The global insulation materials market is experiencing robust growth, driven by rising energy efficiency standards, increasing construction activities, and heightened focus on reducing carbon emissions. According to Grand View Research, the global insulation market was valued at USD 52.7 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. A key segment within this space is plenum-rated insulation, which is critical for HVAC systems in commercial and high-rise buildings due to its fire-resistant and low-smoke properties required by safety codes. As demand for safer, energy-efficient building materials grows—particularly in North America and Europe—the plenum insulation sector is witnessing increased innovation and competition among manufacturers. This rising trajectory positions plenum insulation not only as a compliance necessity but also as a strategic component in sustainable building design. In this context, the following nine manufacturers stand out for their product quality, technical certifications, market reach, and commitment to innovation.

Top 9 Plenum Insulation Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

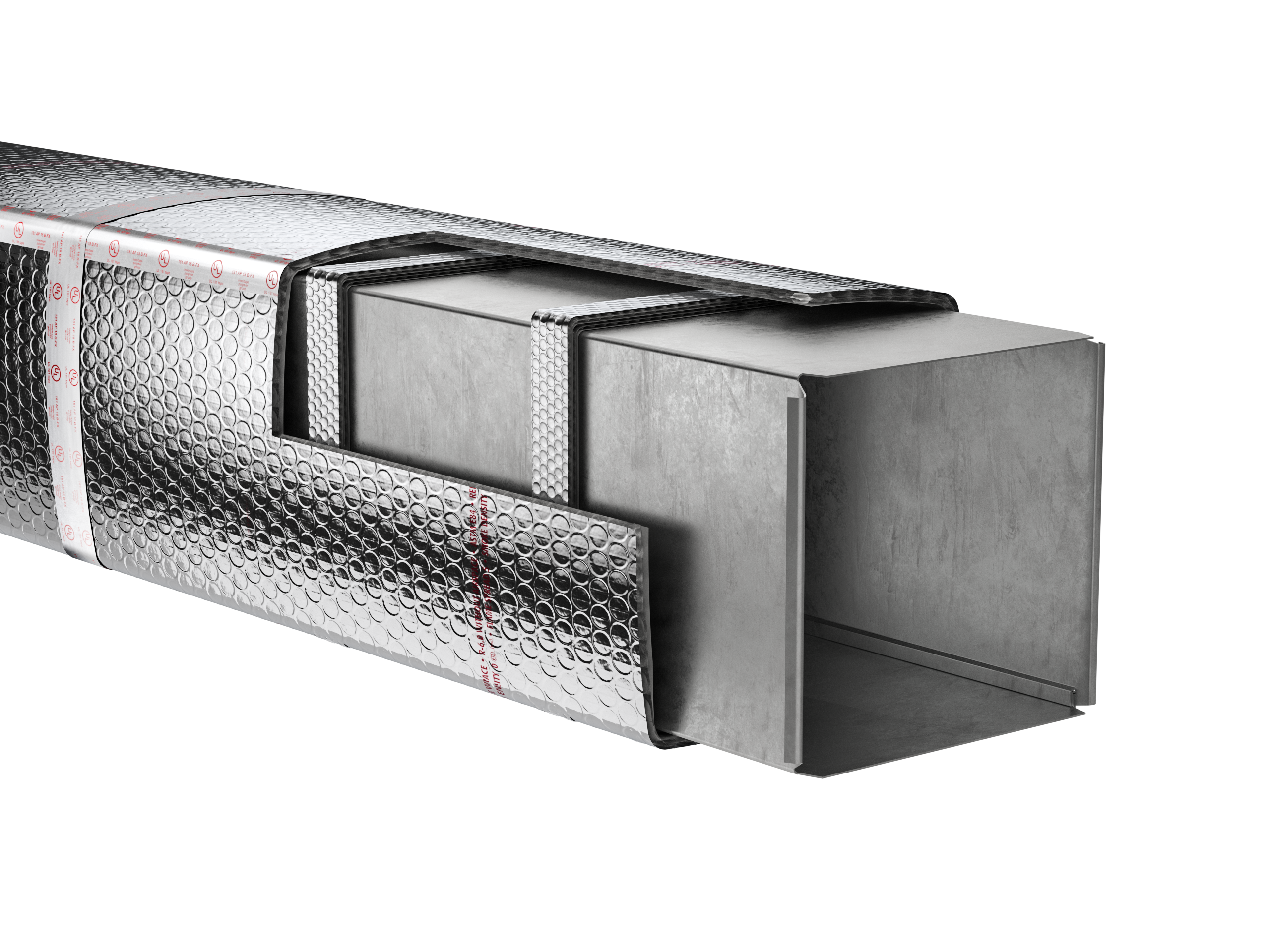

#1 Duct Insulation (Indoor and Outdoor)

Domain Est. 1996

Website: reflectixinc.com

Key Highlights: The Reflectix Duct Insulation is an excellent fiber-free alternative to other types of duct insulations….

