The global portable stack rack market is experiencing robust growth, driven by rising demand for efficient material handling solutions across logistics, manufacturing, and retail sectors. According to a 2023 report by Mordor Intelligence, the material handling equipment market—which includes portable stack racks—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. This expansion is fueled by increasing warehouse automation, e-commerce fulfillment needs, and the push for space optimization in supply chain operations. Portable stack racks, known for their durability, reusability, and modular design, are becoming essential in just-in-time inventory systems and closed-loop supply chains. With sustainability and operational efficiency at the forefront, manufacturers are innovating to meet evolving customer demands—making it critical to identify the leading players shaping this competitive landscape. Based on market presence, production capacity, innovation, and global reach, here are the top 10 portable stack rack manufacturers leading the industry today.

Top 10 Portable Stack Racks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Portable stack racks manufacturers

Website: stackrackpro.com

Key Highlights: Warehouse Storage Racks Manufacturer. From design to production, we provide full-service customized warehouse racking solutions with factory-direct pricing….

#2 Stack Racks

Domain Est. 1997

Website: globalindustrial.com

Key Highlights: 30-day returnsGlobal Industrial™ Portable Stack Rack, 48″W x 48″D x 44.8″H · WB798923 · $369.95 ; Global Industrial™ Modular Bar Stack Rack, 19″W x 14″D x 18 ……

#3

Domain Est. 2000

Website: dyna-rack.com

Key Highlights: Dyna-Rack is a leading manufacturer of custom portable and stackable racking solutions tailored to meet the diverse needs of businesses and industries….

#4 Stack Rack & Shipping Racks & Industrial Wire Baskets

Domain Est. 2023

Website: nsmc-steel-racks.com

Key Highlights: We specialize in fabricating heavy duty steel stacking racks and industrial wire baskets for manufacturing, distribution and warehouse customers….

#5 Portable Stack Racks

Domain Est. 1998

Website: steelking.com

Key Highlights: Portable stack racks provide storage, handling, and transport. Stacking pallet racks let materials move through your production process on the same rack….

#6 Portable Stacking Racks

Domain Est. 1998

Website: egaproducts.com

Key Highlights: EGA Products Portable Stack Racks maximize your warehouse storage space. Stack racks can replace traditional pallet racking or wood pallets….

#7 Portable Stacking Racks

Domain Est. 1998

Website: rackandshelf.com

Key Highlights: Optimize warehouse storage with our stackable pallet racks. These portable stacking racks offer space-saving solutions for any inventory setup. Shop now!…

#8 Tier-Rack: Warehouse Storage Racks

Domain Est. 1999

Website: tier-rack.com

Key Highlights: Tier-Rack provides an extensive array of warehouse storage solutions, including portable stack racks, pallet racks, and custom storage applications….

#9 Coosa Racks

Domain Est. 2007

Website: coosaracks.com

Key Highlights: Maximize warehouse space with durable and customizable collapsible or rigid steel stacking racks from Coosa Racks. Built to last. Fast delivery….

