The global 3D printing polymer filament market has experienced robust growth in recent years, driven by increasing adoption across industries such as aerospace, healthcare, automotive, and consumer goods. According to a report by Grand View Research, the global 3D printing materials market was valued at USD 1.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 22.3% from 2023 to 2030—with polymer filaments like PLA, ABS, PETG, and specialty nylons representing a dominant share. Similarly, Mordor Intelligence projects the 3D printing filament market to grow at a CAGR of over 20% during the forecast period of 2024–2029, fueled by advancements in material science, rising demand for rapid prototyping, and the proliferation of desktop 3D printing. As demand surges, a select group of manufacturers have emerged as leaders, setting benchmarks in quality, innovation, and scalability. These top 10 polymer filament manufacturers are shaping the future of additive manufacturing through consistent R&D investment, sustainable practices, and broad material portfolios tailored to evolving industrial and consumer needs.

Top 10 Polymer Filament Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fillamentum

Domain Est. 2013

Website: fillamentum.com

Key Highlights: Manufacturer of high-quality filaments for 3D printing – focused on development, innovations and precize production. Fillamentum – addictivepolymers….

#2 Dream Polymers

Domain Est. 2014

#3 Fiberlogy

Domain Est. 2015

Website: fiberlogy.com

Key Highlights: European 3D filament manufacturer for professionals and enthusiasts. PLA, PETG, ABS, ASA, Flex. Tested materials, consistent quality….

#4 A warm to Perlon®

Domain Est. 2003

Website: perlon.com

Key Highlights: We are an innovative, global group of companies specialized in the manufacture of synthetic filaments in diverse areas of application….

#5 High

Domain Est. 2012

Website: colorfabb.com

Key Highlights: $31.55 delivery 14-day returnsColorFabb offers a wide range of high-quality 3D printing filaments for professionals and hobbyists. Our filaments are made from the finest materials …

#6 Polymaker

Domain Est. 2013

Website: polymaker.com

Key Highlights: Polymaker is an international team passionate about 3D printing. We produce the very best 3D printing materials by controlling every stage of production….

#7 3DXTech: 3D Printing Filament

Domain Est. 2013

Website: 3dxtech.com

Key Highlights: We are the leading supplier of ultra-polymer 3D printing filaments in the world. Our portfolio of materials allows us to offer solutions to the most ……