#2 J P Lamborn Co.

Domain Est. 1999 | Founded: 1961

Website: jplflex.com

Key Highlights: BEST IN CLASS FLEXIBLE DUCT-WORK. JPL IS THE OLDEST AND MOST RESPECTED FLEXIBLE DUCT MANUFACTURER IN THE USA SINCE 1961….

#3 Pre

Domain Est. 2016

Website: gfiduct.com

Key Highlights: GFI offers PIR/PUR/Phenolic Pre-insulated Air Duct Panels, PID Duct Accessories & Pre-insulated HVAC Ductwork Tools, PIR/Phenolic Foam Insulation Board….

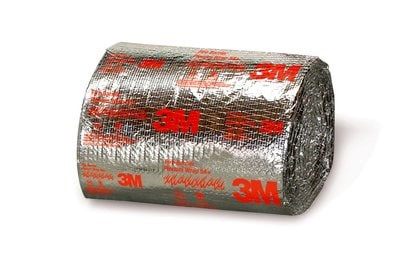

#4 3M™ Fire Barrier Plenum Wrap 5A+

Domain Est. 1988

Website: 3m.com

Key Highlights: 3M™ Fire Barrier Plenum Wrap 5A+ is a fire-resistant wrap that consists of an inorganic fiber blanket encapsulated with a scrim-reinforced foil….

#5 to Lamtec Corporation

Domain Est. 1996

Website: lamtec.com

Key Highlights: Lamtec Corporation is the leading source of high-quality insulation vapor retarders, laminators and fabricators of fiberglass, rockwool, foam board and ……

#6

Domain Est. 1996

Website: kflex.com

Key Highlights: K-FLEX products are safe to handle, easy to install, available in different sizes and based on innovative and sustainable technologies….

#7 HVAC Air Distribution

Domain Est. 1996

Website: owenscorning.com

Key Highlights: See the difference Owens Corning HVAC insulation can make. Our duct insulation helps keep homes and buildings cool in the summer and warm in the winter….

#8 Pipe Insulation

Domain Est. 1997

Website: jm.com

Key Highlights: Our pipe insulation portfolio includes fiberglass and foam insulations and can cover a broad spectrum of temperatures, ranging from -237°F to 800°F….

#9 General Insulation

Domain Est. 2001

Website: generalinsulation.com

Key Highlights: A wholesale distributor, providing a full line of sustainable products and solutions for thermal efficiency, condensation/moisture control, and life safety….

Expert Sourcing Insights for Plenum Insulation

H2: Projected Market Trends for Plenum Insulation in 2026

As the global focus intensifies on energy efficiency, building safety, and sustainable construction, the plenum insulation market is poised for notable transformation by 2026. Plenum insulation—used in air handling spaces above drop ceilings and below structural slabs where air circulation occurs—must meet stringent fire safety and low-smoke emission standards due to its location in commercial and high-occupancy buildings. The following are key market trends expected to shape the plenum insulation sector in 2026:

1. Increased Demand Driven by Building Codes and Regulations

Regulatory environments in North America, Europe, and parts of Asia-Pacific are tightening fire safety requirements for building materials, especially in plenum spaces. The adoption of updated versions of standards such as NFPA 90A and the International Building Code (IBC) will compel commercial developers to use insulation materials with higher fire resistance and lower flame spread ratings (typically Class 1 or UL 263/ASTM E84 compliant). This regulatory push is expected to drive demand for certified plenum-rated insulation, particularly in new construction and retrofit projects.

2. Growth in Commercial and High-Rise Construction

Urbanization and the expansion of office complexes, data centers, healthcare facilities, and educational institutions—sectors where plenum spaces are common—will contribute to market growth. The rise in smart buildings and mixed-use developments, especially in emerging economies like India, Southeast Asia, and the Middle East, will further boost demand for compliant insulation solutions. Data centers, in particular, are expected to be a high-growth segment due to their extensive HVAC requirements and strict safety codes.

