The global water jet cutting machine market is experiencing robust growth, driven by increasing demand for precision cutting solutions across industries such as aerospace, automotive, and manufacturing. According to a report by Mordor Intelligence, the market was valued at USD 1.27 billion in 2023 and is projected to grow at a CAGR of 7.8% from 2024 to 2029. A key trend fueling this expansion is the rising adoption of portable water jet cutting systems, which offer enhanced mobility, reduced setup time, and operational flexibility—especially beneficial for on-site fabrication and repair work. As industries prioritize efficiency and cost-effective solutions, manufacturers are investing heavily in compact, high-performance portable models. This growing ecosystem has led to increased competition and innovation among leading suppliers. Based on market presence, technological advancement, and product reliability, the following nine companies have emerged as the top manufacturers of portable water jet cutting machines worldwide.

Top 9 Portable Water Jet Cutting Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 TCI Cutting

Domain Est. 2010

Website: tcicutting.com

Key Highlights: As a manufacturer of industrial laser cutting machines, we offer our customers the cutting machine and automation solutions that best suit production needs….

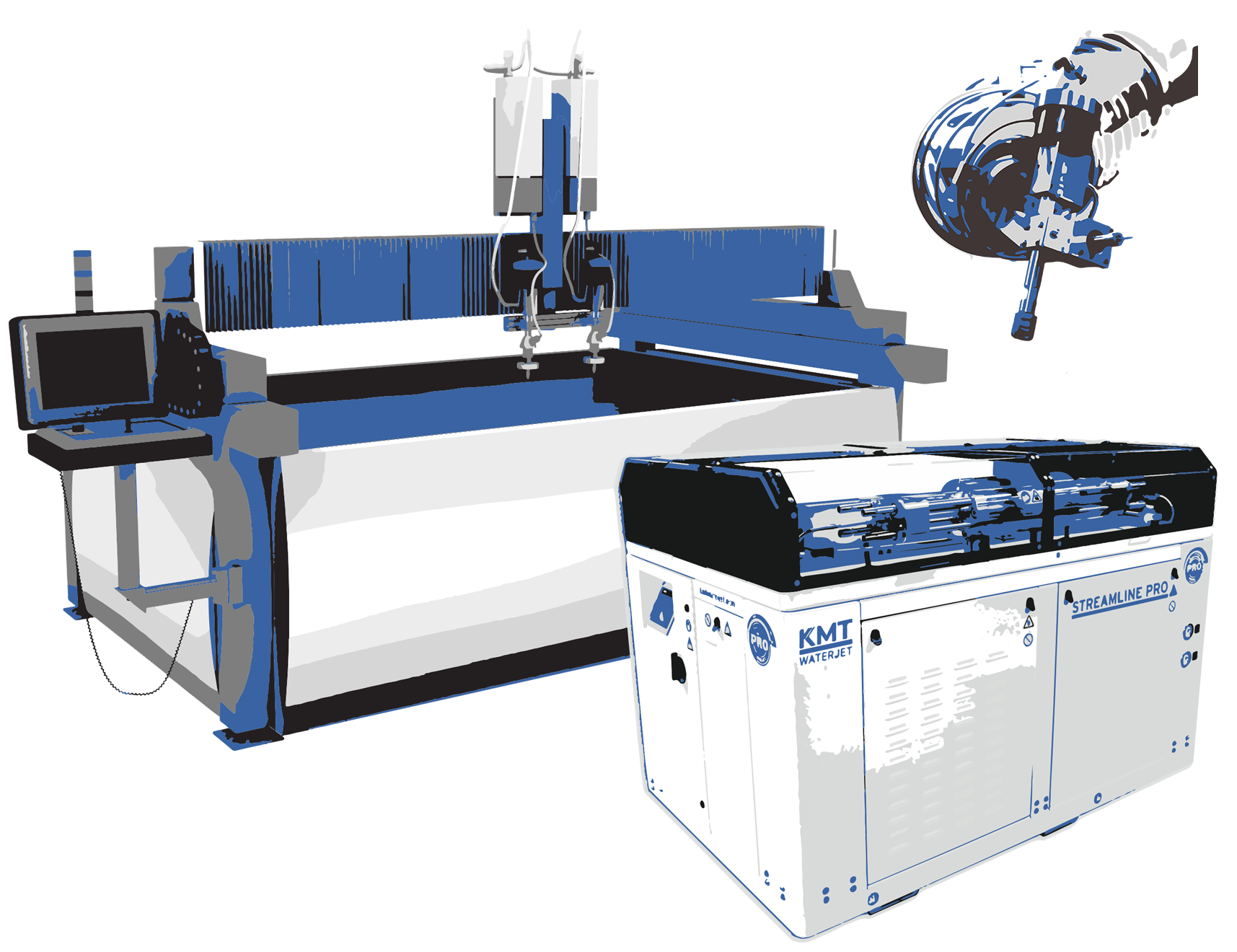

#2 KMT Waterjet

Domain Est. 2003

Website: kmtwaterjet.com

Key Highlights: KMT Waterjet: Pioneers in waterjet cutting technology. Discover pumps, parts, and complete systems for precision solutions….

#3 Portable Water Jet

Domain Est. 2013

Website: nuwaveindustries.com

Key Highlights: NuWave Industries offers state-of-the-art portable water jet solutions for efficient and precise cutting across various industrial applications….

#4 Jet Edge Waterjet Systems

Domain Est. 2018

Website: jetedgewaterjets.com

Key Highlights: Jet Edge Waterjet Systems is a leading manufacturer of waterjet and abrasive waterjet Cutters, ultra high pressure pumps, and accessories….

#5 CNC waterjet cutting, numerically controlled machine

Domain Est. 2002

Website: mecanumeric.com

Key Highlights: MÉCANUMÉRIC manufactures and markets CNC waterjet cutting machines, precision cutting for a wide range of materials and products….

#6 Flow Waterjet

Domain Est. 2003

Website: flowwaterjet.com

Key Highlights: Flow is the inventor and world leader in waterjet cutting solutions. With waterjet, you’ve got the versatility to cut any material, any shape, and any size….

#7 Waterjet Cutting Machine, Water Jet Cutter and Portable waterjet …

Domain Est. 2005

Website: iwmwaterjet.com

Key Highlights: IWM manufactures waterjet cutting machine including waterjet pipe cutting, portable waterjet cutter and spare parts for the waterjet cutting machines….