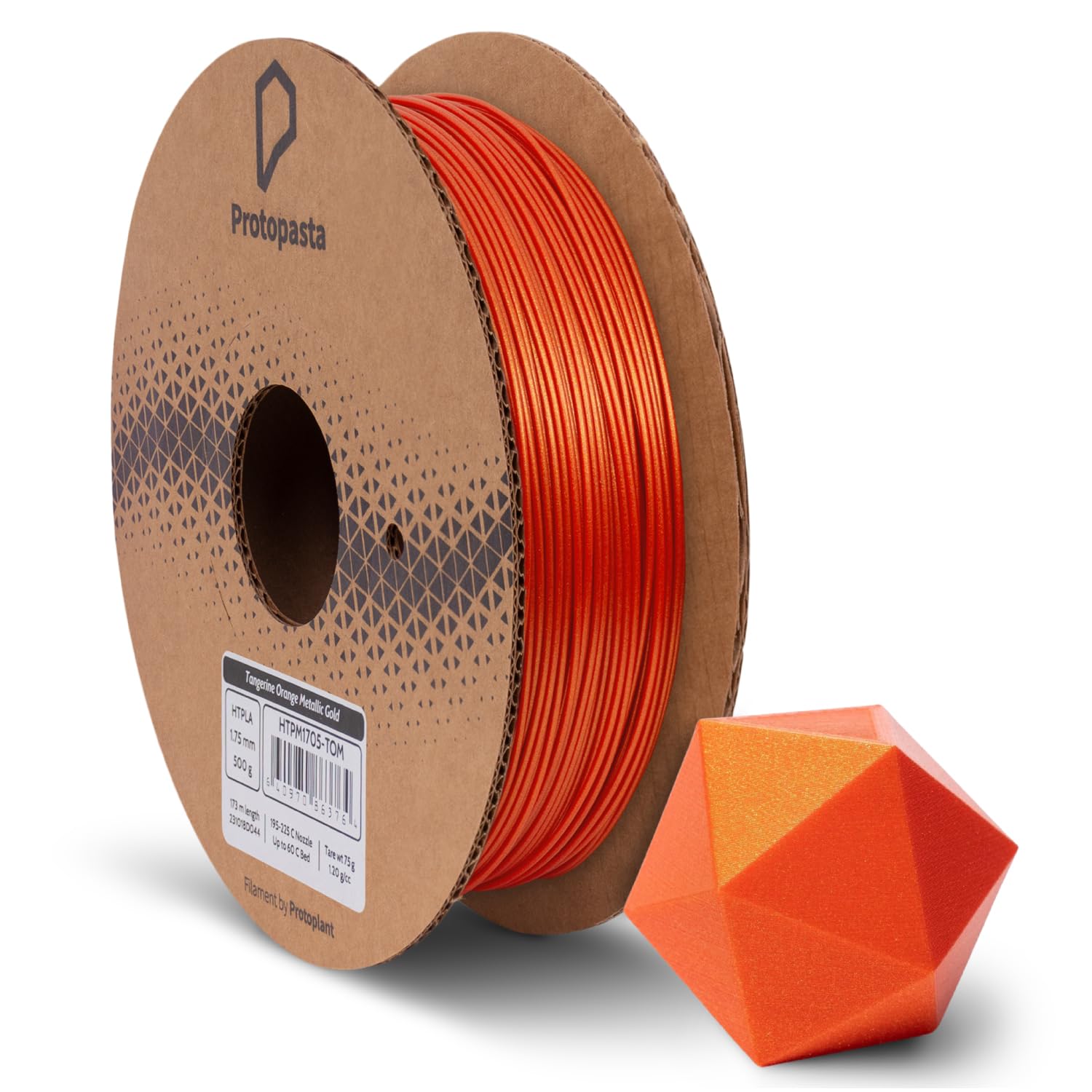

#8 Protopasta Brand 3D Printer Filament

Domain Est. 2013

#9 Spectrum Filaments

Domain Est. 2015

Website: spectrumfilaments.com

Key Highlights: Spectrum Filaments to firma specjalizująca się w produkcji materiałów do druku 3D wykorzystywanych w drukarkach 3D klasy FDM / FFF….

#10 Product categories 3D printing filament

Domain Est. 2020

Website: nanovia.tech

Key Highlights: 14-day returnsNanovia develops a premium range of composites, metal, and ceramic thermoplastic filaments for the additive manufacturing and plastic injection industries….

Expert Sourcing Insights for Polymer Filament

H2: Market Trends in the Polymer Filament Industry for 2026

As the global additive manufacturing (AM) sector continues to mature, the polymer filament market is poised for significant transformation by 2026. Driven by technological advancements, expanding industrial applications, and growing sustainability concerns, the market is expected to experience robust growth and strategic evolution. Below is an analysis of key trends shaping the polymer filament landscape in 2026.

1. Rising Demand from Industrial and Automotive Sectors

By 2026, industrial manufacturing and the automotive industry are anticipated to be primary growth drivers for high-performance polymer filaments. Materials such as PEEK (Polyether Ether Ketone), PEKK (Polyether Ketone Ketone), and ULTEM™ (PEI) are gaining traction due to their thermal stability, mechanical strength, and chemical resistance. These properties make them ideal for end-use parts in aerospace, automotive components, and industrial tooling, where reliability under stress is critical.

2. Expansion of Specialty and Engineering Polymers

While PLA and ABS remain dominant in the consumer and prototyping markets, there is a notable shift toward engineering-grade thermoplastics. The demand for filaments with enhanced properties—such as flame retardancy, ESD protection, and low outgassing—is increasing, particularly in electronics, medical devices, and defense sectors. This shift is encouraging filament manufacturers to innovate with composites (e.g., carbon fiber-, glass fiber-, or metal-infused filaments) to meet stringent performance requirements.

3. Sustainability and Bio-Based Filaments

Environmental regulations and corporate sustainability goals are accelerating the adoption of bio-based and biodegradable filaments. In 2026, PLA continues to lead in eco-conscious 3D printing, but newer materials like PHA (Polyhydroxyalkanoates) and recycled PETG are gaining market share. Filament producers are investing in closed-loop recycling systems and transparent sourcing to appeal to environmentally aware consumers and B2B clients alike. Certifications such as ASTM D6400 (compostability) and ISO 14001 are becoming differentiators in product positioning.

