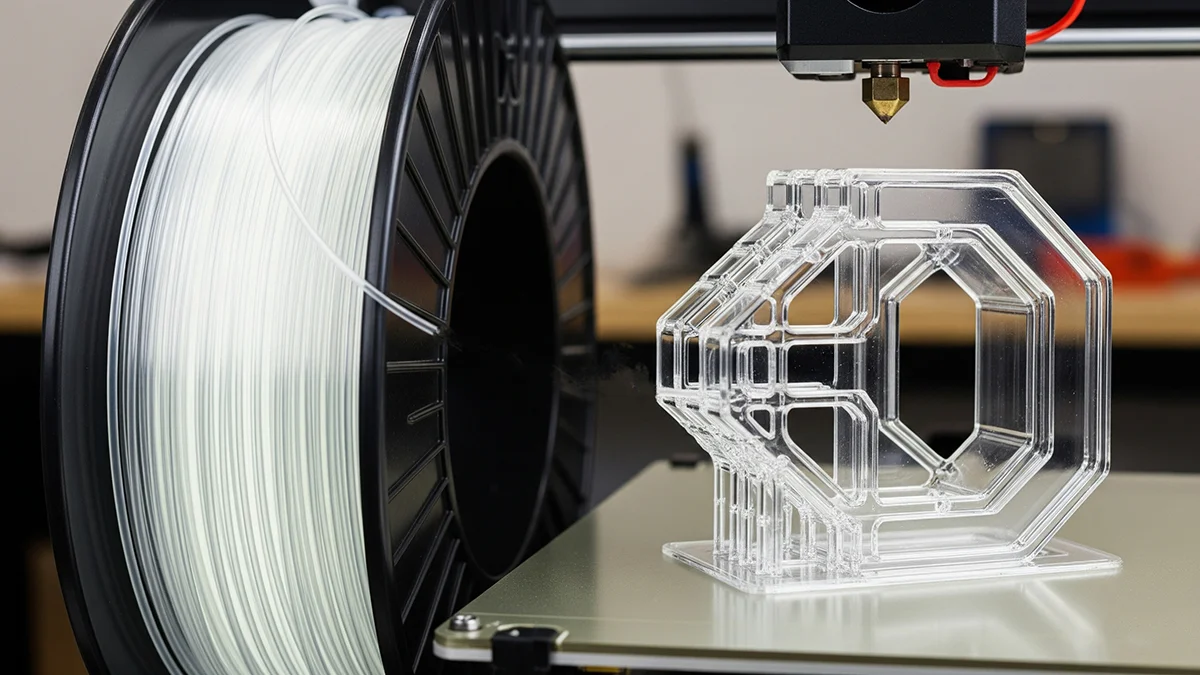

The global polycarbonate 3D printing market is experiencing robust growth, driven by increasing demand for high-performance thermoplastics in aerospace, automotive, and healthcare industries. According to Grand View Research, the global polycarbonate market size was valued at USD 21.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is mirrored in the additive manufacturing sector, where polycarbonate’s exceptional strength-to-weight ratio, heat resistance, and optical clarity make it a preferred material for functional prototyping and end-use parts. As industrial applications of 3D printing expand, manufacturers specializing in polycarbonate filaments and resins are scaling innovation and production capacity. Based on market presence, material performance, and technological advancement, we’ve identified the top 10 polycarbonate 3D printing manufacturers shaping the future of industrial additive manufacturing.

Top 10 Polycarbonate For 3D Printing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 PC Filament – Premium Filament

Domain Est. 2014

Website: raise3d.com

Key Highlights: In stock Rating 4.6 9 Raise3D Premium PC Filament. PC or Polycarbonate is one of the advanced industrial thermoplastics, which is extremely tough, durable and with great firmness…

