The global plumbing fittings market is experiencing steady growth, driven by increased construction activity, urbanization, and the ongoing need for water infrastructure upgrades. According to Grand View Research, the global plumbing fixtures and fittings market size was valued at USD 84.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. Mordor Intelligence similarly projects a robust outlook, citing rising residential and commercial building investments, particularly in emerging economies, as key growth catalysts. Within this expanding landscape, drain pipe fittings—critical components for efficient wastewater management—represent a vital segment. As demand for durable, corrosion-resistant, and code-compliant fittings grows, manufacturers leveraging innovation in materials like PVC, CPVC, and cast iron are positioning themselves at the forefront. The following list highlights the top 10 plumbing drain pipe fittings manufacturers leading this market, evaluated based on product range, global reach, compliance standards, and industry reputation.

Top 10 Plumbing Drain Pipe Fittings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 HDPE Pipe Solutions

Domain Est. 1995

Website: isco-pipe.com

Key Highlights: ISCO is the leading HDPE pipe & fusion equipment supplier in North America, providing expert solutions for municipal, industrial & oil/gas HDPE piping ……

#2 Jay R. Smith Mfg. Co.

Domain Est. 1996

Website: jrsmith.com

Key Highlights: Jay R. Smith Mfg. Co. is a leading manufacturer of quality engineered plumbing and drainage products in the non-residential construction industry….

#3 Sioux Chief: Rough Plumbing Products

Domain Est. 1997

Website: siouxchief.com

Key Highlights: We are an American manufacturer. Sioux Chief believes in making our products right here in America. American manufacturing is important….

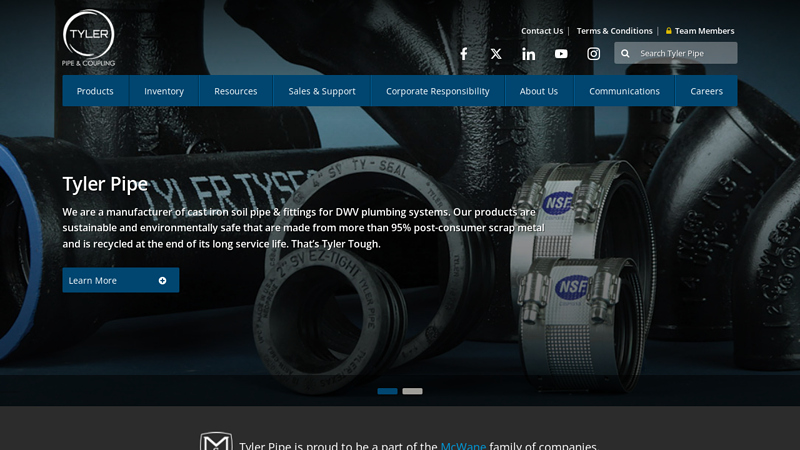

#4 Tyler Pipe

Domain Est. 1997

Website: tylerpipe.com

Key Highlights: We are a manufacturer of cast iron soil pipe & fittings for DWV plumbing systems. Our products are sustainable and environmentally safe that are made from more ……

#5 JM Eagle™

Domain Est. 2007

Website: jmeagle.com

Key Highlights: JM Eagle · Delivering life’s essentials through the most eco-friendly plastic pipe products on the market. · Express Service Trucks (ESTs) Deliver within 24 hours ……

#6 IPEX Inc.

Domain Est. 2009

Website: ipexna.com

Key Highlights: IPEX Inc. manufactures advanced PVC & CPVC piping systems for several applications for the Canadian market. Learn more….

#7 Spears Manufacturing, PVC & CPVC Plastic Pipe Fittings & Valves

Domain Est. 1996

Website: spearsmfg.com

Key Highlights: ISO9001 Certified – PVC & CPVC Sch 40 and 80 fittings molded from 1/8 – 14 inch….