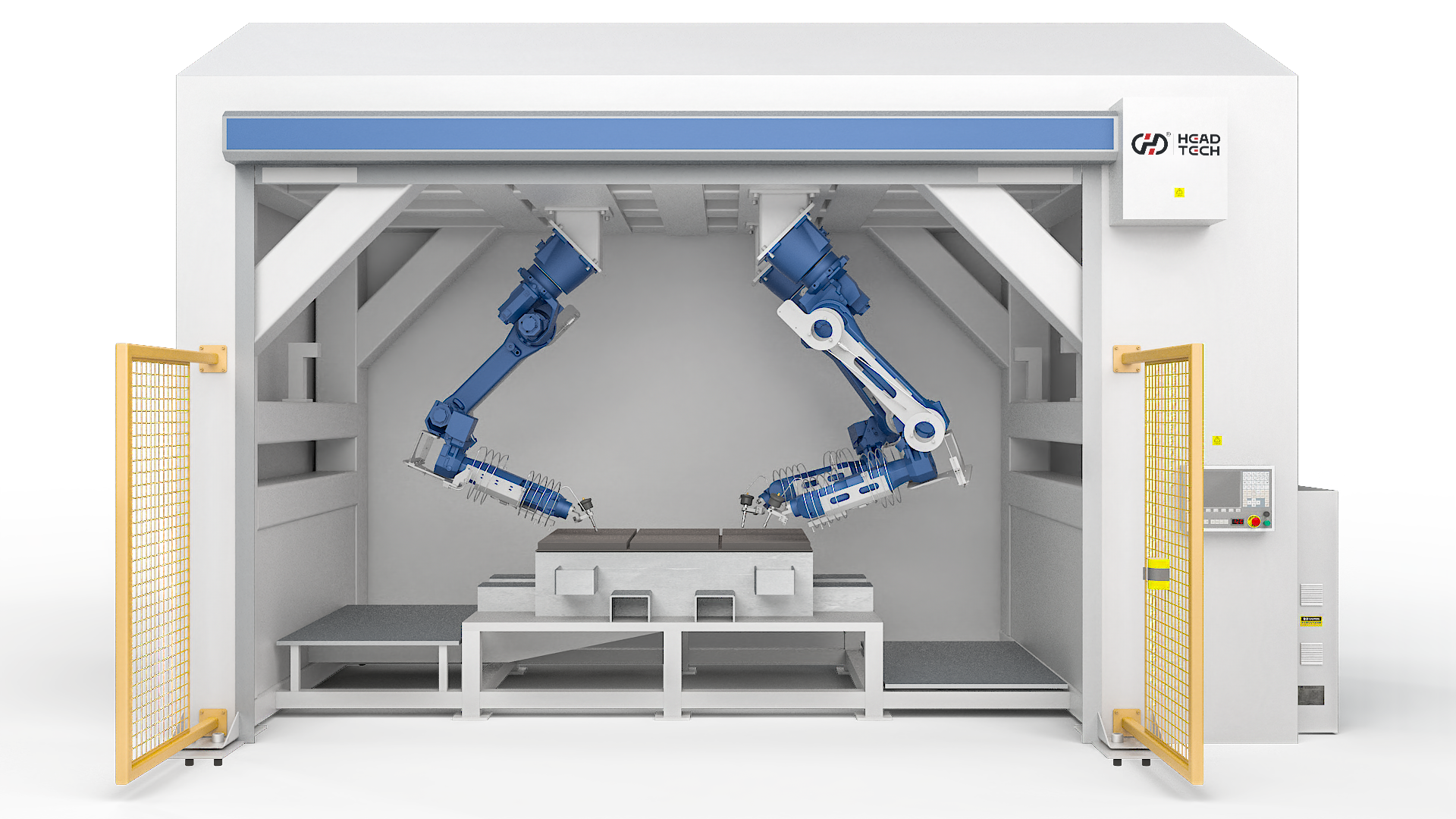

#8 Portable Water Cutting

Domain Est. 2013

Website: hdwaterjet.net

Key Highlights: Our Powerful, Versatile Water Jet Cutter Cut Virtually Any Material With Precision At Low Costs. Contact Us Get Offer! Free Trial Cut….