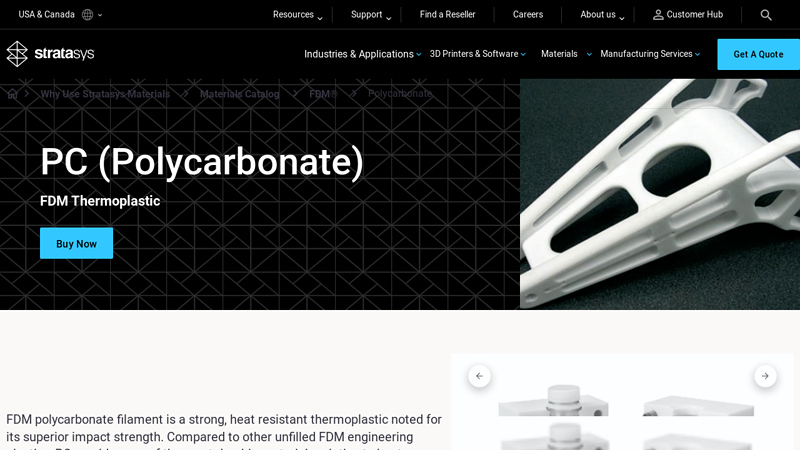

#2 PC (Polycarbonate) FDM Filament

Domain Est. 1993

Website: stratasys.com

Key Highlights: FDM Polycarbonate is applicable to any industry using 3D printing for applications demanding tough, impact-resistant prototypes, parts and tooling….

#3 Polycarbonate: PC/PC-ABS 3D Printing Filament

Domain Est. 1997

Website: dynamism.com

Key Highlights: 1–3 day deliveryChoose from the best Polycarbonate 3d printing filament for high quality prints. Strong, durable. Available in variety of colors, diameters and weight….

#4 PC Polycarbonate Material for Stratasys FDM 3D Printers

Domain Est. 1998

Website: goengineer.com

Key Highlights: 6-day deliveryPC is a bio-compatible thermoplastic that lets medical, pharmaceutical and food-packaging engineers and designers 3D print strong, reliable products….

#5 Online 3D Printing Service for Custom Parts

Domain Est. 2006

Website: protolabs.com

Key Highlights: Our online 3D printing service provides you with instant quoting, six 3D printing technologies, and unmatched capacity. Choose from plastic and metal 3D ……

#6 PC: 3D Printing Materials Overview

Domain Est. 2012

Website: zmorph3d.com

Key Highlights: Polycarbonate is a 3D printing material for special applications and it won’t have any secrets before you after reading this article….

#7 PC (Polycarbonate)

Domain Est. 2013

Website: prusa3d.com

Key Highlights: $127.86 deliveryPolycarbonate (PC) is a technical material with great mechanical and heat resistance. Polycarbonates in general are very hard to print and are suitable mainly ……

#8 ezPC Polycarbonate 3

Domain Est. 2013

Website: 3dxtech.com

Key Highlights: In stock Rating 5.0 1 ezPC Polycarbonate is an excellent choice for printing parts that would ordinarily fail when using standard materials such as PLA, PETG, or ABS….

#9 PolyLite™ PC

Domain Est. 2013

Website: us.polymaker.com

Key Highlights: PolyLite™ PC is crafted from a polycarbonate resin specifically designed for 3D printing, ensuring reliable performance and ease of use. This formulation ……

#10 PC

Domain Est. 2019

Website: ca.store.bambulab.com

Key Highlights: In stock Free deliveryPC (Polycarbonate) is an extremely tough and durable material for 3D printing, with good temperature and impact resistance. It is highly recommended for ……

Expert Sourcing Insights for Polycarbonate For 3D Printing

H2: 2026 Market Trends for Polycarbonate in 3D Printing

The market for polycarbonate (PC) in 3D printing is poised for significant evolution by 2026, driven by technological advancements, expanding industrial applications, and growing demand for high-performance materials. Here’s a detailed analysis of key trends likely to shape this niche but critical segment:

1. Accelerated Adoption in Industrial and Aerospace Sectors

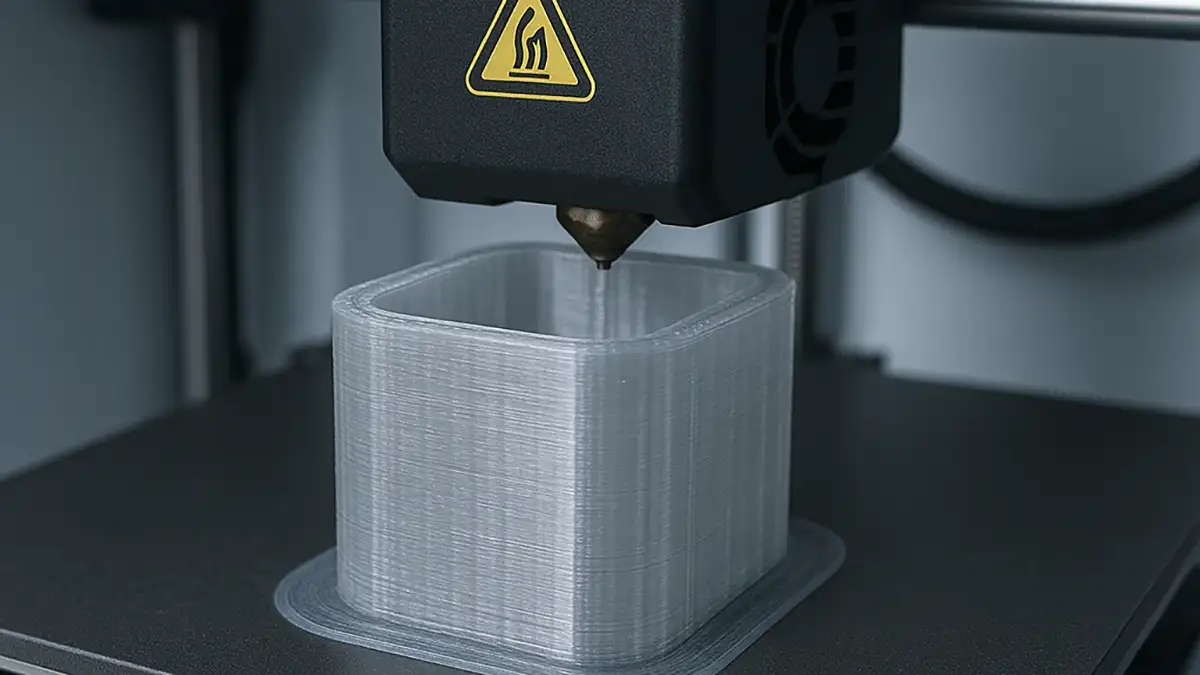

By 2026, polycarbonate is expected to see widespread adoption in industrial manufacturing and aerospace due to its high strength-to-weight ratio, thermal stability (up to ~110–135°C), and impact resistance. Industries requiring durable, lightweight components—such as drone parts, jigs, fixtures, and interior aircraft components—will increasingly turn to PC-based 3D printing (especially FFF/FDM and SLS) to replace traditional materials like ABS or metals in non-critical applications. Regulatory acceptance of printed PC parts in certified environments will also improve, further driving use.

2. Advancements in Printability and Material Formulations

One of the major historical barriers to PC adoption—difficult printability due to warping and high printing temperatures—will be significantly mitigated by 2026. Expect:

– Enhanced composite blends: Wider availability of PC blends with carbon fiber, glass fiber, or other polymers (e.g., PC-ABS, PC-PETG) that improve layer adhesion, reduce warping, and increase dimensional stability.

– Improved filament quality: Higher consistency in filament diameter, moisture resistance, and optimized drying protocols from leading material suppliers.

– Better printer compatibility: More desktop and industrial FDM printers with fully enclosed chambers, heated beds (>100°C), and active airflow control specifically tuned for PC.

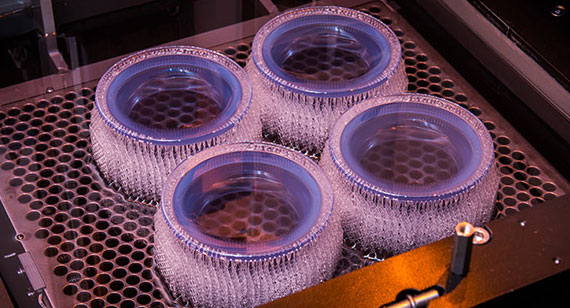

3. Rise of High-Temperature Resins in Vat Photopolymerization

Beyond filament-based printing, polycarbonate-like materials in resin 3D printing (SLA/DLP/LCD) will emerge. While pure polycarbonate resins remain challenging, 2026 will see commercialization of tough, heat-resistant photopolymers engineered to mimic PC’s mechanical and thermal properties. These will find use in rapid prototyping for automotive, electronics, and medical device housings where fine detail and temperature endurance are essential.