#8 Advanced Drainage Systems

Domain Est. 2000

Website: adspipe.com

Key Highlights: Advanced Drainage Systems provides high-performing, durable pipe and innovative stormwater management solutions. Discover our industry-leading products ……

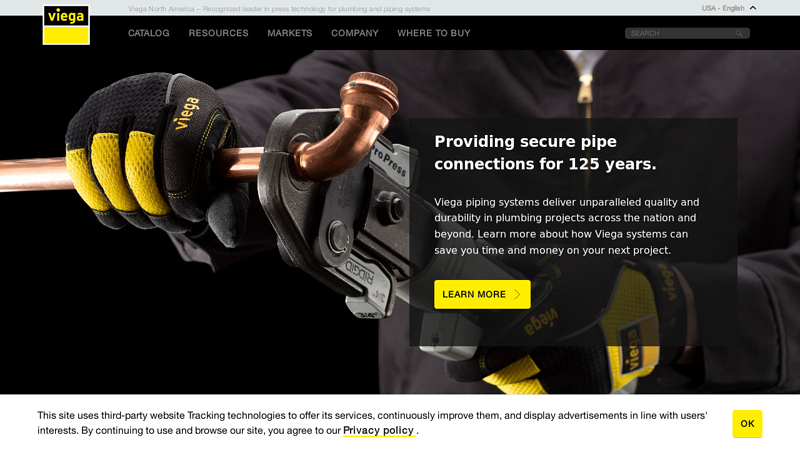

#9 Viega USA

Domain Est. 2002

Website: viega.us

Key Highlights: Providing secure pipe connections for 125 years. Viega piping systems deliver unparalleled quality and durability in plumbing projects across the nation and ……

#10 Midland Industries

Domain Est. 2011

Website: midlandindustries.com

Key Highlights: NOW IN STOCK · Lead-Free Brass Forged Bodies · Full Port 3/4″ Drain Outlets · Ready to ship from Midland….

Expert Sourcing Insights for Plumbing Drain Pipe Fittings

H2: 2026 Market Trends for Plumbing Drain Pipe Fittings

The global market for plumbing drain pipe fittings is anticipated to witness steady growth through 2026, driven by urbanization, infrastructure development, and increasing demand for water-efficient building systems. Several key trends are shaping the industry landscape, including technological advancements, regulatory standards, sustainability initiatives, and regional market dynamics.

-

Growth in Residential and Commercial Construction

Rising urban populations, particularly in Asia-Pacific, Latin America, and Africa, are fueling demand for new housing and commercial infrastructure. Countries like India, China, and Indonesia are investing heavily in smart cities and affordable housing projects, directly boosting the need for reliable plumbing systems. As a result, the demand for durable and corrosion-resistant drain pipe fittings—especially those made from PVC, ABS, and cast iron—is expected to increase significantly by 2026. -

Adoption of Sustainable and Eco-Friendly Materials

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing manufacturers and contractors to adopt sustainable plumbing solutions. Recycled polymers and bio-based plastics are gaining traction as eco-friendly alternatives to traditional materials. Additionally, fittings designed for water conservation and reduced leakage are becoming standard in modern plumbing systems, aligning with global sustainability goals. -

Technological Innovation and Smart Plumbing Integration

Smart building technologies are influencing the design and functionality of plumbing systems. By 2026, there will be greater integration of IoT-enabled sensors within drain systems to monitor blockages, leaks, and flow rates in real time. While the fittings themselves may not be “smart,” their compatibility with intelligent plumbing networks will become a competitive advantage for manufacturers offering modular, sensor-ready designs. -

