust emission | Milk powder, baking mixes, infant formula | + Minimises product loss, clean neck finish – Slower (10–25 fills/min), higher initial cost |

| Inline Check-Weigher Combo | Real-time weight feedback, automatic auger or cup speed trim, 21 CFR Part 11 data logging, reject flap | High-value pharma, CBD, enzymes | + 100 % weight verification, trend reports for FDA – Complex validation, higher OPEX |

| Stick-Pack / Sachet Filler | Multi-lane auger or cup, 4–14 lanes, 40–120 cuts/min, photo-cell registration, tear-notch | Collagen, energy powders, probiotic sachets | + High throughput per m², single-serve format – Film waste, frequent sealing-jaw cleaning |

1. Auger (Net-Weight) Filler

Most common in US & EU GMP plants.

– Principle: Servo motor rotates an auger; load-cell stops rotation at target net weight.

– Key specs: Accuracy ±0.25–1 %; speeds 20–70 containers/min (dual-head).

– Options: Sanitary tri-clamp hopper, nitrogen purge collar, ATEX-rated panel.

– Buyers’ note: Specify auger pitch & tube diameter for each SKU; request USDA/3-A dairy finish when supplying Costco or Tesco co-packers.

2. Cup Filler (Volume)

Low-cost entry point for contract packers.

– Principle: Product flows by gravity into a fixed-volume cup; excess is scraped off.

– Key specs: 0.5–200 ml cups; outputs to 120 fills/min on 8-head rotary.

– Limitation: Density changes from humidity can create ±3 % weight drift—install in humidity-controlled area if supplying EU retailers with e-mark requirements.

3. Vacuum / Level Fill (Net-Weight)

Preferred for dairy and infant formula to avoid segregation.

– Principle: Vacuum holds powder until target weight is reached; suck-back leaves a clean container neck.

– Key specs: 1–50 kg; accuracy ±1–5 g; stainless 316L product path.

– Validation: Ask vendor for SAT protocol including recovery-rate test (<0.1 % loss).

4. Inline Check-Weigher Combo

Safeguards high-value powders.

– Principle: Every container is weighed; deviations trigger automatic auger speed adjustment.

– Data: Ethernet/IP to MES; 21 CFR Part 11 compliant audit trails for FDA submissions.

– ROI: Reduces giveaway 0.5–1 %; typical payback <12 months on $50k+ product lines.

Illustrative Image (Source: Google Search)

5. Stick-Pack / Sachet Filler

Single-serve trend driver in US sports nutrition & EU pharma OTC.

– Principle: Multi-lane auger doses into formed sachets; photo-cell ensures cut registration.

– Key specs: 1–50 g per sachet; 4–14 lanes; 40–120 sachets/min per lane.

– Compliance: Ensure ultrasonic sealing option for moisture-sensitive APIs; validate seal integrity per ASTM F2029.

Use the matrix above to shortlist technologies that match your powder’s flow function, target speed, and regulatory market (FDA, EU 1935/2004, ATEX).

Key Industrial Applications of powder filling machine

Key Industrial Applications of Powder Filling Machine

| Industry | Typical Powders | Primary Benefits | Compliance / Market Drivers |

|---|---|---|---|

| Pharmaceutical & Nutraceutical | APIs, antibiotics, protein powders, probiotic blends, effervescent formulations | Dose-to-weight accuracy ±0.1 g, low-dust containment for potent compounds, fast change-over between SKUs, integration with IPC & serialization lines | cGMP, FDA 21 CFR Part 11, EU Annex 1, DSCSA traceability |

| Food & Beverage | Coffee creamer, spice blends, protein shakes, infant formula, sports-nutrition premixes | Oxygen-free / nitrogen-flush filling to extend shelf life, hygienic (CIP/SIP) auger & hopper designs, allergen segregation, 30–60 % throughput gain vs. manual | BRC, SQF, FSMA, EU 1169/2011 labelling |

| Cosmetics & Personal Care | Talc, mineral make-up, face masks, dry shampoo, glitter | Non-clogging agitator augers for micron-size particles, inert gas blanket to prevent oxidation, servo-driven no-drip nozzles cut giveaway by 2–3 % | REACH, US Clean Beauty, Prop-65 |

| Chemical & Specialty Powders | Photocopy toner, epoxy hardeners, pesticide adjuvants, catalysts | Explosion-proof ATEX/IECEx auger drives, anti-static PTFE seals, closed-loop nitrogen for hygroscopic powders, drum/BIB formats up to 25 kg | OSHA HazCom, ATEX 2014/34/EU, OSHA combustible-dust NEP |

| Battery & Advanced Materials | Lithium-carbon, cathode / anode powders, conductive carbon black | Inert atmosphere (<1 % O₂) to prevent Li degradation, high-accuracy ±0.05 g for active-material loading, magnetic-stainless product path | ISO 14001, RoHS, IMDS, OEM-specific particle-size specs |

| Agriculture & Animal Feed | Milk replacer, vitamin premixes, urea, mineral licks | UV-protected hoppers, anti-bridging ribbon agitator for cohesive powders, 5–50 kg valve-bag or open-mouth sack lines at 6–8 bpm | FDA medicated-feed, EU 767/2009 animal nutrition |

| Building & Construction | Grout, tile-adhesive polymers, self-leveling compounds, pigments | Dust-tight clamped spouts, bag-in-box 10–25 kg option, IP65 wash-down for dusty job-site conditions | OSHA silica rule, EU CE marking for packaged goods |

Implementation Notes for Procurement Teams

- Micro-dosing (≤1 g) – Specify servo-driven auger with load-cell feedback; target pharmaceutical & nutraceutical SKUs.