4. Sustainability and Recyclability Initiatives

Environmental pressures will push the development of recyclable or bio-based polycarbonate filaments. While still in early stages, companies will invest in chemically recycled PC or partially bio-sourced variants to meet ESG goals. Closed-loop recycling systems within industrial 3D printing facilities may begin incorporating post-print PC waste, enhancing sustainability credentials.

5. Growth in Automotive and Consumer Electronics

The automotive sector will increasingly use PC 3D printing for custom interior trims, sensor housings, and under-hood prototypes. In consumer electronics, PC’s clarity and durability make it ideal for custom enclosures, lens prototypes, and wearables. By 2026, these industries will contribute significantly to market growth, especially as mass customization gains traction.

6. Regional Market Expansion

While North America and Europe lead in high-performance 3D printing adoption, Asia-Pacific—particularly China, Japan, and South Korea—will see accelerated growth in PC 3D printing by 2026. This is fueled by strong manufacturing bases, rising R&D investment, and increasing access to advanced industrial printers capable of handling engineering thermoplastics.

7. Integration with Digital Supply Chains

Polycarbonate 3D printing will play a key role in digital warehousing and on-demand manufacturing. Companies will leverage PC’s durability to store digital part inventories and print end-use components locally, reducing logistics costs and lead times—especially for spare or legacy parts in aerospace and industrial machinery.

Conclusion:

By 2026, polycarbonate will transition from a niche, challenging material to a mainstream option in industrial 3D printing. Driven by improved material science, printer technology, and industry demand for durable, heat-resistant parts, the PC 3D printing market will experience steady growth. Key players in materials (e.g., SABIC, Covestro, Stratasys, UltiMaker) and industrial printers will continue to innovate, making PC a cornerstone of additive manufacturing’s expansion into end-use part production.

Common Pitfalls Sourcing Polycarbonate for 3D Printing (Quality, IP)

Sourcing polycarbonate (PC) filament for 3D printing presents unique challenges, particularly concerning material quality consistency and intellectual property (IP) risks. Overlooking these pitfalls can lead to failed prints, compromised part performance, or legal exposure.

Quality Inconsistencies and Lack of Traceability

One of the most prevalent issues when sourcing PC filament is inconsistent quality across batches or suppliers. Polycarbonate is highly sensitive to moisture and processing conditions, making tight control during manufacturing critical. Low-cost or unbranded suppliers may use recycled or mixed-grade resins, resulting in:

- Poor layer adhesion due to inconsistent melt flow or moisture content

- Excessive warping and cracking from thermal stress caused by variable crystallinity or residual stress

- Weak mechanical properties that fall short of datasheet claims

- Unreliable dimensional accuracy, affecting fit and function

Moreover, many suppliers provide limited or falsified technical data, with no third-party certification or batch traceability. Without access to ISO-certified testing reports (e.g., tensile strength, impact resistance, heat deflection temperature), users cannot verify performance claims, increasing the risk of part failure in functional applications.

Intellectual Property and Brand Misrepresentation

The 3D printing filament market is rife with IP violations, particularly involving polycarbonate. Major polymer producers like Covestro (formerly Bayer) and SABIC hold proprietary rights over high-performance PC grades (e.g., Makrolon®, Lexan®). A common pitfall is sourcing filament labeled as “industrial-grade” or “Makrolon-based” from third-party vendors who:

- Misrepresent material origin, falsely claiming to use authentic branded resins without licensing

- Sell counterfeit or rebranded filament, potentially infringing on trademarks and patents

- Lack proper licensing agreements, exposing end-users to indirect IP liability in commercial or regulated industries

Using such materials may not only degrade print quality but also pose legal risks, especially in sectors like aerospace, medical devices, or automotive, where material traceability and IP compliance are mandatory.

To mitigate these risks, users should source PC filament from reputable, transparent suppliers who provide full material disclosure, batch-specific test data, and evidence of IP compliance or licensing agreements with original resin manufacturers.

Logistics & Compliance Guide for Polycarbonate for 3D Printing

Overview

Polycarbonate (PC) is a high-performance thermoplastic renowned for its exceptional strength, heat resistance, and optical clarity, making it a popular choice for industrial and engineering 3D printing applications. However, due to its properties and regulatory status, strict logistics and compliance protocols must be followed during handling, storage, transportation, and use.