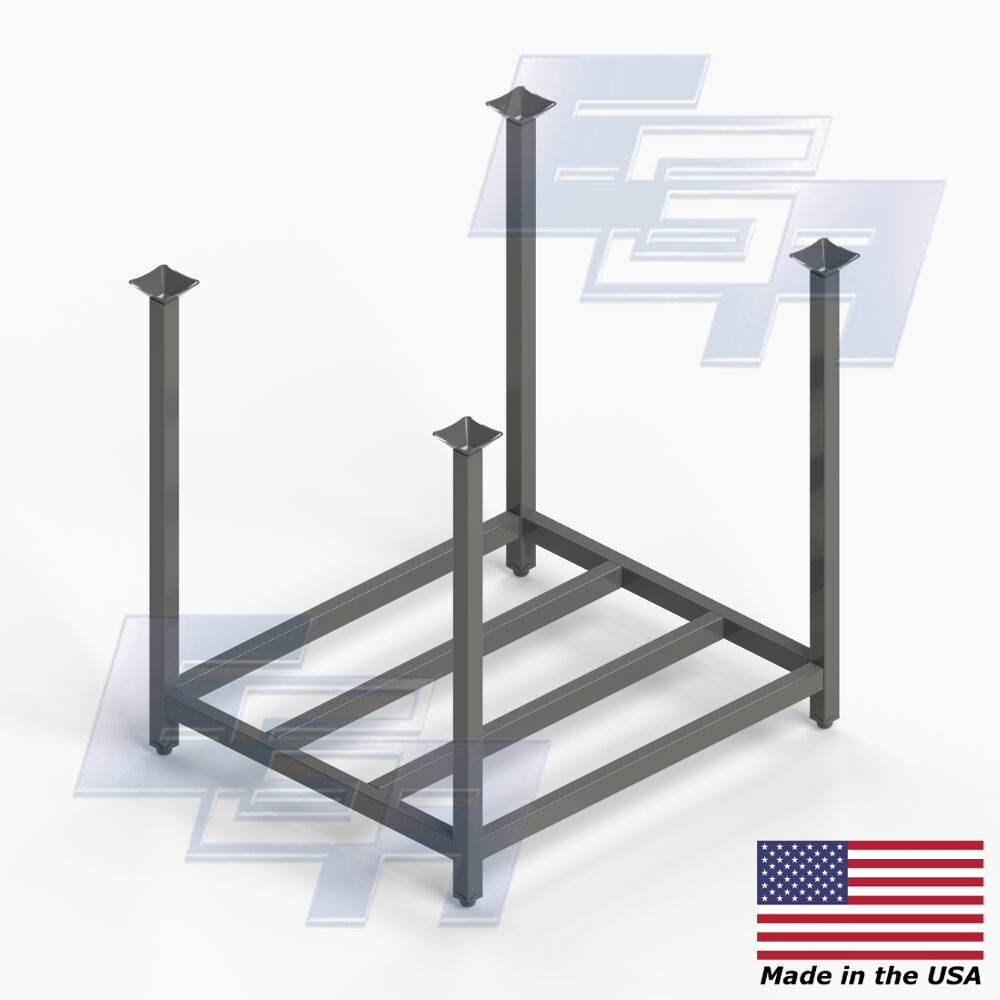

#10 Custom Designed Stackable Racks

Domain Est. 2023

Website: calderamfg.com

Key Highlights: Our portable stack racks are made from high-quality, durable materials and are customized to your specifications, so they fit your company’s specific stacking ……

Expert Sourcing Insights for Portable Stack Racks

H2: 2026 Market Trends for Portable Stack Racks

The global market for portable stack racks is poised for significant transformation by 2026, driven by evolving logistics demands, technological advancements, and shifting industrial practices. These durable, modular storage solutions are increasingly adopted across sectors such as warehousing, manufacturing, retail, and e-commerce due to their flexibility, space efficiency, and cost-effectiveness. Below is an analysis of key trends expected to shape the portable stack racks market in 2026:

-

Rise of E-Commerce and Omnichannel Logistics

The continued expansion of e-commerce is a major catalyst for portable stack rack adoption. As companies strive to optimize fulfillment operations and reduce delivery times, there is growing demand for agile storage systems. Portable stack racks enable quick reconfiguration of warehouse layouts and support rapid order picking—critical features in omnichannel distribution centers. By 2026, integration with automated guided vehicles (AGVs) and robotic systems will further enhance their utility in high-velocity fulfillment environments. -

Adoption of Lightweight, High-Strength Materials

Manufacturers are increasingly using advanced materials such as high-tensile steel, aluminum alloys, and reinforced polymers to improve rack durability while reducing weight. This trend supports easier portability and safer handling, especially in facilities with mobile operations. The shift toward lightweight yet robust designs will be especially prominent in industries like aerospace, automotive, and electronics, where protecting sensitive components during transport is crucial. -

Smart and IoT-Enabled Stack Racks

By 2026, a growing number of portable stack racks are expected to incorporate smart technologies, including embedded sensors, RFID tags, and IoT connectivity. These features allow real-time tracking of inventory location, load conditions, and rack utilization. Integration with warehouse management systems (WMS) will enable predictive maintenance, optimized stacking patterns, and improved inventory accuracy—enhancing overall supply chain visibility and efficiency. -