- Moisture-sensitive powders – Look for nitrogen-purge manifold and VFD-controlled hopper vent to maintain <30 % RH.

- Explosive dust (ST class) – Confirm ATEX-certified panels, grounded stainless steel auger, and 10-bar pressure-shock resistance.

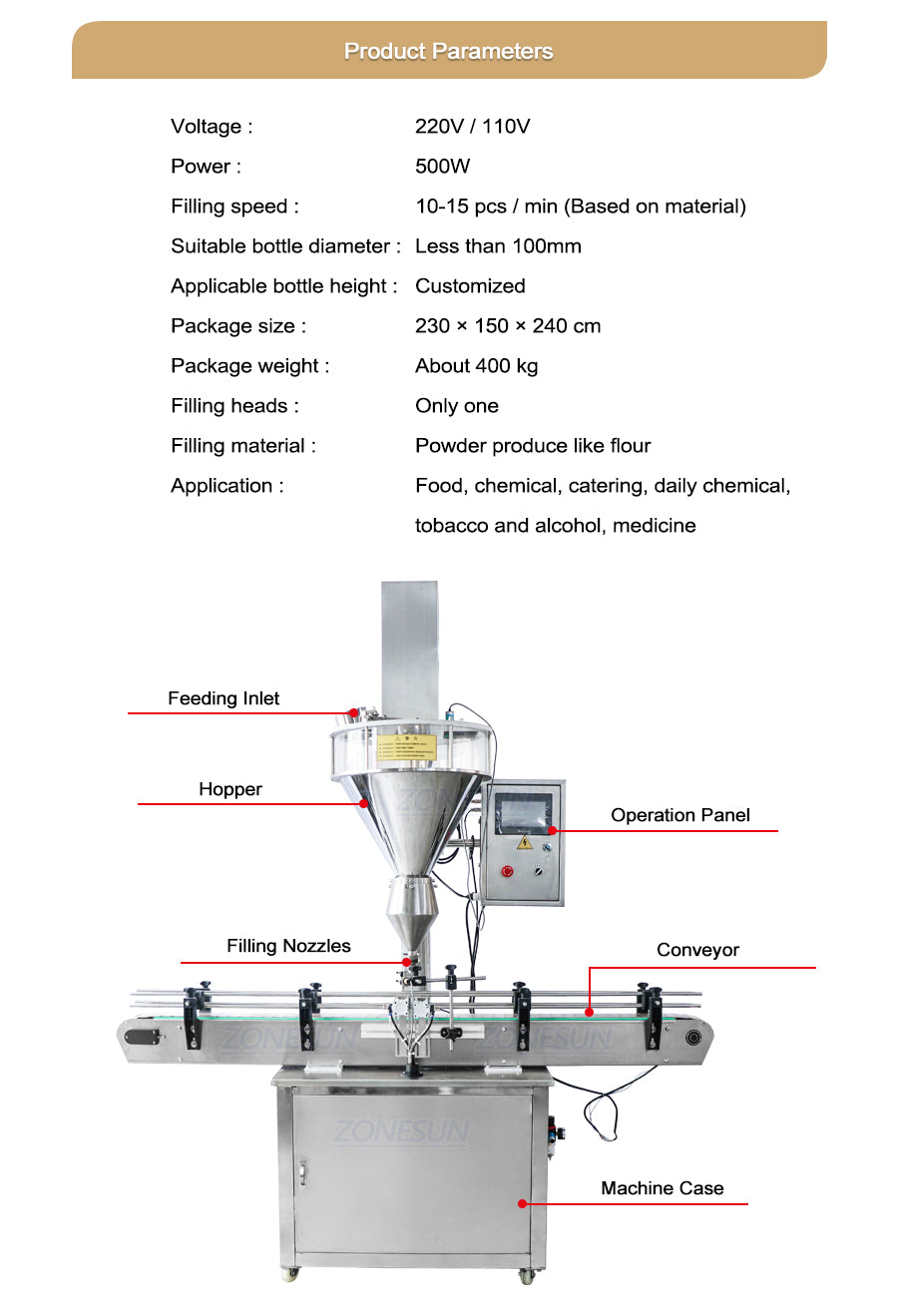

- Throughput scaling – Bench-top units (Amazon-listed) cover 1–100 g at 10–15 cpm; for >1 t h⁻¹, migrate to twin-head rotary auger on palletized IBC feed.

3 Common User Pain Points for ‘powder filling machine’ & Their Solutions

3 Common User Pain Points for Powder Filling Machines & Their Solutions

| # | Scenario | Problem | Solution |

|---|---|---|---|

| 1 | High-variance, low-margin contract packaging | Weight drift of ±1–2 g on a 50 g target forces giveaway of 2–4 % product per pouch; over 1 M pouches/yr this equals >$50 k lost powder. | 1. Specify gravimetric fillers with 0.1 g load-cell resolution and active feedback that tares every cycle. 2. Insist on servo-driven augers with automatic bulk-/dribble-speed shift to hit target weight in ≤2 s. 3. Demand 21 CFR Part 11 data export so QA can trend drift by shift and recalibrate before giveaway exceeds 0.5 %. |

| 2 | Frequent recipe changeovers in multi-spec nutraceutical plant | Manual disassembly takes 45 min, tool marks contaminate stainless, and 8 kg of “flush” powder is wasted each swap—costing €30 k/yr in scrap alone. | 1. Choose tri-clamp, tool-less hopper & auger modules that release in <5 min. 2. Order FDA-approved UHMW-PE auger sleeves that are disposable between allergen and non-allergen runs—eliminates flush waste. 3. Specify recipe memory PLC: enter SKU code, machine auto-loads auger RPM, dosing time, and reject limits; changeover downtime falls to <10 min. |

| 3 | Explosive organic turmeric & starch blends in USDA bakery | Fine, combustible dust clouds reach 2,000 g/m³ inside open-fill stations; existing CE-marked unit lacks ATEX certification—voiding insurer coverage. | 1. Require ATEX Zone 20/22-certified auger filler with IP66 enclosed drive, nitrogen-purged load-cell chamber, and 304 stainless sealed to ≤0.2 bar over-pressure. 2. Add intrinsically safe foot pedal & HMI rated II 2D Ex h IIIC T125 °C Db. 3. Integrate reverse-jet dust extractor with <1 m/s capture velocity at fill point; keeps dust ≤10 % of LEL and satisfies NFPA 652 & ATEX 137 employer duties. |

