The pocket hole joinery market has experienced steady momentum alongside the broader woodworking and do-it-yourself (DIY) furniture trends, driven by rising demand for efficient, cost-effective, and accessible joinery solutions. According to Grand View Research, the global woodworking tools market was valued at USD 11.42 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. A significant portion of this growth is attributed to increased adoption of specialized fastening systems, including pocket hole jigs, particularly in residential construction, cabinetry, and home improvement projects. As demand for simplified assembly methods rises among both professionals and hobbyists, manufacturers of pocket hole joinery systems have innovated rapidly—improving precision, ease of use, and compatibility across materials. This report identifies the top six manufacturers leading the space based on product performance, market presence, customer reviews, and technological advancements.

Top 6 Pocket Hole Joinery Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SPM301HD Screw Pocket Machine

Domain Est. 1998

Website: safetyspeed.com

Key Highlights: In stock $349 deliveryPocket-hole joinery for high production woodworkers made easy with our SPM301HD Screw Pocket Machine. A two-in-one motion simultaneously drills a 6 degree ……

#2 to Kreg Tool

Domain Est. 1999

Website: kregtool.com

Key Highlights: There’s a new pocket hole jig in town. The kregjig Rebel is a battery powered pocket hole jig on Kreg’s new Ionic Drive system of tools….

#3 Pocket Hole Joinery and Outdoor Furniture

Domain Est. 1999

Website: castleusa.com

Key Highlights: Pocket hole joints are great for outdoor furniture manufacturing. We have a number of customers who build their outdoor product lines using ……

#4 UJK Pocket Hole Jig

Domain Est. 2009

Website: tsoproducts.com

Key Highlights: Built for woodworkers who value accuracy, consistency, and the feel of quality tooling, the UJK Pocket Hole Jig replaces the flex and wear of plastic housings ……

#5 Kreg Europe – Buy DIY woodworking tools online

Domain Est. 2019

Website: kreg-europe.com

Key Highlights: Kreg offers you a whole system of drilling templates for pocket hole joinery, our “Pocket-Hole Jigs”. Our products help you to make clean, consistently high ……

#6 Pocket Hole Guide

Domain Est. 2007

Website: tool-r-us.com

Key Highlights: Pocket Hole Guide provides an effective way of making strong hidden joints that are fast and easy to produce….

Expert Sourcing Insights for Pocket Hole Joinery

H2: 2026 Market Trends for Pocket Hole Joinery

The pocket hole joinery market is poised for significant evolution by 2026, driven by advancements in DIY culture, evolving woodworking technologies, and shifting consumer preferences in home improvement and furniture manufacturing. This analysis explores key trends shaping the industry over the next few years.

1. Growth in DIY and Home Renovation Demand

The surge in do-it-yourself (DIY) projects, accelerated by the pandemic and sustained by platforms like YouTube, Instagram, and TikTok, continues to fuel demand for accessible woodworking solutions. Pocket hole joinery—known for its simplicity, speed, and strength—remains a favorite among amateur and intermediate woodworkers. By 2026, increased consumer confidence in home projects and rising home ownership rates in emerging markets are expected to expand the user base for pocket hole systems.

2. Innovation in Pocket Hole Jigs and Tools

Manufacturers such as Kreg Tool are investing heavily in ergonomic design, compactness, and versatility. Anticipated developments by 2026 include smart jigs with alignment sensors, modular systems compatible with various drill brands, and enhanced portability for on-site use. Additionally, integration with augmented reality (AR) apps for real-time guidance could streamline the joinery process, reducing errors and improving precision.

3. Expansion in Commercial and Light Industrial Applications

While traditionally popular in residential woodworking, pocket hole joinery is gaining traction in small-scale manufacturing, custom cabinetry, and modular furniture production. Its cost-effectiveness and reduced need for skilled labor make it attractive to small businesses. By 2026, expect broader adoption in prefabricated housing and flat-pack furniture, where speed and repeatability are critical.

4. Sustainability and Material Trends

As environmental concerns influence consumer choices, there is growing interest in sustainable wood and eco-friendly joinery methods. Pocket hole joinery supports the use of engineered wood and reclaimed lumber, aligning with green building standards. Manufacturers may respond by promoting low-waste techniques and marketing systems that minimize material usage, further boosting appeal in eco-conscious markets.

5. E-Commerce and Global Market Penetration

Online retail platforms are making pocket hole tools more accessible worldwide. By 2026, emerging markets in Asia-Pacific, Latin America, and Africa are expected to see rising adoption, driven by urbanization, rising disposable incomes, and digital access to tutorials and tools. Localized marketing and multilingual support will be crucial for global expansion.

6. Competitive Landscape and Market Consolidation

The market may experience consolidation as larger tool companies acquire niche pocket hole brands or develop proprietary systems. Increased competition will likely drive innovation and affordability, benefiting end-users. However, brand loyalty—especially toward established names like Kreg—will remain a strong market differentiator.