3. Shift Toward Sustainable and Low-VOC Materials

Environmental and health concerns are driving demand for low-VOC (volatile organic compound) and formaldehyde-free insulation products. By 2026, manufacturers are expected to increasingly offer bio-based or recycled-content plenum insulation that meets green building certifications such as LEED, BREEAM, and WELL. This shift aligns with corporate ESG (Environmental, Social, and Governance) goals and tenant demand for healthier indoor environments.

4. Innovation in Material Technology

Advancements in insulation materials—such as aerogel composites, nano-coated fiberglass, and fire-retardant mineral wool—are expected to enhance thermal performance while maintaining plenum safety standards. These next-generation products may offer thinner profiles with higher R-values, allowing for space optimization in ceiling plenums. Additionally, antimicrobial and moisture-resistant treatments will gain traction, especially in humid climates or sensitive environments like hospitals.

5. Supply Chain Resilience and Regional Manufacturing

Post-pandemic supply chain disruptions have led to a strategic shift toward localized production. By 2026, key players in the plenum insulation market are anticipated to expand regional manufacturing capabilities to mitigate logistics risks and reduce lead times. This trend is particularly evident in North America and Europe, where nearshoring is supported by government incentives for domestic construction materials.

6. Competitive Landscape and Consolidation

The plenum insulation market remains dominated by established players such as Owens Corning, Johns Manville, Knauf Insulation, and Saint-Gobain. However, increasing demand for specialized products is fostering partnerships with HVAC system integrators and building envelope consultants. Mergers and acquisitions are likely as larger firms seek to broaden their high-performance insulation portfolios.

7. Digital Integration and Building Information Modeling (BIM)

By 2026, BIM adoption in construction planning will influence insulation selection. Manufacturers are expected to provide detailed digital product data (including fire ratings, thermal values, and environmental impact) to facilitate seamless integration into BIM platforms. This enables architects and engineers to specify plenum insulation more accurately, reducing installation errors and improving compliance.

Conclusion

The plenum insulation market in 2026 will be shaped by a confluence of regulatory pressures, sustainability imperatives, and technological innovation. As buildings become smarter and safer, the demand for high-performance, code-compliant insulation in plenum spaces will grow steadily, particularly in commercial and institutional sectors. Companies that invest in eco-friendly materials, digital tools, and regional supply chains are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls Sourcing Plenum Insulation (Quality, IP)

Sourcing plenum insulation requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to safety hazards, regulatory non-compliance, project delays, and legal exposure. Below are key pitfalls to avoid:

Poor Material Quality and Non-Compliance

One of the most critical risks when sourcing plenum insulation is receiving substandard materials that fail to meet fire safety and performance standards. Plenum spaces—areas used for air circulation in HVAC systems—require insulation that is low-smoke, flame-retardant, and compliant with building codes (e.g., NFPA 90A, UL 181). Sourcing from unreliable suppliers may result in:

- Inadequate fire resistance: Materials that do not meet UL 723/ASTM E84 flame spread and smoke development ratings can pose serious safety hazards.

- Off-gassing and indoor air quality issues: Low-quality insulation may emit volatile organic compounds (VOCs), compromising occupant health.

- Dimensional instability: Poorly manufactured insulation may compress or degrade over time, reducing thermal performance and airflow efficiency.

- Lack of traceability or certification: Some suppliers provide forged or outdated compliance documentation, making it difficult to verify product authenticity.

To mitigate this, always source from certified manufacturers, request current test reports, and verify compliance with local building codes.

Intellectual Property (IP) Infringement Risks

Plenum insulation technologies—especially those involving proprietary materials, formulations, or manufacturing processes—may be protected by patents, trademarks, or trade secrets. Sourcing from unauthorized or counterfeit suppliers increases the risk of:

- Patent infringement: Using insulation that replicates patented technology without a license can lead to costly litigation and product recalls.

- Counterfeit products: Some suppliers repackage or imitate branded insulation (e.g., Owens Corning, Johns Manville), falsely claiming performance equivalency while lacking IP rights.

- Voided warranties: Original equipment manufacturers (OEMs) often void warranties if non-genuine or unauthorized materials are installed, leaving contractors or building owners liable for repairs.

- Reputational damage: Being associated with IP violations can harm relationships with clients and specifiers, especially in public or commercial projects.

To avoid IP issues, work only with authorized distributors, verify supplier credentials, and ensure procurement contracts include IP indemnification clauses.

By focusing on verified quality and respecting intellectual property rights, stakeholders can ensure safe, compliant, and legally sound plenum insulation sourcing.

Logistics & Compliance Guide for Plenum Insulation

This guide outlines the key logistics and compliance considerations for handling, transporting, storing, and installing plenum insulation. Adherence to these guidelines ensures safety, regulatory compliance, and optimal product performance in commercial and industrial applications.