Strategic Material Selection Guide for powder filling machine

Strategic Material Selection Guide for Powder Filling Machine

The material of every product-contact part determines whether your line runs 24/7 or stops every shift for de-blinding, rust removal, or FDA re-validation. Below is the decision matrix that North-American and EU plants use to match filler construction to powder risk class, throughput target, and total cost of ownership (TCO).

1. Product-Contact Surfaces – Where 90 % of Failures Start

| Powder Risk Class | Typical Products | Recommended Contact Material | Why It Wins | Watch-outs |

|---|---|---|---|---|

| Low-risk dry & free-flowing | Salt, sugar, sand | 304 SS (mirror-polish ≤0.4 µm Ra) | Lowest Capex, food-grade accepted worldwide | Chloride wash >200 ppm → pitting |

| Hygroscopic / slightly corrosive | Whey, caseinate, pharma excipients | 316L SS (≤0.3 µm Ra) + PTFE seals | Mo resists chloride & acid fumes; PTFE stops stickiness | Price delta ≈ +18 % vs 304 |

| Highly abrasive | Alumina, TiO₂, SiC | 316L SS with tungsten-carbide (WC) overspray on dosing disc & auger tip | 5× life vs hard-ox plates; keeps FDA compliance | WC re-spray every 18-24 months |

| API / potent (OEB 4-5) | Sterile antibiotics, hormones | 316L SS + Hastelloy C22 wetted parts + FFKM O-rings | Pit-free in Cl⁻, survives VHP cycles | Part cost ≈ 3× 316L; validate elastomer extractables |

| Explosive metal powders | Al- Mg alloy dust | 316L SS + conductive PTFE + copper-free tooling | Eliminates spark source; <1 mΩ surface resistance | Earth-bond every flange |

2. Non-Contact Frames & Guards

| Option | Specification | Region-Specific Driver |

|---|---|---|

| 304 SS frame | AISI 304, 2B finish | EU food code (EC) 1935/2004 |

| Painted carbon steel | Powder-coated RAL 9010, 80 µm | USA budget lines; deduct ≈ €2k per m² of envelope |

| Aluminium profile | 40×40 mm, anodised | Lightweight for bench-top units <50 kg |

3. Gaskets & Elastomers – The Hidden Validation Cost

| Elastomer | Temp Range | USP <661> | EU 10/2011 | Typical Use |

|---|---|---|---|---|

| EPDM | −50…150 °C | Pass | Pass | General food |

| Silicone (VMQ) | −60…200 °C | Pass | Restricted on fat | High-temp whey |

| PTFE (virgin) | −190…250 °C | Inert | Inert | Stick-sensitive API |

| FFKM (Kalrez®) | −15…320 °C | Pass | Pass | Solvent or CIP/SIP |

4. Quick-Selection Table (Save as Checklist)

| Specification | 304 SS | 316L SS | 316L+WC | Hastelloy |

|---|---|---|---|---|

| Initial price index (base = 1.0) | 1.0 | 1.18 | 1.45 | 2.9 |

| Chloride resistance | Fair | Good | Good | Excellent |

| Abrasion index (ASTM G65) | 1.0 | 1.0 | 4.5 | 1.2 |

| FDA / EU compliance | ✔ | ✔ | ✔ | ✔ |

| Typical service life (abrasive duty) | 2 yr | 2 yr | 8 yr | 2 yr |

| Lead time (weeks, EU mill) | 4 | 6 | 7 | 10 |

5. Procurement Tips (North-America vs EU)

- Mill certificate minimums:

- USA: ASTM A240, 2.1 certificate, δ ≤0.75 mm for hopper wall.

-

EU: EN 10088-2, 3.1 certificate, CE-traceable heat number etched on every weld seam.

Illustrative Image (Source: Google Search)

-

Surface finish validation:

Insist on Ra map (5-point grid) for welds; reject any spot >0.8 µm Ra—regardless of sales folder claims. -

Copper-free requirement (explosive powders):

Specify Cu ≤0.3 % in mill cert; most “316L” bar stock is 0.4-0.5 % Cu—enough to void ATEX assessment. -

Spare-part harmonisation:

Keep one elastomer material family site-wide; switching EPDM ↔ Silicone triggers new USP <665> extractables package (~€7k cost).

Bottom line: Pick 316L as default, upgrade to WC-facing for abrasive duty, and reserve Hastelloy only when chloride or VHP sterilisation makes it the cheaper option over a five-year TCO window.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for powder filling machine

In-depth Look: Manufacturing Processes & Quality Assurance for Powder Filling Machines

| Phase | Objective | Key Inputs | Typical Duration* |

|---|---|---|---|

| 1. Prep & Incoming QC | Verified, traceable components | 304/316L SS, anodized Al, servo drives, load cells | 1–2 days |

| 2. Forming & Machining | Tight-tolerance, food/pharma-safe parts | 5-axis CNC, laser cutting, RA ≤0.4 µm surface finish | 3–5 days |

| 3. Sub-Assembly | Modular, clean-room-ready modules | Hopper, auger, agitator, dosing chamber, HMI | 2 days |

| 4. Final Assembly & FAT | Integrated, calibrated machine | PLC, servo, VFD, dust-tight guarding | 2 days |

| 5. QC & Certification | ISO-compliant, export-ready unit | Calibration certs, IQ/OQ docs, CE/UL labels | 1 day |

*Per standard 1–2-head auger filler; multi-head lines scale linearly.

