The global pop rivet market is experiencing steady growth, driven by increasing demand from industries such as automotive, aerospace, construction, and electronics. According to Grand View Research, the global rivet market size was valued at USD 7.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by the rising need for lightweight, durable fastening solutions in manufacturing and assembly processes. As pop rivets offer quick, cost-effective, and reliable joining methods—especially in hard-to-reach areas—key manufacturers are scaling production and innovating designs to meet evolving industrial standards. In this competitive landscape, a select group of eight leading pop rivet size manufacturers stand out for their product range, global reach, and technical expertise, shaping the way industries fasten components across critical applications.

Top 8 Pop Rivet Sizes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Rivet & Fastener Company

Domain Est. 1995

Website: rivet.com

Key Highlights: We have the most diverse range of blind rivets in the industry with over 1.4 billion pieces of the highest quality rivets on the shelf….

#2 Rivet Guns & POP Rivet Tooling

Domain Est. 2012

Website: poprivettooling.com

Key Highlights: We stock all POP rivet tool parts with competitive pricing, and our POP rivet guns such as the popular Proset XT3 are heavy duty, industrial strength air ……

#3 Manufacturer of Rivets & Blind Rivet by Anish Rivets LLP, Vasai

Domain Est. 2024

Website: anishrivets.com

Key Highlights: Established in the year of 2000, “Anish Rivets LLP” are Manufacturer of Solid Rivets, Semi-Tubular Rivets And Blind Rivets etc….

#4 Know Your Rivets

Domain Est. 1996

Website: hansonrivet.com

Key Highlights: Blind rivets (or “pop” rivets) are available in standard, structural, closed end and various other styles for a wide range of applications….

#5 Rivets Online

Domain Est. 2009 | Founded: 1948

Website: rivetsonline.com

Key Highlights: Founded in 1948, Jay-Cee Sales & Rivet is the nation’s largest distributor of aluminum blind rivets & special fasteners. Contact us or buy online today!…

#6 Pop Rivet Sizes and Dimensions

Domain Est. 2016

Website: fastenere.com

Key Highlights: Pop rivets come in various sizes and dimensions to suit different applications. The size of a pop rivet is determined by its diameter, length, and grip range….

#7 Rivets

Domain Est. 2024

Website: arrowtoolgroup.com

Key Highlights: 5-day delivery 30-day returnsOur rivets offer strong, permanent fastening for metal, plastic, and more. Ideal for automotive, construction, and DIY use. Available in multiple sizes…

#8 POP® Rivet Measurements & Sizes Guide for Optimal Selection

Domain Est. 2012

Website: stanleyengineeredfastening.com

Key Highlights: Explore the ideal pop rivet measurements and sizes for your application, focusing on grip range, joint strength, and hole size for optimal performance….

Expert Sourcing Insights for Pop Rivet Sizes

H2: 2026 Market Trends for Pop Rivet Sizes

The global pop rivet market is poised for steady evolution by 2026, driven by sector-specific demands, material innovations, and manufacturing advancements. While demand for the core product remains robust, distinct trends are emerging in the preferred sizes of pop rivets across industries. Here’s an analysis of key size-related trends expected to shape the market:

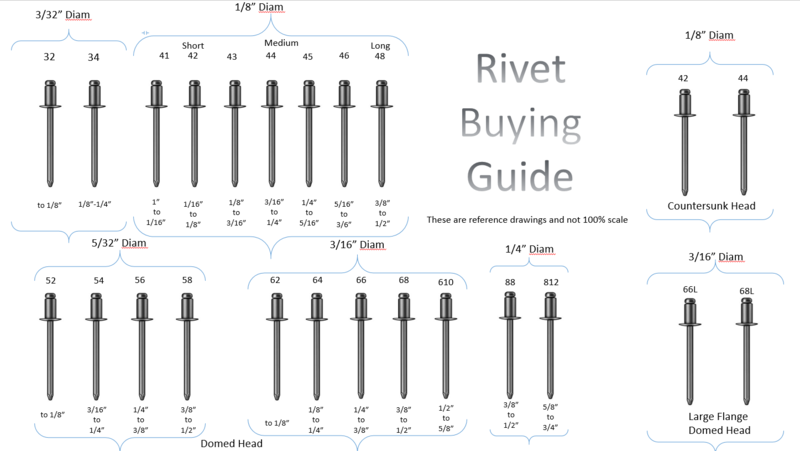

1. Growth in Smaller Diameter Rivets (≤ 3/32″ & 1/8″)

– Aerospace & UAVs: Continued demand for lightweight, high-strength fasteners in commercial aircraft, drones, and electric vertical takeoff and landing (eVTOL) vehicles will drive the use of smaller-diameter aluminum and titanium rivets (e.g., 1/16″, 5/64″, 3/32″). These sizes reduce weight while maintaining structural integrity.

– Electronics & Consumer Devices: Miniaturization trends in consumer electronics, medical devices, and robotics will increase demand for micro-pop rivets (e.g., 1/32″ to 3/32″), especially blind rivets that can be installed in tight spaces.

– Automotive Interiors & EVs: As electric vehicles prioritize weight reduction for battery efficiency, smaller rivets will be increasingly used in non-structural interior components and battery enclosures.

2. Steady Demand for Mid-Range Sizes (5/32″ & 3/16″)

– General Manufacturing & Industrial Equipment: The 5/32″ and 3/16″ sizes remain the workhorses of the industry, widely used in sheet metal fabrication, HVAC, enclosures, and machinery. These sizes offer a balance of strength, ease of installation, and cost-effectiveness.

– Automotive Body & Chassis: Despite the rise of adhesives and welding, mid-size pop rivets are still critical for attaching non-load-bearing panels, brackets, and trim in both traditional and electric vehicles.

– Construction & Infrastructure: Use in light gauge steel framing, metal roofing, and facade systems will sustain demand for 3/16″ rivets, particularly structural blind rivets with enhanced shear and tensile strength.

3. Increased Use of Larger Diameters (1/4″ & Above) in Structural Applications

– Heavy Equipment & Transportation: Growing adoption of structural blind rivets (e.g., 1/4″, 5/16″) in agricultural machinery, railcars, and truck manufacturing will be fueled by innovations in rivet materials (stainless steel, alloy steels) and pull mandrel designs that meet higher load requirements.

– Renewable Energy: Wind turbine nacelle enclosures and solar panel mounting systems increasingly use large-diameter, corrosion-resistant rivets (especially stainless steel 1/4″) for durability in harsh environments.

– Defense & Marine: High-performance rivets in larger sizes will see demand due to requirements for vibration resistance, saltwater corrosion protection, and rapid field assembly.

4. Length Customization and Specialty Sizes

– Custom Length Demand: As product designs become more complex, there will be a rising need for non-standard rivet lengths tailored to specific material stack-ups, particularly in aerospace and automotive applications.

– Bifurcated and Multi-Grip Rivets: These specialty rivets, available in a range of diameters, will gain traction due to their ability to join uneven or variable-thickness materials—driving demand across diverse size categories.

5. Regional and Material Influences on Size Trends

– Asia-Pacific Growth: Rapid industrialization in India, Vietnam, and Indonesia will boost demand across all sizes, but particularly mid-range (3/32″–3/16″) for electronics and light manufacturing.

– Material Shifts: Increased use of aluminum and composite materials in automotive and aerospace will favor smaller, lighter rivets, while stainless steel and structural rivets in larger sizes will grow in infrastructure and renewables.

Conclusion:

By 2026, the pop rivet market will reflect a bifurcated size trend—growth in micro and small diameters driven by high-tech industries, and sustained or increased use of larger diameters in heavy-duty and structural applications. Mid-size rivets will remain dominant in general industrial use. Manufacturers who offer a broad size range, including specialty and custom options with advanced materials, will be best positioned to capture emerging opportunities across sectors.