4. Regional Market Growth and Localization

Asia-Pacific is expected to emerge as the fastest-growing region for polymer filament consumption by 2026, fueled by rapid industrialization, government support for advanced manufacturing, and a growing base of SMEs adopting 3D printing. China, India, and South Korea are investing heavily in domestic AM ecosystems, including filament production. Meanwhile, North America and Europe maintain leadership in R&D and high-value applications, with localized filament production reducing supply chain risks and import dependencies.

5. Advancements in Filament Consistency and Smart Materials

Quality control and material uniformity remain critical. In 2026, filament manufacturers are leveraging AI-driven extrusion monitoring, IoT-enabled production lines, and blockchain for traceability to ensure batch consistency. Additionally, research into “smart” filaments—such as conductive, thermochromic, or shape-memory polymers—is progressing, opening doors for applications in wearable tech, soft robotics, and responsive design.

6. Price Competition and Consolidation

The market is witnessing increased competition among filament suppliers, leading to price pressures, especially in commoditized segments like standard PLA and ABS. To maintain margins, companies are differentiating through value-added services—custom formulations, technical support, and industry-specific certifications. Mergers and acquisitions are likely as larger players seek vertical integration or proprietary material IP.

7. Regulatory and Standardization Developments

As polymer filaments are increasingly used in regulated industries (e.g., medical and aerospace), compliance with material standards (e.g., ISO/ASTM 52900, UL 94 for flammability) becomes essential. By 2026, regulatory clarity and standardized testing protocols are expected to improve market trust and facilitate broader adoption across critical sectors.

Conclusion

The polymer filament market in 2026 will be characterized by innovation, diversification, and regional dynamism. Success will depend on a manufacturer’s ability to balance performance, sustainability, and cost while aligning with evolving industry standards and end-user demands. Companies that invest in R&D, sustainable practices, and application-specific solutions are likely to lead the next phase of growth in the global 3D printing ecosystem.

Common Pitfalls When Sourcing Polymer Filament: Quality and Intellectual Property Concerns

Sourcing polymer filament for 3D printing applications involves more than just comparing prices and specifications. Two critical areas where companies often encounter challenges are material quality consistency and intellectual property (IP) risks. Overlooking these aspects can lead to production delays, compromised product performance, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inconsistent Material Properties

One of the most frequent issues is batch-to-batch variability in filament properties such as diameter tolerance, moisture content, melt flow index, and mechanical strength. Low-cost suppliers may lack rigorous quality control systems, leading to filament that clogs nozzles, results in poor layer adhesion, or fails in end-use applications. Always request material test reports (MTRs) and conduct incoming inspections.

Lack of Material Certification and Traceability

Reputable applications (e.g., healthcare, aerospace, or automotive) require certified materials with full traceability. Sourcing from uncertified suppliers can mean missing crucial documentation such as ISO certifications, RoHS compliance, or UL recognition. Without traceability, validating filament origin and composition becomes impossible, increasing risk during audits or product recalls.

Improper Packaging and Moisture Exposure

Many polymers (e.g., nylon, PETG, PCTG) are hygroscopic and degrade rapidly when exposed to humidity. Poor packaging—such as non-sealed bags or missing desiccants—can render filament unusable before printing even begins. Evaluate suppliers based on their packaging standards and storage practices.

Misrepresented Filament Specifications

Some suppliers exaggerate performance claims (e.g., heat resistance, tensile strength) without supporting data. This misrepresentation can lead to failed prototypes or underperforming final parts. Validate claims through independent testing or third-party certification.

Intellectual Property-Related Pitfalls

Unauthorized Use of Proprietary Polymers

Sourcing filaments labeled as equivalents to branded materials (e.g., “ULTEM-like” or “PEEK-grade”) from unlicensed suppliers may involve counterfeit or illegally reverse-engineered products. This exposes your company to IP infringement claims, especially if the filament is used in commercial products.

Lack of Licensing and Technical Support

Original polymer manufacturers (e.g., SABIC, Arkema, BASF) often license their materials to select filament producers. Sourcing from non-licensed converters means losing access to technical support, processing guidelines, and material warranties. This increases R&D risk and time-to-market.

Ambiguous Formulation Disclosure

Some suppliers obscure the exact composition of their filaments, making it difficult to assess compliance with regulatory standards (e.g., FDA, REACH) or to ensure the material is free of patented additives. Always require full material disclosure and review formulation agreements carefully.