1. Prep & Incoming QC

- Material certificates: EN 10204 3.1 for stainless; RoHS & REACH compliance for electronics.

- Dimensional gate: ±0.05 mm tolerance on auger flights; 0.1 % accuracy on load cells.

- Surface audit: Ra ≤0.4 µm on product-contact areas; passivation per ASTM A967.

- Rejection log: Non-conforming lots quarantined in MRP; supplier CAPA tracked.

2. Forming & Machining

| Operation | Tolerance | Critical Tooling | In-line Check |

|---|---|---|---|

| CNC turning (auger) | h7 | CVD-coated carbide | Laser micrometer every 10th part |

| Hopper deep-drawing | ±0.2 mm | 500 t press | Ring-gauge template |

| Sheet-metal laser cut | ±0.1 mm | 3 kW fiber laser | CMM sample 5 % |

- Coolant policy: Food-grade coolant only; full wash-down before assembly.

- Edge finish: Radius ≥2 mm on all product-contact corners to eliminate powder traps.

3. Sub-Assembly (Modular Build)

- Dosing module: Auger + servo motor + keyed coupling; dynamic balance test ≤0.5 g mm.

- Hopper module: Mirror-polished weld seams; dye-penetrant tested; 100 % passivation.

- Control module: UL-listed panel; Ethernet/IP & 21 CFR Part 11 compliant data logging.

- Dust-tight module: IP65 gaskets compressed 20 %; leak-test at 5 mbar for 30 s.

4. Final Assembly & Factory Acceptance Test (FAT)

- Integration: EtherCAT cycle time ≤1 ms; servo accuracy ±0.1 g on 5 g target.

- Recipe validation: 3 consecutive batches, RSD ≤1 %; speed 40–80 bpm (bottles/min).

- Safety circuits: Category 3 PL-e per ISO 13849-1; dual-channel interlocks.

- Documentation pack: FAT protocol, calibration certs, spare-parts list, multilingual HMI.

5. Quality Standards & Certifications

| Standard | Scope | Plant Evidence |

|---|---|---|

| ISO 9001:2015 | QMS | Annual external audit; NCR closure ≤30 days |

| ISO 13849-1 | Machine safety | Validation of SRP/CS; MTTFd ≥100 years |

| cGMP (21 CFR 211) | Pharma builds | IQ/OQ/PQ protocols; material traceability 10 years |

| CE/UL | Market access | TÜV or UL test report; technical file retained 10 years |

| ISO 22000 optional | Food safety | HACCP plan; food-grade lubricants list |

QC Instruments & Calibration

- Load cell: OIML C3 class; calibrated with ASTM E617-18 class F1 weights.

- Torque sensor: ±0.25 % full scale; 12-month NIST-traceable cert.

- Particle counter: ISO 14644-1 for clean-room variants; 0.5 µm channel.

- Surface roughness: Perthometer M400; calibrated per ISO 4287.

Key Takeaway

A repeatable, ISO-driven build flow—coupled with calibrated in-line checks—delivers filling accuracy ≤±0.5 % and OEE >85 % for both USDA dairy lines and EC pharmaceutical plants, ensuring your CAPEX is audit-ready on day one.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘powder filling machine’

Practical Sourcing Guide: Step-by-Step Checklist for Powder Filling Machines

| # | Checkpoint | USA-Specific Notes | EU-Specific Notes | B2B Red Flags |

|---|---|---|---|---|

| 1 | Define powder & fill spec | FDA-granulation curve, bulk density (g/cc), moisture %, USP <616> flow index | CE-tested explosive dust class (ST1-ST3), ATEX zone inside machine | Supplier cannot provide material test data |

| 2 | Map throughput range | Packs/min vs. shift hours; include 20 % seasonal peak | Same; add metric tonnes/h for bulk sack lines | Quoted speed is “max” with no fine-powder derate |

| 3 | Choose dosing principle | Auger for <1 % free-flow; vacuum drum for sticky; net-weigh for value >$8/kg | Same; insist on IP65 stainless for dairy/nutraceutical | Vendor offers only volumetric cup for all powders |

| 4 | Validate accuracy need | ±0.3 g legal-for-trade (NTEP) if sold by weight | ±1 % of target OIML R61 class Y(b) for pre-packs | Accuracy spec given without std-dev at 3σ |

| 5 | Request IQ/OQ/PQ docs | 21 CFR Part 11 electronic signatures | CE Declaration + ATEX certificate + EHEDG cleanability sheet | Missing FAT protocol or no serial-number trace |

| 6 | Check change-over time | Tool-less auger/ funnel swap <10 min; video evidence | Same; document in SOP translated to local language | Advertised “quick” but requires two tools & 30 min |

| 7 | Confirm contact parts | 316L (≤0.08 % carbon) Ra ≤0.4 µm, passivation certificate | Same + EN 10204 3.1 mill cert; no Chinese 304 substitute | 304 quoted as “food grade” with no cert |

| 8 | Verify after-sales net | US-based parts warehouse, 24 h phone, <48 h field tech | EU-based tech, spare-part Schengen ship ≤72 h, local language | Only Alibaba chat support; no VAT invoice |

| 9 | Ask for utility draw | 110 V 15 A vs. 230 V 1-ph; confirm compressor cfm | 400 V 3-ph 50 Hz; check kW for ATEX overload | Motor nameplate 60 Hz only—will overheat on 50 Hz |

| 10 | Compare TCO, not price | Include auger life (500 k cycles), annual cal cost, scrap % | Add WEEE recycling fee, ATEX inspection every 3 yrs | Lowest bid excludes auger, spare seals, freight |

Next Actions

- Send above table to ≥3 shortlisted OEMs; request line-by-line reply.