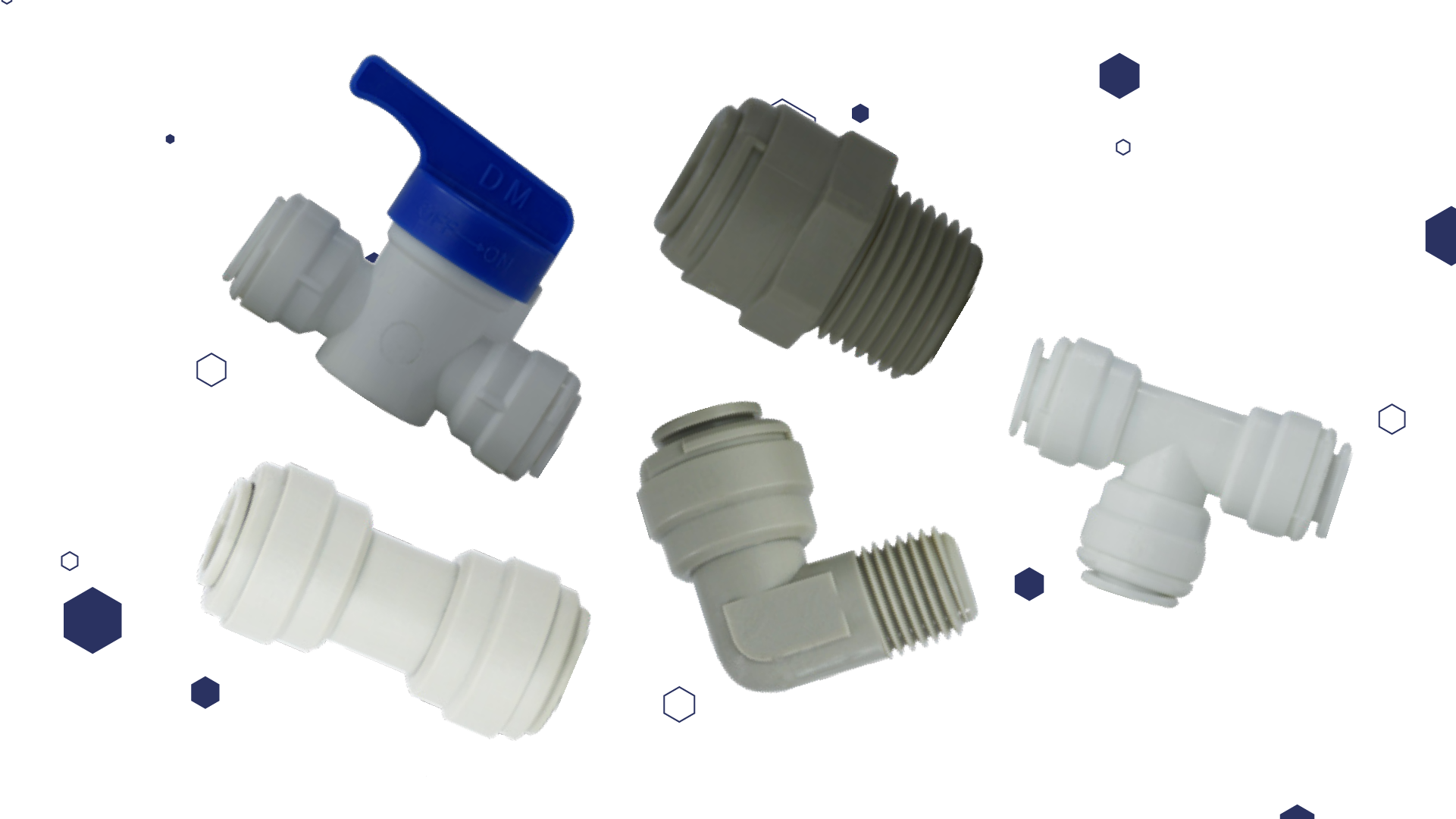

Shift Toward Lightweight and Easy-to-Install Solutions

The construction industry’s focus on reducing labor costs and installation time is accelerating the adoption of lightweight plastic fittings (PVC-U, PP, HDPE) over heavier materials like cast iron. Push-fit and solvent-weld fittings are growing in popularity due to their ease of installation and lower maintenance requirements. This trend is especially prominent in retrofit and renovation projects, which are expected to rise as aging infrastructure is upgraded in North America and Europe. -

Stringent Regulatory Standards and Building Codes

Governments worldwide are updating plumbing codes to enhance safety, hygiene, and environmental performance. For example, regulations limiting lead content in plumbing components and mandating seismic-resistant fittings in earthquake-prone regions will shape product development. Compliance with ISO, ASTM, and local standards will be critical for market access, particularly in developed economies. -

Regional Market Dynamics

- Asia-Pacific: Expected to dominate the market due to rapid urbanization and government-led infrastructure programs. China and India will be key growth engines.