Sustainability and Circular Economy Focus

Environmental concerns are driving demand for reusable and recyclable storage solutions. Portable stack racks, being long-lasting and often 100% recyclable, align with corporate sustainability goals. Manufacturers are emphasizing modular designs that allow for easy repair and part replacement, reducing waste. Leasing and rental models are also gaining traction, promoting a circular economy and lowering the total cost of ownership for end users. -

Expansion in Emerging Markets

Asia-Pacific, Latin America, and parts of Africa are expected to see accelerated adoption of portable stack racks due to rapid industrialization, urbanization, and growth in logistics infrastructure. Local manufacturing hubs and government investments in smart warehouses will fuel demand. Cost-effective, scalable storage solutions like portable stack racks will be particularly attractive in these regions. -

Customization and Modular Design Innovation

As operational needs become more diverse, customization is becoming a key differentiator. By 2026, suppliers will offer highly configurable rack systems with adjustable heights, foldable frames, and compatibility with various handling equipment. This modularity allows businesses to adapt storage configurations to changing product sizes and workflow requirements without significant capital investment. -

Focus on Ergonomics and Workplace Safety

Regulatory pressures and a focus on worker well-being are pushing companies to adopt safer material handling solutions. Portable stack racks with ergonomic designs—such as rounded edges, non-slip surfaces, and easy-grip handles—are expected to gain preference. Features that reduce manual handling injuries and improve load stability will be critical selling points.

In conclusion, the 2026 market for portable stack racks will be defined by innovation, sustainability, and digital integration. As supply chains grow more dynamic and customer expectations rise, these versatile storage systems will play a pivotal role in optimizing material flow and operational resilience across industries. Companies investing in next-generation portable stack racks will be better positioned to respond to market volatility and maintain competitive advantage.

Common Pitfalls When Sourcing Portable Stack Racks

Poor Build Quality and Material Selection

Many suppliers offer portable stack racks made from substandard steel or inadequate welding techniques, leading to structural weaknesses, warping, or premature failure under load. Buyers often overlook material thickness (gauge), coating quality (e.g., powder coating vs. basic paint), and corner reinforcement, resulting in racks that degrade quickly in demanding environments.

Inaccurate or Misleading IP (Ingress Protection) Ratings

A frequent issue is suppliers advertising IP ratings (e.g., IP65) without independent certification. Some racks may claim dust- and water-resistance but lack proper seals, gaskets, or enclosure designs needed to meet those standards. This can lead to equipment damage in harsh conditions, especially in outdoor or industrial settings.

Inconsistent Dimensional Tolerances

Poor manufacturing control results in stack racks that don’t align or nest properly when stacked, causing instability, safety hazards, and inefficient storage. Slight variances in frame squareness or caster placement can compound when multiple units are stacked.

Overstated Load Capacity

Suppliers may advertise high load ratings based on ideal lab conditions rather than real-world use. Factors like dynamic loading, uneven weight distribution, and long-term use are often not accounted for, increasing the risk of collapse or deformation.

Lack of Certification and Compliance Documentation

Many low-cost suppliers fail to provide proof of compliance with international standards (e.g., ISO, CE, ANSI). This can create risks for safety audits, insurance claims, and regulatory acceptance, especially in regulated industries like pharmaceuticals or aerospace.

Inadequate Casters and Mobility Features

Low-quality or improperly rated casters can hinder maneuverability, cause floor damage, or fail under load. Issues include incorrect wheel material (e.g., non-marking vs. hard rubber), lack of swivel locks, or insufficient load rating per caster.

Poor After-Sales Support and Spare Parts Availability

Once a rack is damaged or a component fails, sourcing replacements (e.g., panels, casters, hinges) can be difficult with overseas or budget suppliers. Lack of technical support and long lead times disrupt operations and increase total cost of ownership.

Logistics & Compliance Guide for Portable Stack Racks

Portable stack racks are widely used across industries for efficient storage and transport of materials. Ensuring proper logistics handling and compliance with safety and regulatory standards is critical to operational efficiency and workplace safety. This guide outlines key considerations for the logistics and regulatory compliance of portable stack racks.