- Schedule FAT at factory with your actual powder; record video.

- Insert clause: 5 % retention until Site Acceptance Test (SAT) sign-off.

Comprehensive Cost and Pricing Analysis for powder filling machine Sourcing

Comprehensive Cost & Pricing Analysis for Powder Filling Machine Sourcing (USA & Europe)

| Cost Driver | Typical % of Ex-Works Price | 2024 USD Range (Bench-top / 1-head) | Notes for Buyers |

|---|---|---|---|

| Materials & Components | 45 – 55 % | $1,050 – $2,750 | AISI 304/316L SS, servo motors, HMI, load-cells; 10–15 % surcharge if NEMA 4X or IP66 required |

| Labor & Assembly | 12 – 18 % | $280 – $900 | China: $4.50/hr; Eastern-EU: $11/hr; USA: $28/hr; add 25 % for UL-certified panel wiring |

| Logistics & Duties | 8 – 15 % | $220 – $750 | Ocean FCL Shanghai → LA: $1,300–1,800/40 ft; Air: $4.50 kg; Import duty USA 3.9 %, EU 1.7 % |

| Factory Margin | 15 – 25 % | $350 – $1,250 | Drops 3–5 pp at ≥ 5-unit order; OEM/ODM orders 8–12 pp extra margin |

| After-Sales & Spares | 2 – 4 % | $50 – $200 | 1-yr parts-only vs. 3-yr on-site; factor 0.8 % of machine price per additional year |

1. Material Cost Breakdown (Bench-top Auger Filler, 1–100 g, 2024)

| Component | Share | Cost (USD) | Cost-Saving Tactics |

|---|---|---|---|

| Stainless-steel frame & hopper | 18 % | 270 | Accept 304 instead of 316 if product pH 5–9 |

| Servo motor & drive | 12 % | 180 | Specify domestic-brand servo (Inovance, Delta) vs. Allen-Bradley (-25 %) |

| Load cell & weighing module | 8 % | 120 | Use OIML-approved cell; avoid “custom” specs |

| PLC + HMI | 7 % | 105 | Ask for Codesys-based PLC; no Siemens surcharge |

| Auger & agitator (PTFE-coated) | 5 % | 75 | Order 5 spare augers → 15 % volume discount |

| Pneumatics & sensors | 4 % | 60 | Standardize 24 VDC; reduce variety |

| Paint, cables, small parts | 3 % | 45 | Powder-coat instead of brushed finish (-10 %) |

| Sub-total Materials | 57 % | 855 |

2. Labor & Assembly Cost Map

| Region | Hourly Rate | Added Cost for UL/CE | Lead-Time Impact |

|---|---|---|---|

| Jiangsu/Zhejiang | $4.50 | +$120 (UL panel) | 15 days |

| Poland/Czech | $11.00 | Included | 25 days |

| Midwest USA | $28.00 | Included | 35 days |

Rule of thumb:

Every $1 increase in hourly labor adds ≈ $65 to the finished machine price (bench-top, 6.5 man-hours).

3. Logistics & Incoterms Cheat-Sheet

| Mode | Cost/kg | Effective for | Hidden Charges to Negotiate |

|---|---|---|---|

| FCL Ocean (40 ft) | $0.11 | ≥ 12 units | DTHC, chassis split, chassis usage (>7 days) |

| LCL Ocean | $0.28 | 1–3 units | CFS fee, document fee ($75–110) |

| Air Freight | $4.50 | < 250 kg | Fuel & security surcharge (25–30 %) |

| Express Courier | $6.80 | Samples | Remote-area surcharge |

Import Duties & Tax (2024)

– USA HTS 8422.30.91: 3.9 % + 0.125 % MPF (min $31.67)

– EU TARIC 8422 30 91: 1.7 % + 20 % VAT (recoverable)

Illustrative Image (Source: Google Search)

4. Total Landed Cost Example (1-head Auger Filler)

| Item | USD |

|---|---|

| Ex-Works Shanghai | 2,200 |

| 5 % OEM discount | –110 |

| Export crating | 90 |

| Ocean FCL (12 units) | 180 |

| USA import duty (3.9 %) | 86 |

| MPF & brokerage | 45 |

| Inland freight to Ohio | 220 |

| Landed Cost / unit | 2,711 |

5. Cost-Saving Checklist for Procurement Teams

- Consolidate SKUs: one auger diameter covers ±30 % fill range → save $110 per spare.

- Order 3–5 units per PO; unlock 4–7 % volume rebate and split freight.

- Specify “China-brand” servos with 2-year warranty; cuts BOM by $180.

- Choose FOB instead of CIF; control freight & insurance (~$150 saving).

- Pre-book 40 ft container 6 weeks ahead; avoid peak-season GRI ($600–1,000).

- Ask supplier to ship PLC & HMI separately via air (2 kg) and pre-wire in USA; reduces power-up failure risk and on-site labor.

- Negotiate extended payment (30/70) with Sinosure cover; improves cash-flow by 45 days, worth ~1 % of machine cost in WACC terms.