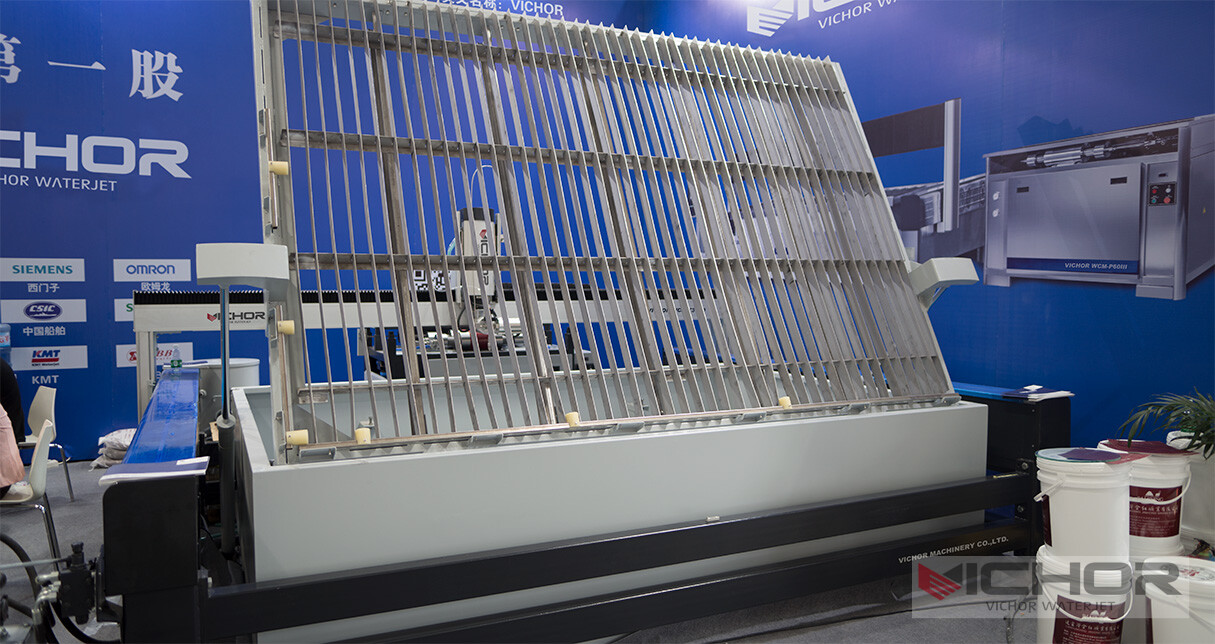

#9 WMT Portable Waterjet Cutting Machine

Domain Est. 2014

Website: wamitwaterjet.com

Key Highlights: WAMIT’s portable waterjet cutting machine—compact, mobile, and powerful, delivering precise, on-site cutting across materials with high-pressure water jet ……