Conclusion

By 2026, pocket hole joinery is expected to maintain its relevance and expand its footprint across both consumer and professional sectors. Advances in tool design, alignment with sustainability trends, and growing digital connectivity will position it as a go-to solution for efficient, strong, and user-friendly wood connections. As the line between hobbyist and professional tools blurs, the pocket hole system is set to become an even more integral part of modern woodworking.

Common Pitfalls When Sourcing Pocket Hole Joinery (Quality and Intellectual Property)

Poor Material Quality and Inconsistent Manufacturing

One of the most frequent issues when sourcing pocket hole joinery systems—especially from overseas suppliers or budget brands—is inconsistent material quality. Components such as jig bodies, drill guides, and clamping mechanisms may be made from brittle plastics or soft metals that wear quickly or fail under repeated use. Poor tolerances in manufacturing can lead to misaligned pocket holes, reducing joint strength and accuracy. This compromises the reliability of the final product and increases long-term costs due to replacements or repairs.

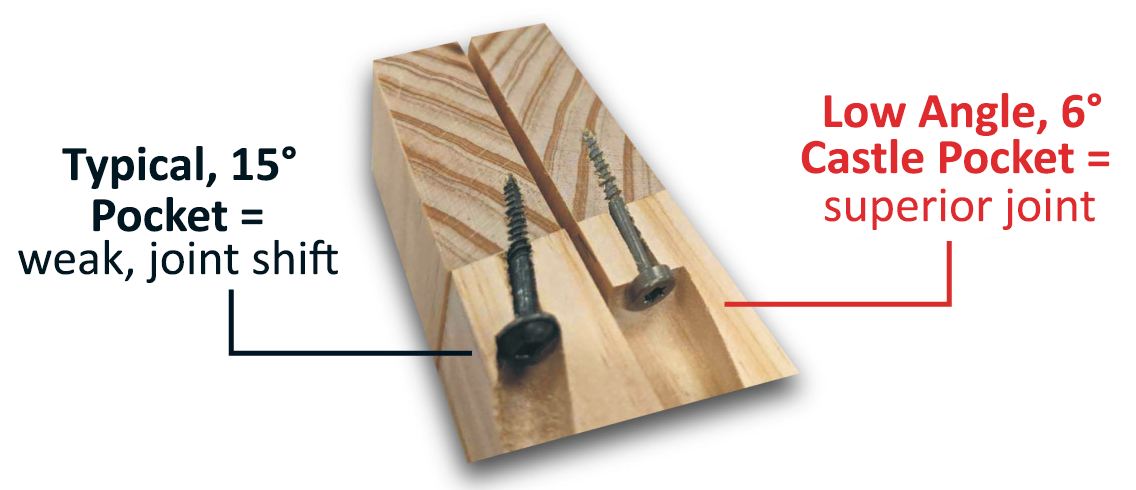

Lack of Precision in Drill Guide Alignment

A critical function of any pocket hole jig is precise alignment of the drill bit at the correct angle (typically 15 degrees). In lower-quality or unbranded systems, drill guide sleeves may be poorly machined or loosely fitted, causing bit wobble or inconsistent hole angles. This leads to screws that don’t seat properly or joints that are weak and misaligned. Buyers often overlook this until after assembly begins, resulting in rework and material waste.

Inadequate Clamping and Workpiece Support

Many budget pocket hole jigs skimp on clamping mechanisms or workpiece stabilization features. Without secure and adjustable clamps, the workpiece can shift during drilling, creating inaccuracies and safety hazards. This is particularly problematic when working with smaller or irregularly shaped pieces. Inferior clamps may also strip or break over time, reducing the jig’s lifespan.

Intellectual Property (IP) Infringement Risks

Pocket hole joinery technology is heavily associated with patented designs, most notably those held by Kreg Tool Company. Sourcing generic or “compatible” jigs from third-party manufacturers—especially those based in regions with lax IP enforcement—can expose buyers to legal risks. Some suppliers may produce near-identical copies of patented jigs, violating design and utility patents. Companies using or reselling these infringing products may face cease-and-desist letters, lawsuits, or import restrictions.

Misrepresentation of Compatibility and Features

Suppliers may falsely advertise compatibility with leading-brand accessories (e.g., Kreg screws, drill guides, or fence extensions) or exaggerate performance specifications. For example, a jig might claim “professional-grade accuracy” but lack micro-adjustments or durability under workshop conditions. This misrepresentation can lead to integration issues and operational inefficiencies, especially in commercial furniture or cabinetry production.

Insufficient Technical Support and Documentation

Lower-cost or offshore-sourced jigs often come with inadequate user manuals, no multilingual support, or limited customer service. When issues arise—such as calibration problems or part breakage—users may struggle to find replacement parts or troubleshooting guidance. This lack of post-purchase support increases downtime and reduces overall value.