- Opt for 304 SS unless 316L is mandated by FDA auditor; saves 8 % of material cost.

- Request digital FAT via Teams; eliminate one round-trip airfare ($1,200).

- Bundle annual consumables (gaskets, augers) into initial PO; lock steel price, avoid 5–8 % inflation surcharge next year.

Use the above matrix to benchmark quotes quickly and defend landed-cost projections in internal CAPEX requests.

Alternatives Analysis: Comparing powder filling machine With Other Solutions

Alternatives Analysis: Comparing Powder Filling Machines With Other Solutions

| Evaluation Criteria | Bench-Top Semi-Automatic Powder Filler | Pre-Made Pouch (Doypack) Bagger | Manual Scoop + Weigh Station |

|---|---|---|---|

| Typical CAPEX (USD) | $2k – $8k | $35k – $90k | $200 – $1k (scale + table) |

| Throughput | 8 – 25 fills/min (1 operator) | 30 – 60 pouches/min (1 operator) | 2 – 4 fills/min |

| Fill Accuracy | ±0.2 – 1 g (load-cell or auger) | ±1 – 2 % (servo-auger) | ±3 – 5 g (operator-dependent) |

| Change-over Time | 5 – 10 min (hopper & auger swap) | 15 – 30 min (film & former) | <1 min (new scoop) |

| Labor per Shift | 1 semi-skilled | 1 skilled | 2 – 3 unskilled |

| Floor Space | 0.5 m² | 6 – 8 m² | 1 m² |

| Dust Control | Optional vacuum collar | Integrated dust hood | Nil (open station) |

| SKU Flexibility | 1 – 100 g (same auger) | 10 – 2 000 g (film size limit) | Unlimited |

| Validation Package | IQ/OQ templates available | Full 21 CFR Part 11 | None |

| 3-Year OEE | 75 – 80 % | 85 – 90 % | 45 – 55 % |

Analysis

- Pre-Made Pouch Bagger

- Strength: Highest throughput and lowest labor cost per unit—ideal for >1 M pouches/year SKUs.

- Weakness: Capital hurdle and long change-over penalize short runs; film waste adds 2–3 ¢/pouch.

-

Decision Rule: Choose when forecast volume ≥ 30 pouches/min for 2 shifts and SKU count < 15.

-

Manual Scoop + Weigh Station

- Strength: Zero CAPEX and instant flexibility for pilot or R&D batches.

- Weakness: Labor cost dominates above 50 k units/year; poor repeatability triggers giveaway and rejection risk.

-

Decision Rule: Retain only for <10 k units/year, seasonal overflow, or allergen-segregated lines where cross-contamination risk outweighs speed.

-

Bench-Top Semi-Automatic Powder Filler (baseline)

- Sweet Spot: 50 k – 1 M units/year, 5–25 fills/min, frequent SKU swaps, and FDA/EC regulatory documentation required.

- Upgrade Path: Add check-weigher feedback and vacuum transfer to close accuracy gap with fully automatic line while preserving 3-year payback.

Essential Technical Properties and Trade Terminology for powder filling machine

2. Essential Technical Properties & Trade Terminology for Powder Filling Machines

2.1 Key Technical Properties

| Property | Typical Range | B2B Implication |

|---|---|---|

| Fill Weight Accuracy | ±0.2–2 % of target weight | Validates savings on giveaway; ask for “±% of set-point” not “±g” to compare machines. |

| Fill Range (per dose) | 0.1 g – 5 kg | Match auger/tunnel set to your SKU spread; verify “min-max without change parts”. |

| Throughput | 10 – 120 doses/min | Request “doses/min at 1-σ accuracy” (not free-flow speed). |

| Hopper Volume | 10 – 150 L | 1 L ≈ 0.4–0.8 kg bulk density powder; size for ≤3 refills/shift to cut labour. |

| Auger / Cup / Vacuum Disc | Tool-steel, SS304, SS316L | Specify 316L for pharma/dairy; ask for Ra ≤0.4 µm finish if CIP/SIP required. |

| Power Supply | 110 V 1-ph (USA) / 230 V 1-ph (EU) / 400 V 3-ph | Quote voltage & hertz on PO; OEMs will swap motor free if declared up-front. |

| Control System | Relay, PLC, or IPC | PLC ≥32 I/O preferred for check-weigher feedback & batch reporting. |

| Ingress Protection | IP54 standard, IP65 wash-down | EU food plants often demand IP65; verify cabinet seals are FDA CFR 21 compliant. |

| Compressed Air | 4–6 bar, 100–300 L/min | State “oil-free, dew-point ≤3 °C” to avoid valve clogging. |

| Communication Ports | RS-232, Ethernet/IP, Modbus TCP | Needed for MES/OEE dashboards; request protocol manual in sales package. |

2.2 Critical Performance Metrics (include in RFQ)

- Cpk ≥ 1.67 at target fill weight (FDA process-validation expectation).

- Change-over time: <10 min tool-less auger removal (UTS format).

- Reject rate: <0.5 % at 3-σ (include penalty clause).

- MTBF ≥ 2,000 h, MTTR ≤ 30 min (get OEM FMEA sheet).

- OEE guarantee: ≥85 % on 3-shift trial (define powder, ambient T, RH).