Regulatory Compliance Requirements

Plenum insulation must meet stringent fire safety and air quality standards due to its installation in air-handling spaces (plenums). The following regulations are critical:

- NFPA 90A: Standard for the Installation of Air-Conditioning and Ventilating Systems. Requires plenum-rated materials to have low flame spread and smoke development indices.

- UL 723 / ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials. Plenum insulation must achieve a flame spread index of 25 or less and a smoke-developed index of 50 or less.

- ASHRAE Standard 189.1 and IECC: May impose additional requirements for energy efficiency and material sustainability in plenum spaces.

- Local Building Codes: Always verify jurisdiction-specific amendments to national codes. Permits and inspections may be required.

- Indoor Air Quality (IAQ): Products should comply with VOC emission standards such as CA Section 01350 or UL GREENGUARD Gold certification, especially in occupied buildings.

Ensure all insulation products used in plenum spaces are explicitly labeled as “plenum-rated” and accompanied by valid test reports.

Product Handling and Storage

Proper handling and storage preserve the integrity and performance of plenum insulation:

- Storage Conditions: Store in a dry, covered area, off the ground, and protected from moisture, direct sunlight, and extreme temperatures. Prolonged exposure to humidity can degrade performance and promote mold growth.

- Packaging: Keep insulation in original manufacturer packaging until ready for installation to prevent contamination and physical damage.

- Stacking: Do not stack packages higher than recommended by the manufacturer. Over-stacking may compress lower layers, reducing R-value and structural integrity.

- Handling: Use appropriate lifting techniques or equipment (e.g., forklifts, dollies) to prevent material damage. Avoid dragging rolls or boards across surfaces to prevent tearing or fiber shedding.

Transportation Guidelines

Transporting plenum insulation requires careful planning to maintain compliance and product quality:

- Securement: Insulation must be securely strapped or shrink-wrapped on pallets to prevent shifting during transit.

- Weather Protection: Use waterproof tarps or enclosed trailers to protect against rain, snow, or high humidity during delivery.

- Vehicle Compatibility: Ensure vehicles are clean and free of debris, contaminants, or sharp objects that could damage packaging.

- Documentation: Shipments should include product data sheets, fire test reports (e.g., ASTM E84), and compliance certificates for inspection and job-site verification.

Installation Best Practices

Compliant installation ensures safety and effectiveness:

- Qualified Personnel: Only trained HVAC or insulation professionals should install plenum-rated insulation.

- Clearance from Equipment: Maintain manufacturer-recommended clearances from heat sources, electrical fixtures, and moving parts.

- Seam Sealing: Use UL-listed foil or fire-resistant tapes to seal joints and seams, maintaining fire and vapor barrier integrity.

- Support and Fastening: Follow engineering specifications for spacing of supports and fasteners to prevent sagging or detachment.

- Labeling: Clearly label installed insulation with manufacturer name, fire rating, and compliance standard (e.g., “Plenum Rated – ASTM E84 Class 1”).

Documentation and Recordkeeping

Maintain comprehensive records to support compliance audits and future inspections:

- Retain copies of product cut sheets, fire test reports, and certificates of compliance.

- Document installation dates, locations, and personnel involved.

- Provide as-built drawings indicating insulation types and locations within plenum spaces.

Adherence to this logistics and compliance guide ensures that plenum insulation installations meet safety standards, protect occupant health, and comply with all applicable codes and regulations.

Conclusion for Sourcing Plenum Insulation:

Sourcing plenum-rated insulation requires a careful balance of regulatory compliance, performance requirements, and cost-efficiency. Plenum spaces, due to their role in air circulation within commercial buildings, demand insulation materials that meet stringent fire safety and low smoke emission standards—most notably compliance with NFPA 90A and UL 181 standards. Materials such as fiberglass duct board with a foil-facing, or flexible elastomeric foam with UL-listed plenum ratings, are commonly selected for their thermal performance and code adherence.

Key considerations in the sourcing process include verifying third-party certifications, assessing environmental impact (e.g., low VOC emissions), and ensuring compatibility with HVAC system design. Additionally, working with reputable suppliers who provide full documentation and product traceability helps mitigate project risks and supports smooth inspections.

In conclusion, successful sourcing of plenum insulation hinges on selecting code-compliant, high-performance materials from trusted manufacturers, while aligning with project specifications, sustainability goals, and long-term building safety. Proper due diligence at the procurement stage ensures compliance, occupant safety, and system efficiency throughout the building’s lifecycle.