Overlooking Safety and Ergonomic Design

Some imported pocket hole jigs lack essential safety features like chip ejection ports, secure bit retention, or stable base designs. Poor ergonomics—such as awkward handle placement or excessive weight—can lead to user fatigue and injuries over time. These shortcomings are often overlooked during procurement but become significant in high-volume or industrial applications.

Conclusion

When sourcing pocket hole joinery systems, it’s essential to evaluate both product quality and IP compliance. Prioritize suppliers with verifiable manufacturing standards, clear intellectual property disclaimers, and proven reliability. Conduct due diligence through product testing, patent searches, and supplier audits to avoid long-term operational and legal pitfalls.

Logistics & Compliance Guide for Pocket Hole Joinery

Overview of Pocket Hole Joinery

Pocket hole joinery is a popular woodworking technique that involves drilling an angled hole (the “pocket”) into one workpiece and securing it to another using a specialized screw. This method is widely used in cabinetry, furniture assembly, and DIY projects due to its speed, strength, and ease of alignment. However, proper logistics and compliance considerations are essential in both industrial and retail applications.

Equipment and Material Logistics

- Tool Procurement and Maintenance: Ensure consistent availability of high-quality pocket hole jigs (e.g., Kreg, JessEm), drill drivers, and stepped drill bits. Maintain a schedule for bit replacement and jig calibration.

- Screw Inventory Management: Stock appropriate pocket hole screws (typically self-tapping, washer-headed, and made from hardened steel or coated for moisture resistance). Maintain inventory levels based on project volume and material types (softwood, hardwood, engineered wood).

- Material Compatibility: Verify compatibility of fasteners and jigs with substrates being used (e.g., MDF, plywood, solid wood). Adjust drilling depth and screw length accordingly to prevent blowout or insufficient grip.

Workplace Safety Compliance

- Personal Protective Equipment (PPE): Require safety glasses, hearing protection, and dust masks/respirators when operating drills and sanding assembled joints.

- Tool Safety Standards: Ensure all power tools meet OSHA (Occupational Safety and Health Administration) and/or ANSI (American National Standards Institute) safety requirements. Use guards and emergency shutoffs where applicable.

- Dust Control: Implement dust extraction systems or vacuums when drilling pocket holes, especially when working with MDF or particleboard containing formaldehyde. Comply with OSHA permissible exposure limits (PELs) for wood dust.

Environmental and Regulatory Compliance

- Material Emissions Standards: When using engineered wood products (e.g., plywood, MDF), ensure compliance with CARB (California Air Resources Board) Phase 2 or EPA TSCA Title VI regulations for formaldehyde emissions.

- Hazardous Waste Disposal: Dispose of drill shavings and used bits according to local environmental regulations. Segregate waste materials when working with treated or composite woods.

- Sustainable Sourcing: Where possible, use screws and wood materials certified by organizations such as FSC (Forest Stewardship Council) or SFI (Sustainable Forestry Initiative) to support environmental responsibility.

Quality Control and Industry Standards

- Joint Strength and Durability: Follow manufacturer guidelines for screw size, depth, and pilot hole angles. Conduct periodic pull-tests to ensure joint integrity meets industry benchmarks (e.g., ANSI/BIFMA for furniture).

- Dimensional Accuracy: Use calibrated jigs and fixtures to maintain consistent pocket hole placement. Train personnel on proper alignment techniques to avoid misalignment and weak joints.

- Documentation and Traceability: Maintain records of materials used, equipment maintenance, and quality inspections, especially in commercial manufacturing environments.

Training and Certification

- Operator Training: Provide formal training for all personnel using pocket hole systems, covering setup, operation, safety procedures, and troubleshooting common issues (e.g., tear-out, stripped screws).

- Compliance Awareness: Educate staff on relevant safety and environmental regulations, including proper handling of materials and emergency procedures.

- Certification Programs: Encourage participation in woodworking safety or joinery certification programs offered by industry groups or equipment manufacturers.

Conclusion

Effective logistics and compliance in pocket hole joinery ensure not only efficient production and high-quality results but also adherence to safety, environmental, and industry standards. By managing equipment, materials, and personnel responsibly, businesses and hobbyists alike can minimize risks and enhance the reliability of their woodworking projects.

In conclusion, sourcing pocket hole joinery offers a practical, cost-effective, and efficient solution for both DIY enthusiasts and professional woodworkers. Its ease of use, speed of assembly, and strong, reliable joints make it an ideal choice for a wide range of woodworking projects—from cabinetry and furniture to framing and trim work. When sourcing pocket hole jigs, screws, and accessories, it’s important to prioritize quality tools and materials from reputable suppliers to ensure consistent results and long-term durability. By investing in reliable equipment and practicing proper techniques, woodworkers can achieve professional-grade craftsmanship with minimal effort. Overall, pocket hole joinery is a versatile and accessible method that enhances productivity and precision, making it a valuable addition to any workshop.