2.3 Trade & Commercial Terms

| Term | Meaning | Typical Benchmark |

|---|---|---|

| MOQ | Minimum order quantity | 1 unit for standard auger filler; 3–5 units for OEM colours. |

| OEM / ODM | Original (Design) Manufacturing | OEM logo swap free ≥5 units; ODM new frame = 30-unit MOQ + NRE. |

| EXW | Ex-Works (factory gate) | Subtract ~8 % from FOB quote if you control freight. |

| FOB | Free On Board (Chinese port) | Budget USD 900–1,200 to LA or Hamburg for 2 CBM crate. |

| CIF | Cost-Insurance-Freight | Adds 8–12 %; secure “all-risks” clause covering electronics. |

| Lead-time | Down-payment to readiness | Standard filler 25–35 days; 316L pharma spec 45–55 days. |

| Warranty | Parts & labour | 12 months unlimited cycles; negotiate 24-month servo drive. |

| Incoterms 2020 | Use DAP warehouse for EU to avoid import surprise VAT. |

2.4 Compliance & Documentation Checklist

- CE declaration (Machinery Directive 2006/42/EC) + technical file

- UL508A panel label for US installations (ask for E-file number)

- FDA 21 CFR material contact statements & migration tests

- ISO 9001:2015 certificate of manufacturing site

- FAT/SAT protocol & IQ/OQ templates (pharma buyers)

- Spare-parts list with 10-year availability guarantee

Tip: Attach this section as a one-page RFQ addendum; suppliers respond faster and deviations become visible before PO placement.

Navigating Market Dynamics and Sourcing Trends in the powder filling machine Sector

Navigating Market Dynamics & Sourcing Trends in the Powder Filling Machine Sector

1. Macro Demand Drivers (2024-2026)

| Driver | North America | EU-5 |

|---|---|---|

| Pharma OSD capacity expansion | 7 % CAGR | 5 % CAGR |

| Sports-nutrition sachets | 12 % CAGR | 9 % CAGR |

| Plant-protein pouches | 18 % CAGR | 15 % CAGR |

| Battery-powder anodes | 22 % CAGR | 19 % CAGR |

Take-away: High-value, low-density powders (pharma, battery) justify fully automated, containment-ready lines; nutrition powders favour mid-speed, quick-format-change machines.

2. Technology Adoption Curve

| Segment | 2020 | 2024 | 2026 (est.) |

|---|---|---|---|

| Semi-automatic auger | 55 % | 44 % | 35 % |

| Servo-auger with IPC | 28 % | 38 % | 45 % |

| Vacuum/Drum micro-dose | 12 % | 15 % | 18 % |

| Net-weight & Coriolis | 5 % | 3 % | 2 % |

Servo-driven auger fillers with in-process check-weigh feedback are becoming the default for 1 g–1 kg packs; vacuum drum technology wins for <1 g pharma doses.

Illustrative Image (Source: Google Search)

3. Sustainability & Regulatory Signals

EU

- PPWR (Packaging & Packaging Waste Regulation) 2024: 25 % recycled content in plastic pouches by 2027 → machine buyers demand sealed-jaw film fillers with lower sealing temperature to run rPE & rPP.

- EcoDesign for Sustainable Products (ESPR) draft: CE-marked machines must ship with energy-consumption file (kWh/kg filled) starting 2026.

USA

- FDA Food Traceability Final Rule (Nov 2022): 2-year compliance window for dry mix producers → fillers need Allen-Bradley or Beckhoff controllers capable of electronic batch records (21 CFR §11).

- Inflation Reduction Act domestic-manufacturing credits: battery-grade powder packagers sourcing >60 % U.S.-built equipment qualify for 10 % capital credit.

Global

- ATEX & IECEx: rising demand for nitrogen-purged, IP66 enclosures when handling fine chemical, TiO₂ or battery powders.

4. Sourcing Matrix: Make-vs-Buy-vs-Rent

| Criteria | Buy New | Buy Used | Lease/RaaS |

|---|---|---|---|

| Lead time | 16–24 wks | 4–6 wks | 2–4 wks |

| Capex (USD, 500 g servo-auger) | $45–65 k | $22–30 k | $1.8 k /mo |

| Warranty | 24 mo | 0–6 mo | Included |

| Upgrade path | Full | Limited | Mid-life swap |

| ESG score impact | Low (new EFF1 motors) | High (older drives) | Neutral (circular) |

Procurement tip: RaaS (Equipment-as-a-Service) contracts now cover validation, OEE monitoring and EU recycling at end-of-life—preferred by mid-size nutraceutical co-packers.

5. Supply-Chain Hotspots & Risk Outlook

| Component | 2023 Disruption | Mitigation 2024 |

|---|---|---|

| Servo motors & VFDs | 28 wk LT (Siemens, Bosch Rexroth) | Dual-source from Nidec, Schneider; hold safety stock 6 wks |

| Stainless-steel 316L | +22 % price vs 2021 | Lock 12-month index-based contracts; consider duplex 2205 |

| Load cells (EMFR) | 18 wk LT (Minebea) | Validate strain-gauge alternatives (HBM, Flintec) early in FAT |

6. Specification Checklist for RFQs

- Accuracy target: ≤±0.5 % @ 2σ for pharma, ≤±1 % for food

- OEE guarantee: ≥85 % on 3-shift operation (include change-over <15 min)

- Containment option: split-butterfly valve, continuous liner, or IBC passive

- Digital thread: OPC-UA data model, PackML state model, MQTT push to cloud

- Sustainability add-ons: IE4 motor, auto stand-by, recyclable stretch film kit

- Service package: 24 h remote support, VR-assisted troubleshooting, local spares hub within 500 km

Use the above framework to align internal stakeholders, de-risk sourcing, and future-proof capital investments against tightening ESG and regulatory standards on both sides of the Atlantic.