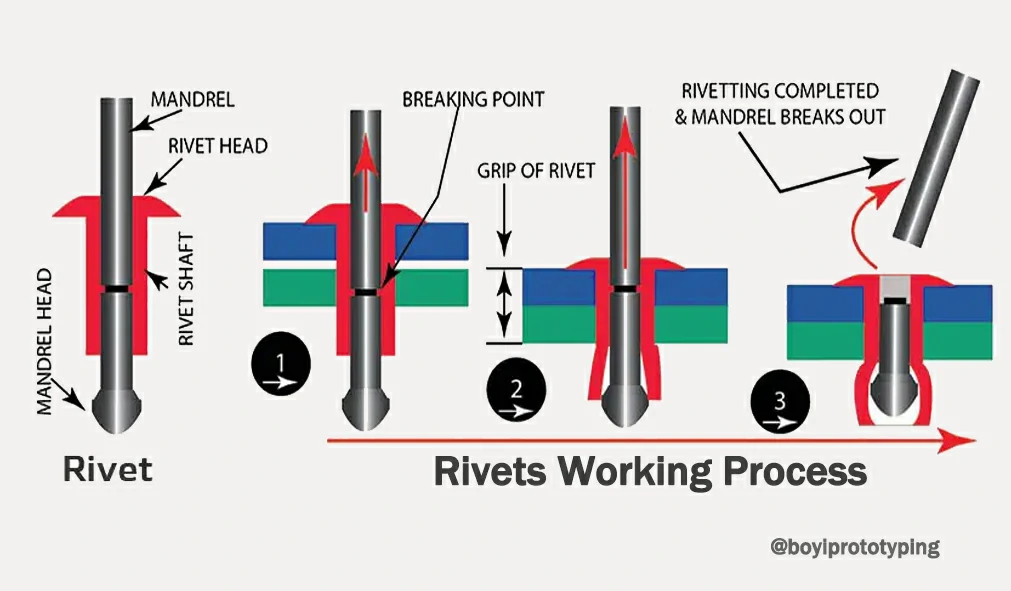

Common Pitfalls When Sourcing Pop Rivet Sizes (Quality, IP)

Sourcing the correct pop rivets involves more than just matching diameter and length. Overlooking key quality and intellectual property (IP) considerations can lead to structural failures, compliance issues, or legal risks. Below are common pitfalls to avoid:

Choosing Incorrect Material Grade

Using rivets made from substandard or incorrect materials (e.g., low-grade aluminum instead of 5056 aluminum or improper stainless steel grades) can compromise joint strength and corrosion resistance. Always verify material specifications match your application requirements, especially in harsh environments.

Ignoring Tensile and Shear Strength Ratings

Different rivet sizes and materials offer varying strength profiles. Selecting a rivet based solely on size without considering load requirements may result in premature failure. Ensure the specified tensile and shear strengths meet or exceed design demands.

Assuming All Rivets Are Interchangeable

Not all rivets of the same nominal size perform identically. Variations in mandrel design, grip range, and manufactured tolerances affect performance. Generic or off-brand rivets may not meet the same standards as OEM or certified brands.

Overlooking Grip Range Mismatch

Selecting a rivet with an inappropriate grip range—too short or too long for the material stack—results in poor clamping force or incomplete setting. Always calculate total material thickness and choose a rivet with a grip range that matches.

Failing to Verify Certification and Standards Compliance

In regulated industries (e.g., aerospace, automotive), rivets must comply with standards such as NAS, MS, or ISO. Sourcing non-certified rivets risks non-compliance and audit failures. Request mill certificates or test reports where required.

Sourcing from Unverified Suppliers

Purchasing from uncertified or unknown suppliers increases the risk of counterfeit or substandard products. These may mimic reputable brands but fail under stress or lack traceability. Stick to authorized distributors or reputable manufacturers.

Intellectual Property (IP) Infringement Risks

Using or sourcing rivets that copy patented designs (e.g., specialized head styles, mandrel mechanisms) without authorization can lead to legal action. Avoid reverse-engineered or “compatible” rivets that infringe on proprietary technology.

Neglecting Environmental and Corrosion Resistance

Mismatched plating or incorrect alloy selection (e.g., using steel rivets in marine environments) can cause galvanic corrosion. Confirm environmental compatibility, especially when joining dissimilar materials.

Skipping Sample Testing and Qualification

Relying solely on supplier claims without testing samples in actual conditions can lead to unexpected failures. Always conduct pull tests, shear tests, and environmental exposure trials during the qualification phase.