- North America: Steady demand driven by residential remodels and aging infrastructure replacement. The U.S. Infrastructure Investment and Jobs Act will support public sector projects involving drainage systems.

- Europe: Growth will be moderate but steady, with emphasis on energy efficiency and compliance with EU environmental directives.

-

Middle East & Africa: Increasing investments in urban development, especially in Saudi Arabia (Vision 2030) and UAE, will drive demand for modern plumbing solutions.

-

Supply Chain Resilience and Localized Manufacturing

Post-pandemic supply chain disruptions have prompted companies to diversify sourcing and increase regional production. By 2026, more manufacturers are expected to establish localized facilities to reduce logistics costs and improve delivery times, particularly near high-growth markets.

In conclusion, the plumbing drain pipe fittings market in 2026 will be shaped by a confluence of infrastructure development, sustainability mandates, and technological evolution. Companies that innovate in material science, comply with global standards, and adapt to regional needs will be best positioned to capitalize on emerging opportunities.

Common Pitfalls Sourcing Plumbing Drain Pipe Fittings (Quality, IP)

Sourcing plumbing drain pipe fittings involves more than just finding the lowest price. Overlooking quality and intellectual property (IP) considerations can lead to significant problems down the line, including system failures, safety hazards, legal issues, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Non-Compliance

One of the most frequent issues is receiving fittings made from substandard materials that do not meet required industry standards (e.g., ASTM, ISO, or local plumbing codes). Low-quality PVC, ABS, or cast iron fittings may degrade quickly, crack under pressure or temperature fluctuations, or fail to form watertight seals. This leads to leaks, structural damage, and costly repairs. Always verify that products are certified and tested for drain, waste, and vent (DWV) applications.

Counterfeit or Non-Genuine Products

The market is flooded with counterfeit fittings that mimic trusted brands but lack the engineering, durability, and safety certifications of authentic products. These fake components often use inferior resins, incorrect wall thicknesses, or poor mold tolerances. Sourcing from unauthorized suppliers increases the risk of receiving counterfeit goods, undermining system reliability and potentially voiding warranties.

Lack of Intellectual Property Due Diligence

Sourcing from manufacturers or suppliers that infringe on patented designs or registered trademarks exposes buyers to legal risks. Using fittings that replicate patented geometries (e.g., proprietary sealing mechanisms or connection systems) without licensing can result in cease-and-desist orders, fines, or product recalls. Always ensure that the supplier holds proper IP rights or licenses for the designs they produce.

Inadequate Traceability and Documentation

Reputable plumbing fittings should come with batch traceability, material certifications (e.g., mill test reports), and compliance documentation. Suppliers that cannot provide these records may be sourcing from unregulated factories with inconsistent quality control. This lack of transparency makes it difficult to address defects or conduct recalls if issues arise.

Ignoring Regional Code Requirements

Drain pipe fittings must comply with local plumbing codes, which vary by region (e.g., UPC in the U.S. vs. IPC, or EN standards in Europe). Sourcing generic or off-spec fittings that aren’t approved for use in a specific jurisdiction can result in failed inspections, project delays, and liability for non-compliant installations.

Overlooking Long-Term Performance Data

Many low-cost fittings lack long-term performance testing data (e.g., resistance to UV exposure, chemical corrosion, or thermal cycling). Without this information, it’s difficult to predict lifespan or suitability for specific environments, such as underground installations or high-moisture areas.

By focusing on certified suppliers, conducting supplier audits, requiring full documentation, and verifying IP compliance, buyers can avoid these common pitfalls and ensure reliable, code-compliant plumbing systems.

Logistics & Compliance Guide for Plumbing Drain Pipe Fittings

Product Classification and HS Code

Plumbing drain pipe fittings are typically classified under the Harmonized System (HS) Code 7307.19 for steel fittings or 7609.00 for aluminum, depending on material. For plastic fittings (e.g., PVC, ABS), the applicable HS codes include 3917.33 or 3917.40. Accurate classification is essential to determine import duties, taxes, and regulatory requirements in the destination country.