Frequently Asked Questions (FAQs) for B2B Buyers of powder filling machine

Frequently Asked Questions (FAQs) – B2B Buyer Edition

| # | Question | Quick Answer |

|---|---|---|

| 1 | What production throughput justifies an automatic vs. semi-automatic powder filler? | ≥30 fills/min or ≥1 shift/day sustained output. |

| 2 | Which dosing system gives ±0.5 % accuracy for micronized pharma powders? | Auger with servo-driven, load-cell feedback. |

| 3 | How do I validate Clean-in-Place (CIP) for FDA/EU GMP compliance? | Request IQ/OQ documents, 3.1 material certs, and riboflavin test video. |

| 4 | What spare-parts lead time should US/EU plants budget? | 5–7 days ex-US Midwest; 48 h ex-EU Central if vendor has VMI contract. |

| 5 | Can one machine handle both free-flow (salt) and non-free-flow (talc) powders? | Yes—specify interchangeable auger/twin-head and VFD agitator. |

| 6 | What is the total cost of ownership (TCO) delta between cheap tabletop units and industrial line? | 3-yr TCO: tabletop ≈ $0.08/container; servo-line ≈ $0.015/container (≥2M fills/yr). |

| 7 | How do I integrate check-weigher & metal detector without voiding warranty? | Demand vendor-supplied Ethernet/IP or OPC-UA module; third-party retrofits void CE mark. |

| 8 | What export packaging prevents corrosion during 6-week sea freight? | VCI film + desiccant + plywood crate with ISPM-15 stamp; request salt-spray test report. |

1. What production throughput justifies an automatic vs. semi-automatic powder filler?

- Rule-of-thumb:

- <500 containers/shift → semi-automatic (foot-pedal, $3–8 k).

- ≥500 containers/shift or single SKU >30 fills/min → automatic auger or cup-filler ($25–120 k).

- Labor ROI: One automatic head saves 1.2 FTE/year at $45 k loaded cost (US), payback <14 months.

2. Which dosing system gives ±0.5 % accuracy for micronized pharma powders?

- Auger + servo motor + real-time load cell (closed-loop).

- Specs to request:

- Servo resolution ≤0.001 rev.

- Hopper agitator with VFD to prevent de-aeration.

- Anti-static PTFE-coated funnel.

- Certification: Provide 10-run GR&R study <5 %.

3. How do I validate Clean-in-Place (CIP) for FDA/EU GMP compliance?

- Documentation package:

- IQ/OQ/PQ templates.

- 3.1 stainless-steel certificates (316L, Ra ≤0.4 µm).

- Riboflavin wash-down video (≥90 % fluorescence removal).

- Design points: Tri-clamp connections, tool-less auger removal, IP66 wash-down rating.

4. What spare-parts lead time should US/EU plants budget?

| Region | Standard | VMI Contract | Critical Kit Price |

|---|---|---|---|

| US Midwest | 5–7 days | 24 h | $1,200 (auger, seals, clutch) |

| EU Central | 48 h | Same day | €1,050 |

| – Tip: Negotiate “first-flight-out” courier credit in SLA. |

5. Can one machine handle both free-flow (salt) and non-free-flow (talc) powders?

- Yes—if specified upfront:

- Quick-change auger & funnel kit (≤10 min swap).

- Variable-pitch agitator blade + drip-proof valve.

- HMI recipe storage (≥50 sets).

- Avoid: Volumetric cup fillers—only suitable for free-flow.

6. What is the total cost of ownership (TCO) delta between cheap tabletop units and industrial line?

| Scenario | Tabletop $239 (Amazon) | Servo-Auger Line $85 k |

|---|---|---|

| Output | 6–8 fills/min | 60 fills/min |

| Labor | 1 operator/shift | 0.2 operator/shift |

| 3-yr electricity | $1,200 | $3,500 |

| Scrap (±2 g) | 1.5 % | 0.3 % |

| 3-yr TCO/1 k containers | $80 | $15 |

| – Break-even: 1.2 M containers. |

7. How do I integrate check-weigher & metal detector without voiding warranty?

- Demand:

- OEM-supplied Ethernet/IP or OPC-UA module.

- Native reject confirmation signal (24 VDC).

- Red flag: Any third-party drilling or wiring on CE-certified panel voids Declaration of Conformity—use DIN-rail pass-through glands.

8. What export packaging prevents corrosion during 6-week sea freight?

- Spec:

- VCI film wrap (≥0.12 mm).

- 4 × 1 kg silica-gel desiccant packs per m³.

- ISPM-15 heat-treated plywood crate, PE liner inside.

- Proof: Request 720 h salt-spray test certificate (ASTM B117) on unpainted SS parts.

Strategic Sourcing Conclusion and Outlook for powder filling machine

Strategic Sourcing Conclusion & Outlook: Powder Filling Machine

| Key Take-away | Action |

|---|---|

| Total Cost of Ownership beats sticker price | Negotiate 5-year service & spare-parts bundle; budget $0.03–$0.05 per 1,000 fills for auger/belt wear |

| Compliance Ready | Demand ATEX II 3D & FDA 21 CFR compliance documentation up-front; EU buyers add CE/UKCA files |

| Scalability | Specify modular PLC/I-O ports; servo-driven units cut change-over to <5 min for SKU growth |

| Data Integration | Require OPC-UA & Ethernet/IP as standard; ties into MES/ERP for track-and-trace mandates |

Outlook 2024-2026

- Servo+load-cell accuracy will reach ±0.2 g at 80 fills/min for ≤$15k machines.

- IIoT predictive maintenance contracts drop unplanned downtime 30 %; negotiate SLA with 95 % OEE guarantee.

- Sustainability clauses—energy-use data & recyclable contact parts—will enter RFP scoring; secure life-cycle report now.

Secure frame agreement with two qualified vendors, locking pricing for 18 months while piloting one IoT-enabled unit.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.