Supply Chain Transparency Gaps

Without visibility into the filament’s production chain—from resin supplier to spooling facility—it’s difficult to ensure IP integrity. Filament produced in unauthorized facilities may infringe on process patents or formulation rights, implicating downstream users.

Best Practices to Avoid Pitfalls

- Conduct supplier audits and request quality certifications (ISO 9001, IATF 16949, etc.).

- Require material datasheets, MTRs, and compliance documentation.

- Engage only with authorized distributors or licensed converter partners.

- Include IP indemnification clauses in procurement contracts.

- Perform in-house or third-party material validation before scaling production.

Avoiding these pitfalls requires due diligence, clear specifications, and a focus on long-term reliability over short-term cost savings.

Logistics & Compliance Guide for Polymer Filament

Overview

Polymer filament, commonly used in 3D printing applications, requires careful handling and compliance with international and regional regulations throughout the supply chain. This guide outlines key logistics considerations and compliance requirements for the safe and legal transport, storage, and use of polymer filament.

Classification and Identification

Polymer filaments are typically thermoplastic materials such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and Nylon. While most are non-hazardous, proper identification using product specifications, Safety Data Sheets (SDS), and labeling is essential. Confirm the UN number, if applicable, and ensure correct classification for shipping.

Regulatory Compliance

Compliance with transportation regulations is critical. Most polymer filaments are classified as non-dangerous goods under IATA, IMDG, and ADR regulations when shipped in standard spool formats. However, manufacturers must verify this through testing and documentation. Always include a current Safety Data Sheet (SDS) compliant with GHS and local regulations (e.g., REACH in the EU, TSCA in the US).

Packaging Requirements

Polymer filament must be packaged to prevent damage, moisture exposure, and tangling. Use sealed plastic bags with desiccants for moisture-sensitive materials (e.g., Nylon, PETG). Spools should be protected with rigid outer packaging (e.g., cardboard boxes) that meet drop-test standards. Label packages with product name, batch number, weight, manufacturer details, and handling instructions (e.g., “Keep Dry,” “Fragile”).

Storage Conditions

Store filament in a cool, dry place with controlled humidity (ideally below 50% RH). Use sealed containers or dry boxes for long-term storage, especially for hygroscopic materials. Avoid direct sunlight and extreme temperatures to prevent degradation. Segregate incompatible materials and ensure good ventilation in storage areas.

Transportation Guidelines

Use standard parcel or freight services for non-hazardous filament. Ensure packages are properly secured to prevent shifting during transit. For international shipments, include commercial invoices, packing lists, and SDS. Verify import regulations in destination countries—some may require product registration or conformity assessments (e.g., CE marking in Europe, FCC or EPA rules if additives are present).

Environmental and Disposal Compliance

Dispose of damaged or expired filament according to local waste regulations. Most thermoplastics can be recycled through specialized programs. Avoid incineration without proper emission controls. Document waste disposal procedures to meet environmental compliance standards.

Documentation and Traceability

Maintain full traceability through batch records, shipping logs, and quality certifications. Include RoHS, REACH SVHC, and Prop 65 compliance statements where applicable. For business-to-business sales, provide technical documentation and certifications upon request.

Special Considerations for Additive Manufacturing Filaments

Filaments with additives (e.g., carbon fiber, metal powders, flame retardants) may be subject to additional regulations. Carbon-fiber-reinforced filaments, for example, may require hazard classification due to dust generation. Always evaluate composite materials for potential hazardous properties and update SDS accordingly.

Conclusion

Adhering to logistics and compliance best practices ensures the safe and efficient distribution of polymer filament. Regular audits, staff training, and staying updated on regulatory changes are essential for maintaining compliance across global supply chains.

In conclusion, sourcing polymer filament requires a comprehensive evaluation of material specifications, supplier reliability, cost-efficiency, and intended application requirements. Selecting the right filament involves balancing factors such as print quality, mechanical properties, thermal resistance, and compatibility with specific 3D printing technologies. Building relationships with reputable suppliers, ensuring consistent quality control, and considering sustainability aspects can significantly enhance the efficiency and success of production processes. As the demand for high-performance and specialty polymers continues to grow, a strategic and informed sourcing approach is essential to maintaining competitive advantage and achieving optimal printing outcomes.