Packaging and Marking Requirements

Drain pipe fittings must be packaged to prevent damage during transit. Industrial-grade cartons, shrink-wrapped pallets, or wooden crates are commonly used, especially for metal or large-diameter fittings. Each package must be clearly marked with the product description, quantity, material type, size specifications, batch/lot number, manufacturer name, and country of origin. For international shipments, markings should comply with ISO and carrier-specific standards.

Shipping and Transportation

Shipments must comply with international freight regulations (e.g., IMDG for sea, IATA for air if applicable). Due to their generally non-hazardous nature, drain fittings can be transported via containerized ocean freight, LTL (Less-Than-Truckload), or FTL (Full Truckload) for domestic moves. Ensure proper stacking and securing on pallets to prevent shifting. Climate-controlled transport is recommended if fittings are made from temperature-sensitive materials like certain plastics.

Import and Export Documentation

Key documentation includes:

– Commercial Invoice

– Packing List

– Bill of Lading (or Air Waybill)

– Certificate of Origin

– Import/Export License (if required by jurisdiction)

For regulated markets, additional documents such as conformity assessment reports or test certifications may be required.

Regulatory Compliance

Plumbing drain fittings must meet regional building and plumbing codes:

– United States: Must comply with IPC (International Plumbing Code) and be certified by IAPMO or NSF/ANSI 14 and 372 (for lead content).

– European Union: Must carry CE marking under the Construction Products Regulation (CPR) EN 1329 (for plastic pipes) or EN 877 (for cast iron).

– Canada: Must meet cUPC certification under the Canadian Plumbing Code (CSA B125).

– Australia/New Zealand: Must comply with AS/NZS 1260 and be WaterMark certified.

Testing and Certification

Suppliers must provide valid test reports from accredited laboratories demonstrating compliance with mechanical strength, pressure resistance, chemical resistance, and dimensional standards. Third-party certification (e.g., NSF, UL, KIWA) is often mandatory for market access.

Environmental and Safety Regulations

Ensure compliance with environmental regulations such as:

– REACH (EU): Registration of chemical substances used in manufacturing.

– RoHS (EU): Restriction of hazardous substances, especially relevant for metal alloys.

– Prop 65 (California): Warning requirements for products containing listed chemicals like lead.

Customs Clearance and Duties

Engage a licensed customs broker to facilitate clearance. Provide accurate valuation and product specifications to avoid delays. Be prepared to pay applicable tariffs, which vary by country and material type. Duty rates for plastic fittings are often lower than for metal counterparts in many jurisdictions.

Storage and Handling

Upon arrival, fittings should be stored in a dry, well-ventilated area away from direct sunlight and extreme temperatures. Plastic fittings are especially prone to UV degradation and warping. Use proper handling equipment (e.g., forklifts, pallet jacks) to avoid physical damage.

Traceability and Record Keeping

Maintain detailed records of batch numbers, certifications, test reports, and shipping documents for a minimum of 5–7 years, depending on jurisdiction. This supports product traceability and facilitates recalls or audits if required.

Sustainability and End-of-Life Compliance

Where applicable, comply with local waste management regulations such as WEEE (EU) for electronic components in smart fittings or recycling requirements for plastics and metals. Use recyclable packaging materials and document environmental compliance for corporate sustainability reporting.

In conclusion, sourcing plumbing drain pipe fittings requires careful consideration of material quality, compatibility with existing systems, compliance with local building codes, and supplier reliability. Whether opting for PVC, ABS, cast iron, or other materials, it is essential to select fittings that ensure durability, leak resistance, and long-term performance. Partnering with reputable suppliers who offer certified products, competitive pricing, and timely delivery can significantly impact project efficiency and success. Additionally, evaluating factors such as availability, lead times, and after-sales support contributes to a seamless procurement process. Ultimately, a well-informed sourcing strategy helps maintain plumbing system integrity, reduces maintenance costs, and supports overall project sustainability.