Regulatory Classification & Documentation

Polycarbonate filament or pellets for 3D printing are generally classified as non-hazardous solids under most international transport regulations when in solid, non-powder form. However, proper documentation is essential:

– UN Number: Not typically assigned for solid PC filament (UN3082 may apply if in solution or classified as environmentally hazardous).

– Safety Data Sheet (SDS): Must be available per OSHA (U.S.) and REACH/CLP (EU) regulations. Ensure the SDS is compliant with GHS standards and includes handling, storage, and disposal guidelines.

– Customs Classification: Use HS Code 3907.40 (Polycarbonates) for import/export. Confirm with local authorities for regional variations.

Storage Requirements

Proper storage ensures material integrity and safety:

– Environment: Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources (ideally 15–25°C, <50% RH).

– Moisture Protection: Polycarbonate is highly hygroscopic. Keep sealed in original moisture-barrier packaging with desiccant until use.

– Shelf Life: Typically 12–24 months if unopened and stored properly. Monitor for brittleness or discoloration.

Handling & Worker Safety

Follow occupational health and safety practices:

– Personal Protective Equipment (PPE): Wear gloves and safety glasses when handling. Use respiratory protection if machining or sanding printed parts (risk of fine particulates).

– Ventilation: Ensure adequate ventilation in printing areas, especially when using high-temperature printers (PC typically prints at 260–310°C).

– Fumes: PC can emit styrene and other VOCs when overheated. Use enclosed printers with HEPA and activated carbon filtration.

Transportation Guidelines

- Packaging: Use durable, sealed containers to prevent moisture absorption and physical damage. Spools should be protected from impact.

- Labeling: Clearly label packages with contents, batch number, manufacturer, and “Keep Dry” warnings. No hazardous labels required for solid filament unless otherwise specified.

- Modes of Transport: Suitable for road, air, and sea freight under general cargo rules. Comply with IATA (air) and IMDG (sea) if shipping internationally.

Environmental, Health & Safety (EHS) Compliance

- Disposal: Follow local regulations. Unused or waste PC filament is typically non-hazardous and can be disposed of as non-reactive solid waste or recycled.

- Recycling: PC is recyclable (Resin ID Code #7). Encourage closed-loop recycling or use certified e-waste recyclers for printed waste.

- REACH & RoHS: Confirm PC filament is free from SVHCs (Substances of Very High Concern) and complies with RoHS directives if used in electrical/electronic applications.

Import/Export Considerations

- Documentation: Commercial invoice, packing list, bill of lading/air waybill, and SDS required.

- Duties & Tariffs: Check country-specific import duties under HS 3907.40. Some regions may impose anti-dumping duties.

- Import Licenses: Generally not required, but verify with customs brokers for destination country (e.g., China, India may have specific polymer import rules).

Quality Control & Traceability

- Batch Tracking: Maintain records of lot numbers, expiration dates, and supplier certifications.

- Testing: Conduct periodic checks for moisture content (e.g., Karl Fischer titration) and print performance.

- Certifications: Prefer suppliers with ISO 9001, UL, or equivalent quality management systems.

Emergency Response

- Spills: Collect dry material and place in sealed container. Avoid creating dust.

- Fire: Use dry chemical, CO₂, or foam extinguishers. PC burns with intense heat and may emit toxic fumes (carbon monoxide, phenol).

- First Aid: If inhaled, move to fresh air. For eye/skin contact, rinse with water. Seek medical attention if irritation persists.

Conclusion

Safe and compliant logistics for polycarbonate in 3D printing hinge on moisture control, proper documentation, regulatory alignment, and worker protection. By adhering to this guide, businesses can ensure material performance, regulatory compliance, and operational safety throughout the supply chain.

In conclusion, sourcing polycarbonate for 3D printing requires careful consideration of material quality, supplier reliability, and compatibility with your specific printing setup. Polycarbonate offers exceptional strength, heat resistance, and durability, making it ideal for demanding applications; however, it also presents challenges such as high printing temperatures, warping, and moisture sensitivity. To ensure successful outcomes, it is essential to source high-quality, properly dried filament from reputable suppliers that provide consistent diameter, low moisture content, and detailed technical specifications. Additionally, having a 3D printer capable of handling high temperatures and equipped with an enclosed build chamber and robust adhesion solutions is crucial. By prioritizing these factors when sourcing polycarbonate, users can leverage its superior mechanical properties for high-performance 3D printed parts across industrial, automotive, and engineering applications.