Design and Construction Standards

Portable stack racks must be engineered and manufactured in accordance with recognized industry standards. Key requirements include:

- Compliance with ANSI MH26.1 or equivalent standards for industrial steel racks.

- Use of high-strength steel or approved composite materials with documented load ratings.

- Welding and fabrication processes must meet AWS D1.1 or equivalent codes.

- Load capacity labels must be permanently affixed and clearly visible on each rack unit.

Load Capacity and Weight Distribution

Proper loading practices are essential to maintain structural integrity and prevent accidents.

- Never exceed the maximum load capacity as specified by the manufacturer.

- Distribute weight evenly across the rack base to prevent tipping or deformation.

- Center heavy loads over the rack’s support frame to avoid stress on side panels or legs.

- Reassess load limits when stacking multiple racks; cumulative weight must remain within safe parameters.

Stacking and Stability

Safe stacking procedures are crucial to prevent rack collapse and ensure transport stability.

- Only stack racks that are specifically designed for vertical stacking.

- Use alignment guides or interlocking mechanisms to secure stacked units.

- Limit stack height based on manufacturer recommendations and facility clearance.

- Conduct regular inspections of stacked racks for signs of misalignment or damage.

Transportation and Handling

Portable stack racks must be secured during transit to comply with transportation regulations.

- Secure racks on pallets or within containers using straps, chains, or locking systems.

- Ensure racks are not overloaded beyond vehicle weight limits (DOT or local regulations).

- Use forklifts or material handling equipment with appropriate capacity and attachments.

- Follow OSHA guidelines for material handling to prevent workplace injuries.

Workplace Safety and OSHA Compliance

Employers must ensure rack usage complies with occupational safety standards.

- Train personnel on proper loading, stacking, and handling procedures.

- Conduct routine inspections for cracks, bent frames, or worn components.

- Remove damaged racks from service immediately and tag for repair or disposal.

- Maintain clear aisleways and ensure racks do not obstruct emergency exits or sprinkler systems.

International and Regional Regulations

When shipping across borders, compliance with international standards may be required.

- For EU shipments, ensure racks comply with CE marking requirements and relevant EN standards.

- Follow IATA or IMDG Code guidelines if transporting racks by air or sea with hazardous materials.

- Verify country-specific labeling, packaging, and import documentation requirements.

Maintenance and Inspection Protocols

Regular maintenance ensures long-term compliance and safety.

- Implement a documented inspection schedule (e.g., monthly or quarterly).

- Keep maintenance logs detailing repairs, replacements, and load testing.

- Replace worn or damaged components with manufacturer-approved parts.

- Recertify racks after significant repairs or modifications.

Environmental and Sustainability Considerations

Sustainable practices support compliance with environmental regulations.

- Use recyclable materials in rack construction where possible.

- Implement a rack lifecycle management program to extend service life.

- Partner with vendors who follow ISO 14001 environmental management standards.

By adhering to these logistics and compliance guidelines, organizations can ensure the safe, efficient, and regulatory-compliant use of portable stack racks in their operations.

Conclusion for Sourcing Portable Stackable Racks

In conclusion, sourcing portable stackable racks requires a strategic approach that balances durability, space efficiency, cost-effectiveness, and operational needs. These racks offer significant advantages in logistics, warehousing, and manufacturing environments by maximizing vertical storage, improving inventory accessibility, and facilitating transportation. When selecting a supplier, it is essential to evaluate factors such as material quality (e.g., steel vs. plastic), load capacity, stackability, collapsibility, and compliance with safety standards.

Additionally, considering customization options, long-term maintenance requirements, and the supplier’s reliability and lead times will ensure a seamless integration into existing workflows. Investing in high-quality, durable stackable racks may involve higher initial costs but often results in substantial long-term savings through improved efficiency, reduced product damage, and optimized space utilization.

Ultimately, the right portable stackable rack solution enhances supply chain agility and supports lean operational practices. A well-informed sourcing decision—based on thorough research, supplier vetting, and alignment with organizational goals—will deliver lasting value and operational resilience.