Overlooking Packaging and Traceability

Poor packaging can damage rivets or cause mixing of sizes and materials. Inconsistent batch labeling or lack of traceability hampers quality control and recall management. Require clear labeling and lot tracing.

By addressing these pitfalls, you ensure that the pop rivets you source meet both performance expectations and regulatory standards, reducing risk across your supply chain and end-use applications.

Logistics & Compliance Guide for Pop Rivet Sizes

Understanding the logistics and compliance requirements for pop rivets—especially in regard to their sizes—is essential for efficient sourcing, transportation, storage, and use in regulated industries. This guide outlines key considerations related to size specifications, packaging, shipping, safety, and regulatory standards.

Size Specifications and Standardization

Pop rivets are available in a wide range of sizes, primarily defined by diameter, grip range, and length. Common diameters include 1/8″, 5/32″, 3/16″, and 1/4″, with grip ranges varying from 1/16″ to over 1/2″. Ensuring compliance begins with using standardized sizing per international specifications such as ISO 15977 or ASME B18.7.1. Always verify that rivet dimensions match project engineering drawings and procurement documentation to avoid assembly issues or structural failures.

Packaging and Labeling Requirements

Proper packaging is critical to prevent damage during transit and ensure traceability. Rivets should be packaged by size and material type (e.g., aluminum, steel, stainless steel) in sealed, moisture-resistant containers or bags. Each package must be clearly labeled with:

– Rivet size (diameter and grip length)

– Material specification

– Quantity

– Manufacturer or supplier ID

– Lot or batch number

– Compliance markings (e.g., RoHS, REACH, or MIL-SPEC if applicable)

Labels must be durable and legible to support inventory management and quality audits.

Storage and Handling Logistics

Store pop rivets in a dry, temperature-controlled environment to prevent corrosion—especially important for aluminum and steel variants. Organize inventory by size and material to reduce picking errors. Use first-in, first-out (FIFO) inventory practices to maintain material integrity. Avoid bulk stacking that may deform smaller rivets. Handle with clean tools to prevent contamination, particularly in aerospace or medical applications.

Transportation and Shipping Compliance

When shipping pop rivets, especially internationally, follow IATA, IMDG, or DOT regulations as applicable. While most rivets are not hazardous, coatings or platings (e.g., cadmium) may trigger hazardous material classifications. Declare accurate Harmonized System (HS) codes for customs clearance—common codes include 7318.15 for steel rivets. Ensure packaging withstands vibration and pressure changes during transit.

Regulatory and Industry Compliance

Compliance varies by industry:

– Aerospace: Rivets must meet NASM (National Aerospace Standard) specs and may require AS9100 certification for suppliers.

– Automotive: Follow ISO/TS 16949 standards; material traceability is mandatory.

– Construction: Comply with ASTM F468 for stainless steel blind rivets.

– Electronics: Adhere to RoHS and REACH directives to restrict hazardous substances.

Always request Certificates of Conformance (CoC) or Material Test Reports (MTRs) from suppliers for critical applications.

Quality Assurance and Documentation

Maintain records of:

– Incoming inspection reports

– Calibration of measuring tools (for verifying rivet dimensions)

– Supplier audits

– Non-conformance reports (if incorrect sizes are received)

Regular audits ensure continued compliance with size tolerances and logistical processes.

Conclusion

Effective logistics and compliance for pop rivet sizes require attention to standardization, accurate labeling, proper storage, regulatory alignment, and thorough documentation. By following this guide, organizations can minimize supply chain disruptions, ensure product reliability, and meet industry-specific requirements.

In conclusion, sourcing the correct pop rivet size is essential for ensuring strong, reliable, and durable fastening in any application. Key factors such as material type, joint strength requirements, rivet diameter, grip range, and rivet length must be carefully evaluated to match the specific needs of the project. Consulting manufacturer specifications, using sizing charts, and considering environmental conditions can further aid in selecting the optimal rivet. By accurately determining the required pop rivet size and sourcing quality components from reputable suppliers, you can achieve efficient installation and long-term performance, minimizing the risk of joint failure and ensuring structural integrity.