Expert Sourcing Insights for Portable Water Jet Cutting Machine

H2: 2026 Market Trends for Portable Water Jet Cutting Machines

The global market for portable water jet cutting machines is poised for significant transformation by 2026, driven by technological innovation, expanding industrial applications, and growing demand for precision cutting solutions in remote and on-site environments. As industries increasingly prioritize efficiency, sustainability, and operational flexibility, portable water jet cutting systems are emerging as a preferred alternative to traditional thermal and mechanical cutting methods.

One of the dominant trends shaping the 2026 market is the integration of advanced automation and smart technologies. Portable units are increasingly equipped with IoT-enabled sensors, real-time monitoring systems, and user-friendly interfaces powered by AI algorithms. These enhancements allow for remote diagnostics, predictive maintenance, and improved precision, reducing downtime and operator dependency. Manufacturers are investing in compact control consoles and mobile-compatible software platforms to enhance usability in field applications.

Another key trend is the rising demand from sectors such as construction, shipbuilding, oil & gas, and emergency rescue operations. The ability of portable water jet machines to cut through a wide range of materials—including metals, composites, concrete, and stone—without generating heat-affected zones makes them ideal for sensitive or hazardous environments. In particular, the oil & gas industry is adopting these systems for maintenance and decommissioning tasks due to their non-sparking nature and compliance with safety regulations.

Sustainability is also influencing market dynamics. Water jet cutting produces no toxic emissions or fumes, aligning with global environmental standards and corporate sustainability goals. As regulatory pressures increase, industries are shifting toward eco-friendly alternatives, further boosting demand for portable systems that offer clean, cold-cutting solutions.

Geographically, North America and Europe are expected to lead the market in 2026, supported by strong industrial infrastructure and early adoption of advanced manufacturing technologies. However, the Asia-Pacific region is witnessing rapid growth due to expanding manufacturing bases in China, India, and Southeast Asia, along with rising investments in infrastructure development.

Moreover, advancements in pump technology—such as the development of lighter, more energy-efficient intensifier and direct-drive pumps—are enhancing portability and operational efficiency. These innovations are reducing machine weight and power consumption, enabling deployment in remote or confined spaces where traditional cutting equipment cannot operate.

In conclusion, the 2026 market for portable water jet cutting machines will be defined by smarter, lighter, and more sustainable solutions that meet the evolving needs of diverse industries. As competition intensifies, manufacturers who focus on innovation, durability, and ease of use will likely capture significant market share in this dynamic landscape.

Common Pitfalls When Sourcing a Portable Water Jet Cutting Machine (Quality, IP)

Sourcing a portable water jet cutting machine involves navigating several potential pitfalls, particularly concerning quality and intellectual property (IP). Overlooking these can lead to equipment failure, legal issues, and operational inefficiencies.

Poor Build Quality and Component Selection

One of the most prevalent issues is acquiring machines constructed with substandard materials and components. Many low-cost suppliers use inferior pumps, seals, hoses, and cutting heads to reduce prices. This results in frequent breakdowns, inconsistent cutting performance, and shortened machine lifespan. Poor machining tolerances in critical parts can lead to misalignment and premature wear, increasing downtime and maintenance costs.

Inadequate IP Protection and Design Copying

Many portable water jet systems, especially from certain regions, are direct copies of patented designs from established manufacturers. Purchasing such equipment can expose the buyer to intellectual property infringement risks. If the machine incorporates patented technology—such as proprietary intensifier pump designs or control systems—using it may result in legal action from original innovators, especially in regions with strict IP enforcement.

Lack of Certification and Safety Compliance

A frequently overlooked aspect is compliance with international safety and quality standards (e.g., CE, UL, ISO). Some machines lack proper certifications, indicating they haven’t undergone rigorous testing for pressure safety, electrical integrity, or ergonomic design. This not only compromises operator safety but can also void insurance coverage and prevent use in regulated industries.

Misrepresentation of Performance Specifications

Suppliers may exaggerate cutting pressure (e.g., claiming 60,000 psi when actual is lower), flow rates, or material thickness capabilities. Without third-party verification or performance testing, buyers may receive equipment that fails to meet project requirements. This is especially problematic in field applications where cutting efficiency directly impacts productivity.

Incomplete or Missing Technical Documentation

Low-quality or counterfeit machines often come with poor or nonexistent technical documentation, including manuals, schematics, or maintenance guides. This hinders troubleshooting, servicing, and training, leading to longer downtimes and increased dependency on the supplier—often located overseas with limited support.

Hidden Costs from Poor After-Sales Support

While the initial purchase price may seem attractive, many budget machines lack reliable after-sales service, spare parts availability, or software updates. When components fail, sourcing replacements can be difficult and expensive, negating any upfront savings. Additionally, lack of firmware or software support can limit machine functionality over time.

Risk of Using Counterfeit or Reverse-Engineered Software

Some portable systems use cloned control software that mimics legitimate brands. This raises IP concerns and often lacks updates, security patches, and compatibility with modern CAD/CAM systems. Using such software may breach licensing agreements and expose operations to cybersecurity vulnerabilities.

To avoid these pitfalls, conduct thorough due diligence: verify supplier credentials, request performance testing, review IP disclaimers, and prioritize vendors with transparent manufacturing practices and strong service networks.

Logistics & Compliance Guide for Portable Water Jet Cutting Machine

Transportation and Handling

Ensure the portable water jet cutting machine is securely packaged in a robust, weather-resistant crate or container suitable for ground, air, or sea freight, depending on the shipping method. Use protective padding to prevent vibration and impact damage during transit. Clearly label the package with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. For road transport, secure the machine firmly to prevent shifting. If disassembled for shipping, follow the manufacturer’s guidelines for safe reassembly upon delivery.

Import and Export Regulations

Verify import/export requirements based on the origin and destination countries. Obtain necessary licenses or permits, especially if the machine contains high-pressure components or electrical systems that may be subject to trade restrictions. Provide a detailed commercial invoice, packing list, and bill of lading/airway bill. Classify the machine under the appropriate Harmonized System (HS) code—typically under 8464 (machines for working stone, ceramics, etc.)—to determine duties and tariffs.

Electrical and Safety Compliance

Confirm that the machine meets electrical safety standards for the destination country, such as CE marking (EU), UL certification (USA), or CCC (China). Ensure voltage and frequency compatibility with local power supplies. Include documentation proving compliance with relevant safety directives, including IEC 60204-1 (safety of machinery – electrical equipment of machines). Operators must be trained in safe handling procedures to prevent high-pressure water or abrasive injection injuries.

Environmental and Waste Management

Portable water jet cutting typically produces slurry waste containing abrasive media and material particles. Comply with local environmental regulations for wastewater discharge and slurry disposal. Use filtration or settling tanks to separate solids before releasing water. Transport and dispose of collected waste at licensed facilities, maintaining records of disposal for compliance audits. Avoid discharging untreated effluent into storm drains or natural water bodies.

Onsite Operational Compliance

Ensure operators adhere to local occupational health and safety (OHS) regulations. Provide appropriate personal protective equipment (PPE), including safety glasses, hearing protection, gloves, and protective footwear. Install emergency stop systems and conduct regular maintenance checks as per manufacturer recommendations. Maintain a log of inspections, repairs, and operator training to demonstrate regulatory compliance during audits.

Documentation and Recordkeeping

Retain all compliance-related documents, including equipment manuals, safety certifications, import/export filings, maintenance logs, and training records. These records support regulatory compliance and are essential for warranty claims, insurance purposes, and customs inspections. Provide translated documentation if required by local authorities.

Conclusion:

After a comprehensive evaluation of the market, technical capabilities, and supplier options, sourcing a portable water jet cutting machine presents a strategic investment for enhancing operational flexibility, precision, and efficiency. These machines offer eco-friendly cutting solutions without generating heat-affected zones, making them ideal for a wide range of materials including metals, composites, stone, and glass. The portability factor allows for on-site processing, reducing material handling and transportation costs while improving project turnaround times.

Key considerations such as cutting capacity, pump pressure, abrasive delivery system, reliability, after-sales support, and ease of maintenance have been assessed across multiple suppliers. Based on performance-to-cost ratio, service network, and technological features, [insert preferred supplier or model, if applicable] emerges as the most suitable option.

In conclusion, procuring a portable water jet cutting machine aligns with long-term objectives of operational versatility and sustainability. It empowers the organization to take on diverse projects with greater agility and precision. With proper training and maintenance protocols, this equipment will deliver a strong return on investment and reinforce competitive advantage in the marketplace.